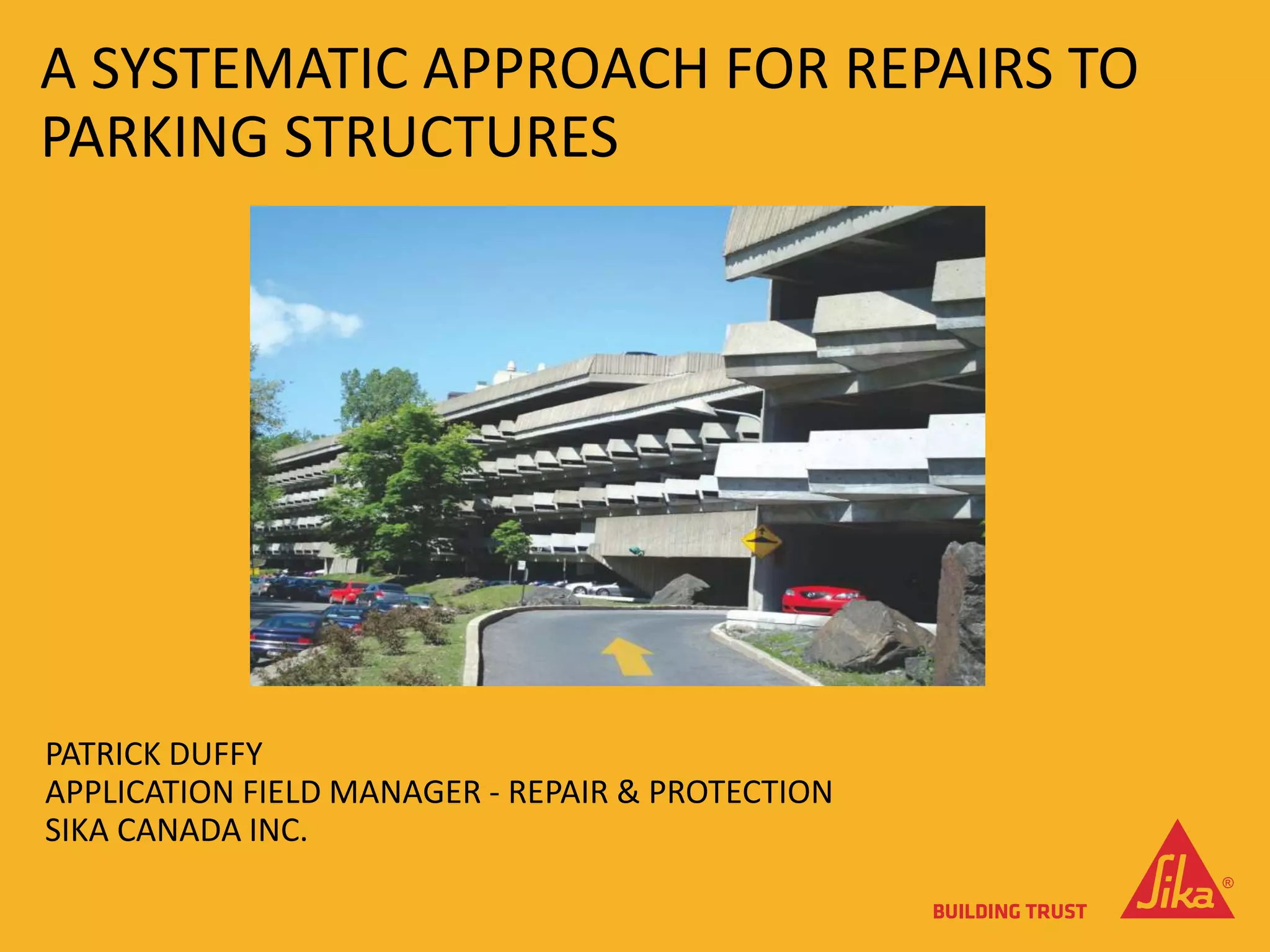

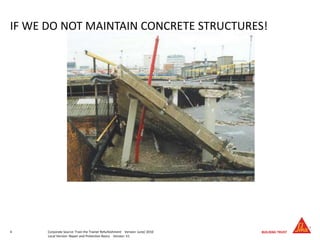

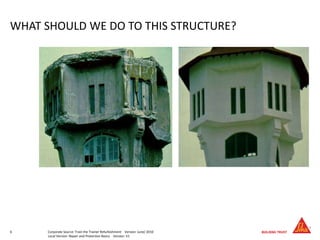

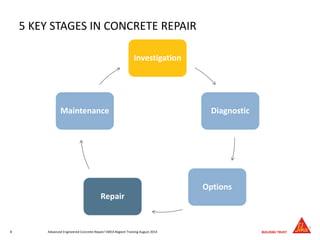

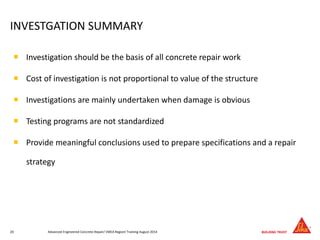

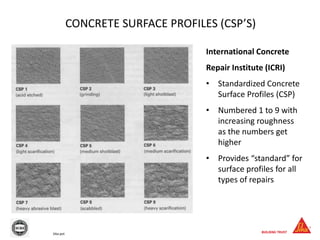

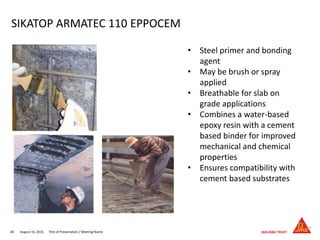

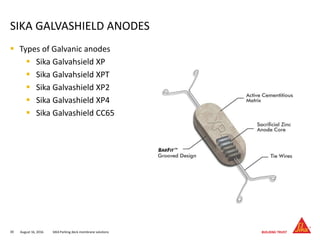

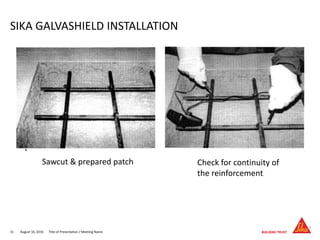

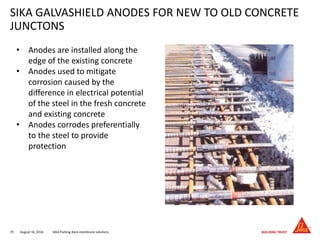

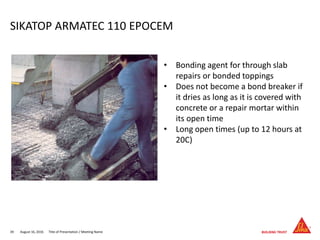

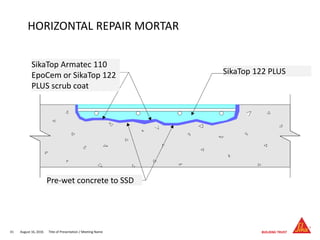

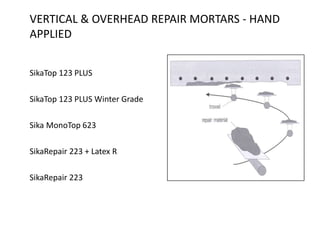

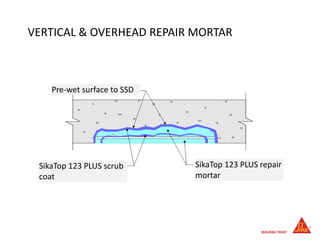

The document outlines a comprehensive approach to the repair and protection of concrete parking structures, emphasizing the importance of systematic investigations and maintenance. Key processes include assessing damage, implementing repair strategies, and utilizing appropriate materials and techniques, such as corrosion mitigation systems and bonding agents. It stresses that thorough preparation and supervision by qualified engineers are crucial for successful concrete refurbishment projects.