Trf products catalogues

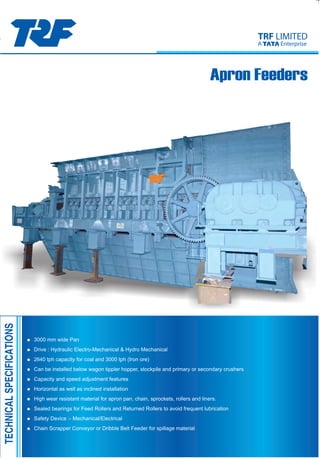

- 1. Apron Feeders = 3000 mm wide Pan = Drive : Hydraulic Electro-Mechanical & Hydro Mechanical = 2640 tph capacity for coal and 3000 tph (Iron ore) = Can be installed below wagon tippler hopper, stockpile and primary or secondary crushers = Capacity and speed adjustment features = Horizontal as well as inclined installation = High wear resistant material for apron pan, chain, sprockets, rollers and liners. = Sealed bearings for Feed Rollers and Returned Rollers to avoid frequent lubrication = Safety Device :- Mechanical/Electrical = Chain Scrapper Conveyor or Dribble Belt Feeder for spillage material TRF LIMITED A Enterprise TECHNICALSPECIFICATIONS TRF LIMITED A EnterpriseApron Feeders TRF Limited 11, Station Road Burma Mines, Jamshedpur-831007, Jharkhand Phone : +91- 657-3046500/ 598 Fax no. : +91- 657-2345732, e-mail : co@trf.co.in HYDERABAD Business Development Department Block - D, 3rd Floor, 22 Camac Street, Kolkata - 700 016 Ph : +91-33-44033553 e-mail : biz.development@trf.co.in Bulk Material Handling Systems Port &Yard Equipment Division Assistant General Manager Cell : + 91 - 9334002278 Ph : +91-657 - 3046242 Fax : +91-657-2345214 e-mail : dcjha@trf.co.in NEW DELHI Himalaya House, 11th Floor 23, Kasturba Gandhi Marg Ph : +91-11-223310788 / 23314540 Fax : +91-11-23722447 e-mail : nd@trf.co.in Flat No. 601, 6th Floor, Paigah Plaza, Basheerbagh, Ph : +91-40-23297630 / 23297631 Fax : +91-40-23297363 e-mail : hyd@trf.co.in MUMBAI Magnet House, 1st Floor, Narottam Morarji Marg, Ballard Estate, Ph : +91-22-22616853 / 22641320 Fax : +91-22-22614085 e-mail : mum@trf.co.in REGIONAL OFFICES MARKETING OFFICES HEAD OFFICE & WORKS Bulk Material Handling Equipment Assistant Divisional Manager Cell: +91-9304813195 Ph: +91-657-3046259 Fax: +91 - 657-2345724 e-mail: r.k.shukla@trf.co.in TYPICAL VIEW OF LINK CHAIN FOR APRON FEEDER TYPICAL VIEW OF FEED ROLLER FOR APRON FEEDER TYPICAL VIEW OF TRACK CHAIN ASSRMBLY FOR APRON FEEDER Likhra/Jsr.(0657)2291356 ApronFeeders Introduction ApronFeederisamechanicalequipmentwidelyusedinBulk materialHandling.Itsapplicationisfoundinalmostallsectors likepower,steel,cementplant,etc. TheApronFeedersarebroadlyclassifiedas a)ExtraheavydutyApronFeederwithcrawlerchain-sprocket assembly. b)ExtraheavydutyApronFeederwithlink-chainassembly. c)HeavydutyApronFeederwithlink-chainassembly. TheApronFeederconsistsofoneormoreendlesschainsto whichoverlappingpansareattachedtoformacontinuous movingbedparticularlysuitedforconveyingheavydutyraw materialssuchascoal,coke,ore,slag,rock,stone,gravel,clay, etc.Theyarefrequentlyusedasfeederslocatedundercrushers andhoppers.ApronFeederscanbeinstalledinhorizontaland inclinedconditiondependingonthefeedingzoneofsystem layout. Itisrecommendedthatforhigherconveyingefficiency,the feeder’sinclinationshouldbewithin10degrees. It’suselendsitselftosituationwhereabeltconveyorisnot suitablei.e.,forhotmaterialsandlargemateriallumps.Pan widthisnormallyselectedinbetween700mm.to3000mm. dependingonmaterial,feedsizeandcapacity. ApronPan,chain,rollersandothercomponentsareofrobustas theyhavetotakedirectfeedandwithstandfreedropping materialsfromanappreciableheightontotheApronPan. ItisrecommendedthatApronFeedersoperateatlowest possiblespeedtoavoidearlywearofmachineparts.Thespeed normallydependsonbulk-densityofmaterialandlumpsize. TheExtraHeavy-DutyApronFeedercanbeinstalledatthe dischargesectionofdumptruckorstoragebinwhichreceives strongfallingimpactload,rawmaterialpressureandlumps upto2000mm. TRFextraheavy-dutytypeApronFeederissorationallyand stronglydesignedandmanufacturedthatitcanbeoperatedina stablemannerevenundersevereconditions. Specificationofeachpart (1)ApronPanandConveyorChain TheApronPanismadeofsteelplateandhassufficiently highstrengthtofallingimpactloadoflargelumps.The materialofapronmaybewear-resistantsteelplateorhigh manganesecaststeel. TheConveyorChainisahighprecisionlinkchainor crawlerchainwithspecialshapehavingenoughstrength andlife.ItisfittedwithApronPan,eitheratbottomorside. (2)Feed TheFeedRollercanwithstandfallingimpactloadthrough Apronandisarrangedatregularintervalstoensure smoothrunningoftheApron.Rollersurfacehaswear resistibility,andsealedbearingisusedforbearingpart. (3)Drivingmachine Thedrivingmachineiscomposedofsprocketwheeland tailwheelforconveyorchain,headshaft,tailshaft,take-up device,plummerblockswithbearingandsafetycovers. Drivingmethodistodriveheadshaftbyvariablespeed motorthroughreducingspeedbyreducer.Caststeel plummerblockwithself-aligningrollerbearingisused. Hydraulicdriveisalsousedinsomecases. (4)Frame,Hopper,Skirt,Chute Eachpartismadebyweldingofshapesteelandsteelplate andsostronglyconstrictedthatitcansufficiently withstandfallingimpactloadoffeedmaterialorhopper pressure. Exchangeablelinerofwearresistantsteelisprovided insidehopperandskirt.LinerslikeArco,Hardox,Hadfield, Sailhard,etc.areused. (5)Lubricatingdevice LubricatingofeachbearingofPlummerblockiseffectedby thehandpumpfromoneplaceorbythecentralized forcedlubricatingsystemconsistingofmanydistributing valves. (6)Overloadsafetydevice Incaseexcessiveloadoroverloadisplaced,motorand machineareprotectedbyovercurrentrelay. Settingofoverloadtimeanddetectionpointcanbe adjustedarbitrarily. TRFLIMITED AEnterprise ListofApronFeederssuppliedtovariouscustomers ApronChainCapacityApronInclinationMaterialLumpMotorRemarks Sl.No.Size Ap.WidthLengthPitch(mm)Stren.(ton)(t.p.h.)Speed(m/min.)(degree)(Max.)Power 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 1800 2000 1200 2000 2000 2000 1600 1800 2000 1800 1800 1800 1800 2200 1800 2000 2000 2400 2000 2200 2400 2400 2400 2400 1700 2150 3000 17825 17200 13500 16160 17200 13700 4350 14100 16650 18150 17825 7870 17825 6635 16100 15300 4350 18100 15300 6735 18100 16100 18100 9000 6000 17000 18100 300 300 175.5 228.6 300 228.6 300 300 300 300 300 300 300 203.2 400 400 300 400 400 203.2 400 400 400 203.2 171.1 203.2 400 120 120 84 164 120 164 100 100 120 120 120 120 120 124 160 160 100 200 160 124 200 160 200 124 59 124 250 1320 300-1700 1000 1430 1500 750 150-900 1100 1500 350-1320 350-1320 1320 1320 2000 2000 1800 1500 2420 1800 800 2420 2200 2420 2400 1320 470 2640 13.5 12.3 14.44 11.07 12.02 6.4 17.86 5.14-12.84 12.2 13.5 13.5 8.34 13.5 7.2 15.35 14.65 14 13.87 13.35 2.3 15 15.3 14.5 12 10.5 3 11 0 0 0 0 0 10 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 Coal Coal Clinker, Gypsum Coal Coal Coal Coal Coal Coal Coal Coal Ironore Coal Ironore Coal Coal Coal Coal Coal IronOre Coal Coal Coal IronOre Ironore IronOre Coal 400 300 100 350 300 1000 300 250 250 400 400 250 400 350 300 300 100 250 300 150 250 250 250 340 340 340 250 110kw 132kw 75kw 110kw 132kw 110kw 30kw 90kw 132kw 132kw 132kw 55kw 132kw 55kw 110kw 110kw 55kw 180kw 132kw 22kw 160kw 160kw 180kw 132kw 37kw 55kw 180kw HydraulicDrive HydraulicDrive HydraulicDrive TYPICALDETAILOFAPRONPAN TYPICALVIEWOFAPRONPAN(SIDEBOLTEDTYPE) TYPICALVIEWOFAPRONPAN(BOTTOMBOLTEDTYPE) 10 January 2015

- 2. ApronFeeders =3000mmwidePan =Drive:HydraulicElectro-Mechanical&HydroMechanical =2640tphcapacityforcoaland3000tph(Ironore) =Canbeinstalledbelowwagontipplerhopper,stockpileandprimaryorsecondarycrushers =Capacityandspeedadjustmentfeatures =Horizontalaswellasinclinedinstallation =Highwearresistantmaterialforapronpan,chain,sprockets,rollersandliners. =SealedbearingsforFeedRollersandReturnedRollerstoavoidfrequentlubrication =SafetyDevice:-Mechanical/Electrical =ChainScrapperConveyororDribbleBeltFeederforspillagematerial TRFLIMITED AEnterprise TECHNICALSPECIFICATIONS TRFLIMITED AEnterprise ApronFeeders TRFLimited 11,StationRoadBurmaMines,Jamshedpur-831007,Jharkhand Phone:+91-657-3046500/598 Faxno.:+91-657-2345732,e-mail:co@trf.co.in HYDERABAD BusinessDevelopmentDepartment Block-D,3rdFloor, 22CamacStreet,Kolkata-700016 Ph:+91-33-44033553 e-mail:biz.development@trf.co.in BulkMaterialHandlingSystems Port&YardEquipmentDivision AssistantGeneralManager Cell:+91-9334002278 Ph:+91-657-3046242 Fax:+91-657-2345214 e-mail:dcjha@trf.co.in NEWDELHI HimalayaHouse, 11thFloor23,KasturbaGandhiMarg Ph:+91-11-223310788/23314540 Fax:+91-11-23722447 e-mail:nd@trf.co.in FlatNo.601,6thFloor, PaigahPlaza,Basheerbagh, Ph:+91-40-23297630/23297631 Fax:+91-40-23297363 e-mail:hyd@trf.co.in MUMBAI MagnetHouse,1stFloor, NarottamMorarjiMarg,BallardEstate, Ph:+91-22-22616853/22641320 Fax:+91-22-22614085 e-mail:mum@trf.co.in REGIONALOFFICES MARKETINGOFFICES HEADOFFICE&WORKS BulkMaterialHandlingEquipment AssistantDivisionalManager Cell:+91-9304813195 Ph:+91-657-3046259 Fax:+91-657-2345724 e-mail:r.k.shukla@trf.co.in TYPICALVIEWOFLINKCHAINFORAPRONFEEDERTYPICALVIEWOFFEEDROLLERFORAPRONFEEDER TYPICALVIEWOFTRACKCHAINASSRMBLYFORAPRONFEEDER Likhra/Jsr.(0657)2291356 Apron Feeders Introduction Apron Feeder is a mechanical equipment widely used in Bulk material Handling. Its application is found in almost all sectors like power, steel, cement plant, etc. The Apron Feeders are broadly classified as a) Extra heavy duty Apron Feeder with crawler chain-sprocket assembly. b) Extra heavy duty Apron Feeder with link-chain assembly. c) Heavy duty Apron Feeder with link-chain assembly. The Apron Feeder consists of one or more endless chains to which overlapping pans are attached to form a continuous moving bed particularly suited for conveying heavy duty raw materials such as coal, coke , ore, slag, rock, stone, gravel, clay, etc. They are frequently used as feeders located under crushers and hoppers. Apron Feeders can be installed in horizontal and inclined condition depending on the feeding zone of system layout. It is recommended that for higher conveying efficiency, the feeder’s inclination should be within 10 degrees. It’s use lends itself to situation where a belt conveyor is not suitable i.e., for hot materials and large material lumps. Pan width is normally selected in between 700 mm. to 3000 mm. depending on material, feed size and capacity. Apron Pan, chain, rollers and other components are of robust as they have to take direct feed and withstand free dropping materials from an appreciable height on to the Apron Pan. It is recommended that Apron Feeders operate at lowest possible speed to avoid early wear of machine parts. The speed normally depends on bulk-density of material and lump size. The Extra Heavy-Duty Apron Feeder can be installed at the discharge section of dump truck or storage bin which receives strong falling impact load, raw material pressure and lumps upto 2000 mm. TRF extra heavy-duty type Apron Feeder is so rationally and strongly designed and manufactured that it can be operated in a stable manner even under severe conditions. Specification of each part (1) Apron Pan and Conveyor Chain The Apron Pan is made of steel plate and has sufficiently high strength to falling impact load of large lumps. The material of apron may be wear-resistant steel plate or high manganese cast steel. The Conveyor Chain is a high precision link chain or crawler chain with special shape having enough strength and life. It is fitted with Apron Pan, either at bottom or side. (2) Feed The Feed Roller can withstand falling impact load through Apron and is arranged at regular intervals to ensure smooth running of the Apron. Roller surface has wear resistibility, and sealed bearing is used for bearing part. (3) Driving machine The driving machine is composed of sprocket wheel and tail wheel for conveyor chain, head shaft, tail shaft, take-up device, plummer blocks with bearing and safety covers. Driving method is to drive head shaft by variable speed motor through reducing speed by reducer. Cast steel plummer block with self-aligning roller bearing is used. Hydraulic drive is also used in some cases. (4) Frame, Hopper, Skirt, Chute Each part is made by welding of shape steel and steel plate and so strongly constricted that it can sufficiently withstand falling impact load of feed material or hopper pressure. Exchangeable liner of wear resistant steel is provided inside hopper and skirt. Liners like Arco, Hardox, Hadfield, Sailhard, etc. are used. (5) Lubricating device Lubricating of each bearing of Plummer block is effected by the hand pump from one place or by the centralized forced lubricating system consisting of many distributing valves. (6) Overload safety device In case excessive load or overload is placed, motor and machine are protected by overcurrent relay. Setting of overload time and detection point can be adjusted arbitrarily. TRF LIMITED A Enterprise List of Apron Feeders supplied to various customers Apron Chain Capacity Apron Inclination Material Lump Motor RemarksSl. No. Size Ap. Width Length Pitch (mm) Stren. (ton) (t.p.h.) Speed(m/min.) (degree) (Max.) Power 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 1800 2000 1200 2000 2000 2000 1600 1800 2000 1800 1800 1800 1800 2200 1800 2000 2000 2400 2000 2200 2400 2400 2400 2400 1700 2150 3000 17825 17200 13500 16160 17200 13700 4350 14100 16650 18150 17825 7870 17825 6635 16100 15300 4350 18100 15300 6735 18100 16100 18100 9000 6000 17000 18100 300 300 175.5 228.6 300 228.6 300 300 300 300 300 300 300 203.2 400 400 300 400 400 203.2 400 400 400 203.2 171.1 203.2 400 120 120 84 164 120 164 100 100 120 120 120 120 120 124 160 160 100 200 160 124 200 160 200 124 59 124 250 1320 300-1700 1000 1430 1500 750 150-900 1100 1500 350-1320 350-1320 1320 1320 2000 2000 1800 1500 2420 1800 800 2420 2200 2420 2400 1320 470 2640 13.5 12.3 14.44 11.07 12.02 6.4 17.86 5.14-12.84 12.2 13.5 13.5 8.34 13.5 7.2 15.35 14.65 14 13.87 13.35 2.3 15 15.3 14.5 12 10.5 3 11 0 0 0 0 0 10 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 Coal Coal Clinker, Gypsum Coal Coal Coal Coal Coal Coal Coal Coal Iron ore Coal Iron ore Coal Coal Coal Coal Coal Iron Ore Coal Coal Coal Iron Ore Iron ore Iron Ore Coal 400 300 100 350 300 1000 300 250 250 400 400 250 400 350 300 300 100 250 300 150 250 250 250 340 340 340 250 110 kw 132 kw 75 kw 110 kw 132 kw 110 kw 30 kw 90 kw 132 kw 132 kw 132 kw 55 kw 132 kw 55 kw 110 kw 110 kw 55 kw 180 kw 132 kw 22 kw 160kw 160kw 180kw 132kw 37kw 55kw 180kw Hydraulic Drive Hydraulic Drive Hydraulic Drive TYPICAL DETAIL OF APRON PAN TYPICAL VIEW OF APRON PAN (SIDE BOLTED TYPE) TYPICAL VIEW OF APRON PAN (BOTTOM BOLTED TYPE)

- 3. ApronFeeders =3000mmwidePan =Drive:HydraulicElectro-Mechanical&HydroMechanical =2640tphcapacityforcoaland3000tph(Ironore) =Canbeinstalledbelowwagontipplerhopper,stockpileandprimaryorsecondarycrushers =Capacityandspeedadjustmentfeatures =Horizontalaswellasinclinedinstallation =Highwearresistantmaterialforapronpan,chain,sprockets,rollersandliners. =SealedbearingsforFeedRollersandReturnedRollerstoavoidfrequentlubrication =SafetyDevice:-Mechanical/Electrical =ChainScrapperConveyororDribbleBeltFeederforspillagematerial TRFLIMITED AEnterprise TECHNICALSPECIFICATIONS TRFLIMITED AEnterprise ApronFeeders TRFLimited 11,StationRoadBurmaMines,Jamshedpur-831007,Jharkhand Phone:+91-657-3046500/598 Faxno.:+91-657-2345732,e-mail:co@trf.co.in HYDERABAD BusinessDevelopmentDepartment Block-D,3rdFloor, 22CamacStreet,Kolkata-700016 Ph:+91-33-44033553 e-mail:biz.development@trf.co.in BulkMaterialHandlingSystems Port&YardEquipmentDivision AssistantGeneralManager Cell:+91-9334002278 Ph:+91-657-3046242 Fax:+91-657-2345214 e-mail:dcjha@trf.co.in NEWDELHI HimalayaHouse, 11thFloor23,KasturbaGandhiMarg Ph:+91-11-223310788/23314540 Fax:+91-11-23722447 e-mail:nd@trf.co.in FlatNo.601,6thFloor, PaigahPlaza,Basheerbagh, Ph:+91-40-23297630/23297631 Fax:+91-40-23297363 e-mail:hyd@trf.co.in MUMBAI MagnetHouse,1stFloor, NarottamMorarjiMarg,BallardEstate, Ph:+91-22-22616853/22641320 Fax:+91-22-22614085 e-mail:mum@trf.co.in REGIONALOFFICES MARKETINGOFFICES HEADOFFICE&WORKS BulkMaterialHandlingEquipment AssistantDivisionalManager Cell:+91-9304813195 Ph:+91-657-3046259 Fax:+91-657-2345724 e-mail:r.k.shukla@trf.co.in TYPICALVIEWOFLINKCHAINFORAPRONFEEDERTYPICALVIEWOFFEEDROLLERFORAPRONFEEDER TYPICALVIEWOFTRACKCHAINASSRMBLYFORAPRONFEEDER Likhra/Jsr.(0657)2291356 Apron Feeders Introduction Apron Feeder is a mechanical equipment widely used in Bulk material Handling. Its application is found in almost all sectors like power, steel, cement plant, etc. The Apron Feeders are broadly classified as a) Extra heavy duty Apron Feeder with crawler chain-sprocket assembly. b) Extra heavy duty Apron Feeder with link-chain assembly. c) Heavy duty Apron Feeder with link-chain assembly. The Apron Feeder consists of one or more endless chains to which overlapping pans are attached to form a continuous moving bed particularly suited for conveying heavy duty raw materials such as coal, coke , ore, slag, rock, stone, gravel, clay, etc. They are frequently used as feeders located under crushers and hoppers. Apron Feeders can be installed in horizontal and inclined condition depending on the feeding zone of system layout. It is recommended that for higher conveying efficiency, the feeder’s inclination should be within 10 degrees. It’s use lends itself to situation where a belt conveyor is not suitable i.e., for hot materials and large material lumps. Pan width is normally selected in between 700 mm. to 3000 mm. depending on material, feed size and capacity. Apron Pan, chain, rollers and other components are of robust as they have to take direct feed and withstand free dropping materials from an appreciable height on to the Apron Pan. It is recommended that Apron Feeders operate at lowest possible speed to avoid early wear of machine parts. The speed normally depends on bulk-density of material and lump size. The Extra Heavy-Duty Apron Feeder can be installed at the discharge section of dump truck or storage bin which receives strong falling impact load, raw material pressure and lumps upto 2000 mm. TRF extra heavy-duty type Apron Feeder is so rationally and strongly designed and manufactured that it can be operated in a stable manner even under severe conditions. Specification of each part (1) Apron Pan and Conveyor Chain The Apron Pan is made of steel plate and has sufficiently high strength to falling impact load of large lumps. The material of apron may be wear-resistant steel plate or high manganese cast steel. The Conveyor Chain is a high precision link chain or crawler chain with special shape having enough strength and life. It is fitted with Apron Pan, either at bottom or side. (2) Feed The Feed Roller can withstand falling impact load through Apron and is arranged at regular intervals to ensure smooth running of the Apron. Roller surface has wear resistibility, and sealed bearing is used for bearing part. (3) Driving machine The driving machine is composed of sprocket wheel and tail wheel for conveyor chain, head shaft, tail shaft, take-up device, plummer blocks with bearing and safety covers. Driving method is to drive head shaft by variable speed motor through reducing speed by reducer. Cast steel plummer block with self-aligning roller bearing is used. Hydraulic drive is also used in some cases. (4) Frame, Hopper, Skirt, Chute Each part is made by welding of shape steel and steel plate and so strongly constricted that it can sufficiently withstand falling impact load of feed material or hopper pressure. Exchangeable liner of wear resistant steel is provided inside hopper and skirt. Liners like Arco, Hardox, Hadfield, Sailhard, etc. are used. (5) Lubricating device Lubricating of each bearing of Plummer block is effected by the hand pump from one place or by the centralized forced lubricating system consisting of many distributing valves. (6) Overload safety device In case excessive load or overload is placed, motor and machine are protected by overcurrent relay. Setting of overload time and detection point can be adjusted arbitrarily. TRF LIMITED A Enterprise List of Apron Feeders supplied to various customers Apron Chain Capacity Apron Inclination Material Lump Motor RemarksSl. No. Size Ap. Width Length Pitch (mm) Stren. (ton) (t.p.h.) Speed(m/min.) (degree) (Max.) Power 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 1800 2000 1200 2000 2000 2000 1600 1800 2000 1800 1800 1800 1800 2200 1800 2000 2000 2400 2000 2200 2400 2400 2400 2400 1700 2150 3000 17825 17200 13500 16160 17200 13700 4350 14100 16650 18150 17825 7870 17825 6635 16100 15300 4350 18100 15300 6735 18100 16100 18100 9000 6000 17000 18100 300 300 175.5 228.6 300 228.6 300 300 300 300 300 300 300 203.2 400 400 300 400 400 203.2 400 400 400 203.2 171.1 203.2 400 120 120 84 164 120 164 100 100 120 120 120 120 120 124 160 160 100 200 160 124 200 160 200 124 59 124 250 1320 300-1700 1000 1430 1500 750 150-900 1100 1500 350-1320 350-1320 1320 1320 2000 2000 1800 1500 2420 1800 800 2420 2200 2420 2400 1320 470 2640 13.5 12.3 14.44 11.07 12.02 6.4 17.86 5.14-12.84 12.2 13.5 13.5 8.34 13.5 7.2 15.35 14.65 14 13.87 13.35 2.3 15 15.3 14.5 12 10.5 3 11 0 0 0 0 0 10 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 Coal Coal Clinker, Gypsum Coal Coal Coal Coal Coal Coal Coal Coal Iron ore Coal Iron ore Coal Coal Coal Coal Coal Iron Ore Coal Coal Coal Iron Ore Iron ore Iron Ore Coal 400 300 100 350 300 1000 300 250 250 400 400 250 400 350 300 300 100 250 300 150 250 250 250 340 340 340 250 110 kw 132 kw 75 kw 110 kw 132 kw 110 kw 30 kw 90 kw 132 kw 132 kw 132 kw 55 kw 132 kw 55 kw 110 kw 110 kw 55 kw 180 kw 132 kw 22 kw 160kw 160kw 180kw 132kw 37kw 55kw 180kw Hydraulic Drive Hydraulic Drive Hydraulic Drive TYPICAL DETAIL OF APRON PAN TYPICAL VIEW OF APRON PAN (SIDE BOLTED TYPE) TYPICAL VIEW OF APRON PAN (BOTTOM BOLTED TYPE)

- 4. Apron Feeders = 3000 mm wide Pan = Drive : Hydraulic Electro-Mechanical & Hydro Mechanical = 2640 tph capacity for coal and 3000 tph (Iron ore) = Can be installed below wagon tippler hopper, stockpile and primary or secondary crushers = Capacity and speed adjustment features = Horizontal as well as inclined installation = High wear resistant material for apron pan, chain, sprockets, rollers and liners. = Sealed bearings for Feed Rollers and Returned Rollers to avoid frequent lubrication = Safety Device :- Mechanical/Electrical = Chain Scrapper Conveyor or Dribble Belt Feeder for spillage material TRF LIMITED A Enterprise TECHNICALSPECIFICATIONS TRF LIMITED A EnterpriseApron Feeders TRF Limited 11, Station Road Burma Mines, Jamshedpur-831007, Jharkhand Phone : +91- 657-3046500/ 598 Fax no. : +91- 657-2345732, e-mail : co@trf.co.in HYDERABAD Business Development Department Block - D, 3rd Floor, 22 Camac Street, Kolkata - 700 016 Ph : +91-33-44033553 e-mail : biz.development@trf.co.in Bulk Material Handling Systems Port &Yard Equipment Division Assistant General Manager Cell : + 91 - 9334002278 Ph : +91-657 - 3046242 Fax : +91-657-2345214 e-mail : dcjha@trf.co.in NEW DELHI Himalaya House, 11th Floor 23, Kasturba Gandhi Marg Ph : +91-11-223310788 / 23314540 Fax : +91-11-23722447 e-mail : nd@trf.co.in Flat No. 601, 6th Floor, Paigah Plaza, Basheerbagh, Ph : +91-40-23297630 / 23297631 Fax : +91-40-23297363 e-mail : hyd@trf.co.in MUMBAI Magnet House, 1st Floor, Narottam Morarji Marg, Ballard Estate, Ph : +91-22-22616853 / 22641320 Fax : +91-22-22614085 e-mail : mum@trf.co.in REGIONAL OFFICES MARKETING OFFICES HEAD OFFICE & WORKS Bulk Material Handling Equipment Assistant Divisional Manager Cell: +91-9304813195 Ph: +91-657-3046259 Fax: +91 - 657-2345724 e-mail: r.k.shukla@trf.co.in TYPICAL VIEW OF LINK CHAIN FOR APRON FEEDER TYPICAL VIEW OF FEED ROLLER FOR APRON FEEDER TYPICAL VIEW OF TRACK CHAIN ASSRMBLY FOR APRON FEEDER Likhra/Jsr.(0657)2291356 ApronFeeders Introduction ApronFeederisamechanicalequipmentwidelyusedinBulk materialHandling.Itsapplicationisfoundinalmostallsectors likepower,steel,cementplant,etc. TheApronFeedersarebroadlyclassifiedas a)ExtraheavydutyApronFeederwithcrawlerchain-sprocket assembly. b)ExtraheavydutyApronFeederwithlink-chainassembly. c)HeavydutyApronFeederwithlink-chainassembly. TheApronFeederconsistsofoneormoreendlesschainsto whichoverlappingpansareattachedtoformacontinuous movingbedparticularlysuitedforconveyingheavydutyraw materialssuchascoal,coke,ore,slag,rock,stone,gravel,clay, etc.Theyarefrequentlyusedasfeederslocatedundercrushers andhoppers.ApronFeederscanbeinstalledinhorizontaland inclinedconditiondependingonthefeedingzoneofsystem layout. Itisrecommendedthatforhigherconveyingefficiency,the feeder’sinclinationshouldbewithin10degrees. It’suselendsitselftosituationwhereabeltconveyorisnot suitablei.e.,forhotmaterialsandlargemateriallumps.Pan widthisnormallyselectedinbetween700mm.to3000mm. dependingonmaterial,feedsizeandcapacity. ApronPan,chain,rollersandothercomponentsareofrobustas theyhavetotakedirectfeedandwithstandfreedropping materialsfromanappreciableheightontotheApronPan. ItisrecommendedthatApronFeedersoperateatlowest possiblespeedtoavoidearlywearofmachineparts.Thespeed normallydependsonbulk-densityofmaterialandlumpsize. TheExtraHeavy-DutyApronFeedercanbeinstalledatthe dischargesectionofdumptruckorstoragebinwhichreceives strongfallingimpactload,rawmaterialpressureandlumps upto2000mm. TRFextraheavy-dutytypeApronFeederissorationallyand stronglydesignedandmanufacturedthatitcanbeoperatedina stablemannerevenundersevereconditions. Specificationofeachpart (1)ApronPanandConveyorChain TheApronPanismadeofsteelplateandhassufficiently highstrengthtofallingimpactloadoflargelumps.The materialofapronmaybewear-resistantsteelplateorhigh manganesecaststeel. TheConveyorChainisahighprecisionlinkchainor crawlerchainwithspecialshapehavingenoughstrength andlife.ItisfittedwithApronPan,eitheratbottomorside. (2)Feed TheFeedRollercanwithstandfallingimpactloadthrough Apronandisarrangedatregularintervalstoensure smoothrunningoftheApron.Rollersurfacehaswear resistibility,andsealedbearingisusedforbearingpart. (3)Drivingmachine Thedrivingmachineiscomposedofsprocketwheeland tailwheelforconveyorchain,headshaft,tailshaft,take-up device,plummerblockswithbearingandsafetycovers. Drivingmethodistodriveheadshaftbyvariablespeed motorthroughreducingspeedbyreducer.Caststeel plummerblockwithself-aligningrollerbearingisused. Hydraulicdriveisalsousedinsomecases. (4)Frame,Hopper,Skirt,Chute Eachpartismadebyweldingofshapesteelandsteelplate andsostronglyconstrictedthatitcansufficiently withstandfallingimpactloadoffeedmaterialorhopper pressure. Exchangeablelinerofwearresistantsteelisprovided insidehopperandskirt.LinerslikeArco,Hardox,Hadfield, Sailhard,etc.areused. (5)Lubricatingdevice LubricatingofeachbearingofPlummerblockiseffectedby thehandpumpfromoneplaceorbythecentralized forcedlubricatingsystemconsistingofmanydistributing valves. (6)Overloadsafetydevice Incaseexcessiveloadoroverloadisplaced,motorand machineareprotectedbyovercurrentrelay. Settingofoverloadtimeanddetectionpointcanbe adjustedarbitrarily. TRFLIMITED AEnterprise ListofApronFeederssuppliedtovariouscustomers ApronChainCapacityApronInclinationMaterialLumpMotorRemarks Sl.No.Size Ap.WidthLengthPitch(mm)Stren.(ton)(t.p.h.)Speed(m/min.)(degree)(Max.)Power 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 1800 2000 1200 2000 2000 2000 1600 1800 2000 1800 1800 1800 1800 2200 1800 2000 2000 2400 2000 2200 2400 2400 2400 2400 1700 2150 3000 17825 17200 13500 16160 17200 13700 4350 14100 16650 18150 17825 7870 17825 6635 16100 15300 4350 18100 15300 6735 18100 16100 18100 9000 6000 17000 18100 300 300 175.5 228.6 300 228.6 300 300 300 300 300 300 300 203.2 400 400 300 400 400 203.2 400 400 400 203.2 171.1 203.2 400 120 120 84 164 120 164 100 100 120 120 120 120 120 124 160 160 100 200 160 124 200 160 200 124 59 124 250 1320 300-1700 1000 1430 1500 750 150-900 1100 1500 350-1320 350-1320 1320 1320 2000 2000 1800 1500 2420 1800 800 2420 2200 2420 2400 1320 470 2640 13.5 12.3 14.44 11.07 12.02 6.4 17.86 5.14-12.84 12.2 13.5 13.5 8.34 13.5 7.2 15.35 14.65 14 13.87 13.35 2.3 15 15.3 14.5 12 10.5 3 11 0 0 0 0 0 10 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 Coal Coal Clinker, Gypsum Coal Coal Coal Coal Coal Coal Coal Coal Ironore Coal Ironore Coal Coal Coal Coal Coal IronOre Coal Coal Coal IronOre Ironore IronOre Coal 400 300 100 350 300 1000 300 250 250 400 400 250 400 350 300 300 100 250 300 150 250 250 250 340 340 340 250 110kw 132kw 75kw 110kw 132kw 110kw 30kw 90kw 132kw 132kw 132kw 55kw 132kw 55kw 110kw 110kw 55kw 180kw 132kw 22kw 160kw 160kw 180kw 132kw 37kw 55kw 180kw HydraulicDrive HydraulicDrive HydraulicDrive TYPICALDETAILOFAPRONPAN TYPICALVIEWOFAPRONPAN(SIDEBOLTEDTYPE) TYPICALVIEWOFAPRONPAN(BOTTOMBOLTEDTYPE)

- 5. Barrel Reclaimers = = Consistent performance combined with a good ratio between machine weight and capacity = Flexibility of choosing between mechanical or hydraulic drives = VVVF drives for all motions of the equipment = State of the art PLC systems with user friendly interfaces = Custom built and made to order equipments at TRF's own Works at Jamshedpur ensuring minimal erection and start up time at site = Availability of radio communication and fibre composite cables allowing additional space at the tripper = Ergonomically designed operator cabin = Ease of maintenance Economical solution for stockyards where simultaneous stacking and reclaiming is not required TRF LIMITED A Enterprise TECHNICALSPECIFICATIONS BarrelReclaimers TheBarrelReclaimersareusedextensivelyinstockyards andareidealforhavingproperblendingofrawmaterialsfor usinginprocessingplant.TRFhasengineeredandsupplied BarrelReclaimerforBasemix. TRF’sBarrelReclaimersareoperationatmajorsteelplants inIndia.ThereclaimcapacityofTRFBarrelReclaimeris 1500TPHwith40mtrackgaugemakingTRFthepremier supplierinIndia. AllthedrivesoftheBarrelReclaimersareprovidedwith programmablelogiccontrollertoachievesynchronized motions,hydraulicrailclamps,antiskewarrangement,storm anchorandairconditionedelectricroom,dustsuppression system,radiocontrolandfirefightingsystemsarealso providedifrequired. TRFBarrelreclaimeristransferablefromonestockpiletothe other. Theoperator'scabinissolocatedthattheoperatorgetsa clearandunobstructedviewofthereclaimingprocessand theentirestockyard.Thecabinisair-conditionedand ergonomicallydesignedformaximumcomfortofthe operator.Thefrontscreenismountedintheoperator's consoleanddisplaysdetailsofalloperationsenablingthe operatortoprogramaccordingtothereclaimingrequirement. TRFLimited 11,StationRoadBurmaMines,Jamshedpur-831007,Jharkhand Phone:+91-657-3046500/598 Faxno.:+91-657-2345732,e-mail:co@trf.co.in HYDERABAD BusinessDevelopmentDepartment Block-D,3rdFloor, 22CamacStreet,Kolkata-700016 Ph:+91-33-44033553 e-mail:biz.development@trf.co.in BulkMaterialHandlingSystems Port&YardEquipmentDivision AssistantGeneralManager Cell:+91-9334002278 Ph:+91-657-3046242 Fax:+91-657-2345214 e-mail:dcjha@trf.co.in NEWDELHI HimalayaHouse, 11thFloor23,KasturbaGandhiMarg Ph:+91-11-223310788/23314540 Fax:+91-11-23722447 e-mail:nd@trf.co.in FlatNo.601,6thFloor, PaigahPlaza,Basheerbagh, Ph:+91-40-23297630/23297631 Fax:+91-40-23297363 e-mail:hyd@trf.co.in MUMBAI MagnetHouse,1stFloor, NarottamMorarjiMarg,BallardEstate, Ph:+91-22-22616853/22641320 Fax:+91-22-22614085 e-mail:mum@trf.co.in REGIONALOFFICES MARKETINGOFFICES HEADOFFICE&WORKS BulkMaterialHandlingEquipment AssistantDivisionalManager Cell:+91-9304813195 Ph:+91-657-3046259 Fax:+91-657-2345724 e-mail:r.k.shukla@trf.co.in TechnicalParticularsforBarrelReclaimer MachineDescription BarrelReclaimer MaterialHandled BaseMix Rated tph 1200 Design tph 150040m CapacitiesTrackGauge Service TRFtodayofferscomprehensiveoperationandmaintenanceservicesfortheirBarrelReclaimerswithguaranteedup-keeptime forthecustomer.Thisensuresthatcustomerscanplantheirrawmaterialhandlingstrategyandrequirementwithadded precision,reducingrawmaterialinventory. TRFLIMITED AEnterprise Likhra/Jsr.(0657)2291356 Travelling Wagon Loaders TECHNICALSPECIFICATIONS = = One full rake loaded in less than two hrs = Negligible spillage between wagons = Environment friendly = Data logger to minimize loading error Capacity upto 3000 TPH TRF LIMITED A Enterprise TravellingWagonLoaders Loadingofbulkmaterialsinsteel,power&miningindustries TravellingWagonLoadersareessentialequipmentforloadingbulk materialintorailwaywagonsathighspeed.WagonLoaders suppliedbyTRFcanloaduptoo3000tonnesperhour. TRFwagonloadingsystemsaresodesignedthatthereisnospillage betweenthewagonswhentheloaderistravelingfromoneendofthe raketotheother.Fillingefficienciesupto99percentofthedesired capacityhavebeenachieved. ATravellingWagonLoadersmanufacturedatTRFcomprises: Thetripperconveyor Intermediateconveyorwithbeltweigher Crossconveyorwithloadingchutes TRFhassuppliedTravellingWagonLoadersforloadingbulkcargo likecoal,coke,limestoneandironore.TRF’stravellingwagon loaderscanloadrakesplacedonbothsidesofthetrackina2x2 formation.Thecrossconveyorshuttlesoutwhileloadingintorakes atthefartherend.AllcontrolsarethroughPLC.Thetravelspeedof thewagonloaderissynchronizedautomaticallytocompletethe loadingofonewagonandthentravelrapidlytothesecondwagonto minimizedetentiontimeoftherake.Facilitiesonboardinclude checkingofloadingrateandtotalizersonshift,day, = = = andmonthbasis.TRFTravellingWagonLoadersaredesignedto automaticallyidentifysickwagonsintherakeandbypassthese wagonswhilecompletingtheloadingofthefullrake. ThematerialfeedingintothewagonsiskeptuniformbyuseofTRF designedbeltweigheroverthecrossconveyor.Thefeederis synchronizedwiththeloadingrateandcanbeprogrammedtofeed atanydesiredrateuptoitsmaximumcapacity. Theoperator'scabinsaresolocatedthattheoperatorgetsaclear andunobstructedviewoftheloadingprocess.Thecabinisair- conditionedandergonomicallydesignedformaximumcomfortof theoperator.Thefrontscreenismountedintheoperator'sconsole anddisplaysdetailsofalloperationsenablingtheoperatorto programaccordingtotheloadingrequirement. Theair-conditionedelectrichouseisequippedwithonlinefault displayandanalysistooltominimizedowntime.Hydraulicrail clamps,stormanchorandairconditionedelectricroom,dust suppressionsystem,radiocontrolandfirealarmarealsoprovided, ifrequiredbythecustomers. TRF’swagonloadersareprovidedwithpneumaticallyPLC controlledsectorgatestoavoidchokingofmaterial. TRFLimited 11,StationRoadBurmaMines,Jamshedpur-831007,Jharkhand Phone:+91-657-3046500/598 Faxno.:+91-657-2345732,e-mail:co@trf.co.in HYDERABAD BusinessDevelopmentDepartment Block-D,3rdFloor, 22CamacStreet,Kolkata-700016 Ph:+91-33-44033553 e-mail:biz.development@trf.co.in BulkMaterialHandlingSystems Port&YardEquipmentDivision AssistantGeneralManager Cell:+91-9334002278 Ph:+91-657-3046242 Fax:+91-657-2345214 e-mail:dcjha@trf.co.in NEWDELHI HimalayaHouse, 11thFloor23,KasturbaGandhiMarg Ph:+91-11-223310788/23314540 Fax:+91-11-23722447 e-mail:nd@trf.co.in FlatNo.601,6thFloor, PaigahPlaza,Basheerbagh, Ph:+91-40-23297630/23297631 Fax:+91-40-23297363 e-mail:hyd@trf.co.in MUMBAI MagnetHouse,1stFloor, NarottamMorarjiMarg,BallardEstate, Ph:+91-22-22616853/22641320 Fax:+91-22-22614085 e-mail:mum@trf.co.in REGIONALOFFICES MARKETINGOFFICES HEADOFFICE&WORKS BulkMaterialHandlingEquipment AssistantDivisionalManager Cell:+91-9304813195 Ph:+91-657-3046259 Fax:+91-657-2345724 e-mail:r.k.shukla@trf.co.in TRFLIMITED AEnterprise Capacity 720tph 1500tph 2400tph 3000tph Material Coke Coal Coal IronOre&pellets Tracksize 6.0m 6.0m 6.0m 6.0m TypesofFeedingOptions Wagonsononesidewithshiftabledischargeconveyor Wagonsonbothsidesoftrack Wagonsonbothsidesoftrack Wagonsonbothsidesoftrack WagonLoadersDetails Services TRFtodayofferscomprehensiveoperationandmaintenanceservicesfortheirtravellingwagonloaderswithguaranteedup-keep timeforthecustomer.Thisensuresthatcustomerscanplantheirrawmaterialhandlingstrategyandrequirementwithadded precision,reducingrawmaterialinventory. Likhra/Jsr.(0657)2291356

- 6. BarrelReclaimers = =Consistentperformancecombinedwithagoodratiobetweenmachineweightandcapacity =Flexibilityofchoosingbetweenmechanicalorhydraulicdrives =VVVFdrivesforallmotionsoftheequipment =StateoftheartPLCsystemswithuserfriendlyinterfaces =CustombuiltandmadetoorderequipmentsatTRF'sownWorksatJamshedpurensuringminimalerection andstartuptimeatsite =Availabilityofradiocommunicationandfibrecompositecablesallowingadditionalspaceatthetripper =Ergonomicallydesignedoperatorcabin =Easeofmaintenance Economicalsolutionforstockyardswheresimultaneousstackingandreclaimingisnotrequired TRFLIMITED AEnterprise TECHNICALSPECIFICATIONS Barrel Reclaimers The Barrel Reclaimers are used extensively in stockyards and are ideal for having proper blending of raw materials for using in processing plant. TRF has engineered and supplied Barrel Reclaimer for Base mix. TRF’s Barrel Reclaimers are operation at major steel plants in India. The reclaim capacity of TRF Barrel Reclaimer is 1500 TPH with 40 m track gauge making TRF the premier supplier in India. All the drives of the Barrel Reclaimers are provided with programmable logic controller to achieve synchronized motions, hydraulic rail clamps, anti skew arrangement, storm anchor and air conditioned electric room, dust suppression system, radio control and fire fighting systems are also provided if required. TRF Barrel reclaimer is transferable from one stock pile to the other. The operator's cabin is so located that the operator gets a clear and unobstructed view of the reclaiming process and the entire stock yard. The cabin is air-conditioned and ergonomically designed for maximum comfort of the operator. The front screen is mounted in the operator's console and displays details of all operations enabling the operator to program according to the reclaiming requirement. TRF Limited 11, Station Road Burma Mines, Jamshedpur-831007, Jharkhand Phone : +91- 657-3046500/ 598 Fax no. : +91- 657-2345732, e-mail : co@trf.co.in HYDERABAD Business Development Department Block - D, 3rd Floor, 22 Camac Street, Kolkata - 700 016 Ph : +91-33-44033553 e-mail : biz.development@trf.co.in Bulk Material Handling Systems Port &Yard Equipment Division Assistant General Manager Cell : + 91 - 9334002278 Ph : +91-657 - 3046242 Fax : +91-657-2345214 e-mail : dcjha@trf.co.in NEW DELHI Himalaya House, 11th Floor 23, Kasturba Gandhi Marg Ph : +91-11-223310788 / 23314540 Fax : +91-11-23722447 e-mail : nd@trf.co.in Flat No. 601, 6th Floor, Paigah Plaza, Basheerbagh, Ph : +91-40-23297630 / 23297631 Fax : +91-40-23297363 e-mail : hyd@trf.co.in MUMBAI Magnet House, 1st Floor, Narottam Morarji Marg, Ballard Estate, Ph : +91-22-22616853 / 22641320 Fax : +91-22-22614085 e-mail : mum@trf.co.in REGIONAL OFFICES MARKETING OFFICES HEAD OFFICE & WORKS Bulk Material Handling Equipment Assistant Divisional Manager Cell: +91-9304813195 Ph: +91-657-3046259 Fax: +91 - 657-2345724 e-mail: r.k.shukla@trf.co.in Technical Particulars for Barrel Reclaimer Machine Description Barrel Reclaimer Material Handled Base Mix Rated tph 1200 Design tph 1500 40 m Capacities Track Gauge Service TRF today offers comprehensive operation and maintenance services for their Barrel Reclaimers with guaranteed up-keep time for the customer. This ensures that customers can plan their raw material handling strategy and requirement with added precision, reducing raw material inventory. TRF LIMITED A Enterprise Likhra/Jsr.(0657)2291356 TravellingWagonLoaders TECHNICALSPECIFICATIONS = =Onefullrakeloadedinlessthantwohrs =Negligiblespillagebetweenwagons =Environmentfriendly =Dataloggertominimizeloadingerror Capacityupto3000TPH TRFLIMITED AEnterprise Travelling Wagon Loaders Loading of bulk materials in steel, power & mining industries Travelling Wagon Loaders are essential equipment for loading bulk material into railway wagons at high speed. Wagon Loaders supplied by TRF can load up too 3000 tonnes per hour. TRF wagon loading systems are so designed that there is no spillage between the wagons when the loader is traveling from one end of the rake to the other. Filling efficiencies up to 99 percent of the desired capacity have been achieved. A Travelling Wagon Loaders manufactured at TRF comprises : The tripper conveyor Intermediate conveyor with belt weigher Cross conveyor with loading chutes TRF has supplied Travelling Wagon Loaders for loading bulk cargo like coal, coke, limestone and iron ore. TRF’s travelling wagon loaders can load rakes placed on both sides of the track in a 2 x 2 formation. The cross conveyor shuttles out while loading into rakes at the farther end. All controls are through PLC .The travel speed of the wagon loader is synchronized automatically to complete the loading of one wagon and then travel rapidly to the second wagon to minimize detention time of the rake. Facilities on board include checking of loading rate and totalizers on shift, day, = = = and month basis. TRF Travelling Wagon Loaders are designed to automatically identify sick wagons in the rake and bypass these wagons while completing the loading of the full rake. The material feeding into the wagons is kept uniform by use of TRF designed belt weigher over the cross conveyor. The feeder is synchronized with the loading rate and can be programmed to feed at any desired rate up to its maximum capacity. The operator's cabins are so located that the operator gets a clear and unobstructed view of the loading process. The cabin is air- conditioned and ergonomically designed for maximum comfort of the operator. The front screen is mounted in the operator's console and displays details of all operations enabling the operator to program according to the loading requirement. The air-conditioned electric house is equipped with online fault display and analysis tool to minimize downtime. Hydraulic rail clamps, storm anchor and air conditioned electric room, dust suppression system, radio control and fire alarm are also provided, if required by the customers. TRF’s wagon loaders are provided with pneumatically PLC controlled sector gates to avoid choking of material. TRF Limited 11, Station Road Burma Mines, Jamshedpur-831007, Jharkhand Phone : +91- 657-3046500/ 598 Fax no. : +91- 657-2345732, e-mail : co@trf.co.in HYDERABAD Business Development Department Block - D, 3rd Floor, 22 Camac Street, Kolkata - 700 016 Ph : +91-33-44033553 e-mail : biz.development@trf.co.in Bulk Material Handling Systems Port &Yard Equipment Division Assistant General Manager Cell : + 91 - 9334002278 Ph : +91-657 - 3046242 Fax : +91-657-2345214 e-mail : dcjha@trf.co.in NEW DELHI Himalaya House, 11th Floor 23, Kasturba Gandhi Marg Ph : +91-11-223310788 / 23314540 Fax : +91-11-23722447 e-mail : nd@trf.co.in Flat No. 601, 6th Floor, Paigah Plaza, Basheerbagh, Ph : +91-40-23297630 / 23297631 Fax : +91-40-23297363 e-mail : hyd@trf.co.in MUMBAI Magnet House, 1st Floor, Narottam Morarji Marg, Ballard Estate, Ph : +91-22-22616853 / 22641320 Fax : +91-22-22614085 e-mail : mum@trf.co.in REGIONAL OFFICES MARKETING OFFICES HEAD OFFICE & WORKS Bulk Material Handling Equipment Assistant Divisional Manager Cell: +91-9304813195 Ph: +91-657-3046259 Fax: +91 - 657-2345724 e-mail: r.k.shukla@trf.co.in TRF LIMITED A Enterprise Capacity 720 tph 1500 tph 2400 tph 3000 tph Material Coke Coal Coal Iron Ore & pellets Track size 6.0 m 6.0 m 6.0 m 6.0 m Types of Feeding Options Wagons on one side with shiftable discharge conveyor Wagons on both sides of track Wagons on both sides of track Wagons on both sides of track Wagon Loaders Details Services TRF today offers comprehensive operation and maintenance services for their travelling wagon loaders with guaranteed up-keep time for the customer. This ensures that customers can plan their raw material handling strategy and requirement with added precision, reducing raw material inventory. Likhra/Jsr.(0657)2291356

- 7. Barrel Reclaimers = = Consistent performance combined with a good ratio between machine weight and capacity = Flexibility of choosing between mechanical or hydraulic drives = VVVF drives for all motions of the equipment = State of the art PLC systems with user friendly interfaces = Custom built and made to order equipments at TRF's own Works at Jamshedpur ensuring minimal erection and start up time at site = Availability of radio communication and fibre composite cables allowing additional space at the tripper = Ergonomically designed operator cabin = Ease of maintenance Economical solution for stockyards where simultaneous stacking and reclaiming is not required TRF LIMITED A Enterprise TECHNICALSPECIFICATIONS BarrelReclaimers TheBarrelReclaimersareusedextensivelyinstockyards andareidealforhavingproperblendingofrawmaterialsfor usinginprocessingplant.TRFhasengineeredandsupplied BarrelReclaimerforBasemix. TRF’sBarrelReclaimersareoperationatmajorsteelplants inIndia.ThereclaimcapacityofTRFBarrelReclaimeris 1500TPHwith40mtrackgaugemakingTRFthepremier supplierinIndia. AllthedrivesoftheBarrelReclaimersareprovidedwith programmablelogiccontrollertoachievesynchronized motions,hydraulicrailclamps,antiskewarrangement,storm anchorandairconditionedelectricroom,dustsuppression system,radiocontrolandfirefightingsystemsarealso providedifrequired. TRFBarrelreclaimeristransferablefromonestockpiletothe other. Theoperator'scabinissolocatedthattheoperatorgetsa clearandunobstructedviewofthereclaimingprocessand theentirestockyard.Thecabinisair-conditionedand ergonomicallydesignedformaximumcomfortofthe operator.Thefrontscreenismountedintheoperator's consoleanddisplaysdetailsofalloperationsenablingthe operatortoprogramaccordingtothereclaimingrequirement. TRFLimited 11,StationRoadBurmaMines,Jamshedpur-831007,Jharkhand Phone:+91-657-3046500/598 Faxno.:+91-657-2345732,e-mail:co@trf.co.in HYDERABAD BusinessDevelopmentDepartment Block-D,3rdFloor, 22CamacStreet,Kolkata-700016 Ph:+91-33-44033553 e-mail:biz.development@trf.co.in BulkMaterialHandlingSystems Port&YardEquipmentDivision AssistantGeneralManager Cell:+91-9334002278 Ph:+91-657-3046242 Fax:+91-657-2345214 e-mail:dcjha@trf.co.in NEWDELHI HimalayaHouse, 11thFloor23,KasturbaGandhiMarg Ph:+91-11-223310788/23314540 Fax:+91-11-23722447 e-mail:nd@trf.co.in FlatNo.601,6thFloor, PaigahPlaza,Basheerbagh, Ph:+91-40-23297630/23297631 Fax:+91-40-23297363 e-mail:hyd@trf.co.in MUMBAI MagnetHouse,1stFloor, NarottamMorarjiMarg,BallardEstate, Ph:+91-22-22616853/22641320 Fax:+91-22-22614085 e-mail:mum@trf.co.in REGIONALOFFICES MARKETINGOFFICES HEADOFFICE&WORKS BulkMaterialHandlingEquipment AssistantDivisionalManager Cell:+91-9304813195 Ph:+91-657-3046259 Fax:+91-657-2345724 e-mail:r.k.shukla@trf.co.in TechnicalParticularsforBarrelReclaimer MachineDescription BarrelReclaimer MaterialHandled BaseMix Rated tph 1200 Design tph 150040m CapacitiesTrackGauge Service TRFtodayofferscomprehensiveoperationandmaintenanceservicesfortheirBarrelReclaimerswithguaranteedup-keeptime forthecustomer.Thisensuresthatcustomerscanplantheirrawmaterialhandlingstrategyandrequirementwithadded precision,reducingrawmaterialinventory. TRFLIMITED AEnterprise Likhra/Jsr.(0657)2291356 Travelling Wagon Loaders TECHNICALSPECIFICATIONS = = One full rake loaded in less than two hrs = Negligible spillage between wagons = Environment friendly = Data logger to minimize loading error Capacity upto 3000 TPH TRF LIMITED A Enterprise TravellingWagonLoaders Loadingofbulkmaterialsinsteel,power&miningindustries TravellingWagonLoadersareessentialequipmentforloadingbulk materialintorailwaywagonsathighspeed.WagonLoaders suppliedbyTRFcanloaduptoo3000tonnesperhour. TRFwagonloadingsystemsaresodesignedthatthereisnospillage betweenthewagonswhentheloaderistravelingfromoneendofthe raketotheother.Fillingefficienciesupto99percentofthedesired capacityhavebeenachieved. ATravellingWagonLoadersmanufacturedatTRFcomprises: Thetripperconveyor Intermediateconveyorwithbeltweigher Crossconveyorwithloadingchutes TRFhassuppliedTravellingWagonLoadersforloadingbulkcargo likecoal,coke,limestoneandironore.TRF’stravellingwagon loaderscanloadrakesplacedonbothsidesofthetrackina2x2 formation.Thecrossconveyorshuttlesoutwhileloadingintorakes atthefartherend.AllcontrolsarethroughPLC.Thetravelspeedof thewagonloaderissynchronizedautomaticallytocompletethe loadingofonewagonandthentravelrapidlytothesecondwagonto minimizedetentiontimeoftherake.Facilitiesonboardinclude checkingofloadingrateandtotalizersonshift,day, = = = andmonthbasis.TRFTravellingWagonLoadersaredesignedto automaticallyidentifysickwagonsintherakeandbypassthese wagonswhilecompletingtheloadingofthefullrake. ThematerialfeedingintothewagonsiskeptuniformbyuseofTRF designedbeltweigheroverthecrossconveyor.Thefeederis synchronizedwiththeloadingrateandcanbeprogrammedtofeed atanydesiredrateuptoitsmaximumcapacity. Theoperator'scabinsaresolocatedthattheoperatorgetsaclear andunobstructedviewoftheloadingprocess.Thecabinisair- conditionedandergonomicallydesignedformaximumcomfortof theoperator.Thefrontscreenismountedintheoperator'sconsole anddisplaysdetailsofalloperationsenablingtheoperatorto programaccordingtotheloadingrequirement. Theair-conditionedelectrichouseisequippedwithonlinefault displayandanalysistooltominimizedowntime.Hydraulicrail clamps,stormanchorandairconditionedelectricroom,dust suppressionsystem,radiocontrolandfirealarmarealsoprovided, ifrequiredbythecustomers. TRF’swagonloadersareprovidedwithpneumaticallyPLC controlledsectorgatestoavoidchokingofmaterial. TRFLimited 11,StationRoadBurmaMines,Jamshedpur-831007,Jharkhand Phone:+91-657-3046500/598 Faxno.:+91-657-2345732,e-mail:co@trf.co.in HYDERABAD BusinessDevelopmentDepartment Block-D,3rdFloor, 22CamacStreet,Kolkata-700016 Ph:+91-33-44033553 e-mail:biz.development@trf.co.in BulkMaterialHandlingSystems Port&YardEquipmentDivision AssistantGeneralManager Cell:+91-9334002278 Ph:+91-657-3046242 Fax:+91-657-2345214 e-mail:dcjha@trf.co.in NEWDELHI HimalayaHouse, 11thFloor23,KasturbaGandhiMarg Ph:+91-11-223310788/23314540 Fax:+91-11-23722447 e-mail:nd@trf.co.in FlatNo.601,6thFloor, PaigahPlaza,Basheerbagh, Ph:+91-40-23297630/23297631 Fax:+91-40-23297363 e-mail:hyd@trf.co.in MUMBAI MagnetHouse,1stFloor, NarottamMorarjiMarg,BallardEstate, Ph:+91-22-22616853/22641320 Fax:+91-22-22614085 e-mail:mum@trf.co.in REGIONALOFFICES MARKETINGOFFICES HEADOFFICE&WORKS BulkMaterialHandlingEquipment AssistantDivisionalManager Cell:+91-9304813195 Ph:+91-657-3046259 Fax:+91-657-2345724 e-mail:r.k.shukla@trf.co.in TRFLIMITED AEnterprise Capacity 720tph 1500tph 2400tph 3000tph Material Coke Coal Coal IronOre&pellets Tracksize 6.0m 6.0m 6.0m 6.0m TypesofFeedingOptions Wagonsononesidewithshiftabledischargeconveyor Wagonsonbothsidesoftrack Wagonsonbothsidesoftrack Wagonsonbothsidesoftrack WagonLoadersDetails Services TRFtodayofferscomprehensiveoperationandmaintenanceservicesfortheirtravellingwagonloaderswithguaranteedup-keep timeforthecustomer.Thisensuresthatcustomerscanplantheirrawmaterialhandlingstrategyandrequirementwithadded precision,reducingrawmaterialinventory. Likhra/Jsr.(0657)2291356

- 8. BarrelReclaimers = =Consistentperformancecombinedwithagoodratiobetweenmachineweightandcapacity =Flexibilityofchoosingbetweenmechanicalorhydraulicdrives =VVVFdrivesforallmotionsoftheequipment =StateoftheartPLCsystemswithuserfriendlyinterfaces =CustombuiltandmadetoorderequipmentsatTRF'sownWorksatJamshedpurensuringminimalerection andstartuptimeatsite =Availabilityofradiocommunicationandfibrecompositecablesallowingadditionalspaceatthetripper =Ergonomicallydesignedoperatorcabin =Easeofmaintenance Economicalsolutionforstockyardswheresimultaneousstackingandreclaimingisnotrequired TRFLIMITED AEnterprise TECHNICALSPECIFICATIONS Barrel Reclaimers The Barrel Reclaimers are used extensively in stockyards and are ideal for having proper blending of raw materials for using in processing plant. TRF has engineered and supplied Barrel Reclaimer for Base mix. TRF’s Barrel Reclaimers are operation at major steel plants in India. The reclaim capacity of TRF Barrel Reclaimer is 1500 TPH with 40 m track gauge making TRF the premier supplier in India. All the drives of the Barrel Reclaimers are provided with programmable logic controller to achieve synchronized motions, hydraulic rail clamps, anti skew arrangement, storm anchor and air conditioned electric room, dust suppression system, radio control and fire fighting systems are also provided if required. TRF Barrel reclaimer is transferable from one stock pile to the other. The operator's cabin is so located that the operator gets a clear and unobstructed view of the reclaiming process and the entire stock yard. The cabin is air-conditioned and ergonomically designed for maximum comfort of the operator. The front screen is mounted in the operator's console and displays details of all operations enabling the operator to program according to the reclaiming requirement. TRF Limited 11, Station Road Burma Mines, Jamshedpur-831007, Jharkhand Phone : +91- 657-3046500/ 598 Fax no. : +91- 657-2345732, e-mail : co@trf.co.in HYDERABAD Business Development Department Block - D, 3rd Floor, 22 Camac Street, Kolkata - 700 016 Ph : +91-33-44033553 e-mail : biz.development@trf.co.in Bulk Material Handling Systems Port &Yard Equipment Division Assistant General Manager Cell : + 91 - 9334002278 Ph : +91-657 - 3046242 Fax : +91-657-2345214 e-mail : dcjha@trf.co.in NEW DELHI Himalaya House, 11th Floor 23, Kasturba Gandhi Marg Ph : +91-11-223310788 / 23314540 Fax : +91-11-23722447 e-mail : nd@trf.co.in Flat No. 601, 6th Floor, Paigah Plaza, Basheerbagh, Ph : +91-40-23297630 / 23297631 Fax : +91-40-23297363 e-mail : hyd@trf.co.in MUMBAI Magnet House, 1st Floor, Narottam Morarji Marg, Ballard Estate, Ph : +91-22-22616853 / 22641320 Fax : +91-22-22614085 e-mail : mum@trf.co.in REGIONAL OFFICES MARKETING OFFICES HEAD OFFICE & WORKS Bulk Material Handling Equipment Assistant Divisional Manager Cell: +91-9304813195 Ph: +91-657-3046259 Fax: +91 - 657-2345724 e-mail: r.k.shukla@trf.co.in Technical Particulars for Barrel Reclaimer Machine Description Barrel Reclaimer Material Handled Base Mix Rated tph 1200 Design tph 1500 40 m Capacities Track Gauge Service TRF today offers comprehensive operation and maintenance services for their Barrel Reclaimers with guaranteed up-keep time for the customer. This ensures that customers can plan their raw material handling strategy and requirement with added precision, reducing raw material inventory. TRF LIMITED A Enterprise Likhra/Jsr.(0657)2291356 TravellingWagonLoaders TECHNICALSPECIFICATIONS = =Onefullrakeloadedinlessthantwohrs =Negligiblespillagebetweenwagons =Environmentfriendly =Dataloggertominimizeloadingerror Capacityupto3000TPH TRFLIMITED AEnterprise Travelling Wagon Loaders Loading of bulk materials in steel, power & mining industries Travelling Wagon Loaders are essential equipment for loading bulk material into railway wagons at high speed. Wagon Loaders supplied by TRF can load up too 3000 tonnes per hour. TRF wagon loading systems are so designed that there is no spillage between the wagons when the loader is traveling from one end of the rake to the other. Filling efficiencies up to 99 percent of the desired capacity have been achieved. A Travelling Wagon Loaders manufactured at TRF comprises : The tripper conveyor Intermediate conveyor with belt weigher Cross conveyor with loading chutes TRF has supplied Travelling Wagon Loaders for loading bulk cargo like coal, coke, limestone and iron ore. TRF’s travelling wagon loaders can load rakes placed on both sides of the track in a 2 x 2 formation. The cross conveyor shuttles out while loading into rakes at the farther end. All controls are through PLC .The travel speed of the wagon loader is synchronized automatically to complete the loading of one wagon and then travel rapidly to the second wagon to minimize detention time of the rake. Facilities on board include checking of loading rate and totalizers on shift, day, = = = and month basis. TRF Travelling Wagon Loaders are designed to automatically identify sick wagons in the rake and bypass these wagons while completing the loading of the full rake. The material feeding into the wagons is kept uniform by use of TRF designed belt weigher over the cross conveyor. The feeder is synchronized with the loading rate and can be programmed to feed at any desired rate up to its maximum capacity. The operator's cabins are so located that the operator gets a clear and unobstructed view of the loading process. The cabin is air- conditioned and ergonomically designed for maximum comfort of the operator. The front screen is mounted in the operator's console and displays details of all operations enabling the operator to program according to the loading requirement. The air-conditioned electric house is equipped with online fault display and analysis tool to minimize downtime. Hydraulic rail clamps, storm anchor and air conditioned electric room, dust suppression system, radio control and fire alarm are also provided, if required by the customers. TRF’s wagon loaders are provided with pneumatically PLC controlled sector gates to avoid choking of material. TRF Limited 11, Station Road Burma Mines, Jamshedpur-831007, Jharkhand Phone : +91- 657-3046500/ 598 Fax no. : +91- 657-2345732, e-mail : co@trf.co.in HYDERABAD Business Development Department Block - D, 3rd Floor, 22 Camac Street, Kolkata - 700 016 Ph : +91-33-44033553 e-mail : biz.development@trf.co.in Bulk Material Handling Systems Port &Yard Equipment Division Assistant General Manager Cell : + 91 - 9334002278 Ph : +91-657 - 3046242 Fax : +91-657-2345214 e-mail : dcjha@trf.co.in NEW DELHI Himalaya House, 11th Floor 23, Kasturba Gandhi Marg Ph : +91-11-223310788 / 23314540 Fax : +91-11-23722447 e-mail : nd@trf.co.in Flat No. 601, 6th Floor, Paigah Plaza, Basheerbagh, Ph : +91-40-23297630 / 23297631 Fax : +91-40-23297363 e-mail : hyd@trf.co.in MUMBAI Magnet House, 1st Floor, Narottam Morarji Marg, Ballard Estate, Ph : +91-22-22616853 / 22641320 Fax : +91-22-22614085 e-mail : mum@trf.co.in REGIONAL OFFICES MARKETING OFFICES HEAD OFFICE & WORKS Bulk Material Handling Equipment Assistant Divisional Manager Cell: +91-9304813195 Ph: +91-657-3046259 Fax: +91 - 657-2345724 e-mail: r.k.shukla@trf.co.in TRF LIMITED A Enterprise Capacity 720 tph 1500 tph 2400 tph 3000 tph Material Coke Coal Coal Iron Ore & pellets Track size 6.0 m 6.0 m 6.0 m 6.0 m Types of Feeding Options Wagons on one side with shiftable discharge conveyor Wagons on both sides of track Wagons on both sides of track Wagons on both sides of track Wagon Loaders Details Services TRF today offers comprehensive operation and maintenance services for their travelling wagon loaders with guaranteed up-keep time for the customer. This ensures that customers can plan their raw material handling strategy and requirement with added precision, reducing raw material inventory. Likhra/Jsr.(0657)2291356

- 9. Double Roll Crushers = As the material is CRUSHED ONLY ONCE when it passes through the gap, the percentage of FINES IS MUCH LESS. = Used for almost any material and for crushing up to 0.5 mm. = More economical because of its higher production capacity and lower power requirment. = Easy and simple to maintain. = Produces more uniform material than any other crusher having reciprocating motion. = Uniform wearing of crushing surface. TRF LIMITED A Enterprise TECHNICALSPECIFICATIONS Side View of Double Roll Crusher DoubleRollCrushers DescriptionandUses Tworollsrotateinoppositedirectionsinthis crusher.Thematerialisfedbetweenthetwo rollsforcompressiveactionandbreakinginto fragmentsofuniformsize.Simplicityof mechanicalconstructionandeaseof operationarethetwohighlightsofthis crusher.Theamountoffinesgeneratedfrom crushingisrelativelysmall,aperformance featurewhichqualifiesthismachineforusein thefollowinginstallations: TheDoubleRollCrusherisavailable withheavydutyrollsforcrushingsuch hardmaterialsasoreorwithlightduty rollsforcrushingrelativelysoftmaterials. eachrollassemblyconsistofarollbosswith hexagonaloutershaperigidlymountedon therollshaftwhichpermitseasyreplacemant ofrolltyre.Therolltyresareheldtightby meansofbolts.Thisarrangementprovides foreasytyrereplacementandminimizes partssubjecttowear.Therolltyresaremade ofhighmanganesesteel. (3)Bearings Sphericalrollerbearingsareusedto supporttherolls.Thesphericalroller bearingsarecompletewithlabyrinth sealsandpackingsforpreventing entranceofdustandleakageofoil. (4)Drive ThestandardDoublerollcrusherhas independentbeltdrivesfromtwo motors,onemotorforeachroll.This arrangementeliminatestheneedforan intermediatedrivetransmittingdevice resultinginlessspaceutilisationand reducingtheno-loadpowerloss. (1)Frame Acast-ironorsteel-plateframeisused. Thesteel-plateframeisfabricatedby welding.Theplummerblocksoffixedroll assemblyareintegralwiththeframe. ThePlummerBlockforthemovableroll assemblyareelasticallypositionedin horizontaldirectionwithhigh-strength coilspringsorhydraulicaccumulators selectedforthetypeofcrushingduty. Thiselasticmountingincludesameans ofadjustingtheroll-to-rollclearance(roll setting)andservesasaprotective featureforpreventingmotoroverloador damagetothecrusher,astherollwill yieldandbackawaywhenitgripshard foreignmattersliketrampiron. (2)Rolls Rolltyresareofsmoothtype,corrugated typeortoothedtype,dependingonthe crushingduty.Inthestandarddesign SORTINGPLANTSOFMINES COALMINES CEMENTPLANTS CHEMICALPLANTS = = = = (forcrushingore) (forcrushingcoalandwaste) (forcrushingclay,limeandgypsumrocks) (forcrushinglime,coal,coke,rocksalt,etc.) SMELTINGPLANTS COAL-FUELPOWERPLANTS = = (forcrushingcoal) (forcrushingsinteredoreandcinder) Construction TRFLIMITED AEnterprise TRFLimited 11,StationRoadBurmaMines,Jamshedpur-831007,Jharkhand Phone:+91-657-3046500/598 Faxno.:+91-657-2345732,e-mail:co@trf.co.in HYDERABAD BusinessDevelopmentDepartment Block-D,3rdFloor, 22CamacStreet,Kolkata-700016 Ph:+91-33-44033553 e-mail:biz.development@trf.co.in BulkMaterialHandlingSystems Port&YardEquipmentDivision AssistantGeneralManager Cell:+91-9334002278 Ph:+91-657-3046242 Fax:+91-657-2345214 e-mail:dcjha@trf.co.in NEWDELHI HimalayaHouse, 11thFloor23,KasturbaGandhiMarg Ph:+91-11-223310788/23314540 Fax:+91-11-23722447 e-mail:nd@trf.co.in FlatNo.601,6thFloor, PaigahPlaza,Basheerbagh, Ph:+91-40-23297630/23297631 Fax:+91-40-23297363 e-mail:hyd@trf.co.in MUMBAI MagnetHouse,1stFloor, NarottamMorarjiMarg,BallardEstate, Ph:+91-22-22616853/22641320 Fax:+91-22-22614085 e-mail:mum@trf.co.in REGIONALOFFICES MARKETINGOFFICES HEADOFFICE&WORKS BulkMaterialHandlingEquipment AssistantDivisionalManager Cell:+91-9304813195 Ph:+91-657-3046259 Fax:+91-657-2345724 e-mail:r.k.shukla@trf.co.in DIMENSIONS(inMM): SIZEDia.DxL 600X600 750X600 750X750 750X900 750X1200 750X1500 900X900 900X1200 900X1500 900X1800 900X2100 900X2400 1200X1200 1200X1800 1200X2400 1400X2500 D 600 750 750 750 750 750 900 900 900 900 900 900 1200 1200 1200 1400 L 600 600 750 900 1200 1500 900 1200 1500 1800 2100 2400 1200 1800 2400 2500 A 350 596 596 596 596 596 600 600 600 600 600 600 800 800 800 900 B 650 686 850 1050 1300 1500 1000 1350 1600 1900 2200 2500 1400 2000 2600 2700 A1 1100 1850 1850 1850 1850 1850 1850 1850 1850 1850 1850 1850 2200 2200 2200 2300 B1 650 900 1050 1300 1500 1700 1150 1500 1750 2000 2300 2800 1600 2200 2800 2900 A2 660-730 800-870 800-870 800-870 800-870 800-870 900-1000 900-1000 900-1000 900-1000 900-1000 900-1000 1200-1300 1200-1300 1200-1300 1250-1400 K 830 1010 1200 1300 1350 1450 1300 1400 1660 1800 1950 2100 2100 2400 2600 2700 K1 1475 2200 2200 2200 2200 2200 2200 2200 2200 2200 2200 2200 3000 3000 3000 3200 H 1030 1475 1475 1475 1475 1475 1650 1650 1650 1650 1650 1650 1850 1850 1850 1900 H1 930 1375 1375 1375 1375 1375 1500 1500 1500 1500 1500 1500 1700 1700 1700 1800 H2 430 625 625 625 625 625 650 650 650 650 650 650 700 700 700 800 Likhra/Jsr.(0657)2291356 Roller Screens = Higher capacity up to 1500 TPH running at low power compared to conventional screens = Less space required = Higher screen efficiency = Non clogging, smooth, non-vibrating and low noise while running = Length and width of roller screens can be adjusted to suit customers’ requirement TRF LIMITED A Enterprise TECHNICALSPECIFICATIONS RollerScreens Description Application: Construction: Rollerscreensconsistsofarigidmainframeandaseriesof rollerdiscassembliesmountedonshaftsandsupportedon sphericalrollerbearingsacrossthewidthofmainframe.These rollerdiscsareellipticalinshapeandarrangedatapre- determineddistanceinsuchawaythattheyformasquareor rectangularopeningintherollerscreenatseveralplaces.Over sizedmaterialsarepushedforwardbyrotationofelliptical discsandfinallyreachthecrusherasfeed,whileundersized materialfallsthroughthescreenopening.Thescrapper providedbelowtheellipticaldiscsensuresclogfreescreening. Theserollershaftassembliesaredrivenbychainandsprocket arrangement.Allrollershaftassembliesareconnected alternatelywithchainandsprocketandaredriveninsame directionbytwodriveunits.Driveisfullycoveredandoperates inacirculatingoilbath. Eachrollerscreenhastwodriveunitsalongwithelectricmotor, fluidcoupling,gearboxanddrivesprocket. TRFRollerscreensaremostsuitableforseparatingcoars wetandstickyrawmaterial.Rollerscreensareusedinsoftcoal, andlignitehandlingplantsforpreliminaryscreeningofROM coal.Itactsasrelieftocrushersandensuresaclogfreeflowof wetandstickymaterials.TRFrollerscreensareusefulfor separationofundersizedmaterialrangingfrom(-)20mm.to(-) 60mm.Therollerscreenscanbeplacedhorizontallyorat angleofmaximum10degrees. Therollerscreensconsistofarigidframeonwhichaseriesof rollershaftassembliesaremountedwithanti-frictionbearings Drive: MATERIALFLOWDIRECTION FEEDCHUTE OVERSIZE DISCHARGE CHUTE UNDERSIZE DISCHARGECHUTE TRFLIMITED AEnterprise TRFLimited 11,StationRoadBurmaMines,Jamshedpur-831007,Jharkhand Phone:+91-657-3046500/598 Faxno.:+91-657-2345732,e-mail:co@trf.co.in HYDERABAD BusinessDevelopmentDepartment Block-D,3rdFloor, 22CamacStreet,Kolkata-700016 Ph:+91-33-44033553 e-mail:biz.development@trf.co.in BulkMaterialHandlingSystems Port&YardEquipmentDivision AssistantGeneralManager Cell:+91-9334002278 Ph:+91-657-3046242 Fax:+91-657-2345214 e-mail:dcjha@trf.co.in NEWDELHI HimalayaHouse, 11thFloor23,KasturbaGandhiMarg Ph:+91-11-223310788/23314540 Fax:+91-11-23722447 e-mail:nd@trf.co.in FlatNo.601,6thFloor, PaigahPlaza,Basheerbagh, Ph:+91-40-23297630/23297631 Fax:+91-40-23297363 e-mail:hyd@trf.co.in MUMBAI MagnetHouse,1stFloor, NarottamMorarjiMarg,BallardEstate, Ph:+91-22-22616853/22641320 Fax:+91-22-22614085 e-mail:mum@trf.co.in REGIONALOFFICES MARKETINGOFFICES HEADOFFICE&WORKS BulkMaterialHandlingEquipment AssistantDivisionalManager Cell:+91-9304813195 Ph:+91-657-3046259 Fax:+91-657-2345724 e-mail:r.k.shukla@trf.co.in Likhra/Jsr.(0657)2291356

- 10. DoubleRollCrushers =AsthematerialisCRUSHEDONLYONCEwhenitpassesthroughthegap,thepercentageofFINESISMUCHLESS. =Usedforalmostanymaterialandforcrushingupto0.5mm. =Moreeconomicalbecauseofitshigherproductioncapacityandlowerpowerrequirment. =Easyandsimpletomaintain. =Producesmoreuniformmaterialthananyothercrusherhavingreciprocatingmotion. =Uniformwearingofcrushingsurface. TRFLIMITED AEnterprise TECHNICALSPECIFICATIONS SideViewofDoubleRollCrusher Double Roll Crushers Description and Uses Two rolls rotate in opposite directions in this crusher. The material is fed between the two rolls for compressive action and breaking into fragments of uniform size. Simplicity of mechanical construction and ease of operation are the two highlights of this crusher. The amount of fines generated from crushing is relatively small, a performance feature which qualifies this machine for use in the following installations: The Double Roll Crusher is available with heavy duty rolls for crushing such hard materials as ore or with light duty rolls for crushing relatively soft materials. each roll assembly consist of a roll boss with hexagonal outer shape rigidly mounted on the roll shaft which permits easy replacemant of roll tyre. The roll tyres are held tight by means of bolts. This arrangement provides for easy tyre replacement and minimizes parts subject to wear. The roll tyres are made of high manganese steel. (3) Bearings Spherical roller bearings are used to support the rolls. The spherical roller bearings are complete with labyrinth seals and packings for preventing entrance of dust and leakage of oil. (4) Drive The standard Double roll crusher has independent belt drives from two motors, one motor for each roll. This arrangement eliminates the need for an intermediate drive transmitting device resulting in less space utilisation and reducing the no-load power loss. (1) Frame A cast-iron or steel-plate frame is used. The steel-plate frame is fabricated by welding. The plummer blocks of fixed roll assembly are integral with the frame. The Plummer Block for the movable roll assembly are elastically positioned in horizontal direction with high-strength coil springs or hydraulic accumulators selected for the type of crushing duty. This elastic mounting includes a means of adjusting the roll-to-roll clearance (roll setting) and serves as a protective feature for preventing motor over load or damage to the crusher, as the roll will yield and back away when it grips hard foreign matters like tramp iron. (2) Rolls Roll tyres are of smooth type, corrugated type or toothed type, depending on the crushing duty. In the standard design SORTING PLANTS OF MINES COAL MINES CEMENT PLANTS CHEMICAL PLANTS = = = = (for crushing ore) (for crushing coal and waste) (for crushing clay, lime and gypsum rocks) (for crushing lime, coal, coke, rock salt, etc.) SMELTING PLANTS COAL-FUEL POWER PLANTS = = (for crushing coal) (for crushing sintered ore and cinder) Construction TRF LIMITED A Enterprise TRF Limited 11, Station Road Burma Mines, Jamshedpur-831007, Jharkhand Phone : +91- 657-3046500/ 598 Fax no. : +91- 657-2345732, e-mail : co@trf.co.in HYDERABAD Business Development Department Block - D, 3rd Floor, 22 Camac Street, Kolkata - 700 016 Ph : +91-33-44033553 e-mail : biz.development@trf.co.in Bulk Material Handling Systems Port &Yard Equipment Division Assistant General Manager Cell : + 91 - 9334002278 Ph : +91-657 - 3046242 Fax : +91-657-2345214 e-mail : dcjha@trf.co.in NEW DELHI Himalaya House, 11th Floor 23, Kasturba Gandhi Marg Ph : +91-11-223310788 / 23314540 Fax : +91-11-23722447 e-mail : nd@trf.co.in Flat No. 601, 6th Floor, Paigah Plaza, Basheerbagh, Ph : +91-40-23297630 / 23297631 Fax : +91-40-23297363 e-mail : hyd@trf.co.in MUMBAI Magnet House, 1st Floor, Narottam Morarji Marg, Ballard Estate, Ph : +91-22-22616853 / 22641320 Fax : +91-22-22614085 e-mail : mum@trf.co.in REGIONAL OFFICES MARKETING OFFICES HEAD OFFICE & WORKS Bulk Material Handling Equipment Assistant Divisional Manager Cell: +91-9304813195 Ph: +91-657-3046259 Fax: +91 - 657-2345724 e-mail: r.k.shukla@trf.co.in DIMENSIONS (in MM) : SIZE Dia. D x L 600 X 600 750 X 600 750 X 750 750 X 900 750 X 1200 750 X 1500 900 X 900 900 X 1200 900 X 1500 900 X 1800 900 X 2100 900 X 2400 1200 X 1200 1200 X 1800 1200 X 2400 1400 X 2500 D 600 750 750 750 750 750 900 900 900 900 900 900 1200 1200 1200 1400 L 600 600 750 900 1200 1500 900 1200 1500 1800 2100 2400 1200 1800 2400 2500 A 350 596 596 596 596 596 600 600 600 600 600 600 800 800 800 900 B 650 686 850 1050 1300 1500 1000 1350 1600 1900 2200 2500 1400 2000 2600 2700 A1 1100 1850 1850 1850 1850 1850 1850 1850 1850 1850 1850 1850 2200 2200 2200 2300 B1 650 900 1050 1300 1500 1700 1150 1500 1750 2000 2300 2800 1600 2200 2800 2900 A2 660-730 800-870 800-870 800-870 800-870 800-870 900-1000 900-1000 900-1000 900-1000 900-1000 900-1000 1200-1300 1200-1300 1200-1300 1250-1400 K 830 1010 1200 1300 1350 1450 1300 1400 1660 1800 1950 2100 2100 2400 2600 2700 K1 1475 2200 2200 2200 2200 2200 2200 2200 2200 2200 2200 2200 3000 3000 3000 3200 H 1030 1475 1475 1475 1475 1475 1650 1650 1650 1650 1650 1650 1850 1850 1850 1900 H1 930 1375 1375 1375 1375 1375 1500 1500 1500 1500 1500 1500 1700 1700 1700 1800 H2 430 625 625 625 625 625 650 650 650 650 650 650 700 700 700 800 Likhra/Jsr.(0657)2291356 RollerScreens =Highercapacityupto1500TPHrunningatlowpowercomparedtoconventionalscreens =Lessspacerequired =Higherscreenefficiency =Nonclogging,smooth,non-vibratingandlownoisewhilerunning =Lengthandwidthofrollerscreenscanbeadjustedtosuitcustomers’requirement TRFLIMITED AEnterprise TECHNICALSPECIFICATIONS Roller Screens Description Application : Construction : Roller screens consists of a rigid main frame and a series of roller disc assemblies mounted on shafts and supported on spherical roller bearings across the width of main frame. These roller discs are elliptical in shape and arranged at a pre- determined distance in such a way that they form a square or rectangular opening in the roller screen at several places. Over sized materials are pushed forward by rotation of elliptical discs and finally reach the crusher as feed, while undersized material falls through the screen opening. The scrapper provided below the elliptical discs ensures clog free screening. These roller shaft assemblies are driven by chain and sprocket arrangement. All roller shaft assemblies are connected alternately with chain and sprocket and are driven in same direction by two drive units. Drive is fully covered and operates in a circulating oil bath. Each roller screen has two drive units along with electric motor, fluid coupling, gearbox and drive sprocket. TRF Roller screens are most suitable for separating coars wet and sticky raw material. Roller screens are used in soft coal, and lignite handling plants for preliminary screening of ROM coal. It acts as relief to crushers and ensures a clog free flow of wet and sticky materials. TRF roller screens are useful for separation of undersized material ranging from (-) 20 mm. to (-) 60 mm. The roller screens can be placed horizontally or at angle of maximum 10 degrees. The roller screens consist of a rigid frame on which a series of roller shaft assemblies are mounted with anti-friction bearings Drive : MATERIAL FLOW DIRECTION FEED CHUTE OVER SIZE DISCHARGE CHUTE UNDER SIZE DISCHARGECHUTE TRF LIMITED A Enterprise TRF Limited 11, Station Road Burma Mines, Jamshedpur-831007, Jharkhand Phone : +91- 657-3046500/ 598 Fax no. : +91- 657-2345732, e-mail : co@trf.co.in HYDERABAD Business Development Department Block - D, 3rd Floor, 22 Camac Street, Kolkata - 700 016 Ph : +91-33-44033553 e-mail : biz.development@trf.co.in Bulk Material Handling Systems Port &Yard Equipment Division Assistant General Manager Cell : + 91 - 9334002278 Ph : +91-657 - 3046242 Fax : +91-657-2345214 e-mail : dcjha@trf.co.in NEW DELHI Himalaya House, 11th Floor 23, Kasturba Gandhi Marg Ph : +91-11-223310788 / 23314540 Fax : +91-11-23722447 e-mail : nd@trf.co.in Flat No. 601, 6th Floor, Paigah Plaza, Basheerbagh, Ph : +91-40-23297630 / 23297631 Fax : +91-40-23297363 e-mail : hyd@trf.co.in MUMBAI Magnet House, 1st Floor, Narottam Morarji Marg, Ballard Estate, Ph : +91-22-22616853 / 22641320 Fax : +91-22-22614085 e-mail : mum@trf.co.in REGIONAL OFFICES MARKETING OFFICES HEAD OFFICE & WORKS Bulk Material Handling Equipment Assistant Divisional Manager Cell: +91-9304813195 Ph: +91-657-3046259 Fax: +91 - 657-2345724 e-mail: r.k.shukla@trf.co.in Likhra/Jsr.(0657)2291356