HSS Circular Saw

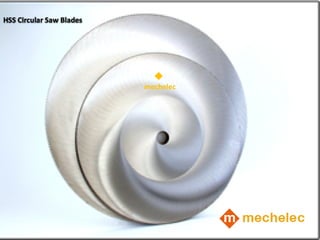

- 1. HSS Circular Saw Blades mechelec

- 2. About us MECHELEC manufactures the largest range of HSS Saws and Knives designed for long-period cutting for diverse applications in various industries. From the very beginning, our efforts have been directed towards producing nothing but the very best. No methods provided by Modern Scientific and Engineering Research have been neglected. Besides using the best imported material, MECHELEC gives great importance to correct heat treatment in the manufacture of Saws and Knives. The PVD coating provided delivers 3 to 10 times longer tool life. MECHELEC Knives give 30% more life MECHELEC Knives are the best in the country MECHELEC Knives are made out of best material MECHELEC Knives are as good as the best in the world MECHELEC Knives are specially treated for extra wear resistance MECHELEC Knives are guaranteed against defective material and workmanship Correct and constant heat treatment is fundamental in order to fully utilize the metallurgical and technological features of high-speed steels and emphasize all their technical features. Mechelec HSS saw blades are heat treated in salt bath to achieve best results.

- 3. Standard MECHELEC HSS saw blades are supplied in high speed steel grade M2 = DIN 1.3343, and can also be made available in cobalt-alloyed steel grades, such as M35 = DIN 1.3243 Diameters vary from 150 to 500 mm in various tooth forms. M2 / DIN 1.3343 Chemical Composition % C Si Mn P S C o Cr Mo V W 0.86 - 0.94 <=0.45 <=0.4 <=0.03 <=0.03 0 3.80 - 4.50 4.70 - 5.20 1.70 - 2.00 6.00 - 6.70 M35 / DIN 1.3243 Chemical Composition % C Si Mn P S Co Cr Mo V W 0.88 - 0.96 <=0.45 <=0.4 <=0.030 <=0.030 4.5 - 5.00 3.80 - 4.50 4.70 - 5.20 1.70 - 2.00 6.00 - 6.70 Alternatively a range of PVD (Physical Vapour Deposition) cutting blades can also be supplied with the following coatings: TiN - Titanium Nitride; a good all round coating which allows saw cutting at much higher speeds than with HSS Steam Treated saw blades and are recommended for cutting steel tubes and profiles TiALN - Titanium Aluminium Nitride; provides better protection against higher temperatures than a TiN coating. Recommended for cutting applications on which fast cutting speeds or very hard materials cause higher temperatures. TiCN - Titanium Carbon Nitride; has a very low friction coefficient, extending the cutting blade life in steel tube cutting applications. Suitable for cutting all steel types including stainless steel. MECHELEC MECHELEC

- 4. Tooth shape A is normally used on fine toothing (<T3) for applications such as brass alloy cutting, jewellery and screw slotting. Tooth shape AW, unlike type A, is alternately beveled, thus optimizing chip shredding. It is particularly suitable for precision cutting. Tooth shape B is normally used for thin- walled pipes and the cutting of structural shapes, especially where chip removal is not an issue. Tooth shape BW is primarily used for cutting pipes and sections. The tooth is alternately beveled at 45°, breaks the chip in two and guarantees good chip evacuation. Tooth shape C is used for solid sections or very thick pipes. The chip is shredded into three parts due to the presence of both a finishing tooth without chamfer and a pre- cutting tooth (longer than 0.25 mm) with two chamfers on each side. MECHELEC HSS circular saws are generally available in BW tooth form. Other tooth form can be provided on request. The circular saw blades are manufactured with the following standard angles: HSS - Dmo5 HSS - Co5 γ = 18⁰± 2⁰ γ = 12⁰± 2⁰ α = 10⁰± 2⁰ α = 8⁰± 2⁰ B Sawblade Thickness T Tooth pitch H Tooth height R Gullet diameter Γ Rake angle Α Relief angle S Thickness of piece • •

- 5. TOOTH PITCH: Once the material and the section to be cut have been identified, the pitch must be chosen. The correct pitch will prevent dangerous vibration and guarantee correct chip evacuation. The following data are approximate. In order to choose the right number of teeth, it is important to consider the section that needs to be cut and the material. The pitch is correct when the teeth to section ratio is at least 1:3 for solid bars and 1:1 for pipes and structural shapes. Pipe and Structural Shapes O Avz = 0.05 to 0.08 mm/Z d s T s T ≤ 20mm ≤ 1mm 3 > 1mm 4 ≤ 30mm ≤ 1.5mm 5 > 1.5mm 5.5 ≤ 40mm ≤ 2mm 6 > 2mm 7 ≤ 50mm ≤ 4mm 6 > 4mm 7 ≤ 60mm ≤ 4mm 7 > 4mm 8 ≤ 70mm ≤ 3mm 7 > 3mm 8 ≤ 80mm ≤ 4mm 8 > 4mm 10 ≤ 90mm ≤ 4mm 8 > 4mm 10 ≤ 100mm ≤ 7mm 10 > 7mm 12 ≤ 120mm ≤ 5mm 10 > 5mm 12 ≤ 140mm ≤ 4mm 10 > 4mm 12 Solid Bar Avz < 0.08 mm/Z Avz > 0.08 mm/Z d T T ≤ 20mm 5.5 ≤ 30mm 7 ≤ 40mm 8 ≤ 50mm 9 ≤ 60mm 10 12 ≤ 70mm 11 12 ≤ 80mm 12 14 ≤ 90mm 12 14 ≤ 100mm 14 16 ≤ 120mm 14 16 ≤ 140mm 14 18

- 6. Problem Cause Solution Clogged tooth gullet Pitch too low Reduce number of teeth Poor quality of the cut surface Wrong tooth form Contact our technicians Wrong cutting parameters Verify cutting parameters on the chart Poor cutting performance Cutting speed too high Reduce the number of revolutions Insufficient lubrication Increase pressure and flow rate of the coolant Wrong feed rate per tooth Verify feed rate with charts Wrong cutting angles Verify cutting angles Filling material at the tip of the tooth Poor sharpening Verify sharpening quality Vibration during cutting Verify stability of piece Filling material on the sides of the tooth Insufficient lubrication Verify flow rate of coolant Excessive disc side run-out Use reduced side run-out sawblades Blade breakage during cutting High working parameters Verify parameters with the charts Poor clamping of the piece being cut Verify the quality and strength of clamp Unsteady feed rate Verify feeding system of the cut-off machine Wrong pitch Verify parameters against the charts Burn marks on the piece being cut Worn saw blade Blade must be resharpened Insufficient lubrication Increase coolant flow / Check concentration Solutions To Frequently Faced Problems

- 8. MATERIAL TO BE CUT RECOMMENDED COATING Low- alloy steel 400 - 600 N/mm2 VAPO Medium hard alloy steel 700 - 900 N/mm2 VAPO / TiN Hard steel 950 - 1100 N/mm2 TiN / TiAlN Stainless steel TiCN / TiAlN Cast iron TiN Copper Bright / CrN Bronze Bright / CrN Brass Bright / CrN Aluminium Bright / CrN D 58 Pace City II, Udyog Vihar Phase VI Sector 37, Gurgaon – 122001 Haryana, INDIA www.mechelec.co.in +91956981100 info@mechelec.co.in Stocked HSS Circular Saw Blade Sizes: Coating: Bright / VAPO Hardness: 60to 62 HRC Outer Dia: 250/275/300/315/350/400mm Bore: 32mm Thickness: 1.5/ 2/2.5mm Tooth Form: BW Pitch T: 4mm Other specifications are made to order