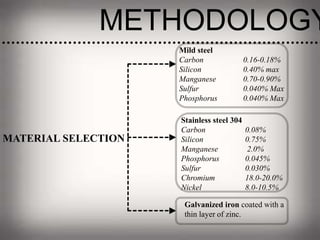

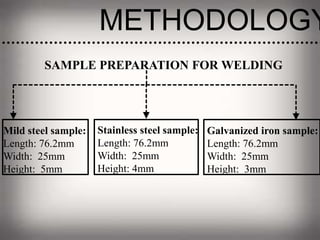

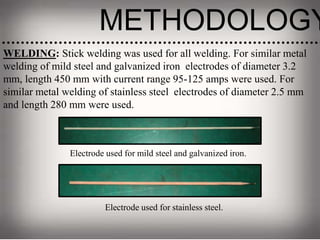

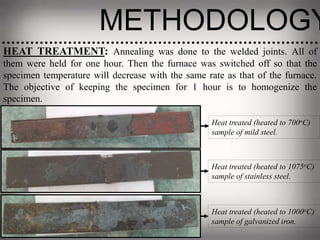

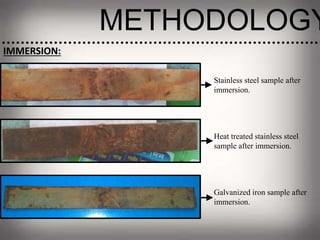

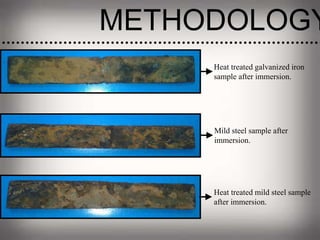

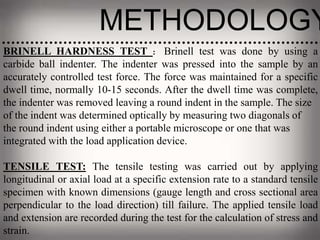

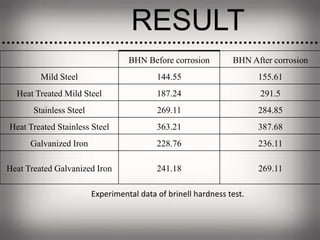

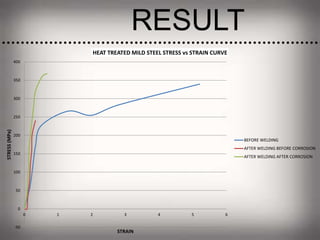

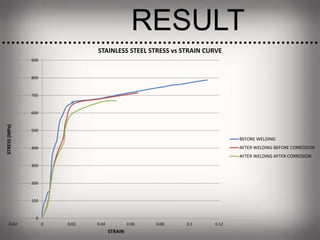

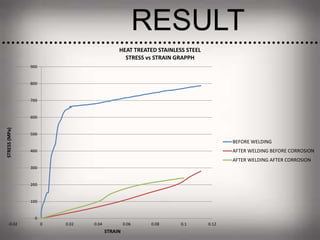

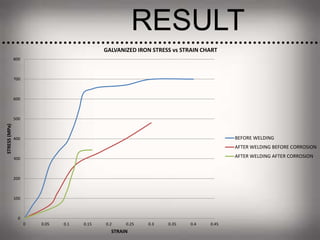

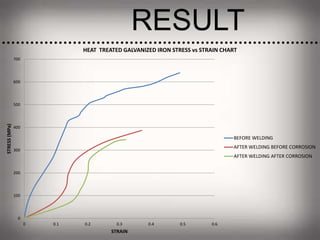

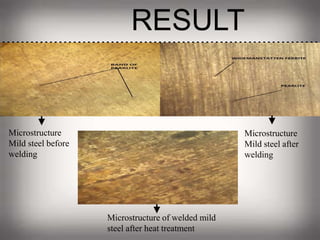

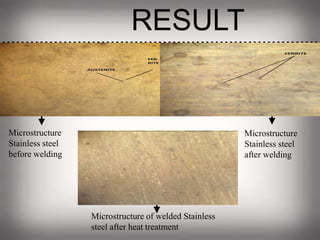

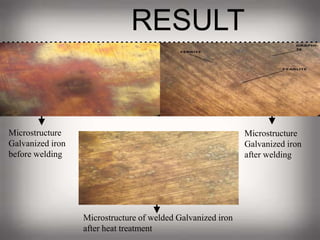

The document summarizes an analysis of welded joints of different metals. Three metals - mild steel, stainless steel, and galvanized iron - were welded together and subjected to heat treatment and corrosion testing. Hardness and tensile tests were conducted before and after corrosion to analyze the effect on mechanical properties. Heat treatment increased hardness but decreased ultimate tensile stress. Corrosion reduced hardness and tensile stress for all welded joints. Stainless steel showed the smallest reduction in properties after corrosion compared to mild steel and galvanized iron. Microstructural analysis also examined the base and welded metals before and after heat treatment.