2002 toyota corolla service repair manual

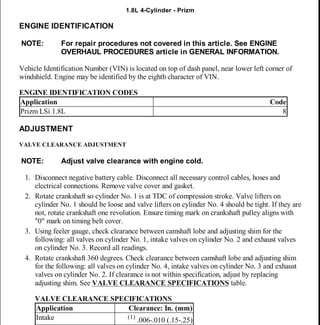

- 1. 2000-01 ENGINES 1.8L 4-Cylinder - Prizm ENGINE IDENTIFICATION Vehicle Identification Number (VIN) is located on top of dash panel, near lower left corner of windshield. Engine may be identified by the eighth character of VIN. ENGINE IDENTIFICATION CODES ADJUSTMENT VALVE CLEARANCE ADJUSTMENT 1. Disconnect negative battery cable. Disconnect all necessary control cables, hoses and electrical connections. Remove valve cover and gasket. 2. Rotate crankshaft so cylinder No. 1 is at TDC of compression stroke. Valve lifters on cylinder No. 1 should be loose and valve lifters on cylinder No. 4 should be tight. If they are not, rotate crankshaft one revolution. Ensure timing mark on crankshaft pulley aligns with "0" mark on timing belt cover. 3. Using feeler gauge, check clearance between camshaft lobe and adjusting shim for the following: all valves on cylinder No. 1, intake valves on cylinder No. 2 and exhaust valves on cylinder No. 3. Record all readings. 4. Rotate crankshaft 360 degrees. Check clearance between camshaft lobe and adjusting shim for the following: all valves on cylinder No. 4, intake valves on cylinder No. 3 and exhaust valves on cylinder No. 2. If clearance is not within specification, adjust by replacing adjusting shim. See VALVE CLEARANCE SPECIFICATIONS table. VALVE CLEARANCE SPECIFICATIONS NOTE: For repair procedures not covered in this article. See ENGINE OVERHAUL PROCEDURES article in GENERAL INFORMATION. Application Code Prizm LSi 1.8L 8 NOTE: Adjust valve clearance with engine cold. Application Clearance: In. (mm) Intake (1) .006-.010 (.15-.25) 2000 Chevrolet Prizm 2000-01 ENGINES 1.8L 4-Cylinder - Prizm 2000 Chevrolet Prizm 2000-01 ENGINES 1.8L 4-Cylinder - Prizm MY Tuesday, March 31, 2009 10:43:14 AM Page 1 © 2005 Mitchell Repair Information Company, LLC. MY Tuesday, March 31, 2009 10:43:23 AM Page 1 © 2005 Mitchell Repair Information Company, LLC.

- 2. 5. Rotate engine until camshaft lobe faces away from valve to be adjusted. Insert Valve Spring Depressor (J-39871-1) between camshaft and adjusting shim. See Fig. 1 . 6. Install Valve Lash Spring Spacer (J-39871-2) between camshaft and valve lifter. Ensure bottom edge of valve lash spring spacer contacts valve lifter, NOT adjusting shim. Remove valve spring depressor. Using small screwdriver and magnet, remove adjusting shim from valve lifter. Fig. 1: Adjusting Valve Clearance (Typical) Courtesy of GENERAL MOTORS CORP. 7. To determine correct adjusting shim thickness for shim replacement, measure and record thickness of removed shim. Locate measured values of removed shim and valve clearance on appropriate adjusting shim selection chart to determine correct shim thickness. See Fig. 2 Exhaust (1) .010-.014 (.25-.35) (1) Adjust valve clearance with engine cold. 2000 Chevrolet Prizm 2000-01 ENGINES 1.8L 4-Cylinder - Prizm MY Tuesday, March 31, 2009 10:43:14 AM Page 2 © 2005 Mitchell Repair Information Company, LLC.

- 3. and Fig. 3 . 8. Install correct shim thickness to obtain proper clearance. See VALVE CLEARANCE SPECIFICATIONS table. Repeat procedure if necessary. Before installing valve cover, install NEW gasket to cylinder head and NEW seal washers to valve cover. Install valve cover in reverse order of removal. Fig. 2: Exhaust Valve Adjusting Shim Selection Chart Courtesy of TOYOTA MOTOR SALES, U.S.A., INC. 2000 Chevrolet Prizm 2000-01 ENGINES 1.8L 4-Cylinder - Prizm MY Tuesday, March 31, 2009 10:43:14 AM Page 3 © 2005 Mitchell Repair Information Company, LLC.

- 4. Fig. 3: Intake Valve Adjusting Shim Selection Chart Courtesy of TOYOTA MOTOR SALES, U.S.A., INC. TROUBLE SHOOTING REMOVAL & INSTALLATION FUEL PRESSURE RELEASE NOTE: To trouble shoot engine mechanical components, see appropriate table in TROUBLE SHOOTING article in GENERAL INFORMATION. NOTE: For installation reference, label all electrical connectors, vacuum hoses and fuel lines before removing. Also place mating marks on engine hood and other major assemblies before removing. 2000 Chevrolet Prizm 2000-01 ENGINES 1.8L 4-Cylinder - Prizm MY Tuesday, March 31, 2009 10:43:14 AM Page 4 © 2005 Mitchell Repair Information Company, LLC.

- 5. 1. Loosen fuel tank cap to release fuel tank pressure. Disconnect circuit opening relay located behind radio. Start engine and allow engine to stall. Crank engine again for an additional 3 seconds, to ensure relief of any remaining pressure. 2. Disconnect negative battery cable. Connect circuit opening relay and tighten fuel filler cap. Wrap fuel component or fitting with shop towel during removal. ENGINE Removal 1. Release fuel pressure. See FUEL PRESSURE RELEASE . Disconnect battery cables, and remove battery. Remove hood. Raise and support vehicle. Drain engine oil and cooling system. Remove lower engine splash covers. 2. Disconnect necessary coolant hoses and fuel lines. Remove air intake duct and control cables from throttle body. Remove air cleaner. Disconnect necessary vacuum hoses, electrical connections and engine ground wires. Remove cruise control actuator (if equipped). Remove 4 ignition coil bolts. Remove ignition coils with spark plug wires attached. 3. Remove serpentine belt. Unplug and remove washer reservoir. On M/T models, remove crankshaft pulley, generator, and drive belt tensioner. Disconnect and remove oxygen sensor and gasket. Unbolt ground wire at engine lift hook. Disconnect starter wiring, then remove starter. Unbolt all wiring harness brackets. Ensure all electrical connectors are disconnected, then reroute harness off to side. 4. On A/T models, remove torque converter access cover, then remove 6 torque converter bolts. Remove power steering through-bolts and nuts. Secure power steering pump aside. Remove exhaust pipe retainer bolts and springs from exhaust manifold. Also remove heat shield around axle shaft boot. Remove the 4 bottom transmission-to-engine mounting bolts. 5. Lower vehicle and connect engine hoist. Unbolt upper transmission-to-engine mounting bolts. Remove right side engine mount and bracket. Verify all hoses and wires are disconnected from engine, then lift engine out of vehicle. Installation To install, reverse removal procedure. Tighten all fasteners to specification. See TORQUE SPECIFICATIONS . Adjust all control cables. Adjust fluid levels. INTAKE MANIFOLD NOTE: Engine and transaxle are removed separately. 2000 Chevrolet Prizm 2000-01 ENGINES 1.8L 4-Cylinder - Prizm MY Tuesday, March 31, 2009 10:43:14 AM Page 5 © 2005 Mitchell Repair Information Company, LLC.

- 6. Removal 1. Disconnect negative battery cable. Drain cooling system. Disconnect throttle cable and TV cable (A/T models) from throttle body. 2. Unhook IAT sensor from air cleaner, and remove air cleaner hose from throttle body. Remove air cleaner top assembly. Disconnect all electrical components and coolant by-pass hoses from throttle body. 3. Disconnect fuel injector connectors. Remove harness bolts, then disconnect wiring harness from intake manifold. Remove intake manifold support bracket bolts and bracket. Disconnect upper radiator hose at radiator, then remove radiator hose support bracket. Remove injector harness support brackets. Remove intake manifold with throttle body. Inspection Check intake manifold for cracks and warpage. Replace intake manifold if warpage exceeds .004" (.10 mm). Installation To complete installation, reverse removal procedure. Tighten all fasteners to specification. See TORQUE SPECIFICATIONS . EXHAUST MANIFOLD Removal Disconnect negative battery cable. Disconnect oxygen sensor wiring connector. Remove exhaust manifold brace. Disconnect exhaust pipe from exhaust manifold. Remove heat shield from exhaust manifold. Remove exhaust manifold bolts/nuts, exhaust manifold and gasket. Inspection Check exhaust manifold for cracks and warpage. Replace exhaust manifold if warpage exceeds .004" (.10 mm). Installation To install, reverse removal procedure. Tighten bolts/nuts to specification. See TORQUE SPECIFICATIONS . NOTE: Always install NEW gasket whenever intake manifold is removed. 2000 Chevrolet Prizm 2000-01 ENGINES 1.8L 4-Cylinder - Prizm MY Tuesday, March 31, 2009 10:43:14 AM Page 6 © 2005 Mitchell Repair Information Company, LLC.

- 7. CYLINDER HEAD Removal 1. Release fuel pressure. See FUEL PRESSURE RELEASE . Disconnect battery. Drain cooling system and engine oil. Disconnect throttle cable, all electrical components and 2 coolant bypass hoses from throttle body. Remove air cleaner hose and upper air cleaner assembly. 2. Disconnect temperature sensor. Disconnect fuel injector connectors and move injector harness aside. Remove upper radiator hose, injector harness brackets, intake manifold support brackets, oxygen sensor and gasket, and all necessary vacuum hoses. 3. Disconnect and remove ignition coils, with spark plug wires attached. Disconnect fuel line at fuel rail, then unbolt and remove fuel rail. Disconnect all electrical connectors, hoses and vacuum lines. Remove coolant bypass pipe. Position wiring harness aside. Remove camshaft position and coolant temperature sensors. 4. Remove exhaust pipe bolts and springs, pipe-to-manifold seal, and support bracket bolt. Remove PCV valve and hoses, then unbolt and remove valve cover. Remove timing chain. See TIMING CHAIN . 5. Remove intake and exhaust camshaft sprockets. Note original location of camshaft bearing caps for installation reference. Remove camshaft bearing cap bolts in sequence. See Fig. 4 . Remove camshafts. 6. Using a wooden block, lift engine with a floor jack and reposition holding fixture. Loosen cylinder head bolts in sequence. See Fig. 5 . Remove head bolts and washers. Remove cylinder head. NOTE: Manufacturer recommends removing timing chain and camshaft sprockets when removing cylinder head. 2000 Chevrolet Prizm 2000-01 ENGINES 1.8L 4-Cylinder - Prizm MY Tuesday, March 31, 2009 10:43:14 AM Page 7 © 2005 Mitchell Repair Information Company, LLC.

- 8. 2000 Chevrolet Prizm 2000-01 ENGINES 1.8L 4-Cylinder - Prizm MY Tuesday, March 31, 2009 10:43:14 AM Page 8 © 2005 Mitchell Repair Information Company, LLC.

- 9. Fig. 4: Camshaft Bearing Cap Bolt Removal & Installation Sequence Courtesy of TOYOTA MOTOR SALES, U.S.A., INC. Fig. 5: Cylinder Head Bolt Removal & Installation Sequence 2000 Chevrolet Prizm 2000-01 ENGINES 1.8L 4-Cylinder - Prizm MY Tuesday, March 31, 2009 10:43:14 AM Page 9 © 2005 Mitchell Repair Information Company, LLC.

- 10. Courtesy of TOYOTA MOTOR SALES, U.S.A., INC. Fig. 6: Exploded View Of Cylinder Head & Timing Chain Components Courtesy of TOYOTA MOTOR SALES, U.S.A., INC. 2000 Chevrolet Prizm 2000-01 ENGINES 1.8L 4-Cylinder - Prizm MY Tuesday, March 31, 2009 10:43:14 AM Page 10 © 2005 Mitchell Repair Information Company, LLC.

- 11. Inspection Inspect cylinder head surface and manifold sealing areas for cracks and warpage. Replace cylinder head if warpage exceeds specification. Inspect cylinder block deck warpage along all 4 edges and diagonally across cylinder head. Replace cylinder block if warpage exceeds specification. See CYLINDER HEAD and CYLINDER BLOCK tables under ENGINE SPECIFICATIONS. Installation 1. Before installing cylinder head bolts, apply light coat of engine oil onto threads and below bolt heads. Using multiple steps, tighten cylinder head bolts in sequence to specification. See Fig. 5 . See TORQUE SPECIFICATIONS . Install manifolds, if removed. See INTAKE MANIFOLD and EXHAUST MANIFOLD . 2. Reposition engine holding fixture, and support engine by support hook. Remove floorjack. Install camshafts and timing chain. See CAMSHAFT and TIMING CHAIN . If cylinder head components were serviced, check valve clearance. See VALVE CLEARANCE ADJUSTMENT under ADJUSTMENTS. Install valve cover. 3. Install coolant temperature and camshaft position sensors. Tighten camshaft position sensor bolt to specification. See TORQUE SPECIFICATIONS . Install coolant bypass pipe to cylinder head, and tighten bolt to specification. See TORQUE SPECIFICATIONS . 4. Reinstall engine ground wires. Use new "O" rings on fuel injectors and install fuel rail to cylinder head. Secure fuel rail with 3 bolts, and reconnect fuel line to fuel rail. Install 2 ignition coils and spark plug wires. Tighten 4 bracket bolts to specification. See TORQUE SPECIFICATIONS . Reconnect coil connectors. 5. Raise vehicle and install exhaust manifold bracket bolt. Replace exhaust pipe seal, and secure pipe onto manifold using 2 springs and bolts. Tighten exhaust pipe-to-manifold bolts to specification. See TORQUE SPECIFICATIONS . Lower vehicle. Install oxygen sensor, harness and manifold support brackets, all vacuum hoses, and all electrical connectors. 6. Install upper radiator hose and reconnect coolant bypass hoses to throttle body. Install air cleaner, and reconnect IAT sensor. Use 2 bolts to attach generator to engine. Tighten bolts to specification. See TORQUE SPECIFICATIONS . Connect positive cable and electrical connector to generator. Install serpentine belt. 7. Reconnect fluid line and washer pump connector to window washer reservoir, then reinstall reservoir. Refill engine oil and coolant. CRANKSHAFT FRONT SEAL Removal & Installation 2000 Chevrolet Prizm 2000-01 ENGINES 1.8L 4-Cylinder - Prizm MY Tuesday, March 31, 2009 10:43:14 AM Page 11 © 2005 Mitchell Repair Information Company, LLC.

- 12. 1. Crankshaft front seal is mounted in timing chain cover. See Fig. 6 . Remove serpentine belt and crankshaft pulley bolt. Using puller, remove crankshaft pulley. Pry seal from timing chain cover. DO NOT damage sealing surfaces. 2. Coat lip of NEW seal with grease. Using hammer and Seal Installer (SST 09309-37010), install seal until seal surface is flush with timing chain cover. Install crankshaft pulley and torque to specifications. See TORQUE SPECIFICATIONS . To install remaining components, reverse removal procedure. TIMING CHAIN Removal IMPORTANT: When performing any service procedure that pertains to the camshaft or the camshaft actuator, unlock the camshaft actuator locking pin. 2000 Chevrolet Prizm 2000-01 ENGINES 1.8L 4-Cylinder - Prizm MY Tuesday, March 31, 2009 10:43:14 AM Page 12 © 2005 Mitchell Repair Information Company, LLC.

- 13. Fig. 7: Removing Or Installing Serpentine Belt Courtesy of GENERAL MOTORS CORP. 1. Remove the accessory drive belt. 2. Remove the generator from the engine. CAUTION: Before servicing any electrical component, the ignition and start switch must be in the OFF or LOCK position and all electrical loads must be OFF, unless instructed otherwise in these procedures. If a tool or equipment could easily come in contact with a live exposed electrical terminal, also disconnect the negative battery cable. Failure to follow these precautions may cause personal injury and/or damage to the vehicle or its 2000 Chevrolet Prizm 2000-01 ENGINES 1.8L 4-Cylinder - Prizm MY Tuesday, March 31, 2009 10:43:14 AM Page 13 © 2005 Mitchell Repair Information Company, LLC.

- 14. 3. Disconnect the negative battery cable. 4. Drain the cooling system. 5. Remove the windshield washer fluid reservoir mounting bolt. 6. Disconnect the windshield washer pump connector. 7. Disconnect the windshield washer pump fluid line. 8. Plug the pump outlet. 9. Remove the windshield washer fluid reservoir. 10. Install the engine support fixture. Fig. 8: Engine Mounting Hardware Courtesy of GENERAL MOTORS CORP. components. 2000 Chevrolet Prizm 2000-01 ENGINES 1.8L 4-Cylinder - Prizm MY Tuesday, March 31, 2009 10:43:14 AM Page 14 © 2005 Mitchell Repair Information Company, LLC.

- 15. 11. Remove the following fasteners from the right side engine mount: The 2 nuts (3), The 4 bolts (1). 12. Loosen the A/C receiver pinch clamp. 13. Lift the A/C receiver in order to access the right side engine mount. 14. Remove the right side engine mount. 15. Remove the cylinder head cover. Fig. 9: Aligning Engine To TDC Courtesy of GENERAL MOTORS CORP. 16. Set the number one piston to the top dead center position. 2000 Chevrolet Prizm 2000-01 ENGINES 1.8L 4-Cylinder - Prizm MY Tuesday, March 31, 2009 10:43:14 AM Page 15 © 2005 Mitchell Repair Information Company, LLC.

- 16. 17. Align the camshaft timing sprockets. 18. Disconnect the power steering oil pressure switch connector. 19. Raise and properly support the vehicle. 20. Remove the right side lower engine splash shield. Fig. 10: Power Steering Mounting View Courtesy of GENERAL MOTORS CORP. 21. Remove the two power steering pump through bolts and the nuts (1). 22. Remove the power steering pump from the mounting surface. Move the pump to the side. 2000 Chevrolet Prizm 2000-01 ENGINES 1.8L 4-Cylinder - Prizm MY Tuesday, March 31, 2009 10:43:14 AM Page 16 © 2005 Mitchell Repair Information Company, LLC.

- 17. Fig. 11: Loosening/Tightening Crankshaft Bolt Courtesy of GENERAL MOTORS CORP. 23. Remove the crankshaft pulley retaining bolt using J 8614-01 to prevent crankshaft rotation when loosening the bolt. 24. Remove the crankshaft pulley. 2000 Chevrolet Prizm 2000-01 ENGINES 1.8L 4-Cylinder - Prizm MY Tuesday, March 31, 2009 10:43:14 AM Page 17 © 2005 Mitchell Repair Information Company, LLC.

- 18. Fig. 12: Identifying Engine Components Courtesy of GENERAL MOTORS CORP. 25. Remove the following components: The crankshaft position sensor bolt (5), The sensor. 26. Lower the vehicle. 27. Remove the following components from the mounting surface: The drive belt tensioner bolt, The drive belt tensioner nut, The drive belt tensioner. 2000 Chevrolet Prizm 2000-01 ENGINES 1.8L 4-Cylinder - Prizm MY Tuesday, March 31, 2009 10:43:14 AM Page 18 © 2005 Mitchell Repair Information Company, LLC.

- 19. Fig. 13: Chain Tensioner Bolts Courtesy of GENERAL MOTORS CORP. 28. Remove the timing chain tensioner bolts (1,2). 29. Remove the timing chain tensioner. 2000 Chevrolet Prizm 2000-01 ENGINES 1.8L 4-Cylinder - Prizm MY Tuesday, March 31, 2009 10:43:14 AM Page 19 © 2005 Mitchell Repair Information Company, LLC.

- 20. Fig. 14: Timing Chain Cover Fasteners Courtesy of GENERAL MOTORS CORP. 30. Remove the following fasteners: The timing chain cover bolts (1-14), The timing chain cover nut (15). 31. Remove the timing chain cover. 2000 Chevrolet Prizm 2000-01 ENGINES 1.8L 4-Cylinder - Prizm MY Tuesday, March 31, 2009 10:43:14 AM Page 20 © 2005 Mitchell Repair Information Company, LLC.

- 21. Fig. 15: Crankshaft Sensor Reluctor Courtesy of GENERAL MOTORS CORP. 32. Remove the crankshaft sensor reluctor (1). 2000 Chevrolet Prizm 2000-01 ENGINES 1.8L 4-Cylinder - Prizm MY Tuesday, March 31, 2009 10:43:14 AM Page 21 © 2005 Mitchell Repair Information Company, LLC.

- 22. Fig. 16: Timing Chain Components Courtesy of GENERAL MOTORS CORP. 33. Remove the following components: The timing chain dampener bolt (1), The timing chain dampener, The timing chain shoe bolts (2), The timing chain shoe. 2000 Chevrolet Prizm 2000-01 ENGINES 1.8L 4-Cylinder - Prizm MY Tuesday, March 31, 2009 10:43:15 AM Page 22 © 2005 Mitchell Repair Information Company, LLC.

- 23. Fig. 17: Removing Crankshaft Sprocket & Chain Courtesy of GENERAL MOTORS CORP. 34. Remove the following components: The crankshaft sprocket, The timing chain. 35. Remove the three bolts from the front camshaft bearing cap. 36. Remove the front camshaft bearing cap in order to access the oil passage to the CMP actuator. 2000 Chevrolet Prizm 2000-01 ENGINES 1.8L 4-Cylinder - Prizm MY Tuesday, March 31, 2009 10:43:15 AM Page 23 © 2005 Mitchell Repair Information Company, LLC.

- 24. Fig. 18: Applying Air Pressure To Advance Passage Courtesy of GENERAL MOTORS CORP. 37. Ensure that the CMP actuator will not turn. 38. Apply air pressure of approximately 100 kPa (14 psi) to the advance passage of the camshaft. 39. Turn the CMP actuator to the advanced angle side by hand. 40. Rotate the actuator back and forth through the advanced positions to ensure 21 degrees of movement. 41. Remove the air pressure and turn the CMP actuator back to the minimum advanced angle position to lock it. 42. Replace the CMP actuator if the following conditions exist: CMP actuator does not lock with air pressure removed. CMP actuator does not unlock with air pressure applied. CMP actuator does not rotate smoothly through the advanced positions. 2000 Chevrolet Prizm 2000-01 ENGINES 1.8L 4-Cylinder - Prizm MY Tuesday, March 31, 2009 10:43:15 AM Page 24 © 2005 Mitchell Repair Information Company, LLC.

- 25. CMP actuator does not rotate completely through the advance positions. 43. Install the front camshaft bearing cap. 44. Install the front camshaft bearing cap bolts. Tighten the camshaft bearing cap bolts to 23 N.m (17 lb ft). Installation Fig. 19: Align The Camshaft Timing Marks Courtesy of GENERAL MOTORS CORP. 1. Use a wrench in order to align the camshaft timing marks. Be sure to place the wrench on the hexagonal portion of the camshafts. 2000 Chevrolet Prizm 2000-01 ENGINES 1.8L 4-Cylinder - Prizm MY Tuesday, March 31, 2009 10:43:15 AM Page 25 © 2005 Mitchell Repair Information Company, LLC.

- 26. Fig. 20: Timing Mark Alignment Courtesy of GENERAL MOTORS CORP. 2. Turn the camshafts in order to align the timing marks. 2000 Chevrolet Prizm 2000-01 ENGINES 1.8L 4-Cylinder - Prizm MY Tuesday, March 31, 2009 10:43:15 AM Page 26 © 2005 Mitchell Repair Information Company, LLC.

- 27. Fig. 21: Crankshaft Keyway Facing Up Courtesy of GENERAL MOTORS CORP. 3. Temporarily install the crankshaft bolt. 4. Turn the crankshaft until the crankshaft keyway (1) faces upward. 2000 Chevrolet Prizm 2000-01 ENGINES 1.8L 4-Cylinder - Prizm MY Tuesday, March 31, 2009 10:43:15 AM Page 27 © 2005 Mitchell Repair Information Company, LLC.

- 28. Fig. 22: Installing Timing Chain Courtesy of GENERAL MOTORS CORP. 5. Install the following components: The timing chain (2), The crankshaft timing sprocket 2000 Chevrolet Prizm 2000-01 ENGINES 1.8L 4-Cylinder - Prizm MY Tuesday, March 31, 2009 10:43:15 AM Page 28 © 2005 Mitchell Repair Information Company, LLC.

- 29. Fig. 23: Timing Chain Shoe Bolts Courtesy of GENERAL MOTORS CORP. 6. Install the timing chain shoe. Secure the timing chain shoe using two bolts (1,2). Tighten the bolts to 10 N.m (89 lb in). 2000 Chevrolet Prizm 2000-01 ENGINES 1.8L 4-Cylinder - Prizm MY Tuesday, March 31, 2009 10:43:15 AM Page 29 © 2005 Mitchell Repair Information Company, LLC.

- 30. Fig. 24: Aligning All Timing Marks Courtesy of GENERAL MOTORS CORP. 7. Install the timing chain (1) onto the exhaust camshaft sprocket (4) and the intake camshaft sprockets (5). Ensure that the timing chain links (2) are aligned with the timing marks (3). The intake cam phaser mark (7) should be at the 9 o'clock position and the "Ex" timing mark (8) on the exhaust camshaft sprocket (4) should be at the 3 o'clock position. The colored links (2) will line up around the 12 o'clock position with the double dots (3) on the exhaust sprocket and the line (6) on the cam phaser body. 2000 Chevrolet Prizm 2000-01 ENGINES 1.8L 4-Cylinder - Prizm MY Tuesday, March 31, 2009 10:43:15 AM Page 30 © 2005 Mitchell Repair Information Company, LLC.

- 31. Fig. 25: Timing Chain Components Courtesy of GENERAL MOTORS CORP. 8. Install the timing chain dampener. Secure the timing chain dampener using one bolt (1). Tighten the bolt to 18 N.m (14 lb ft). 2000 Chevrolet Prizm 2000-01 ENGINES 1.8L 4-Cylinder - Prizm MY Tuesday, March 31, 2009 10:43:15 AM Page 31 © 2005 Mitchell Repair Information Company, LLC.

- 32. Fig. 26: Crankshaft Sensor Reluctor Courtesy of GENERAL MOTORS CORP. 9. Install the crankshaft sensor reluctor (1) onto the crankshaft. Insure that the letter "F" on the reluctor is facing outward. 10. Apply a continuous bead of GM P/N 12346240 or an equivalent to the timing chain cover mating surface. 11. Unlock the intake camshaft actuator locking pin. 2000 Chevrolet Prizm 2000-01 ENGINES 1.8L 4-Cylinder - Prizm MY Tuesday, March 31, 2009 10:43:15 AM Page 32 © 2005 Mitchell Repair Information Company, LLC.

- 33. Fig. 27: Tightening Timing Chain Cover Bolts Courtesy of GENERAL MOTORS CORP. 12. Install the timing chain cover. Use the following fasteners in order to secure the cover: Fifteen bolts (1-14), One nut (15) 2000 Chevrolet Prizm 2000-01 ENGINES 1.8L 4-Cylinder - Prizm MY Tuesday, March 31, 2009 10:43:15 AM Page 33 © 2005 Mitchell Repair Information Company, LLC.

- 34. Tighten the timing chain cover nut and bolts (10 mm (0.394 in) head) to 10 N.m (89 lb in). Tighten the timing chain cover nut and bolts (12 mm (0.394 in) head) to 18 N.m (14 lb ft). Fig. 28: Timing Chain Tensioner Courtesy of GENERAL MOTORS CORP. 13. Use the following steps in order to install the timing chain tensioner: A. Fully depress the plunger (4). B. Apply the hook (2) to the pin (3). 2000 Chevrolet Prizm 2000-01 ENGINES 1.8L 4-Cylinder - Prizm MY Tuesday, March 31, 2009 10:43:15 AM Page 34 © 2005 Mitchell Repair Information Company, LLC.

- 35. C. Install the timing chain tensioner. Fig. 29: Installing Timing Chain Tensioner Courtesy of GENERAL MOTORS CORP. 14. Install the timing chain tensioner. Secure the timing chain tensioner using 2 bolts (1). Tighten the bolts to 10 N.m (89 lb in). 2000 Chevrolet Prizm 2000-01 ENGINES 1.8L 4-Cylinder - Prizm MY Tuesday, March 31, 2009 10:43:15 AM Page 35 © 2005 Mitchell Repair Information Company, LLC.

- 36. Fig. 30: Identifying Engine Components Courtesy of GENERAL MOTORS CORP. 15. Install the right side engine mounting bracket. Secure the bracket using 3 bolts. Tighten the bolts to 54 N.m (40 lb ft). 16. Install the drive belt tensioner. Secure the tensioner using one bolt and one nut. Tighten the bolt to 69 N.m (51 lb ft). Tighten the nut to 29 N.m (21 lb ft). 17. Raise the vehicle. Support the vehicle. 18. Install the crankshaft position sensor. Secure the sensor using one bolt (5). 2000 Chevrolet Prizm 2000-01 ENGINES 1.8L 4-Cylinder - Prizm MY Tuesday, March 31, 2009 10:43:15 AM Page 36 © 2005 Mitchell Repair Information Company, LLC.

- 37. Tighten the bolt to 12 N.m (106 lb in). Fig. 31: Torquing Crank Shaft Bolt Courtesy of GENERAL MOTORS CORP. 19. Install the crankshaft pulley. Secure the crankshaft pulley using one bolt. Tighten the crankshaft pulley to 142 N.m (105 lb ft). 2000 Chevrolet Prizm 2000-01 ENGINES 1.8L 4-Cylinder - Prizm MY Tuesday, March 31, 2009 10:43:15 AM Page 37 © 2005 Mitchell Repair Information Company, LLC.

- 38. Fig. 32: Power Steering Mounting View Courtesy of GENERAL MOTORS CORP. 20. Install the power steering pump. 21. Use the following fasteners in order to secure the power steering pump: 2 bolts (1), 2 nuts. Tighten the bolts to 37 N.m (27 lb ft). 22. Install the right side lower engine splash shield. 23. Lower the vehicle. 24. Connect the power steering oil pressure switch connector. 2000 Chevrolet Prizm 2000-01 ENGINES 1.8L 4-Cylinder - Prizm MY Tuesday, March 31, 2009 10:43:15 AM Page 38 © 2005 Mitchell Repair Information Company, LLC.

- 39. Fig. 33: Rotating Engine To Release Plunger Courtesy of GENERAL MOTORS CORP. 25. Rotate the crankshaft clockwise one revolution. Ensure that the plunger on the timing chain tensioner has released. Complete the following steps if the plunger does not release: Use a screwdriver or your finger in order to press the timing chain dampener into the timing chain tensioner. Release the hook from the pin. Verify proper timing chain alignment after the plunger has released. 2000 Chevrolet Prizm 2000-01 ENGINES 1.8L 4-Cylinder - Prizm MY Tuesday, March 31, 2009 10:43:15 AM Page 39 © 2005 Mitchell Repair Information Company, LLC.

- 40. 26. Install the cylinder head cover. Fig. 34: Engine Mounting Hardware Courtesy of GENERAL MOTORS CORP. 27. Install the right side engine mount. 28. Use the following fasteners in order to secure the mount: 3 bolts (1), 2 nuts (3). Tighten the right side engine mount bolts (1,2,4) to 54 N.m (40 lb ft). Tighten the right side engine insulator nuts (3) to 54 N.m (40 lb ft). 29. Lower the A/C receiver. Tighten the pinch clamp. 2000 Chevrolet Prizm 2000-01 ENGINES 1.8L 4-Cylinder - Prizm MY Tuesday, March 31, 2009 10:43:15 AM Page 40 © 2005 Mitchell Repair Information Company, LLC.

- 41. Fig. 35: Using J 28467-A To Support The Engine Courtesy of GENERAL MOTORS CORP. 30. Remove the engine support fixture (J 28467-A). 31. Install the generator. 32. Remove the plug from the windshield washer reservoir. 33. Connect the windshield washer fluid line. 34. Connect the windshield washer pump connector. 35. Install the windshield washer reservoir. Secure the reservoir using one bolt. 36. Fill the cooling system. 37. Connect the negative battery cable. Tighten the cable bolt to 15 N.m (11 lb ft). CAMSHAFT 2000 Chevrolet Prizm 2000-01 ENGINES 1.8L 4-Cylinder - Prizm MY Tuesday, March 31, 2009 10:43:15 AM Page 41 © 2005 Mitchell Repair Information Company, LLC.

- 42. Removal Remove timing chain, valve cover and camshaft sprockets. See TIMING CHAIN . Note original location of camshaft bearing caps for installation reference. Remove cam bearing cap bolts in sequence. See Fig. 4 . Remove camshafts. Inspection Inspect camshaft lobe height, journal diameter and runout. Replace camshaft if not within specifications. See CAMSHAFT table under ENGINE SPECIFICATIONS. Use Plastigage to check camshaft oil clearance. Install camshaft into cylinder head and tighten bearing cap bolts in sequence to specification. See Fig. 4 . See TORQUE SPECIFICATIONS . Replace camshaft and/or cylinder head if oil clearance is not within specifications. See CAMSHAFT table under ENGINE SPECIFICATIONS. Installation Install camshafts into cylinder head. Install camshaft bearing caps, and tighten cap bolts in sequence to specification. See Fig. 4 . See TORQUE SPECIFICATIONS . Install camshaft sprockets and bolts. Tighten camshaft sprocket bolts to specification. Install timing chain. See TIMING CHAIN . VALVE LIFTER Removal Remove camshaft. See CAMSHAFT . Note location of adjusting shims and valve lifters for installation reference. Remove adjusting shims and valve lifters from cylinder head. Inspection Inspect valve lifter and bore for damage. Replace lifter or shim if excessively worn. Installation To install, reverse removal procedure. Ensure components are installed in original location. If camshaft, adjusting shims or valve lifters are replaced, check valve clearance. See VALVE CAUTION: Ensure camshaft bearing caps are install in their original location. NOTE: No further information is available from manufacturer. 2000 Chevrolet Prizm 2000-01 ENGINES 1.8L 4-Cylinder - Prizm MY Tuesday, March 31, 2009 10:43:15 AM Page 42 © 2005 Mitchell Repair Information Company, LLC.

- 43. CLEARANCE ADJUSTMENT under ADJUSTMENTS. CRANKSHAFT REAR OIL SEAL Removal 1. Remove transaxle. For A/T, see appropriate TRANSMISSION REMOVAL & INSTALLATION article in TRANSMISSION SERVICING. For M/T, see appropriate article in CLUTCHES. Place reference mark on crankshaft and flywheel/drive plate. Remove flywheel/drive plate. 2. Pry crankshaft rear oil seal from seal retainer. DO NOT damage seal retainer or crankshaft. Installation 1. Ensure all sealing surfaces are clean. Lubricate seal lip with grease. Using Handle (SST 09951-07100) and Seal Installer (SST 09223-15030), install oil seal until edge is flush with cylinder block. 2. To install remaining components, reverse removal procedure. Ensure reference mark on flywheel/drive plate aligns with mark on crankshaft. WATER PUMP Removal & Installation 1. Raise vehicle and remove lower right engine cover. Drain cooling system. Remove serpentine belt. 2. Note water pump bolt location for installation reference. Remove bolts, water pump and "O" ring. See Fig. 6 . 3. To install, reverse removal procedure using NEW "O" ring. Tighten bolts to specification. See TORQUE SPECIFICATIONS . Fill cooling system. OIL PAN Removal & Installation 1. Raise and support vehicle. Drain engine oil. Remove lower engine covers. Remove oil pan bolts, nuts and oil pan. 2. To install, reverse removal procedure. Apply a continuous bead of RTV silicone sealer/adhesive to oil pan mating surface. Install oil pan. Tighten bolts to specification. See TORQUE SPECIFICATIONS . 2000 Chevrolet Prizm 2000-01 ENGINES 1.8L 4-Cylinder - Prizm MY Tuesday, March 31, 2009 10:43:15 AM Page 43 © 2005 Mitchell Repair Information Company, LLC.

- 44. OVERHAUL CYLINDER HEAD Cylinder Head Inspect cylinder head for cracks and warpage. Using a straightedge and feeler gauge, check cylinder head at manifold and cylinder block surfaces for warpage (along all 4 edges and diagonally across cylinder head). Replace cylinder head if warpage exceeds specification. See CYLINDER HEAD table under ENGINE SPECIFICATIONS. Valve Springs Using a valve spring tester, measure tension of valve springs at specified length. Ensure valve spring free length and out-of-square are within specification. See VALVES & VALVE SPRINGS table under ENGINE SPECIFICATIONS. Valve Stem Oil Seals Install oil seal using Valve Guide Seal Installer (SST 09201-41020). Valve Guides 1. To determine valve stem-to-guide clearance, measure and record valve stem diameter. Measure and record valve guide inside diameter. Subtract valve stem diameter from valve guide inside diameter. Ensure valve stem and guide oil clearance are within specification. Replace as necessary. See VALVES & VALVE SPRINGS and CYLINDER HEAD tables under ENGINE SPECIFICATIONS. 2. To remove valve guide, gradually heat cylinder head to 176-212°F (80-100°C). Heat cylinder head uniformly to prevent head warpage. Using hammer and Valve Guide Remover/Installer (SST 09201-01055), drive valve guide from cylinder head. NOTE: For repair procedures not covered in this article, see ENGINE OVERHAUL PROCEDURES article in GENERAL INFORMATION. NOTE: Intake valve stem oil seal is Light Brown and exhaust valve oil seal is Gray. NOTE: Valve guide bore specifications are not available from manufacturer. 2000 Chevrolet Prizm 2000-01 ENGINES 1.8L 4-Cylinder - Prizm MY Tuesday, March 31, 2009 10:43:15 AM Page 44 © 2005 Mitchell Repair Information Company, LLC.

- 45. 3. To install valve guide, gradually heat cylinder head to 176-212°F (80-100°C). Heat cylinder head uniformly to prevent head warpage. Using hammer and valve guide remover/installer, drive valve guide into cylinder head. Install valve guide so installed height above cylinder head surface is .342-.358" (8.70-9.10 mm). 4. Using .217" (5.5 mm) reamer, ream valve guide to obtain correct valve stem oil clearance. See CYLINDER HEAD table under ENGINE SPECIFICATIONS. Valve Seat Replacement information is not available from manufacturer. Valves Ensure valve stem diameter and valve margin are within specification. Check valve contact pattern and overall length. See VALVES & VALVE SPRINGS table under ENGINE SPECIFICATIONS. Seat Correction Angles To lower valve seat surface on valve, cut seat at 30 degrees and 45 degrees. To raise valve seat surface on valve, cut seat at 75 degrees and 45 degrees. CYLINDER BLOCK ASSEMBLY Piston & Rod Assembly 1. Ensure connecting rod and connecting rod cap are marked with matching cylinder number for installation reference. Piston, connecting rod and connecting rod cap must be installed with front mark toward timing chain end of engine. See Fig. 36 . 2. Before disassembling piston and connecting rod, attempt to move piston back and forth on piston pin. Replace piston and piston pin as a set if any movement is felt. 3. When removing piston from connecting rod, remove snap rings from piston. Note direction of piston installation on connecting rod in relation to front mark (cavity) on piston and front mark (protrusion) on connecting rod. See Fig. 36 . 4. Using hammer and brass drift, tap piston pin from piston and connecting rod. Separate piston from connecting rod. 5. Measure piston skirt diameter at 1.008" (25.60 mm) from top of piston at 90-degree angle to piston pin. Ensure piston and piston pin diameter are within specification. See PISTON, PINS & RINGS table under ENGINE SPECIFICATIONS. 6. Ensure connecting rod bend and twist are within specification. See CONNECTING RODS 2000 Chevrolet Prizm 2000-01 ENGINES 1.8L 4-Cylinder - Prizm MY Tuesday, March 31, 2009 10:43:15 AM Page 45 © 2005 Mitchell Repair Information Company, LLC.

- 46. table under ENGINE SPECIFICATIONS. 7. Bushing in connecting rod may be replaced if bore diameter is not within specification. Ensure bushing oil hole aligns with connecting rod oil hole. Bushing must be honed to obtain correct piston pin-to-rod clearance. See PISTON, PINS & RINGS table under ENGINE SPECIFICATIONS. 8. To reassemble, install NEW snap ring in one side of piston. Ensure ends of snap ring are not aligned with cutout area on piston. Install piston on connecting rod with front mark on top of piston aligned with front mark on connecting rod. See Fig. 36 . 9. Coat piston pin with engine oil and install. Install NEW snap ring on other end of piston. Ensure ends of snap ring are not aligned with cutout area on piston. 2000 Chevrolet Prizm 2000-01 ENGINES 1.8L 4-Cylinder - Prizm MY Tuesday, March 31, 2009 10:43:15 AM Page 46 © 2005 Mitchell Repair Information Company, LLC.

- 47. 2000 Chevrolet Prizm 2000-01 ENGINES 1.8L 4-Cylinder - Prizm MY Tuesday, March 31, 2009 10:43:15 AM Page 47 © 2005 Mitchell Repair Information Company, LLC.

- 48. Fig. 36: Aligning Piston, Connecting Rod & Bearing Caps Courtesy of TOYOTA MOTOR SALES, U.S.A., INC. Fitting Pistons 1. To determine if piston-to-cylinder clearance is within specification, measure piston skirt diameter at 90-degree angle to piston pin, 1.008" (25.6 mm) from top of piston. Ensure piston diameter is within specification. See PISTON, PINS & RINGS table under ENGINE SPECIFICATIONS. 2. Measure cylinder bore diameter at 2 different places, 90 degrees apart at .39" (10.0 mm) from top and bottom of cylinder bore and at middle of cylinder bore. Ensure cylinder bore diameter is within specification. See CYLINDER BLOCK table under ENGINE SPECIFICATIONS. 3. Determine piston-to-cylinder clearance. Replace cylinder block and/or all 4 pistons if clearance exceeds specification. See PISTON, PINS & RINGS table under ENGINE SPECIFICATIONS. Piston Rings Ensure ring end gap and side clearance are within specification. See PISTONS, PINS & RINGS table under ENGINE SPECIFICATIONS. Position piston ring gaps 90 degrees apart. Ensure ring end gaps are not aligned, and ensure ring gaps do not align with piston pin. Rod Bearings 1. Note direction of connecting rod and cap before removal for reassembly reference. If bearings are to be reused, measure bearing oil clearance using Plastigage before removing pistons. Check rod side play. See CONNECTING RODS and CRANKSHAFT, MAIN & CONNECTING ROD BEARINGS tables under ENGINE SPECIFICATIONS. 2. Install piston and rod assembly. Check rod bearing clearance using Plastigage method. Tighten rod bolts in 2 steps to specification. If rod bearing clearance is excessive, measure crankpin journal diameter. If crankpin journal diameter is within specification, replace bearing with a standard bearing. If crankpin journal is less than minimum specification, an undersize bearing is available. Regrind crankshaft to fit undersize bearing if necessary. Crankshaft & Main Bearings 1. Ensure main bearing caps are numbered for location, and arrow on cap points toward timing chain end of crankshaft. Remove main bearing caps and bolts, along with lower bearing NOTE: No other information is available from manufacturer. 2000 Chevrolet Prizm 2000-01 ENGINES 1.8L 4-Cylinder - Prizm MY Tuesday, March 31, 2009 10:43:15 AM Page 48 © 2005 Mitchell Repair Information Company, LLC.

- 49. half. 2. Measure main bearing clearance using Plastigage method. Main bearing clearance should be .0006-.0013" (.015-.032 mm). Maximum wear tolerance is .002" (.050 mm). If bearing clearance is excessive, measure crankshaft main bearing journals. Measure journals at each end of journal and 90 degrees from first readings. Grind crankshaft, or replace crankshaft if journal minimum diameter, taper or out-of-round are not within specification. See CRANKSHAFT, MAIN & CONNECTING ROD BEARINGS table under ENGINE SPECIFICATIONS. 3. When installing main bearing caps, ensure arrow on cap points toward timing chain end of crankshaft. Tighten bolts to specification. See TORQUE SPECIFICATIONS . 4. Ensure crankshaft end play is within specification. See CRANKSHAFT, MAIN & CONNECTING ROD BEARINGS table under ENGINE SPECIFICATIONS. Thrust Bearing Install thrust bearing on main bearing, with grooves toward crankshaft, away from cylinder block. Replace thrust bearing if crankshaft end play is not within specification. See CRANKSHAFT, MAIN & CONNECTING ROD BEARINGS table under ENGINE SPECIFICATIONS. Cylinder Block 1. Using feeler gauge and straightedge, check cylinder block deck surface in 6 places for warpage. If warpage exceeds specification, replace cylinder block. See CYLINDER BLOCK table under ENGINE SPECIFICATIONS. 2. Check cylinder bore wear and taper in 3 places. Cylinder block bore diameter is measured .39" (10 mm) from top and bottom of bore, and at middle of bore. See CYLINDER BLOCK table under ENGINE SPECIFICATIONS. ENGINE OILING ENGINE LUBRICATION SYSTEM The crankshaft-driven oil pump provides lubrication to the main gallery. See Fig. 37 . Crankcase Capacity Crankcase capacity with oil filter change is 3.9 qts. (3.7L). NOTE: No further main bearing size information is available from manufacturer. 2000 Chevrolet Prizm 2000-01 ENGINES 1.8L 4-Cylinder - Prizm MY Tuesday, March 31, 2009 10:43:15 AM Page 49 © 2005 Mitchell Repair Information Company, LLC.

- 50. Oil Pressure With engine at normal operating temperature, oil pressure should be greater than 4.3 psi (.3 kg/cm2 ) at idle and 43-78 psi (3.0-5.5 kg/cm2 ) at 3000 RPM. Fig. 37: Cross-Sectional View Of Engine Oil System Courtesy of TOYOTA MOTOR SALES, U.S.A., INC. 2000 Chevrolet Prizm 2000-01 ENGINES 1.8L 4-Cylinder - Prizm MY Tuesday, March 31, 2009 10:43:15 AM Page 50 © 2005 Mitchell Repair Information Company, LLC.

- 51. 2000 Chevrolet Prizm 2000-01 ENGINES 1.8L 4-Cylinder - Prizm MY Tuesday, March 31, 2009 10:43:15 AM Page 51 © 2005 Mitchell Repair Information Company, LLC.

- 52. Thank you very much for your reading. Please Click Here Then Get More Information.