2016 MRS Fall meeting-Guiqiu Zheng ES5.13.04

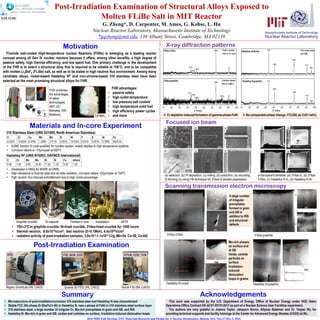

- 1. Post-Irradiation Examination of Structural Alloys Exposed to Molten FLiBe Salt in MIT Reactor G. Zheng*, D. Carpenter, M. Ames, G. Kohse, L. Hu Nuclear Reactor Laboratory, Massachusetts Institute of Technology *gqzheng@mit.edu, 138 Albany Street, Cambridge, MA 02139 2016 MRS Fall Meeting, ES5: Materials Research and Design for A Nuclear Renaissance, Boston, MA, Nov.27-Dec.2, 2016 Motivation Materials and In-core Experiment FHR combines the advantages of latest technologies (MIT, UC- Berkeley, UW- Madison) 7LiF-BeF2 ES5.13.04 Fluoride salt-cooled High-temperature nuclear Reactors (FHRs) is emerging as a leading reactor concept among all Gen IV nuclear reactors because it offers, among other benefits, a high degree of passive safety, high thermal efficiency, and low spent fuel. One primary challenge in the development of the FHR is to select a structural alloy that is required to be reliable at 700°C, and to be compatible with molten Li2BeF4 (FLiBe) salt, as well as to be stable in high neutron flux environment. Among many candidate alloys, nickel-based Hastelloy N® and iron-chrome-based 316 stainless steel have been selected as the most promising structural alloys for FHR. Acknowledgements FHR advantages: • passive safety • high outlet temperature • low pressure salt coolant • high temperature solid fuel • high efficiency power cycles • and more C Cr Cu Mn Mo N Ni P S Si Fe 0.0225 16.8250 0.3795 1.5305 2.0115 0.0510 10.0250 0.0310 0.0016 0.3090 68.8134 C Cr Mn Mo Ni Si Fe others 0.08 7.00 0.80 16.00 71.00 1.00 5.00 1.05 Hastelloy N® (UNS N10003, HAYNES International) • Developed in1960s for MSRE at ORNL • High resistance to fluoride salts and air-side oxidation, corrosion attack <25μm/year at 704ºC • High neutron flux-induced embrittlement due to high nickel percentage • ASME Section III code qualified for nuclear system, widely applied In high temperature systems • Corrosion attack is ~10μm/year at 650ºC 316 Stainless Steel (UNS S31600, North American Stainless) Graphite crucible Ni capsule Thimble in core Installation MITR • 700±3ºC in graphite crucible, Ni-lined crucible, 316ss-lined crucible for 1000 hours • thermal neutron, 8.8x1019n/cm2; fast neutron (E>0.1MeV), 4.4x1020n/cm2 • radiation activity of post-irradiation samples, 3.8x10-3-1.1x10-2 Ci/g (Mn-54, Co-58, Co-60) Post-Irradiation Examination 10 20 30 40 50 60 70 80 90 100 (220) (200) (110) 316ss-316ss (111) FeNi phase due to Cr loss (211) (220) (200) (110) (111) 2 theta 316ss-graphite -ferrite phase due to high C 10 20 30 40 50 60 70 80 90 100 (222) (220) (311) (200) Hastelloy N-Nickel (111) FCC nickel matrix and FeNix (222) (311) (220) (200) (111) 2 theta Hastelloy N-graphite Quanta 3D FEG (INL CAES)Rigaku SmartLab (INL CAES) FIB, SEM, EDSXRD STEM, EDS, TEM Tecnai F30 (INL CAES) X-ray diffraction patterns Cr depletion induced formation of gamma-phase FeNi No comparable phase change, FCC(Ni) as Cr(0-7wt%) Focused ion beam (a) selection, (b) Pt deposition, (c) milling, (d) extraction, (e) mounting, (f) thinning by using FIB technique for 316ss-G lamella preparation e-transparent lamellae, (a) 316ss-G, (b) 316ss- 316ss, (c) Hastelloy N-G, (d) Hastelloy N-Ni Scanning transmission electron microscopy This work was supported by the U.S. Department of Energy, Office of Nuclear Energy under DOE Idaho Operations Office Contract DE-AC07-051D14517 as part of a Nuclear Science User Facilities experiment. The authors are very grateful to Joanna Taylor, Jatuporn Burns, Allyssa Bateman and Dr. Yaqiao Wu for providing technical supports and facility trainings at the Center for Advanced Energy Studies (CAES) at INL. Hastelloy N-nickel Hastelloy N-graphite 316ss-316ss 316ss-graphite Mo-rich phases on surface and at GB Oxide, carbide particles on surface irradiation- induced dislocation loops in grains A large number of irregular precipitates formed in grain and GB in addition to RIS and structural defects Summary • Microstructure of post-irradiation/corrosion 316 stainless steel and Hastelloy N was characterized • Stable FCC (Ni) phase (0-30wt%Cr-Ni) in Hastelloy N, new γ-phase of FeNi in 316 stainless steel surface layer • 316 stainless steel: a large number of irregular Cr, Mo-rich precipitates in grain and GB, and RIS • Hastelloy N: Mo-rich in grain and GB, oxides and carbides on surface, irradiation-induced dislocation loops