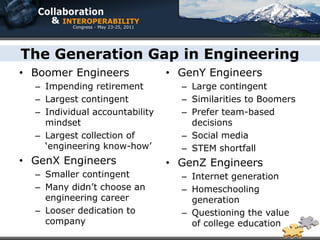

- Managing engineering organizations today is more difficult due to projects being understaffed and shorter schedules as well as generational differences between employees.

- CEOs are more involved in product development and focused on innovation for competitive advantage. They want more visibility into engineering operations.

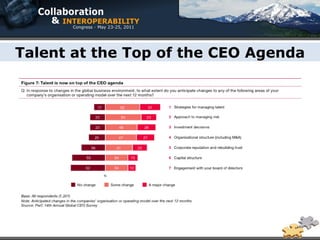

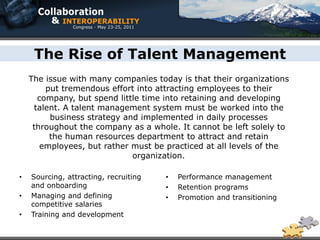

- Talent management must be integrated into business strategy and implemented throughout the organization, not just in HR, to attract and retain employees.

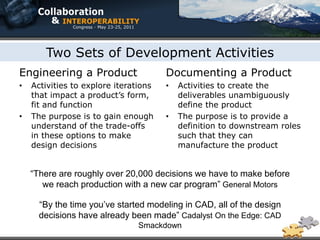

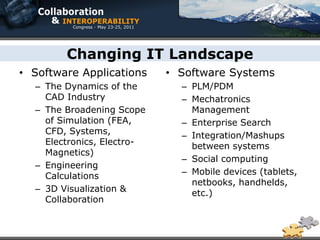

- Different approaches are needed to develop and document products to make design decisions and provide definitions for manufacturing. Changing IT landscapes and tools also impact engineering organizations.