TemplateP 10-04NameSectionEnter the appropriate amount or item i.docx

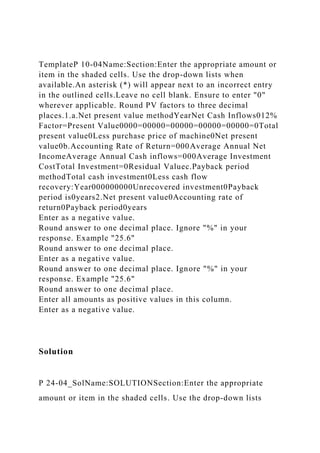

- 1. TemplateP 10-04Name:Section:Enter the appropriate amount or item in the shaded cells. Use the drop-down lists when available.An asterisk (*) will appear next to an incorrect entry in the outlined cells.Leave no cell blank. Ensure to enter "0" wherever applicable. Round PV factors to three decimal places.1.a.Net present value methodYearNet Cash Inflows012% Factor=Present Value0000=00000=00000=00000=00000=0Total present value0Less purchase price of machine0Net present value0b.Accounting Rate of Return=000Average Annual Net IncomeAverage Annual Cash inflows=000Average Investment CostTotal Investment=0Residual Valuec.Payback period methodTotal cash investment0Less cash flow recovery:Year000000000Unrecovered investment0Payback period is0years2.Net present value0Accounting rate of return0Payback period0years Enter as a negative value. Round answer to one decimal place. Ignore "%" in your response. Example "25.6" Round answer to one decimal place. Enter as a negative value. Round answer to one decimal place. Ignore "%" in your response. Example "25.6" Round answer to one decimal place. Enter all amounts as positive values in this column. Enter as a negative value. Solution P 24-04_SolName:SOLUTIONSection:Enter the appropriate amount or item in the shaded cells. Use the drop-down lists

- 2. when available.An asterisk (*) will appear next to an incorrect entry in the outlined cells.Leave no cell blank. Ensure to enter "0" wherever applicable. Round PV factors to three decimal places.1.a.Net present value methodYearNet Cash Inflowsx12% Factor=Present Value1$ 75,000x0.893=$ 66,975270,000x0.797=55,790365,000x0.712=46,280460,000x0. 636=38,160425,000x0.636=15,900Total present value$ 223,105Less purchase price of machine250,000Net present value$ (26,895)b.Accounting Rate of Return=Average Annual Net Income/Average Investment CostAverage Annual Net IncomeAverage Annual Cash inflows=$ 11,250/$ 137,500Average Investment CostTotal Investment=8.2%Residual Valuec.Payback period methodTotal cash investment$ 250,000Less cash flow recovery:Year1$ 75,000270,000365,000440,000(250,000)Unrecovered investment0Payback period is3.7years2.Net present value$ (26,895)Accounting rate of return8.2%Payback period3.7years Round answer to one decimal place. Ignore "%" in your response. Example "25.6" Enter as a negative value. Round answer to one decimal place. Enter as a negative value. Round answer to one decimal place. Ignore "%" in your response. Example "25.6" Round answer to one decimal place.

- 3. Enter all amounts as positive values in this column. Enter as a negative value. Schroeder, R. G., Goldstein, S. M., & Rungusanatham, M. J. (2013). Operations management in the supply chain: Decisions and cases (6th ed.). New York, NY: McGraw-Hill/Irwin. If the products sell extremely well, we will build more in season, and will be back on the shelves in a few weeks. And we'll build even more, and even more, and even more, in that same season. We're not going to wait with a hot new product until next year, when hope- fully the same trend is alive. -Ronald Snyder, CEO of Crocs, lnc. 1 On May 3, 2007, Crocs, Inc. released its results for the first quarter of the year. The footwear company, which had sold its first shoes in 2003, reported reve- nues of $142 million for the quarter, more than three times its sales for the first quarter of 2006. Net in- come, at $0.61 per share was more than 17 percent

- 4. of sales, nearly four times higher than the previous year. 2 These results far exceeded market expecta- tions, which had been for earnings of $0.49 per share on $114 million of revenue. 3 As part of the earnings release, the company announced a two-for-one stock split. Immediately after the announcement, the stock price jumped 15 percent. The growth and profitability of Crocs, which made funky, brightly colored shoes using an extremely com- fortable plastic material, had been astounding. Much of this growth had been made possible by a highly flexible supply chain which enabled the company to build additional product to fulfill new orders quickly within the selling season, allowing it to respond to un- expectedly high demand-a capability that was previ- ously unheard of in the footwear industry. This ability to fulfill the needs of retailers also made the company a very popular supplier to shoe sellers. This success also raised questions about how the company should grow in the future. Should it vertically integrate or grow through product line 1 Quotations are from interviews w ith the authors, unless oth-

- 5. erwise specified. 2 Press Release, "Crocs, Inc. Reports Fiscal 2007 First Quarter Financial Results," May 3, 2007. Online at http://www.crocs. com/consumer/press_details/688244 (accessed May 4, 2007). 3 Rick Munarriz, "Ugly Shoes, Pretty Profits," The Motley Fool, May 4, 2007. Online at http://www.fool.com/investing/high- g rowth/2007 /05/04/ug ly-shoes-pretty-profits.aspx (accessed May 7, 2007). extension? Should it grow organically or through ac- quisition? Would potential growth paths exploit Crocs' core competencies or defocus them? CROCS, INC. In 2002, three friends from Boulder, Colorado went sailing in the Caribbean. One brought a pair of foam clog shoes that he had bought from a company in Canada. The clogs were made from a special mate- rial that did not slip on wet boat decks, was easy to wash, prevented odor, and was extremely com- fortable. The three, Lyndon "Duke" Hanson, Scott Seamans, and George Boedecker, decided to start a business selling these Canadian shoes to sailing en- thusiasts out of a leased warehouse in Florida, as

- 6. Hanson said, "so we could work when we went on sailing trips there." 4 The founders wanted to name the shoes something that captured the amphibious nature ofthe product. Since "Alligator" ha.d already been taken, they chose to name the shoes "Crocs." The shoes were an immediate success, and word of mouth expanded the customer base to a wide range of people who spent much of their days stand- ing, such as doctors and gardeners. In October 2003, as the business began to grow, they contacted Ronald Snyder, a college friend, to become a consultant for the company. Snyder had been an executive with Flextronics, a leading electronics contract manufac- turer, heading up the company's design division. He had extensive experience in manufacturing opera- tions, mergers and acquisitions, and sales and mar- keting. When he first started consulting with Crocs, Snyder said, "I thought I would work a few hours a day. I thought it would be restful." 5 But seeing the rapid growth of the company based on word-of- mouth marketing, Snyder joined Crocs in June 2004 as its president, becoming CEO in January 2005. When Snyder joined the company it was head-

- 7. quartered in Colorado, but essentially distributing shoes made by the Canadian manufacturer Finpro- ject NA. One of Snyder's first moves was to purchase 4 Diane Anderson, "When Crocs Attack," Business 2.0, November 1, 2006. 5 1 bid. David Hoyt and Amanda Silverman prepared this case under the supervision of Michae l Marks, Professors Chuck Holloway and Hau Lee as the basis for class discussion rather than to illustrate either effective or ineffective handling of an adminis- trative situation. Copyright© 2007 by the Board of Trustees of the Leland Stanford Junior University. All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, used in a spreadsheet, or transmitted in any form or by any means-electronic, mechanical, photocopying, recording, or otherwise-without the permission of the Stanford Graduate School of Business. Reprinted with permission. 492

- 8. Crocs: Revolutionizing an Industry's Supply Chain Model for Competitive Advantage 493 Finproject, which was renamed "Foam Designs ." Crocs now owned the formula for the proprietary resin "croslite™" that gave the shoes their unique properties of extreme comfort and odor resistance. The company now also controlled manufacturing. EXHIBIT 1 Crocs executives and directors. Snyder encouraged the company to think big. He brought in a number of key executives from Flex- tronics, and built infrastructure in preparation for growth. (See Exhibit 1 for Crocs executives and direc- tors.) He also launched the product worldwide. Executive Background Ronald Snyder, President, CEO, Director Peter Case, SVP, Finance, CFO, Treasure John McCarvel, SVP, Global Operations

- 9. Michael Margol is, VP, Sales and Marketing . Director Raymond Croghan Ronald Frasch Michael Marks Marie Holman-Rao Richard Sharp, Chairman Thomas Smach Ronald Snyder With Cross since June 2004 (consultant since October 2003). Senior executive with Flextronics. Founder of The Di i Group, w hich was acqu ired by Flextronics. With Crocs since April 2006. Previously EVP, CFO, and treasurer of publicity held sports apparel and

- 10. accessor ies company. With Crocs since January 2005 (consultant beginning in 2004). Previously an executive w ith Flextronics and The Dii Group. With Crocs since January 2005. Led Crocs sales group as a consultant beginning in October 2003. Previously, founder and executive with an apparel and merchandising compan y. Background Board member since August 2004. Prior to retirement in 1999, ran a healthcare information technology consulting firm. Also on the board of several privately- held compan ies. Board member since 2006. Vice Chairman of Saks Fifth Avenue. Background in global retailing. Board member since August 2004. Member of Kohlberg Kravis Roberts & Co., a private equity firm, as a member of the firm since January 1, 2006 . Chairman of Flectronics. Previously, he was wi th Flextronics from

- 11. 1991-2005, serving as CEO and chairman. Also a director of SanDisk Corporation and Schlumberger Limited. Board member since 2006. Background in the apparel business, including Limited Brands, Inc., Gap, Inc., Banana Republic, and Ann Taylor. Board cha irman since April 2005. With Circuit City from 1982 to 2002, serving as president, CEO, and chairman. Also a board member of Flextron ics (formerly chair). And of Carmax, Inc., the nation's largest specialty retailer of used cars and light trucks. Boa rd member since Apri l 2005. With Flextronics since 2000, as CFO, and SVP of finance. Previously SVP, CFO and treasure of The Dii Group, Inc., which was acquired by Flextronics. Also serves on the board of ADVA AG Optical Networking. President of Crocs. See background above under Executives. Sources: Crocs w ebsite, "Board and Management Profiles," http://www.crocs.com/ company/ ln vestor_Relations/Board_Management.jsp

- 12. (April 23, 2007}, Crocs Proxy, October 2006. 494 Part Six Case Studies Snyder explained the rationale behind launching worldwide at an early point in the company's life: The plan was, we're going to launch the world in order to get a brand out that would be a sustain- able brand with th is funky looking, strange product. Other, larger shoe companies, or even larger apparel companies, could have knocked us off, and could have gone into Europe before we got there if they had infrastructure in Europe. So, being Flextronics guys, and understanding that the world is flat, and you can get every- where fairly quickly, we said, "we need to launch the world pretty much at once." We delayed a bit in South America, but now we're there fairly strong, too. But we needed to launch every- where in order to have us be the brand that had sustainability. That's what we've been able to

- 13. pull off at this point. We were in every country you can think of before anybody else had any real capability to ship product in other countries besides the U.S. Certainly, there are knock-offs in all those other places, but they are just known as knock-offs. They are not known as originals, which is what we were hoping to achieve. Crocs started its sales efforts on a grass-roots basis in the U.S. The company participated in many trade shows in every industry that could benefit from the product, such as garden shows, boat shows, and pool supply shows . As stores began carrying the shoes, Crocs personnel worked closely with the stores. Snyder observed, "If you just put up a rack of funny-looking shoes, I don't think they would have done anything. But we got in there with some of our own people, or our reps, and stood around and got people excited." Crocs also went to a wide range of events, such as con- certs, festivals, and sports tournaments, to talk to cus- tomers about the shoes. The company took a similar approach in other countries, but the momentum gen- erated in the U.S. helped foreign adoption. The company initially used representatives and

- 14. distributors in the U.S., but brought this function in- house in order to control costs. In other countries, Crocs had its own sales staff wherever possible, but as of mid-2007 had some 3rd party distributors in some locations. In addition to a popular product and a global strategy, Crocs developed a supply chain that pro- vided a competitive advantage. Traditional industry practice was for retail distributors to place bulk or- ders for each season's inventory many months in ad- vance, with little ability to adjust to changes during the selling season. The Crocs model did not impose these limitations on retailers-the company could fill new orders within the season, quickly manufac- turing and shipping new product to retail stores. The traditional practice, and the Crocs supply chain will be described in detail below. From 2003 through 2006 the company had phenomenal growth. Revenue in 2003 had been $1.2 million . By 2006, it was $355 million, with a net income· of $64 million (18 percent of revemk). Crocs went public in February 2006, with an initial market

- 15. capitalization of over $1 billion. After the Q1 2007 earnings release, the market cap passed $2.7 billion. Sales outside of North America grew from 5 percent of total revenue in 2005 to 25 percent in 2006. In its Q1 2007 earnings release, the company said that it expected 2007 revenue to be between $670 and $680 million. (The company had historically reported results that comfortably exceeded expectations. 6 ) (See Exhibits 2 and 3 for company financial informa- tion .) Crocs' financial performance was far superior in many respects to others in the footwear industry (Exhibit 4). The Crocs Shoe The original Crocs shoe was a clog design. Visually, its two most distinctive features were large ventila- tion holes and bold colors. The key to the shoe, how- ever, was the croslit~ material. This proprietary closed-cell foam material molded to the shape of the wearer's foot, providing an exceptionally com- fortable shoe. It was extremely light, did not skid, was odor resistant, and did not mark surfaces. It could also be washed with water. Croslite could be produced in any color, and the company chose bold colors (described by some as "crayon" colors) which

- 16. further enhanced the distinctive, funky look. Crocs shoes generally sold for about $30-which was not marked down, as retailers found they did not need to unload excess inventory through clearance sales at the end of a selling season. As Crocs grew, it added additional shoe designs. The two original models, Beach and Cayman, ac- counted for about 62 percent of footwear sales in 2006.7 These two models also formed the basis of some of the other Crocs models. By April 2007, the company had a wide range of shoes and other prod- ucts . Its website showed 31 basic footwear models, ranging from sandals to children's rain boots to shoes designed for professionals, such as nurses, who had to stand all day. Some of its shoes were made under a license agreement with Disney, and incorporated Disney characters. In addition, Crocs offered four models of shoes (CrocsRX) that were 6 Munarriz, loc. cit. 7 Crocs Form 1 OK for 2006, pp. 15-16.

- 17. Crocs: Revolutionizing an Industry's Supply Chain Model for Competitive Advantage 495 EXHIBIT 2 Crocs' financial performance through 2006. All amounts in $ millions, except as noted. 2006 2005 2004 2003 2002 Revenue 354.7 108.6 13 .5 1.2 0.0 Cost of goods sold 154.2 47.8 7.2 0.9 0.0 Gross profit 200.6 60.8 6.4 0.3 0.0 Gross profit margin 56.5% 56.0% 47 0% 23.3% 33.3% SG&A expense 97.2 30.6 7.2 1.4 0.5 Depreciation & amortization 8 .1 3.3 0.7 0.1 0.0 Operating income 95.3 26.9 (1 6) (1 .2) (0.4) Operating margin 26.9% 24.8% Net income after taxes 64.4 17.0 (1 .5) (1.2) (0.4) Net profit margin 18.2% 15.6% Geographic distribution of revenue(% of total)

- 18. North America 265.5 (75%) 102.8 (95%) 135 (100%) Asia 54.4 (15%) 4.7 (4%) Europe 30.3 (9%) 1.0 (1%) All Other 4.6 (1%) 0.1 Shoes as percent of total revenue 96% 94% 81% Selected Balance Sheet Items (Calendar year end, all values in $ millions) 2006 2005 2004 2003 Cash 71.2 37.8 6.9 0.5 Net receivables 69.3 20.0 3.3 0.2 Inventories 86.2 28.5 2.4 0.4 Net fixed assets 34.8 14.8 3.7 0.3 Accounts payable 71.2 37.8 6.9 0.5 Short-term debt 0.5 8.5 1.0 Long-term debt 0.1 3.2 1.4 Sources: Hoovers. Product and geographic distribution of revenue from Crocs Form 1 OK for 2006, pp. F-27, 28. EXHIBIT 3 Financial results, Q1 2007.

- 19. The following results were released May 3, 2007, for the quarter ended March 31, 2007 (dollar values in millions, except as otherwise stated): Q1 2007 Q1 2006 % Change Revenues 142.0 44.8 317% Gross profit 84.4 23.7 356% Gross profit(% of sales) 59.4% 52.9% SG&A expenses 47.3 137 345% Net income, after tax 24.9 6.4 389% Net income(% of sales) 17.5% 14.3% Net income per share, diluted $0.61 $0.17 359% Source: Crocs Press Release, May 3, 2007, loc. cit. 496 Part Six Case Studies EXHIBIT 4 Industry comparisons. Comparisons of Crocs with companies selected as "best of group" and industry median.

- 20. Deckers Industry Median Crocs Outdoor Nike Timberland Annual sales ($ million) 355 304 14,9 55 1,568 Market capita lization ($ million) 2,102 897 10,06 5 1,306 Profitability Gross profit margin 56.5% 46.4% Pre-tax profit margin 27.2% 17.8% Net profit margi n 18.2% 10.4% Return on equity 56.7% 16.1% Return on assets 34.1% 13.7% Return on invested capital 51.1% 15. 9% Operations Inve ntory turnover 3.5 5.0 Receivables turn over 8.0 6.0 Valuation Price/Sales ratio 5.9 3.0 Price/Earnings ratio 30.4 28.3 Price/C ash fl ow ratio 170.3 18.5 Growth

- 21. 12 month revenue growth 227% 15% 12 month net income growth 280% (1.0%) 12 month EPS growth 239% (2.3%) 43.7% . 13 .1% 8.7% 21.6% 14.4% 18.4% 4.3 6.5 1.3 20.0 14.1 8.8% 0.4% 2.9% < 47.3% 10.4%

- 22. 6.8% 19.5 % 13 .0% 19.0 % 4.7 7.4 0.8 15.3 11.7 0.1% (35.3%) (3 1.5 %) 24.5% 3.2% 2.7 % 15.5 % 3.4% 4.7%

- 23. 5.6 6.6 0.8 20.1 10.6 7.5% 53.2% 50 .0% Source: Hoovers Online Competitive Landscape (April 27, 2007). Crocs growth numbers are for cale ndar years 2005 and 2006. Crocs in ventory turns from Crocs. designed to meet the special needs of those with medical problems that affected the feet, such as dia- betes. The company offered 17 models of collegiate models that were made in school colors, with the school logos . Universities such as USC, UCLA, Notre Dame, Cal, and Ohio State participated in the pro- gram. (By the start of the 2007/8 academic year, Crocs expected to include many other institutions in its catalog of university logo shoes.) Crocs sponsored

- 24. the AVO beach volleyball tour, and offered two models with the AVP logo .8 (See Exhibit 5 for photos of selected Crocs products.) While shoes comprised 96 percent of company revenues in 2006. 9 Crocs also branched out into other accessory products, such as caps, shirts, shorts, hats, socks, and backpacks. It had products such as kneepads and kneelers that utilized croslite to pro- vide functionality. It also sold decorative inserts that could be put into the shoe ventilation holes, origi- nally made by a family-owned company (Jibbitz) that Crocs purchased in December 2006. 8 Product links from Crocs home page: http://www.crocs.com/ home .jsp (Accessed April 24, 2007) . 9 Crocs Form 10K for 2006, p. F-27 . Crocs made other acquisitions in 2006 and earl y 2007 in the sports protection equipment and ap- parel market, and in action footwear. These acquisi - tions further broadened the company's product line, and introduced products that incorporated conven- tional materials such as leather. (See Exhibit 6 for a list of Crocs acquisitions.)

- 25. Producing a Crocs Shoe The ra w materials for the croslite in Crocs shoes are relatively inexpensive chemicals purchased in pellet form from suppliers such as Dow Chemical. These chemicals are then combined in a process called "compounding," in w hich they are converted into a slurry, mixed, and then reformed into new pellets . As part of the compounding process, color dyes are added. The compounded pellets are then ready to be molded into croslite products. Croslite components for Crocs products are made by injection molding. This requires an injection molding machine, and molds for each style and size. After the parts are molded, they must be assembled. This might involve gluing croslite parts together, or stitching, in the case of components made of leather, canvas, or other materials which had been added to Crocs : Revolutionizing an Industr y's Supply C hain Model for Compe ti tive Advantage 497

- 26. - BIT 5 Selected Crocs products. ~ ~ ~ beach cayman disney beach Beach was the company's most Beach and Cayman were the first two Disney beach was a version of po pular model. Beach and Cayman Crocs products, and formed the basis the Beach model produced ac counted for 62 percent of 2006 for some other shoe models. under license from Disney. shoe sales. ~ ~TM ~ 1-professional jibbitz kneepads Professional was intended for Jibbitz were used to customize Crocs Crocs produced items such as people such as nurses who spent shoes by filling the ventilation kneepads that took advantage all day working on their feet. holes in the shoes. of the properties of croslite. ~

- 27. ~ ti ~ crocs 1" wristband cloud block letter t-shirt Crocs offered branded accessories Cloud was designed to meet the Crocs offered a range of shirts such as wristbands, caps, and socks. special needs of diabetic patients. and shorts. 5ource: Crocs w ebsite (www. crocs.com, accessed Apr il 23, 2007). Images © Crocs, Inc. , reprinted w ith perm ission . EXHI BIT 6 Crocs acquisitions, 2004-2006. Acquisition, Date Acquired, Purshase Price2 Foam Des igns (fo rmerly Finproject NA) June 2004 Fury (formerly 55 Hockey Products) October 2006 1 EXO ltalia October 2006 1 Jibb itz

- 28. December 2006 $13.5 mill ion Ocean Minded, LLC January 2007 Notes $1 .75 mill ion plus potential earn -out of up to $3.75 million. 1. The aggregate purchase price for Fury and EXO ltalia was $9.6 million . 2. Purcha se prices include acquisition-related costs. Description Original man ufacturer of Crocs products and owner of crosl ite intellectual property. Manufacturer of hockey and lacrosse products. Crocs developing protection gear based on croslite , w hich offers low w eight, ene rgy absorption, and mi crob ial resistance.

- 29. Designer of ethylene vinyl acetate (EVA) products, primarily for the f ootw ear industry. Family ow ned company specializing in colorful snap-on products designed as accessories for Crocs footw ear. Designer and manufacturer of high quality leather and EVA ba sed sanda ls for the beach, adventure, and action sports markets. Uses recycled and recyclable material s w henever poss ible. Products target young men and w omen w ho w ant high qua lity fashion sandals w ith an emphasi s on style and comfort. Source : Crocs Form 10K for the year ending December 31,2006, pp. F-11, F-1 2, F-30. 498 Part Six Case Studies the Crocs product line in late 2006 and early 2007. The finished products are then tagged and placed in boxes containing 24 pairs of shoes for distribution to retailers. Standard industry practice -was for each

- 30. pack of 24 to contain only one style and color. Crocs, however, would custom configure 24-packs to meet the needs of its smaller customers. CROCS REVO LUTIONIZES THE FOOTWEAR SU PPLY CHAIN The footwear industry was oriented around two seasons-spring and fall. The standard practice was fo r footwear companies preparing for the upcoming fall season to take their products to shows around the world in January. Buyers would book orders for fall delivery following these shows ("pre-books"). The fall orders that were received at the begin- ning of the year would be planned for delivery in August, September, October, and November. These scheduled shipments would drive the production plan . The manufacturers would add some excess to the build, typ ically about 20 percent of the pre- booked orders, to take advantage of potential ad- ditional orders . A very aggressive compan y might add 50 percent to the build, but all the product would be manufactured before the season began . Most shoes were produced in Asia (primarily China and Vietnam), with some manufactu red in South

- 31. America. This production and supply model had obvious limitations. Retailers had to estimate what their cus- tomers would want well in advance of the selling season. If they underestimated, they w ould have empty shelves and forego potential sales. If they overestimated , they would be stuck w ith unsold stock at the end of the season and be f orced to have clearance sales in order to get rid of this excess stock at discounted prices . Making this even more difficult was the consideration that fashion was subject to trends that were difficult to predict-history was of only limited value, particula r ly w ith new product s that incorporated novel design elements that might either become wildly popular or fall flat. The Cro cs Supply Chain Crocs looked at the supply chain from a ve ry differ- ent perspective than traditional shoe companies. Coming f rom their electronics contract manufactur- ing backgrounds, Snyde r and ot her key Crocs execu- tives were accustomed to producing what the customer needed, when it was needed, and respond- ing rapidly to changes in demand. They decided to

- 32. develop a model focused on customer needs-when a custome r needed more product, they would get it. Snyder described the new model as follows, "If th e products sell extremely well, we will build more in season, and will be back on the shelves in a fe w weeks. And we'll build even more, and even more, and even more, in that same season . We're not go- ing to w ait with a hot new product until next year, when hopeful ly the same trend is alive." · Under the Crocs model, retailers would not need to take a big risk in January by placing large orders for their fall season-they could place smaller pre-booked orders, and order more whe n they saw how w ell the products sold . Traditiona lly, customers had to guess which pr oducts would be hot, and could not get mo re of a product that was in higher demand than they had guessed (and take the risk of end-of-season sales to unload excess in - ventory at reduced prices) . Crocs wanted customers to be able to get more of a product during the sea- son in order to take advantage of unexpectedly high demand. To do that, Crocs would have to be able to make the products during the season, and ship them to customers quickly. One analyst re-

- 33. marked, "They've surprised everybody. Their re- plenishment system is unheard-of in the retail footwear space." 10 The positive• relationship that Crocs developed with its retailers resulted in additional benefits. As Crocs became important to big retailers, they ap- proached Crocs to suggest increasing the Crocs pres- ence . Snyder described one large retailer who said: "Bring us new products, bring us apparel, accesso- ries, T shirts, socks, hats, Jibbitz, and we'll give you a whole area that will be dedicated to the current Crocs offerings and any new stuff you come out w ith." Snyde r observed, "Once you have retail space, it's pretty valuable." Developi ng the Crocs Supply Chain Phase One: Taking over Production As mentioned earlier, one of Snyder's first moves was buying the manufacturer of Crocs shoes (Foam Designs) in June 2004 so that it could own the propr ietary croslite resin and control manufactu r ing. At that point, Crocs purchased the raw material pellets from a variety of companies in Europe and the

- 34. United States, and shipped them to a third-party compounding company in Italy. The Italian com- pany had been the parent of Foam Designs, and had previously done the compounding, so continu- ing to use them for this function avoided supply chain interruptions. 10 Jim Duffy of Thomas W eisel Partners, quoted in Anderson, loc. cit. Crocs: Revo lutionizing an Industry's Supply Chain Model for Competitive Advantage 499 -e co mpounded, colorized pellets were then back to Foam Designs in Canada, where shoes _ =mo lded and assembled. The finished products = : h en shipped to a third-party distribution --::>any in Denver that warehoused the shoes, and - -~ged and shipped them to customers. -;.:e Tw o: Global Production Using Contract

- 35. .:- 'acturers Crocs started production in China in 2005, using a large contract manufacturer. The materials were still being sent to Italy for com- =- di ng, but the compounded pellets were now =-=~a both Canada and China. The shoes that were .::::e in China were shipped to the Denver ware- =~e f or packaging orders and distribution . o cs began to enter the Asian and European -=r ets in the spring of 2005. As described earlier, '€ co mpany's strategy was to launch worldwide, so - ::rou ght on manufacturing capacity to support this =:::> oach. It added capacity through contract manu - :~urers in Florida, Mexico, and Italy (due to the lo- ...::. presence of the compounding company). oming from the contract manufacturing business, ::-. d er and his team expected that the benefits of =-- r act manufacturing they had experienced in the · ronics industry would also be present in this new = iness . Electronics contract manufacturers in all

- 36. --rts of the world were highly responsive to customer :::=mands, and quick to increase or stop production as _ ui red. They soon found that this was not the case · f ootwear manufacturing. Snyder explained: W e realized very quickly that third party [manu- f acturers] with our new model weren't going to w ork [outside of Asia]. Third parties in Asia are absolutely great. They are very flexible. They can b e both flexible and high volume . They move very quickly. They [contract manufacturers] take ri sks with us, where they buy equipment. They invest in helping us grow the business. No [third party manufacturers in] other countries were w illing to even entertain that. We'd have to give t hem long term forecasts, long term contracts, w e'd have to sign away the next few kids . Noth- ing was good about using contractors in any other part of the world, to be honest .... [Third party manufacturers outside of Asia] w ould want to know what we're shipping four months from now, not next week. We were tell- ing them, "no, we actually need you to change

- 37. to morrow, and start shipping different stuff next week, if that's what's required, since that's o ur model." [And they said,] "Oh no, no, we can't do that!" Phase Three: Bringing the Global Supply Chain In-House When Snyder realized that contractor manufacturers outside of Asia would not be able to adopt the com- pany's supply chain model, he developed company- owned manufacturing operations in Mexico, and Italy. Crocs set up a manufacturing operation in Brazil that was scheduled to open by the end of June 2007. It w as also exploring potential manufacturing sites in India, and expected to start production there by the end of the year. Crocs had used a contract manufacturer in Romania to serve European customers, and considered sev- eral options to replace the contractor, including: buying the contractor, setting up a new facility in Romania, or looking elsewhere. They were ap- proached by a company in Bosnia that made shoes for Nike, and seemed to understand the Crocs model. The two companies agreed to an arrange- ment whereby Crocs owned the molding equipment

- 38. and molds, using the contract company's personnel for labor. If this approach did not meet Crocs' re- quirements for flexibility and rapid response to de- mand, it would move to an entirely company-owned manufacturing facility. The Chinese contract manufacturer, who could meet Crocs' needs for flexibility and responsiveness, was maintained. (In 2006, 55 percent of Crocs' unit volume was produced in China 11 ) Crocs also kept the Florida contract manufacturer, who was only making one high volume product, and could ship with a Made in USA label, and continued to manufacture in Canada. While manufacturing in each geographic region added both capacity and the ability to respond to local customers, having the compounding done in Italy led to supply chain inefficiencies. Compounded material had to be sent from Italy to each produc- tion site, in the correct amounts and colors. This re- sulted not only in inefficient shipping of materials around the world, but also reduced manufacturing fle xibility in each location, since they could only pro- cess the colors that they had in stock. The raw mate-

- 39. rials were inexpensive, so centralizing compounding did not result in significant savings through inven- tory consolidation . In 2006, Crocs took control of the compounding activity, creating state-of-the-art compounding fa- cilities in Canada, China, and Mexico. Crocs could now ship raw materials to each of these plants . The plants could compound material as need for production, delaying the colorizing decision until a 11 Crees Form 1 OK for 2006, p. 8. 500 Part Six Case Studies specific color product was needed. Snyder described the results: We can get an order now, and we don't even have to make the compound and colorize it yet, and we can ship it in two weeks. So now the model is starting to really take shape, where we don't have to take risks on even color compound

- 40. at this point. Now we have that in place, which makes a huge difference. Moving compounding in-house also provided IP pro- tection for the croslite compound. Crocs also changed its warehousing model. The company had used a contract warehousing and dis- tribution firm in Colorado to handle all its ship- ments. All production came to the contractor's Colorado warehouse in bulk, where every shoe was removed and labeled, then warehoused. Customer orders were then filled from this central warehouse. This arrangement was inefficient, since bulk orders from large customers could have been shipped directly from the factory to the customers if ware- housing and distribution had been located near each factory. To address these problems, the company added warehousing operations to each factory, including labeling and other value added activities such as in- stalling hand tags and putting products into bags or boxes. For customers that ordered large quantities, such as Nordstrom, Dillard's, or Dick's Sporting

- 41. Goods, the orders could be shipped directly from the Chinese warehouse. The Chinese warehouse was owned by one of the Crocs suppliers, but run by Crocs' personnel and Crocs' systems. Other w are- houses were owned by Crocs, or being transitioned to Crocs ownership (as in the case of Japan). The in- tent was for Crocs to control order fulfillment activi- ties in Asia. Crocs had a similar experience with warehousing contractors as it had with contract manufacturers. The company had tried using a number of third party warehousers, in the U.S. and elsewhere. Crocs found that these companies did a good job for a short time, but soon lost interest . As Snyder noted, "We don't lose interest in our own stuff," leading to the decision to have the company take control of warehousing. Additional Considerations and Benefits of the Crocs Supply Chain Model Small vs. Large Retail Customers Crocs' early sales were to small retailers. These stores were willing to take more risk than the large chains, and work with a new, rapidly growing supplier-particularly one

- 42. that provided a high level of support and rapi d sr ;- ment of product. Small stores were willing to we~ with Crocs through problems such as stockouts a-:. shipment delays-large retailers generally im pose:. financial penalties for such problems. Crocs sa w.:.-= small retailers as important to building the bra -:. and providing a brand presence, even after th e r=- jority of sales went to large retailers . After Crocs' initial success in small stores, large ~=- tailers approached the company. Since the lar;;:= retailers had seen the market acceptance of ~= Crocs shoes, Crocs was in a much stronger neg otic-- ing position than it would have been earlier in -'""' development-it could negotiate favorable te r.-.- which did not include the financial penalties would previously have been required. By mid-2 about 75 percent of revenue came from large reta - ers, split approximately evenly between shoe st ore department stores, and sporting goods stores . 'f-.:; rest of the revenue came from a large number ::- small shops representing many different seg me-c~ such as gift shops, bicycle retailers, specialty fo od-=- tailers, health and beauty stores, surf shops, and ... -

- 43. osks. These small shops ad :ounted for a much l a r~~ percentage of orders (although at much lower do1 :.- levels) than the large retailers, requiring a differe- approach to distribution. To meet the needs of small customers, prod~=- would be shipped to the company-owned w a ·=.- house in Colorado, where the orders were con~;;:- ured and shipped. Snyder explained the comp a approach to fulfilling orders for these custom ers- follows : We had to be able to service that customer baSE [small retailers], because it was a pretty big chunk of our business. Those guys could neve r take stuff direct from the factory. So, we fe lt ".E st ill needed to ha ve a warehouse for quick shi ments for the big guys and refills for the sm all independents that don't have the warehous in"' capabilities that the larger guys would have . A::. almost none of them have distribution cente rs of course-we ship direct to their shops. So, WE still need the Denver operation which ships about half of our product now.

- 44. While these stores might send orders to Crocs- fax for small quantities to be delivered direct ly::: their stores, the large retailers had an entirely di ent fulfillment model. These companies had trE own distribution centers, and sent orders electro~- cally. Their orders were packed and shipped frc-:: the Crocs factories to the customers' distrib utT::- Crocs: Revolutionizing an Industry's Supply Chain Model for Competitive Advantage 501 =--:er. The customer would then ship it to the ap- - ri ate retail store . : == ing with Explosive Gro wth The Cr ocs suppl y ::.·n w as able to support the company's explos ive ~ _ ·lth, enabling the company to ride t he w ave of __ o mer enthusiasm for its products. For instance, er described a new flip-flop sandal that w as -~ d uced in 2006 . This w as Crocs ' first product in - .s segment, and the company did not know how

- 45. ::. y w ould be purchased. Since it w as unique and =-:: emely comfortable, they decided to make :.= ,000 pairs-far more than they had pre-booked : ers for, and perhaps as many as any model selling at category in the world. :a rly in the selling season, there were ind ications -- ::. t he new flip-flop w as going to be even more :: ou lar than they expected, so Crocs made sure that -~ad excess injection molding machine capacity and - Id s available . It continued to get orders, and ::~ il d more product to meet the new orders . By the :=c-d of the season in September, they had shipped -ear ly 2.5 million pairs-more than 10 times what --ey w ould have shipped if they had operated under - -e tr adi t ional model of making all of a season's _ d uct ion prio r to the season based on pre-booked :· ers. he primary requirements for adding capacity er e having enough injection molding machines, ::. d having enough molds for the desired product.

- 46. -·ocs purchased molding machines from t w o pri- ~a ry suppliers, who could init (ally de liver new ma - - ines in about three months . However, as the :~ppl iers observed Crocs' rap id growth, they man- ::.;ed to have new machines available soone r-by ori l 2007, the company could generally get them · hin si x weeks . Molds generally started to arrive in ut si x weeks, but it would be about th ree months :;efore Crocs would have a full set of all sizes . Cro cs would move equipment from one location an other to bette r meet its production needs. ol d ing machines were not t ransferred often , but en they we r e, the company tried to have ma - - in es from just one vendor at each site. Molds, - w ever, were frequently transferred betw een pro- :. ct io n locations. If they needed fast response to - eet a growing demand in the U.S., they might -ove p roduction to Mexico, which was closer to : e cust omers Y Fo r products with lots of pre-

- 47. oo ked orders, a relatively dependable forecast, = I a sty le failed in the mar ketp lace (which had not yet -appene d as of April 2007), molds co uld be rew orked to -a e d iffe rent styles. and high volume, production might be shifted to China. As part of a licensing agreement with Disney, Crocs introduced a shoe with a Mickey Mouse head replacing a Crocs hole . The product was very popu- lar, and the company decided it needed production flexibility, so it moved molds to Mexico to meet U.S. demand. However, product destined for Asian cus- t omers was made in China, and product going to European customers was made in Europe . In order to be able to respond immediately to in- creases in demand, Crocs kept total manufacturing capacity at about 1 million pairs per month beyond the actual production plan . This capacity could be turned on at a moment's notice. The company also planned its infrastructure (both systems and people) slightly ahead of demand, so that it could respond

- 48. quick ly. In marketing, it spent according to what it could afford-when sales went up, it increased mar- keting spending. Consequently, it had ad campaigns ready to go within a week if the business took off enough to support added spend ing . Shifting Production to Reduce Duty Payments The footwear industry was subject to considerable du- ties. For instance, the U.S. imposed duties on all of Crocs shoes coming from China, with tariffs ranging from 3 to 37 .5 percent depending on the materials in the shoe. Shoes that were entirely molded had a low tariff, while those which used leather or other mate- rials would have a high tariff. 13 On the other hand, under the North American Free Trade Agreement, Crocs paid no duty for products made in Mexico and shipped to the U.S. There were trade agreements between many countr ies that allowed duty-free shipments-for instance, there was no duty on Mex- ican shoes sold in Europe. The duty situation was considered from the early stages of new product development. The operations people would tell the designers what duty costs w ould be incurred based on the materials in the new

- 49. product . They would also look at the processes needed to make the new product. This would be in- cluded in the product strategy. If a Ch inese-produced product had a high tariff, they would consider 13 The tariff classification w as extremel y difficult to determine. Crees submitted model s to the customs, authorities for a ruling . If they bel ieved that a product w as put into a category w ith too high a ta riff, t hey w ould appeal. To get a sense of the compli- cate d nature of the tariff classifications, see: United States In- ternational Trade Commission, " Harm oni zed Ta ri ff Schedule of th e United States (2007)(Rev. 1) Section XII, Chapter 64," http://hotdocs.us it c. gov/docs/tata/hts/bychapter/0701 c64.pdf (M ay 7, 2007). 502 Part Six Case Studies production in a low-tariff location. However, if the product required production processes that were

- 50. not yet available in the low-tariff country, those pro- cesses might be developed as part of the new prod- uct plan. Crocs might also make a high-tariff shoe in China at the start, with a plan to reduce costs later by moving the production. The Canadian manufacturing operation was re- tained in part because of duty considerations. For instance, Canada and Israel had a duty-free relation- ship. Crocs shoes were extremely popular in Israel, having sold 1.2 million pairs in the country in 2006 . (The Canadian operation was also very helpful in selling within Canada, as the Made in Canada label provided an important marketing advantage .) New, More Complicated Products In 2007, Crocs was expanding its product lines beyond croslite molded shoes. In part due to its February 2007 acquisition of Ocean Minded, it was starting to make shoes with uppers made of leather and other conventional footwear materials, with croslite used for the shoe soles. This introduced additional complication into the production process. Leather and other materials were also more expensive than croslite.

- 51. Even with a more complicated production pro- cess, Crocs intended to apply the same fast-response model it had brought from Flextronics and had opti- mized for molded shoes. Snyder commented: Now, it does become more complex-people could throw darts at this thing by saying "but they only make injection molded shoes, so they have an ad- vantage over other shoe manufacturers out there." Yes, we certainly did. But now we've got the same model going for more standard shoes, where it might have a croslite bottom, and it would have more standard uppers-it might have canvas, leather, suede, whatever. But we still are using the same model, where if something is popular, hot in the season, we are going to be able to make more. It may not be as much in the first year, as the extra 2 million we did of the sandal, but even the sandal was a difficult process. It wasn't just molding. It had gluing and everything involved. But the model is still there. We are not going to say "no" to a demand of a very popular new prod- uct. That's going to be our model going forw ard, and we still have a lot of room to get better in our

- 52. flexible manufacturing sites. We are continuing to do things in Mexico and Canada and in Europe to make those even more flexible to be able to get stuff to the market faster than the 2, 4, 6 weeks, whatever it would take now depending on theca- pacity or the demand at a given factory. Introducing New Products In its first few yea rs sales, Crocs observed that all products sold eq ua well in each market around the world. This provide-~ an attractive opportunity. A new shoe model co u1:: be tested in the spring/summer season in the soif'J"~ ern hemisphere, and the results could be used to i:-- dicate how it might be accepted in the U.S . ar::: Europe. If the product was a huge hit, productio~ could be planned accordingly for the northern herr: sphere launch. On the other hand, if the pro du sold slowly, those not bought in the southern herr.· sphere could be sold in the northern hemisphe re its spring/summer season. Snyder elaborated: Now we're in a situation where we can bring o~ .• new products that might have more complexity

- 53. in the supply chain-more leather and more other types of materials, grommets, sewing ma- chines, whatever is required . We can now la un those into half of the countries, still be agg res- sive with our build, still build much more tha n the pre-books, thinking that a given product is going to be hot. Suppose we launch a produ ct ir North America first. We've got other seasons coming along in other parts of the world, an d we've got another 10-15,000 stores we can launch this particular new product into very quickly. So, we don't take a huge risk by do ing that. We don't take a huge risk by ordering extrc: raw materials, and even building up extra sh oe stock as we launch a new product. If it sells o ut in the U.S., we build more, and if all that sells out in the US, that's OK-we'll launch in Europe or Asia the next year. Supply Chain Planning As of mid-2007, Crocs was us- ing a home-grown database system for plan nin"' that had evolved over time. However, it was in t he process of bringing up a commercial enterpris e re- source planning system. They had launched th e in- ventory module, which allowed them a global vie

- 54. of inventory, and provided information for the plar·- n ing system. The new planning system was be in brought online. Crocs had planning people in the U.S., Asia , an Europe. Each country had to generate its own re- quirements plan, but there was also a global plan- ning activity for each model type. The glo ba planning personnel worked with the local staff o the requirements for each market. Product planning w as based on pre-books to~ each model, as well as information on what reta ile w ere picking up the model. Crocs analyzed the ex- pected sales of each model, but built the act ua Crocs : Revolutionizing an Industr y's Supply C hain Model for Competitive Advantage 503 product after it could see the demand hit to avoid ending up with unsold inventory. While Crocs did not build inventory in excess of

- 55. expected orders, the company did acquire excess ca- pacity (sometimes as much as 2 to 3 times the ex- pected capacity) in the form of molds and molding machines so that it could quickly ramp capacity in case a product took off. MOVING INTO THE FUTURE Crocs had been enormously successful from its first sales in 2003 through the first quarter of 2007 . It had developed a supply chain that was revolutionary in the industry, and had been a critical factor in this suc- cess. It had products that were very popular in the marketplace. It had positive relationships with its re- tail customers. How could it best build on its success? Discussion Questions 1. What are Croc's core competencies? 2. How do they exploit these competencies in the future? Consider the following alternatives: a. Further vertical integration into materials b. Growth by acquisition

- 56. c. Growth by product extension 3. To what degree do the alternatives in question 2 fit the company's co re competencies, and to what degree do they defocus the company away from its core competencies? 4. How should Crocs plan its production and inven- tory? How do the company's gross margins affect this decision? 134 Lean Thinking and Lean Systems Chapter outline 7.1 Evolution of lean 7.2 Lean tenets

- 57. 7.3 Stabilizing the master schedule 7.4 Controlling flow with the kanban system 7.5 Reducing setup time and lot sizes 7.6 Changing layout and maintaining equipment 7.7 Cross-training, rewarding, and engaging workers 7.8 Guaranteeing quality 7.9 Changing relationships with suppliers 7.10 Implementation of lean 7.11 Key points and terms Jefferson Pilot Financial, a full-service life insurance firm, learned what so many other firms had learned before it: using the concepts of lean thinking and lean sys- tems for processing life insurance applications improved performance. Jefferson's

- 58. goals for its application processing process were twofold. First, it wanted to re- duce throughput time, from receiving an application to issuing a policy, which was averaging between one to two months. Second, it wanted to reduce its 10 per- cent error rate because each error meant that rework and reprocessing were needed. Using the basic lean tenets presented in this chapter, Jefferson was able to achieve a 70 percent reduction in throughput time and a 40 percent reduction in errors. 1 Lean thinking and lean systems have been applied in a wide variety of indus- tries and settings. They are used to improve operations processes in manufactur- ing and services. Lean ideas are also used to improve processes outside of operations, including software application development and maintenance, annual budgeting, and even for collecting on delinquent accounts! What is lean and how do firms use lean ideas to improve their business?

- 59. 1 Swan k (2003) Chapter 7 Lean Thinking and Lean Systems 135 In this chapter we introduce the lean concepts, principles, and techniques that a host of organizations have adopted for performance improvement. These concepts, principles, and techniques can be deployed to reform not only manufacturing sys- tems but also administrative systems, service systems, and entire supply chains. We begin by looking at the evolution of lean before presenting lean thinking as a set of five tenets. We then characterize the lean system-particularly the lean production system-that is created when companies pursue lean. We conclude by highlighting implementation issues to consider when a company is deploying lean. 7.1 EVOLUTION OF LEAN

- 60. "Tri-State: ~onverting to JIT," Vol. V After World War II the U.S. system of mass production was the envy of the world. Mass production-the production of standardized discrete products in high vol- ume by means of repetitive manufacturing technologies-was the norm. Materi- als were produced in large batches, and machines were made to run faster to reduce costs. In some cases this resulted in sacrificing quality in the name of effi- ciency and creating narrow jobs that led to worker dissatisfaction, but still the world bought products manufactured in the United States. In the 1960s a Japanese miracle started at the Toyota manufacturing company. After visiting U.S. manufacturing companies, Toyota determined that it could not copy their system of mass production. Not only was demand for

- 61. Toyota automo- biles low at that time, there was a severe lack of resources. Because of the lack of resources, Toyota developed a strong aversion to waste. Scrap and rework were deemed wasteful, and so was inventory that tied up storage space and valuable resources. Toyota realized that it needed to produce automobiles in much smaller batches, with much lower inventory, using simple but high- quality processes and involving workers as much as possible. This realization became the foundation for what is known today as the Toyota Production System (TPS) and Just-In-Time (JIT) manufacturing. This production system is now known and used around the world. See the Operations Leader Box titled "TPS at the Toyota Plant in Georgetown, Kentucky, USA." JIT manufacturing came to the United States in 1981 at the Kawasaki motorcy- cle plant in Nebraska, which used some of the TPS ideas. However, instead of

- 62. transforming the entire system, JIT manufacturing focused primarily on inventory reduction but ignored other aspects of Toyota's complete system. As a result, many U.S. companies that attempted to copy and implement the Toyota Production Sys- tem achieved only partial improvement. In 1990 Womack, Jones, and Roos studied JIT automobile manufacturing in Japan, the United States, and Europe and popularized the term lean production in their famous book The Machine That Changed the World: The Story of Lean Production. 2 Lean production was defined as systematically eliminating waste in all production processes by providing exactly what the customer needs and no more. They reported that the best plants using lean production had a big edge in automobile assembly performance anywhere in the world. Labor pro- ductivity in the best plants exceeded that in the worst plants in all three regions by a factor of 2 to 1, defects were reduced by half, and

- 63. inventory was reduced 2 The phrase "lean production" was coined in the late 1980s by John Krafcik, who was worki ng w ith Jam es P. Womack and colleagues on the International Motor Vehicle Program at the Massachusetts Institute of Techn ology (http://www.a utofieldgu ide.com/articles/01 0502.html ). 136 Part Two Process Design Operations Leader TPS at the Toyota Plant in Georgetown, Kentucky, USA ® TOYOTA Toyota Motor Manufacturing Kentucky, Inc. (TMMK), is Toyota's flagship manufactur- ing facility in the United States, currently producing 500,000 ve- hicles annually. Established in

- 64. 1986, TMMK occupies 1300 acres in Georgetown, Kentucky, is over 7.5 million square feet in size, and employs approximately 7000 employees to build the Camry, the Avalon, and the Venza. At TMMK, employees have been trained not only in required job skills but also in problem-solving and continuous improvement methods. Job tasks have been standardized to minimize waste and assure qual- ity. Employees can stop and are strongly encouraged to stop the production line when a quality problem is detected. Employees are, moreover, actively involved in suggesting ways to improve their work and work environments, with an astounding 100,000 sugges- tions on average per year. Toyota has done more than transfer the Toyota Pro- duction System to TMMK. Realizing that the perfor- mance of TMMK depends on its suppliers, it has worked aggressively to help its 350 U.S.-based suppliers to imple- ment the Toyota Production System. TMMK created the Toyota Supplier Support Center in Erlanger, Kentucky, to provide consulting services to suppliers. Suppliers, in

- 65. fact, deliver to TMMK frequently, allowing TMMK to hold inside its facility, on average, enough inventory to last for just four hqurs of production. Source: http://www.toyotageorgetown.com/; A. Harris, "Automotive Special Report-Made in the USA-Uprooting the Toyota Production System and Transplanting It to Kentucky in the United States Has Proved to be a Great Success for Toyota," Manufacturing Engineer 86, no. 1 (2007), pp. 14-19. from two weeks, worth to only enough to maintain production for two hours. The best U.S.-owned plants, indeed, had labor productivity (vehicle assembly hours) and quality comparable to the best Japanese -owned plants in the United States, while European plants lagged behind. This showed that the best U.S. plants could adopt the TPS and compete with Japanese plants, but average U.S. Lean thinking is applied in a wide variety of industries, including hospital emergency rooms to speed patient treatment.

- 66. plants were still far behind, particularly behind plants located in Japan. Today, the concepts, principles, and techniques underlying lean production are often referred to as lean thinking and are being deployed across a broad spectrum of global firms. In the United States, 3M, Bendix, Black & Decker, Briggs & Stratton, Deere & Company, Delta Airlines, Eaton, Ford, General Electric, Hewlett-Packard, Honeywell, IBM, United Health Care, Wells Fargo, and Wipro are just a few examples of well-known firms pursuing lean thinking. In virtually all instances, benefits such as increased inventory turnover (50 to 100 times per year), superior quality, and sub- stantial costs savings (15 to 20 percent) have been reported. Chapter 7 Lean Thinking and Lean Systems 137 7.2 LEAN TENETS

- 67. Lean thinking, as the name signals, is a way of thinking about processes at work (and even processes at home). This way of thinking is built around five tenets that subsume specific concepts, principles, and techniques. The five tenets aim to deliver value to customers efficiently. The first tenet in lean thinking is to specify precisely what about a product or service creates value from the customer's perspective. Recall from Chapter 1 that value is defined by the customer and provided in the p roduct or service the customer needs at a place, time, and price the customer is willing to pay. Value is not what the firm says but what the customer says. Value is often a solution to a problem a customer is facing that the customer is willing to pay for. Value, as such, is dynamic in nature and changes over time. Firms should design and deliver product and service features that customers value and stop doing activities that are not valued by cus- tomers (unless required for other reasons, for example, legal).

- 68. This may mean re- moving unvalued product features or eliminating waiting times in service systems. Waste, in lean thinking, is anything that does not contribute value to the product or service being produced and delivered to the customer; rather than adding value, waste adds costs . The Japanese term for waste is muda. In many manufacturing, administrative, and service processes only 5 to 10 percent of total throughput time adds value for the customer. Firms want to eliminate obvious waste, but many forms of waste are hidden. For example, the v alue-added time to produce a product may be only three hours, but it takes a week to complete it. The muda or non-value- adding time might include waiting for machines or labor to become available, deal- ing with backlogs, searching for materials, or correcting processing errors. Table 7.1 defines the seven forms of waste originally identified by Taiichi Ohno,

- 69. Toyota's former chief engineer, who is considered the father of the Toyota Produc- tion System. Womack and Jones in their book on lean thinking introduced an eighth form of waste: underutilization of workers. This stems from not recognizing, developing, and utilizing the mental, creative, and physical abilities of employees. Contributing to this waste are factors such as poor hiring and training practices, high employee turnover, and an organization culture that does not respect people. The second teriet in lean thinking is to identify, study, and improve the value stream of the process for each product or service. The value stream identifies all the processing steps and tasks undertaken to complete a product or deliver a service from • Overproduction: Producing more than the demand of customers, resulting in unnecessary inven- tory, handling, paperwork, and warehouse space. • Waiting time: Operators and machines waiting for parts or

- 70. work to arrive from supp li ers or other operations; customers waiting in line. • Unnecessary transportation: Double or triple movement of materials due to poor layouts, lack of coordination, and poor workplace organization. • Excess processing: Poor design or inadequate maintenance of processes, req uiring additional labor or machine time. · • Too much inventory: Excess inventory due to larg e lot sizes, obsolete items, poor forecasts, or improper production planning. • Unnecessary motion: Wasted movements of people or extra walking to get materials. • Defects: Use of material, labor, and capacity for production of defects, sorting out bad parts, or warranty costs with customers. 138 Part Two Process Design

- 71. FIGURE 7.1 Health care value stream map. Source: Adapted from Sylvia Bush ell, Joyce Mobley, and Becky Shelest, "Discovering Lean Thinking at Progressive H ealth Care," Journal of Quality & Participation 25, no. 2 (Summer 2002), pp. 161- 191. Xo Patient In 15 minutes Wait 40 minutes Check-in Doctor Visit Information Flow · Xo Patient Out

- 72. 20 minutes 45 minutes 120 minutes Wait Time Visit Prep Visit Doctor 11 minutes 40 minutes Processing Time Pharmacy, 1160 minutes u Total Blood Test Throughp u t Time beginning to end. A typical value stream thus can include both value-added and non-value -added processing steps and tasks. The goal in studying the value stream is to eliminate the non-value-adding processing steps and tasks. One technique supporting this tenet is value stream mapping, which creates a visual representation of the value stream of a process, much like process flowcharting (discussed in Chapter 6). Value stream mapping requires direct observation of work

- 73. and the flow of work within a process so that opportunities for improvement can be identified. The Japanese refer to such direct observation of work as gemba. There- sulting value stream map shows the beginning and ending points of the process, the steps and tasks between those points, and relevant performance information abou the process. Figure 7.1 is a simplified value stream map showing how patients flm ,- through a multispecialty clinic. Improvements to the process come from studying the value stream map and then asking and answering the question, "Is this step or task necessary in creating value to the customer?" Processing steps and tasks that are n ot necessary or are non-value-adding, such as the numerous waiting times in the figure, should then be reduced or removed to improve performance and ultimately enhance value in the product or service provided to the customer. The third tenet in lean thinking is to ensure that flow within a process is simple, smooth, and error-free, thereby avoiding waste . To appreciate

- 74. this tenet, look at Fig- ure 7.2, where production is viewed as a stream and the water level as the inventory of raw materials, work-in-progress, and finished goods. At the bottom of the stream are rocks, which represent problems related to quality, suppliers, delivery, machine breakdowns, and so forth. The traditional approach is to hold inventory high enough to cover up the rocks (problems) and thus keep the stream flowing. Lean - RE 7.2 Simple, smooth, and nonwasteful flow: A stream analogy. Original situation ¥en tory covers problems) Water level lowered (problems are exposed) Chapter 7 Lean Thinking and Lean Sys tems 139

- 75. Water flows smoothly (once problems are solved) thinking calls for the opposite: lowering the water (inventory) level to expose the rocks (problems) . When the rocks have been pulverized (i.e., the problems have been solved), the water is lowered again to expose more rocks. This sequence is iter- ated until all rocks are turned into pebbles and the stream (production system) flows smoothly and simply at the desired output rate while only needing a low level of inventory at any given time. Inventory in this analogy is a form of waste that hides problems that contribute to other forms of waste besides inventory. The idea of simple, smooth, and error-free flow means that production flows are simple and direct, and do not change from one production run or one customer to another. Such predictable flows ensure that the exact appropriate resources, includ- ing labor and equipment, can be devoted to each production

- 76. step. It also means that workers should.understand the connection of their own work to work performed upstream (before them in the production process) as well as work that follows their own. These direct and unambiguous links in the process provide complete certainty about exactly who has performed what work within the process. The goal is to avoid repeating the same activities more than once, for example, retightening a bolt, rein- specting paperwork, or reasking the customer for the same information. There are many techniques that are used to help smooth the production flow. These techniques are covered later in the chapter. The goal of ensuring simple, smooth, error-free flow can be extended up the sup- ply chain to include suppliers. In lean manufacturing, both workers and suppliers are charged with the responsibility of producing quality parts just in time to support the next production process. In a production plant, workers are

- 77. required to stop the production process by pulling a cord that triggers a call for help.3 In addition to hav- ing greater responsibility for production in a lean system, workers and suppliers are also charged with developing ideas for improving the production process. Through quality teams, suggestion systems, and other forms of participation by workers and suppliers, the process of production is improved. The idea is that the workers who are performing the work know the most about the work and, therefore, are in the best position to improve the way the work is completed. Thus, lean thinking encour- ages the use of the capabilities of workers and suppliers to a great extent. The fourth tenet in lean thinking is to produce only what is pulled by the customer. Complying with this tenet requires replacing the push system typical in traditional 3 This specific responsibility is known as Jidoka in Japanese (or Autonomation ). The cord that triggers a visual ca ll for help is ca lled an andon cord .

- 78. 140 Part Two Process Design mass production with the pull system of lean production. A push system aims to produce goods or ensure delivery of services well in advance of demand, often ac- cording to a schedule or plan created from potentially inaccurate forecasts. Large batches of materials are pushed from one process or machine to the next regardless of whether the inventory is needed. This allows machines and processes to be u ti- lized at full capacity, and inventory is considered a valuable asset. A pull system, on the contrary, waits for the process customer to signal a need for a good or service before producing it to fulfill that need. The signal from the customer is then sent vi- sually up the various stages of production-and even the supply chain-to signal what and when production and delivery are needed. No upstream process is autho-

- 79. rized to produce a good or service until a downstream customer asks for it, thu minimizing inventory throughout the production system. An example of a push system is the "hub and spoke" system used by many of the major airlines. Flying point to point by some airlines is a pull system based on what the customer wants. No customer wants to connect through a hub to get to their destination. The fifth tenet in lean thinking is to strive for pe1jection. Striving for perfection requires continuous improvement of all processes as well as radical redesign when necessary. When continuous improvement is undertaken, more value is provided by the firm in its search for ultimate perfection for the customer. The definition of perfection used here is an affordable good or service, delivered rapidly and on time, that meets the needs of the customer. When customer needs change, the def- inition of value changes and so does the definition of what constitutes perfection .

- 80. There is therefore no end to the improvements that can b e sought and made. In lean thinking, the process changes necessary in seeking perfection must b e made using scientific methods, including designing experiments and testing h y- potheses. Employees are discouraged from changing a process based on intuition alone. Rather, lean thinking promotes decision making based on scientifically de- rived evidence. One simple and relatively powerful technique for improving a production pro- cess is the 5 Whys technique. This problem-solving technique systematically ex- plores the cause-and-effect relationships that underlie an observed problem (e.g., a defect in a product or lateness in delivery) . By asking why at least five times, this technique is used to deliver insights into the root cause of an observed problem so that proper corrective action can be taken to prevent the root cause from re-creating

- 81. the observed problem. Here is an example: The truck will not start. Why? The bat- tery is dead. Why? The alternator is not functioning. Why? The alternator belt is broken. Why? The alternator b elt was well beyond its useful life and not replaced. Why? The truck was not maintained according to the recommended service sched- ule. Why? Replacement parts are not available because the truck is old. Asking why helps move toward potential solutions: Find a source for replacement parts or pur- chase a different truck that is maintainable.4 Another well-known technique supporting lean thinking is SS. This is a tech- nique for organizing a workspace (e.g., production shop floor, office space, hospital station, tool shop) to improve employee morale, environmental safety, and process efficiency. The name of this technique comes from five Japanese terms, all of which when transliterated and translated begin with the letters. These terms are defined in Table 7.2. Underlying the SS technique is the belief that when a

- 82. workspace is well organized, time will not be wasted looking for "things" (e.g., a tool or paperwork); misplaced items also will be readily noticed. By having employees decide which 4 Adapted from w ikipedia. org (201 2). Chapter? LeanThinkingandLeanS ys tems 141 Operations Leader ss +Safety= 6S! , · The U.S. Environmenta l Protection Agency provides training materials to businesses for safe storage of hazardous chemicals in work environments, calling t he program 65, which stands for 55 + Safety. The training uses standard 55 methods on removing un- used chemicals that are lingering in storage areas, d ecentralizing chemicals by moving them to where th ey are used in work processes, and organ izing and labeling storage areas so that the chemicals are easy t o find and their absence is easily noticed.

- 83. The photos show an examp le from one manufac- t u ring p lant where, before 55 activities w ere con - ducted, chemica ls were disorganized and difficult to locat e. Following 55, the storage cabinet contains o n ly chemica ls that are needed nearby, in quantities th at last only a few days, and labeled shelves can be easily restocked as needed . "A helpful ru le of thumb is that an yone should be ab le to find any item in 30 seconds or less ." The sixth 5 for safety is integrated with standard 55 methods. To promote safe use and storage of chemicals, 65 training helps businesses develop ap- propriate visual warnings in areas near chemica ls, locate spill kits nearby for cleanup , and clear and clean the space around storage cabinets to avoid t ripping hazards. Lean concepts like 55, as seen in this example, can be customized to the pa rticular needs of an organi- zation or situation. Safety is integrated here w ith 55, a logical connection when hazardous chemica ls are being used. Source: Adapted from www. epa .gov, 2012 .

- 84. items should be kept where as well as how they sh ould be stored, SS can instill in employees a sense of ownership, help standardize work, assure a safe work envi- ronment, and keep processes from becoming overly complex. See the Operations Leader b ox titled "SS + Safety = 6S!" As you can see, the five tenets of lean thinking have many techniques and con- cepts associated with them. In the following sections, we dive into more d etail on several of the most commonly u sed techniques . Term Translation Seiri To sort Seiton To straighten or set in order Seiso To shine, sweep, or clean

- 85. Seiketsu To standardize Shitsuke To sustain Meaning Decide what things should be kept and w hat things should be discarded so that on ly the essential things remain. Arrange essential things in a manner that sup ports an efficient flow of work. Assure cleanl iness by returning things to thei r storage locations and removing things that do not belong. Standardize work and adopt seiri-seiton-seiso t hrougho ut so that all employees know w hat their responsibilities are. Mainta in seiri-seiton-seiso-seikutsu as a hab it of work and a way to operate. .. - - -

- 86. 142 Part Two Process Design 7.3 STABILIZING THE MASTER SCHEDULE One of the ways that firms can move toward achieving the lean tenet of simp-=- smooth, and error-free flow is to level the amount of work that is performed ea.- day. For a service, this might mean scheduling a certain number of customers ea- day or using methods such as advertising or pricing to even out the numb er customers who want the service each day. This practice is referred to as stab iliz- ing the master schedule. Although this terminology is generally not used in vices, the concept still applies, as we will see. The process of production plannic; for manufacturing starts with a long-range production plan, which then is bro~ down into annual, monthly, and daily plans. As part of this production planninc sales are considered, profit planning is done, and capacity is planned. This p lan- ning process starts with an aggregate production plan and then

- 87. breaks it dm~ into the daily production volume needed to meet the planned demand. Master scheduling for products is done to achieve a uniform load, the assign- ment of approximately equal amounts of work to each machine or worker. Th production horizon must be set at least one week in advance and possibly one o: two months in advance, depending on lead times for production, purchasing and capacity changes. Assume for the purpose of discussion that a one-mon tl; rolling schedule is used in which one month of production is scheduled ir.. advance . Also assume that the schedule, calls for 10,000 units of product A 5000 units of product B, and 5000 units of product C. If there are 20 days of pro- duction in the month, the daily schedule will call for V20 of each model produceci in each day: 500A, 250B, and 250C. Furthermore, the individual units will be mixed as they go down the production line. The sequence will

- 88. be I AABC t AABC/AABC /. Note how two units of A are produced for every unit of Band C. Then the sequence is repeated continually. Automobile assembly processes are often sequenced in this manner when multiple models are produced on the same line, ensuring that production of each model is completed at approximately th e same rate that it is purchased. Matching supply to demand is illustrated by the concept of takt time. Takt is the German word for the baton that an orchestra director uses to regulate the speed of the music. In lean production systems takt time is the time between successive units of production; this represents the speed of output. For example, a takt time of 2 minutes means that one unit is produced every 2 minutes, or 30 units are pro- duced in an hour (60/ 2) . In lean production systems the takt time of production should be set equal to the average demand rate of the market to match production

- 89. with demand and thus minimize inventories. To establish the beat of the market, takt time can be computed by dividing the time available for production (being sure to subtract for nonproductive time such as holi- days and lunch breaks) by the demand over the same period. For example, if market demand is 1000 units of a product per day and there are 7 hours of production time available in the day (or 420 minutes), the takt time is then (420 + 1000) = 0.42 minute per unit. So, given the available production time, production of one unit will have to be completed every 0.42 minute (about 25 seconds) to meet market demand. Produc- ing at rates less than the takt time will result in shortages in meeting the demand, and producing at rates greater than takt time will result in building up inventory. The idea of takt time is to produce at a constant rate that equals average demand. Once the monthly master schedule has been set, this information must be trans-