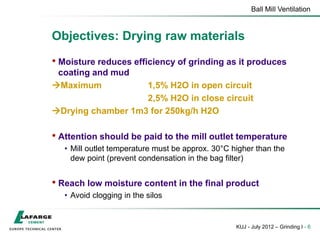

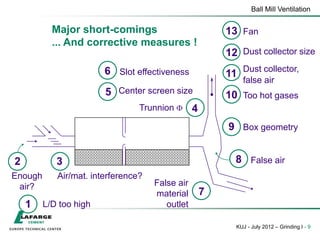

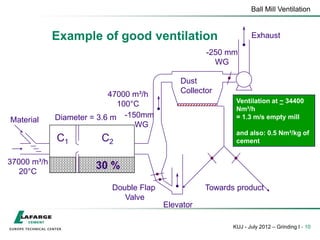

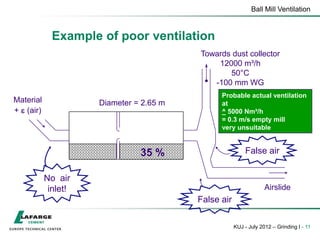

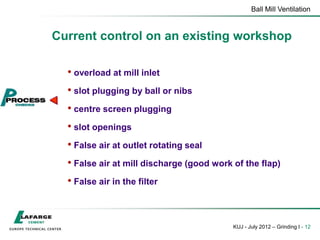

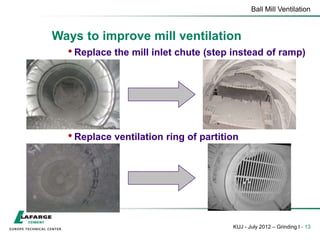

1) Proper ball mill ventilation is important for removing fine particles, cooling cement, and drying raw materials.

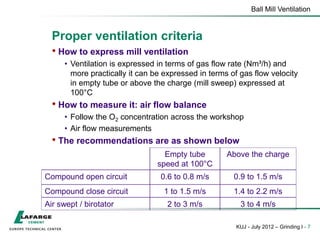

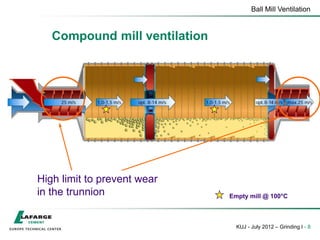

2) Ventilation levels depend on workshop design and mill type, and are typically measured in gas flow velocity in the empty tube or above the charge.

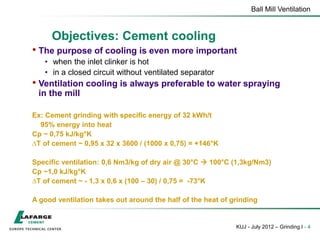

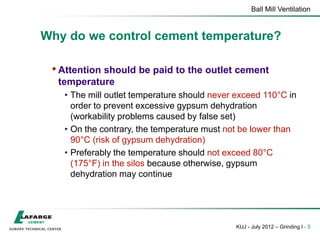

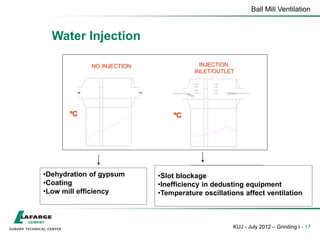

3) Under-ventilation can cause issues like high cement temperatures that damage gypsum, while over-ventilation wastes thermal energy.