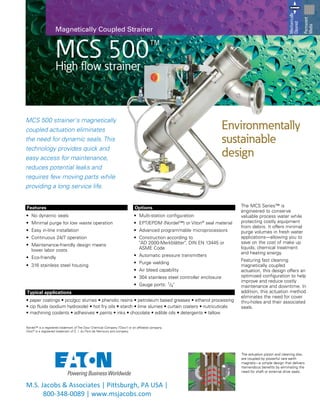

The MCS 500 high flow strainer utilizes magnetically coupled actuation to eliminate dynamic seals, facilitating maintenance and minimizing leaks. This eco-friendly strainer is designed for continuous operation in various applications and features a maintenance-friendly design that reduces labor costs. Its construction includes a 316 stainless steel housing and advanced programmable microprocessors for efficient operation and reduced downtime.