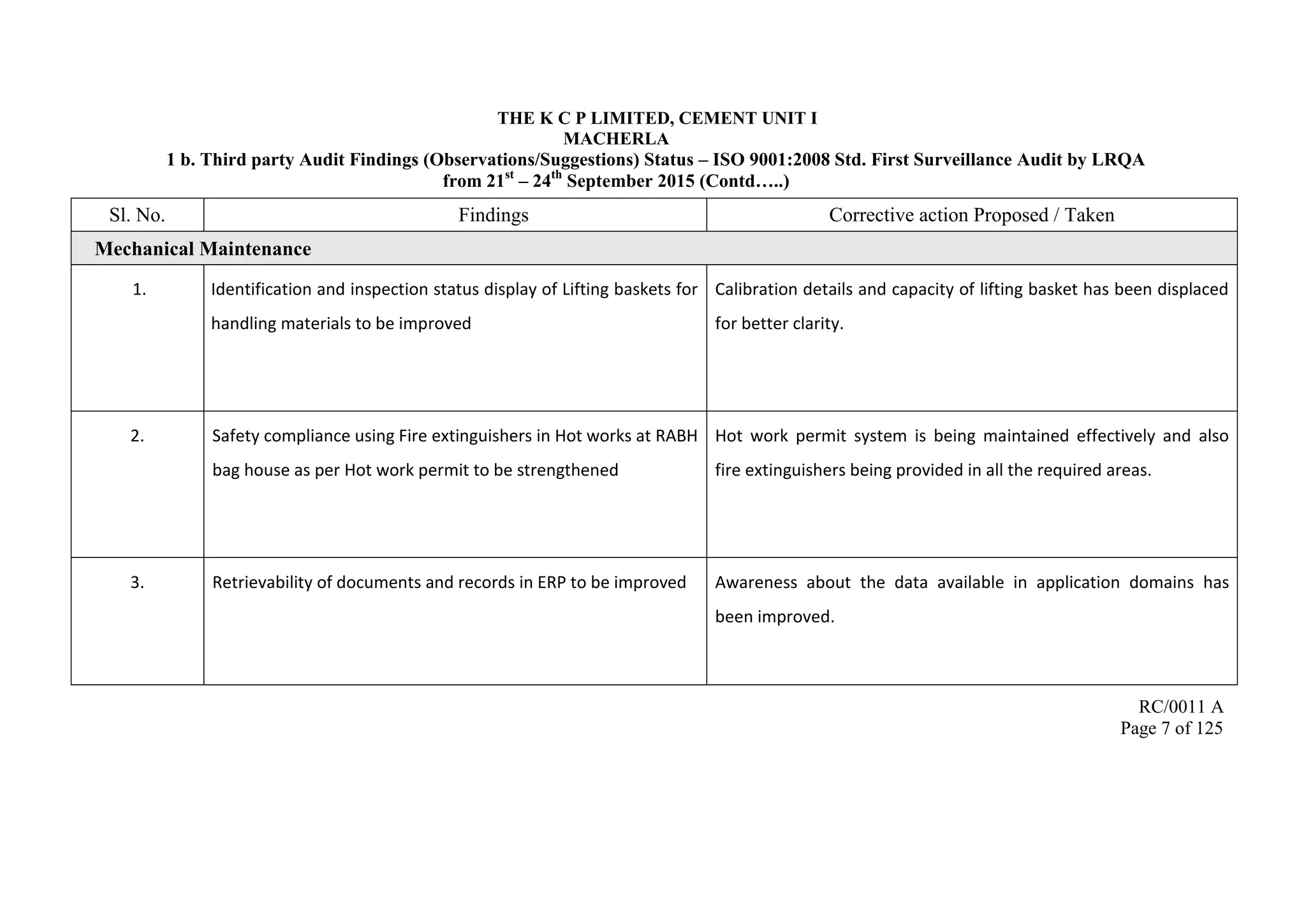

The document summarizes the findings from a third party audit of ISO 9001:2008 standards at a cement plant. It lists three minor non-conformances related to mechanical maintenance and provides details of each. For the first finding about weakness in the corrective action process, the plant responded that they would implement a root cause analysis using a "why why technique" and corrective actions to prevent reoccurrence. For the second and third findings around safety compliance and document retrievability, the plant provided brief details of improvements made.