Yale (f807) erp040 th lift truck service repair manual

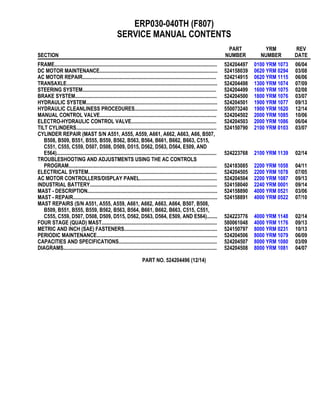

- 1. ERP030-040TH (F807) SERVICE MANUAL CONTENTS SECTION PART NUMBER YRM NUMBER REV DATE FRAME............................................................................................................................ 524204497 0100 YRM 1073 06/04 DC MOTOR MAINTENANCE.......................................................................................... 524158039 0620 YRM 0294 03/08 AC MOTOR REPAIR...................................................................................................... 524214915 0620 YRM 1115 06/06 TRANSAXLE................................................................................................................... 524204498 1300 YRM 1074 07/09 STEERING SYSTEM...................................................................................................... 524204499 1600 YRM 1075 02/08 BRAKE SYSTEM............................................................................................................ 524204500 1800 YRM 1076 03/07 HYDRAULIC SYSTEM.................................................................................................... 524204501 1900 YRM 1077 09/13 HYDRAULIC CLEANLINESS PROCEDURES............................................................... 550073240 1900 YRM 1620 12/14 MANUAL CONTROL VALVE......................................................................................... 524204502 2000 YRM 1085 10/06 ELECTRO-HYDRAULIC CONTROL VALVE................................................................. 524204503 2000 YRM 1086 06/04 TILT CYLINDERS........................................................................................................... 524150790 2100 YRM 0103 03/07 CYLINDER REPAIR (MAST S/N A551, A555, A559, A661, A662, A663, A66, B507, B508, B509, B551, B555, B559, B562, B563, B564, B661, B662, B663, C515, C551, C555, C559, D507, D508, D509, D515, D562, D563, D564, E509, AND E564).......................................................................................................................... 524223768 2100 YRM 1139 02/14 TROUBLESHOOTING AND ADJUSTMENTS USING THE AC CONTROLS PROGRAM................................................................................................................. 524183085 2200 YRM 1058 04/11 ELECTRICAL SYSTEM.................................................................................................. 524204505 2200 YRM 1078 07/05 AC MOTOR CONTROLLERS/DISPLAY PANEL........................................................... 524204504 2200 YRM 1087 09/13 INDUSTRIAL BATTERY................................................................................................. 524158040 2240 YRM 0001 09/14 MAST - DESCRIPTION................................................................................................... 524158890 4000 YRM 0521 03/06 MAST - REPAIR.............................................................................................................. 524158891 4000 YRM 0522 07/10 MAST REPAIRS (S/N A551, A555, A559, A661, A662, A663, A664, B507, B508, B509, B551, B555, B559, B562, B563, B564, B661, B662, B663, C515, C551, C555, C559, D507, D508, D509, D515, D562, D563, D564, E509, AND E564)........ 524223776 4000 YRM 1148 02/14 FOUR STAGE (QUAD) MAST........................................................................................ 580061048 4000 YRM 1176 09/13 METRIC AND INCH (SAE) FASTENERS....................................................................... 524150797 8000 YRM 0231 10/13 PERIODIC MAINTENANCE............................................................................................ 524204506 8000 YRM 1079 06/09 CAPACITIES AND SPECIFICATIONS........................................................................... 524204507 8000 YRM 1080 03/09 DIAGRAMS..................................................................................................................... 524204508 8000 YRM 1081 04/07 PART NO. 524204496 (12/14)

- 2. 100 YRM 1073 Introduction Introduction GENERAL This section contains a description and the service pro- cedures for the parts of the frame. These parts include the frame, counterweight assembly, overhead guard, hood and seat assembly, access panels, and labels. Throughout this section, forward will refer to travel in the direction of the forks and left and right will be deter- mined by an operator sitting in the seat facing forward. See Figure 1. A. LEFT SIDE B. RIGHT SIDE C. FORWARD TRAVEL Figure 1. Truck Orientation DESCRIPTION OF OPERATION The frame is a single weldment with mounts for the counterweight, overhead guard, mast, steering system, hydraulic system and transaxles. See Figure 2. The battery cover opens on hinges to give access to the bat- tery compartment. The weight of the battery is a major part of the counterweight system on an electric lift truck. A slot in the overhead guard permits removal of the battery without removing the overhead guard. Spacers may be added under the battery as required on some models. Each model of lift truck has a cast-iron counterweight with a weight necessary for the indicated capacity. An access panel on the top/rear of the counterweight gives access to the electronic controllers. The hydraulic pump and motor, steering pump and mo- tor, drive motors and transaxles, and hydraulic tank are under the floor plates in the operator compartment. The floor plates are held in position by tabs and can be re- moved to give access to components underneath. The hydraulic control valve is fastened to the front of the battery compartment. Three covers protect the control valve and control linkage. The covers are fastened in position by machine screws. The top covers are locked in place and must be released and swung open before attempting to open the battery cover. Figure 2. Frame 1

- 3. Introduction 100 YRM 1073 DISCHARGING THE CAPACITORS WARNING Do not make repairs or adjustments unless you have both authorization and training. Repairs and adjustments that are not correct can create dangerous operating conditions. Do not operate a lift truck that needs repairs. Report the need for repairs to your supervisor immediately. If repair is necessary, attach a DO NOT OPERATE tag on the steering wheel. Remove the key from the key switch. WARNING Disconnect the battery before opening the drive unit compartment cover or inspecting or repairing the electrical system. If a tool causes a short circuit, the high current flow from the battery can cause personal injury or property damage. WARNING Some checks and adjustments are done with the battery connected. Do not connect the battery until the procedure tells you to do so. Never have any metal on your fingers, arms, or neck. Metal items can accidentally make an electrical connection and cause injury. WARNING Before performing any tests or adjustments, block the lift truck to prevent unexpected movement. WARNING The capacitor in the transistor controller(s) can hold an electrical charge after the battery is dis- connected. To prevent an electrical shock and personal injury, discharge the capacitor(s) before inspecting or repairing any component in the drive unit compartment. Wear safety glasses. Make certain that the battery has been disconnected. CAUTION To avoid controller damage, always disconnect the battery, discharge the capacitor(s), and never put power to the controller while any power wires are disconnected. Never short any controller terminal or motor terminal to the battery. Make sure to use proper procedure when servicing the controller. 1. Turn key switch to OFF position and disconnect the battery. Block load wheels to prevent lift truck from moving. 2. Open the electrical compartment at the rear of the truck. a. Remove the two screws securing the electrical compartment door closed. b. Tilt the door back on its hinges to open the compartment. WARNING DO NOT short across the motor controller terminals with a screwdriver or jumper wire. NOTE: Some lift trucks are equipped with a premium controller, which controls the hydraulic motor as well as the traction motors. 3. Discharge the capacitor in the controller by con- necting a 200-ohm, 2-watt resistor across the con- troller’s BT+ and B terminals for 10 seconds using insulated jumper wires. See Figure 3. 4. On the premium controller, also connect the 200- ohm, 2-watt resistor across the controller’s P+ and B terminals for 10 seconds using insulated jumper wires. See Figure 4. 5. Remove the 200-ohm, 2-watt resistor before recon- necting the battery. 2

- 4. 100 YRM 1073 Covers and Floor Plates 1. POSITIVE CONNECTION (BT+) 2. NEGATIVE CONNECTION (B ) 3. INSULATED JUMPER WIRES 4. 200-OHM, 2-WATT RESISTOR Figure 3. Discharging the Capacitors (Standard) 1. POSITIVE CONNECTION (BT+) 2. NEGATIVE CONNECTION (B ) 3. INSULATED JUMPER WIRES 4. 200-OHM, 2-WATT RESISTOR 5. POSITIVE CONNECTION (P+) Figure 4. Discharging the Capacitors (Premium) Covers and Floor Plates Many system components, such as hydraulic hoses, pump and motor, and wiring harnesses, are located in the area around and under the operator compartment. Various covers and floor plates provide access to these components during service and securely cover these areas during normal operation. See Figure 5. 3

- 5. Covers and Floor Plates 100 YRM 1073 1. CAPSCREW 2. ATTACHING HARDWARE 3. CLIP NUT 4. HARNESS COVER (ELECTRIC VALVE) 5. HARNESS COVER (MANUAL VALVE) 6. CAPSCREW 7. ANTI-SLIP PAD 8. ANTI-SLIP PAD 9. RIGHT FLOOR PLATE 10. CENTER FLOOR PLATE 11. LEFT FLOOR PLATE 12. HOSE COVER Figure 5. Covers and Floor Plates 4

- 6. 100 YRM 1073 Overhead Guard Repair Overhead Guard Repair WARNING The overhead guard is part of the operator protec- tion system. Do not operate the lift truck without the overhead guard correctly fastened to the lift truck. The overhead guard is designed to provide protection to the operator from falling objects and in the event of a tip over. A high visibility design allows for an unob- structed view while maintaining structural integrity. Re- moval of the battery is simplified by the slot in the over- head guard. This provides access to the battery with an overhead lifting device without removing the overhead guard. REMOVE WARNING The overhead guard is heavy. Make sure the sling, chain, eyebolts, and crane or lifting device have the capacity to lift the overhead guard. 1. Remove the six capscrews, washers, and nuts that secure the supports of the overhead guard to the counterweight and cowl. See Figure 6. 2. Use an overhead lifting device and sling to lift the overhead guard until it is just higher than the coun- terweight mounts. NOTE: Tie a cord around the wires from each post of the overhead guard before removal. Remove the wires from the post. Untie the cord from the wires and tape each end of the cord to the overhead guard where it en- ters the post. Use the cord to pull the wires up through the post when installing the overhead guard. 3. Tag and disconnect the wiring from each post of the overhead guard. Carefully remove the wiring if necessary. 4. Completely remove the overhead guard from the lift truck. INSTALL 1. Position overhead guard just above mounts on the counterweight and cowl using an overhead lifting device and sling. 2. Route the wires through each overhead guard post and install to lights as removed. 3. Lower overhead guard supports onto the mounts. 4. Install and tighten six capscrews, washers, and nuts securing overhead guard to the lift truck. Tighten capscrews to 134 N•m (99 lbf ft). 5. Remove sling and overhead guard. 1. OVERHEAD GUARD 2. COUNTERWEIGHT 3. FRAME 4. CAPSCREWS (4) FRONT 5. CAPSCREWS (2) REAR 6. CAPSCREWS (2) UPPER 7. CAPSCREWS (2) LOWER Figure 6. Overhead Guard Mounting 5

- 7. Hood and Seat Assembly 100 YRM 1073 Hood and Seat Assembly The hood is the platform for the seat assembly and is located above the battery. It functions as a battery re- straint that completely covers the battery compartment. See Figure 7. Its function as the battery restraint, when correctly locked to the frame, is to hold the battery in the battery compartment if an accident causes the lift truck to tip over. The hood is composed of a plastic cover attached to a metal frame. Two hinges at the back of the hood attach it to the frame. A sliding latch mech- anism on the front of the hood locks the hood closed during operation. A double-dampened, gas-controlled strut holds the hood in the open position. Opening the sliding latch unlocks the hood from the frame so the hood can be raised to access the battery. See Figure 8. The latch can only be accessed after releasing and raising the hydraulic levers and linkage assembly up and out of the way. A button on each side of the assembly can be pressed to release the assem- bly so it can be moved clear of the hood on its hinged bracket. The latch must be in good condition and prop- erly secured before the lift truck can be operated. If the latch does not lock the hood in the closed position, the hydraulic levers and linkage assembly will not lock into position and the lift truck will not operate. A large, red button switch is mounted on the hood at the right side of the seat assembly. This switch is an emergency battery disconnect that allows the operator to quickly disconnect the battery while seated on the lift truck in case of an emergency. The seat assembly slides on seat rails that are fas- tened to the hood by four capscrews. A lever at the left front side of the base controls the adjustment of the seat to the forward and backward positions. Optional seats are available in cloth or vinyl with features such as semi-suspension, full suspension, and limited swivel. All seats have a seat switch installed in the bottom cush- ion that senses operator presence. When the operator is not on the seat, the seat switch opens and interrupts the controller stopping operation of the lift truck. The hood, seat belt, hip restraint brackets, seat, and seat mount are all parts of the operator restraint sys- tem. Checks and adjustments for the operator restraint system are described in the Operating Manual and the section Periodic Maintenance 8000 YRM 1079. To raise the hood and seat assembly, move the seat to the rear of the hood if necessary. Move the steering column to the most forward position. Release and raise the hydraulic levers and linkage. Open the latch mech- anism and raise the hood. 1. SEAT 2. HOOD 3. SEAT SWITCH CONNECTOR Figure 7. Hood and Seat Assembly 6

- 8. 100 YRM 1073 Hood and Seat Assembly 1. SLIDING LATCH MECHANISM 2. HOOD 3. FRAME Figure 8. Latch Mechanism REMOVE 1. Disconnect the battery connector. 2. Tag and disconnect the electrical connectors to the emergency battery disconnect, the seat switch, and the hood and latch position switches. Remove hood and latch switches if necessary. 3. Remove the emergency battery disconnect switch and hood and latch position switches, if necessary. NOTE: The seat assembly does not have to be removed from the hood to remove the hood from the lift truck. To remove the seat, remove the four capscrews that fasten the seat base to the hood. Lift the seat assembly from the hood. If the seat is not being removed, raise the hood. 4. Remove the stop screws from the seat assembly, hold the slide function lever in the open position, and slide the seat from the mounting bracket. Re- move mounting bracket from hood if necessary. 5. Disconnect the double-dampened, gas-controlled struts by removing the locking clips retaining the struts to the hood and the capscrews securing the lower ends to frame. Move the hood to the closed position. 6. Remove capscrews securing hood mounting brack- ets to hood and lift hood from truck. 7. Slide hood mounting brackets from studs on coun- terweight brackets. Replace bushings if necessary. 8. Remove the capscrews, washers, and nuts retain- ing the hood cover to its metal frame if necessary. INSTALL 1. Install the capscrews, washers, and nuts to secure the hood cover to its metal frame. 2. Install new bushings to mounting brackets if neces- sary. Slide hood mounting brackets onto counter- weight bracket studs as removed. 3. With the aid of an assistant or overhead lifting de- vice and sling, position the hood on the hinges and install the four capscrews. Tighten snugly but do not torque at this time. Place the hood in the closed position. 4. Open and close the hood to check for proper clear- ance. The minimum clearance between the hood and the front plate of the frame is 3.5 mm (0.14 in.). Check to ensure the proper clearance. 5. Tighten the capscrews to 86 N•m (63 lbf ft). 6. Raise the hood. Align and install the gas-filled struts and install the locking clips to retain the struts to the hood and install capscrews to secure the lower ends to frame. 7. If the seat assembly has been removed, install the mounting bracket to the hood using capscrews, washers, and nuts. Hold the slide function lever in the open position and slide the seat into mounting bracket tracks. Release the lever and install the stop screws. 8. Install hood and latch switches and emergency bat- tery disconnect switch, if removed, and adjust as necessary. 9. Connect the wiring harnesses to the seat switch, emergency battery disconnect, and the hood and latch position switches. 10. Close the hood. Make certain that the locking mechanism to retain the hood is properly engaged. Close the hydraulic linkage and covers. 11. Connect the battery connector. 7

- 9. Counterweight 100 YRM 1073 Counterweight WARNING Do not operate the lift truck if the capscrews for the counterweight are not installed. When the capscrews are removed, the counterweight can fall from the lift truck. A one-piece, cast iron counterweight is used to offset the weight of the load. See Figure 9. The counterweight is mounted to the rear of the truck using four mount- ing bolts and is supported by a protruding flange of the frame. See Figure 9. A compartment space, accessed by a hinged door, has been designed into the center of the counterweight to house the electrical connections. A battery platform is used to support the battery on the lift truck frame. The battery platform also serves as part of the counterweight system and requires the use of an overhead lifting device for removal or installation. Be sure to replace the same battery platform, or one of equal weight, if the platform must be removed. Figure 9. Counterweight REMOVE 1. Remove battery. See the section Periodic Mainte- nance 8000 YRM 1079 for instructions on removing the battery. NOTE: It may not be necessary to remove the battery platform. Perform only the steps necessary to complete the required service. 2. Remove battery platform if necessary: a. Remove the battery spacer and the acid tray positioned on top of the battery platform. b. Remove the two capscrews, washers, and nuts retaining the platform to the frame. c. Use a lifting device to lift the platform out of the lift truck. 3. Remove overhead guard. See Overhead Guard Repair. 4. Remove the two large screws securing the electri- cal compartment access door in the closed position and pull open the door. 5. Discharge the capacitor(s). See Discharging the Capacitors. NOTE: Make note of wires and cable routing for proper reassembly. 6. Remove socket head screws and detach the con- troller panel from the electrical compartment ac- cess door. Remove wire ties securing wires and cables to the door hinge mechanism. 7. Remove the electrical compartment access door and hinges if necessary. WARNING The counterweight is very heavy. Make sure the chains, eyebolts, and overhead lifting device have the capacity to lift the counterweight. 8. Install a clevis on each of the overhead guard mounts. See Figure 10. Install tempered, grade 8 bolts and nuts or the proper pins for each clevis. Attach a chain to each clevis. Use an overhead lifting device to hold the weight of the counter- weight. Make sure the sling, chain, eyebolts, and overhead lifting device have the capacity to lift the counterweight. 8

- 10. 100 YRM 1073 Counterweight 1. CHAIN 2. OVERHEAD GUARD MOUNTS 3. CLEVIS Figure 10. Lifting the Counterweight 9. Remove the four M20 × 2.5 × 60 capscrews and hardened flat washers that hold the counterweight to the frame. Four capscrews hold the counter- weight to the frame from the inside and can be ac- cessed from the battery compartment. Two of the capscrews are located at the bottom of the coun- terweight, while the other two are located approxi- mately in the center of the counterweight. The nuts for the capscrews are cast in the counterweight. Refer to Figure 6. 10. Use the overhead lifting device to lift the counter- weight off the mounting flange and away from the frame. See Figure 9. INSTALL WARNING The counterweight is very heavy. Make sure the chains, eyebolts, and overhead lifting device have the capacity to lift the counterweight. 1. Use an overhead lifting device to lift the counter- weight into position. See Remove, Step 8. Some assistance will be required to align the mounting holes in the counterweight with those in the frame. 2. Install the four capscrews and hardened flat wash- ers that hold the counterweight to the frame. Tighten the capscrews to 435 N•m (321 lbf ft). 3. Disconnect the chain. Remove the clevis from each overhead guard mount. 4. If removed, install the electrical compartment hinges and door. 5. Install the controller panel to the inside of the electri- cal compartment door using the proper socket head screws. Secure wires and cables inside the electri- cal compartment as removed. 6. Close the door to the electrical compartment and secure using two large screws. 7. Install the battery platform and the acid tray in the battery compartment. a. Use an overhead lifting device to place the plat- form into the lift truck. b. Install the two capscrews, washers, and nuts retaining the platform to the frame. c. Install the battery spacer and the acid tray on top of the battery platform. 8. Install the overhead guard. See Overhead Guard Repair. 9. Install the battery. See the section Periodic Main- tenance 8000 YRM 1079. 9

- 11. Thank you very much for your reading. Please Click Here. Then Get COMPLETE MANUAL. NO WAITING NOTE: If there is no response to click on the link above, please download the PDF document first and then click on it.

- 12. Safety Labels 100 YRM 1073 Safety Labels WARNING Safety labels are installed on the lift truck to give information about operation and possible hazards. It is important that all safety labels are installed on the lift truck and can be read. DO NOT add to or modify the lift truck. Any change to the lift truck, the tires, or its equipment can change the lifting capacity. The lift truck must be rated as equipped and the nameplate must show the new capacity rating. Contact your Yale lift truck dealer for a replacement nameplate. If a label must be replaced, use the following procedure to install a new label. See Figure 11, Figure 12, and Figure 13. WARNING Always use solvents and paints in an area with ad- equate ventilation. Do not use solvents or paints near heat, fire, or electrical equipment that can cre- ate sparks. Follow the manufacturer’s instructions and cautions. 1. Clean the painted surface. Use household clean- ing products to clean new paint and clean old paint with cleaning solvent. DO NOT use solvent on new paint. Make sure the surface is dry and is clean of dirt, oil, and grease. 2. Remove the paper from the back of the label and hold the label by the edges. Do not touch the ad- hesive surface. CAUTION The label cannot be moved after it touches the sur- face. 3. Carefully hold the label in the correct position above the surface and carefully apply to the correct loca- tion. Make sure that all air is removed from under the label by smoothing any wrinkles or bubbles with your fingers working from the center out. Check that the corners and edges are tight against the sur- face. 10

- 13. 100 YRM 1073 Safety Labels A. SIDE VIEW B. REAR VIEW C. FRONT VIEW 1. OVERHEAD GUARD IMPACT RATING PLATE 2. MAST WARNING 3. YALE 4. OPERATOR RESTRAINT 5. TILT COLUMN 6. MAST WARNING 7. PINCH POINT 8. UNIT NUMBER DECAL 9. YALE 10. CORROSION/FREEZER 11. EE CONSTRUCTION 12. BATTERY SPACER WARNING 13. YALE 14. PATENTS AND TRADEMARKS 15. UL LABEL 16. AUXILIARY FUNCTION 17. SIDESHIFT 18. TILT 19. LIFT 20. LABEL (EUROPEAN ONLY) Figure 11. Label Locations - General 11

- 14. Safety Labels 100 YRM 1073 1. BRAKE SYSTEM FLUID LABEL 2. HYDRAULIC OIL FILL LABEL 3. BRAKE SYSTEM FLUID TAG Figure 12. Label Locations - Below Floor Plates 1. LOCK/UNLOCK 2. NAMEPLATE 3. PINCH POINT 4. PINCH POINT 5. OPERATOR WARNING 6. BATTERY DISCONNECT 7. PINCH POINT 8. NO RIDERS 9. PINCH POINT Figure 13. Label Locations - Battery Compartment Cover 12

- 15. 100 YRM 1073 Painting Instructions Painting Instructions WARNING Always use solvents and paints in an area with ventilation. Do not use solvents or paints near heat, fire, or electrical equipment that can make sparks. Follow the manufacturer’s instructions and cautions. 1. Remove all dirt from the surface to be painted. Clean the area to be painted. Use a solvent for painted surfaces to remove grease and oil before sanding. Do not use solvent on new paint. Make sure all oil and grease is removed. 2. Use sandpaper to remove the top surface of paint and rust from the metal. All metal surfaces where the paint is completely removed, must be primed. Apply primer before applying the paint. CAUTION DO NOT put tape on cylinder rods to protect from paint. Use a thick layer of multipurpose grease to protect cylinder rods. Cylinders can be damaged if operated with tape on the cylinder rod. 3. Protect all surfaces that will not be painted. DO NOT paint: Pedal Pads Lever Knobs Instrument Panel Steering Wheel Labels and Information Plates Seat Assembly and Rails Information Case Tires Mast Chains and Hoses Battery Connector Key Switch Cylinder Rods All Plastic Covers CAUTION Do not paint the pads, plastic covers or knobs, ca- bles, labels, information plates, or controls. Paint can make some assemblies not operate correctly. 4. Paint the surfaces. Use the correct paint from your dealer for Yale lift trucks. Follow the directions on the container. WARNING Make sure all labels are installed after painting is complete. Safety labels are installed on the lift truck to give information about possible hazards. It is important that all safety labels are installed on the lift truck and can be read. 5. Check that all labels are installed in the correct lo- cations on the lift truck. See Safety Labels. NOTE: Use colors approved by Yale Material Handling Corporation. 13

- 16. 1300 YRM 1074 Introduction Introduction GENERAL This section contains the removal, disassembly, repair, inspection, assembly, and installation instructions for the transmission and traction motor that make up the transaxle assemblies used on these models. Some components associated with the transaxle are not covered in this section because they are more closely associated with other systems. See the section Brake System 1800 YRM 1076 for information on the electric brake and the service brake lines and master cylinder. See the section Periodic Maintenance 8000 YRM 1079 for information on the tire and wheel assem- blies. WARNING DO NOT make repairs or adjustments unless you are properly trained and have authorization to do so. Improper repairs and adjustments correct can create dangerous operating conditions. Do not op- erate a truck in need of repair. Report the need for repairs to your supervisor immediately. If repair is necessary, attach a DO NOT OPERATE tag to the steering wheel and disconnect the battery connec- tor. Throughout this section, forward will refer to travel in the direction of the forks and left and right will be deter- mined by sitting in the seat facing forward. See Figure 1. A. LEFT SIDE B. RIGHT SIDE C. FORWARD TRAVEL Figure 1. Truck Orientation DISCHARGING THE CAPACITORS WARNING DO NOT make repairs or adjustments unless you are properly trained and have authorization to do so. Improper repairs and adjustments correct can create dangerous operating conditions. Do not op- erate a truck in need of repair. Report the need for repairs to your supervisor immediately. If repair is necessary, attach a DO NOT OPERATE tag to the steering wheel and disconnect the battery connec- tor. WARNING Disconnect the battery before opening the electric compartment cover or inspecting or repairing the electrical system. If a tool causes a short circuit, the high current flow from the battery can cause personal injury or equipment damage. WARNING Some checks and adjustments are performed with the battery connected. DO NOT connect the bat- tery until the procedure tells you to do so. Never wear jewelry or other metal items on your fingers, arms, or neck when performing service to the lift truck. Metal items can accidentally make an electri- cal connection and cause injury. WARNING Block the lift truck drive tires to prevent unexpected movement before performing any tests or adjust- ments. WARNING The capacitor in the transistor controller can hold an electrical charge after the battery is dis- connected. To prevent an electrical shock and personal injury, discharge the capacitor before inspecting or repairing any component in the elec- trical compartment. Wear safety glasses. Make certain that the battery has been disconnected. 1

- 17. Introduction 1300 YRM 1074 CAUTION To avoid controller damage, always disconnect the battery and discharge the capacitor before perform- ing service or repairs inside the electrical compart- ment. NEVER apply power to the controller when any wires are disconnected. NEVER short any con- troller terminal or motor terminal to the battery. Al- ways use proper procedure when servicing the con- troller. 1. Block load wheels to prevent lift truck from moving. 2. Turn the key switch to the OFF position and discon- nect the battery. 3. Open the electrical compartment: a. Remove two screws securing the electrical compartment door. b. Pull the compartment door open on its hinges. WARNING DO NOT short across the motor controller terminals with a screwdriver or jumper wire. NOTE: Some lift trucks are equipped with a premium controller, which controls the hydraulic motor as well as the traction motors. 4. Discharge the capacitor in the controller by con- necting a 200-ohm, 2-watt resistor across the con- troller’s BT+ and B terminals for 10 seconds using insulated jumper wires. See Figure 2. 5. On the premium controller, also connect the 200- ohm, 2-watt resistor across the controller’s P+ and B terminals for 10 seconds using insulated jumper wires. See Figure 3. 6. Remove the 200-ohm, 2-watt resistor before recon- necting the battery. 1. POSITIVE CONNECTION (BT+) 2. NEGATIVE CONNECTION (B ) 3. INSULATED JUMPER WIRES 4. 200-OHM, 2-WATT RESISTOR Figure 2. Discharging the Capacitors (Standard) 1. POSITIVE CONNECTION (BT+) 2. NEGATIVE CONNECTION (B ) 3. INSULATED JUMPER WIRES 4. 200-OHM, 2-WATT RESISTOR 5. POSITIVE CONNECTION (P+) Figure 3. Discharging the Capacitors (Premium) 2

- 18. 1300 YRM 1074 Description Description TRANSMISSION The lift truck uses two transmissions. One transmission is mounted on each side of the lift truck frame beneath the cowl. The transmission is an in-line gear set that in- corporates a wet disk brake assembly within the trans- mission housing. The traction motor is mounted on one side of the transmission, and the drive wheel and tire assemblies are mounted to the other side of the trans- mission. See Figure 4. The transmission is secured to the lift truck frame using a series of five capscrews. The transmission housing provides the mounts needed to attach the mast to the lift truck. Power from the traction motor is transmitted to the trans- mission through an internal spline in the input gear. The input gear drives the first reduction gear. The input and first reduction gear are helical gears. The first reduc- tion gear acts as the power input to a three-planet, sin- gle-reduction, planetary gear set. This planetary gear set drives the output (wheel hub) to rotate the drive tire and move the lift truck. Figure 4. Transmission Mounting Legend for Figure 4 1. LEFT TRANSMISSION 2. TRACTION MOTORS 3. RIGHT TRANSMISSION TRACTION MOTOR The traction motor is a three-phase AC induction motor. DC battery current is converted into AC current in the motor controller and then supplied to the traction motor. The traction controller controls motor speed and direc- tion. Each traction motor contains a speed encoder de- vice that provides continuous motor speed and direction information to the motor controller. Each traction mo- tor also contains a temperature sensor that continually monitors motor temperature and communicates that in- formation to the motor controller. See Figure 5. Figure 5. Traction Motor 3

- 19. Maintenance 1300 YRM 1074 Maintenance OIL LEVEL CHECK Each transaxle has a separate oil supply which must be maintained. See Figure 6. Make sure the lift truck is parked in a level area. To check the oil level, remove the oil fill plug. The oil should be level with the bottom of the oil fill hole. If necessary, add oil through the oil fill hole until the oil is level with the bottom of the hole. Replace the oil fill plug and torque to 40 N•m (30 lbf ft). Check the oil level in both transaxles every 500 hours or every three months. 1. OIL FILL PLUG 2. R.H. TRANSAXLE 3. TRACTION MOTOR 4. PARKING BRAKE Figure 6. Transaxle Oil Fill Plug OIL CHANGE WARNING The oil is hot at normal operating temperatures. Be careful when draining the oil. NOTE: Operate the lift truck for 5 minutes or until the transaxle is warm to the touch. Oil is thick and will drain easier and more thoroughly when it is warm. Each transaxle uses separate, self-contained oil supplies. The oil in the transaxle should be changed after the first 200 hours of operation and every 1000 hours or every six months thereafter. 1. Raise and safety-chain the mast to access the transaxle assemblies. See Periodic Maintenance 8000 YRM 1079. 2. Turn the key switch to the OFF position and discon- nect the battery. Block the wheels to prevent unex- pected movement. 3. Place a drip pan with at least a 3.8 liter (4 qt) ca- pacity under each transaxle. 4. Remove the fill plugs on each transaxle. See Fig- ure 7. 5. Remove the drain plugs on each transaxle. CAUTION Disposal of lubricants and fluids must meet local environmental regulations. 6. After both transaxles have drained completely, replace the drain plugs and torque to 40 N•m (30 lbf ft). Remove the drip pans and dispose of waste oil properly. 7. Fill the transaxles with oil until level with the bottom of the oil fill holes. See Figure 6. 8. Install the fill plugs and torque to 40 N•m (30 lbf ft). 1. BRAKE BLEED VALVE 2. TRANSAXLE HOUSING 3. DRAIN PLUG Figure 7. Transaxle Drain Plug 4