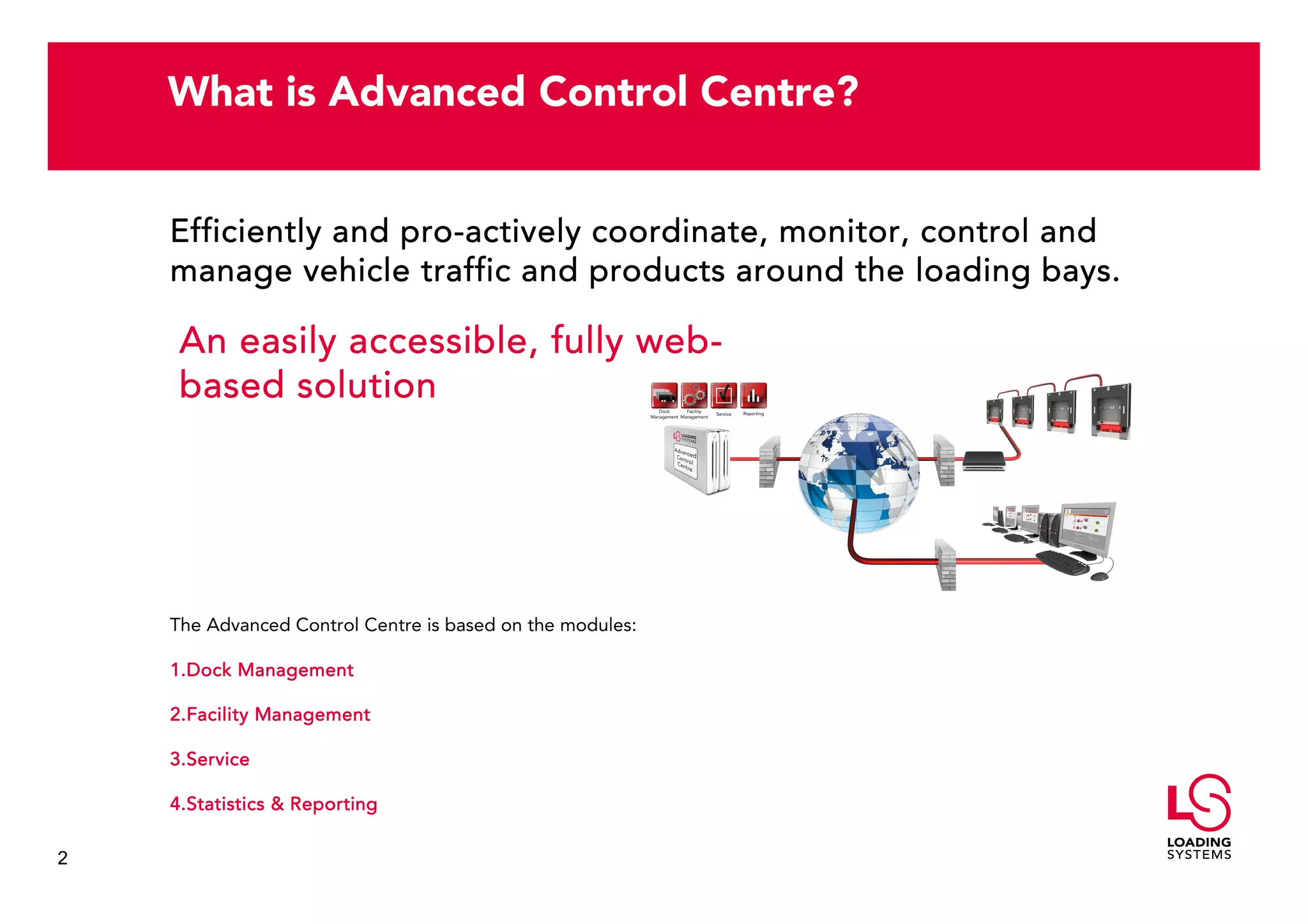

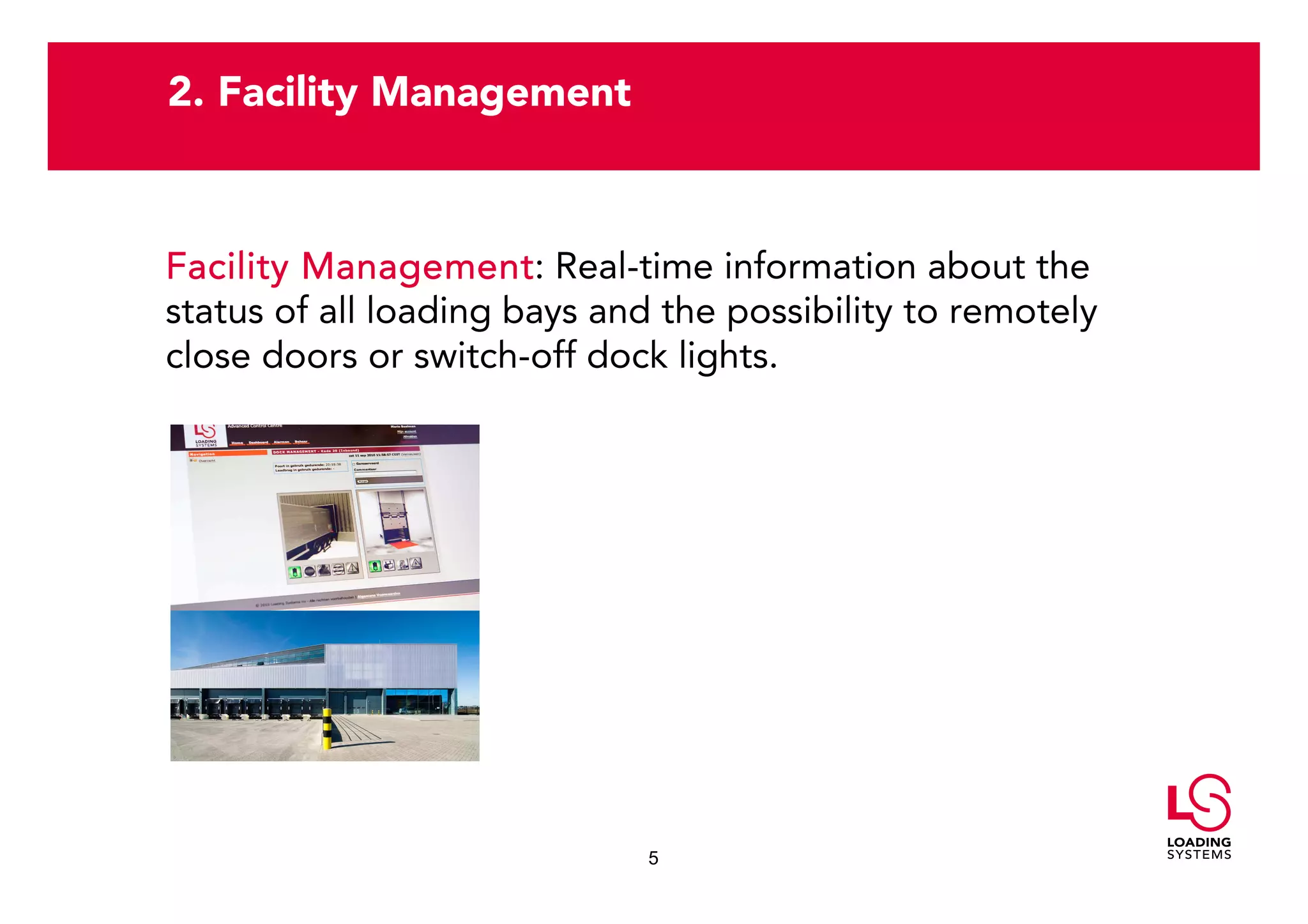

The Advanced Control Centre provides 24/7 online monitoring, control, and management of vehicle traffic and product loading at bays. It has four modules: 1) Dock Management for remote vehicle reservation and bay status monitoring, 2) Facility Management for remote control of bay doors and lights, 3) Service for 24/7 monitoring of bay equipment and alerts, and 4) Statistics & Reporting for data analysis. The web-based system requires minimal hardware/software and provides benefits such as increased safety, efficiency, and reduced maintenance costs.