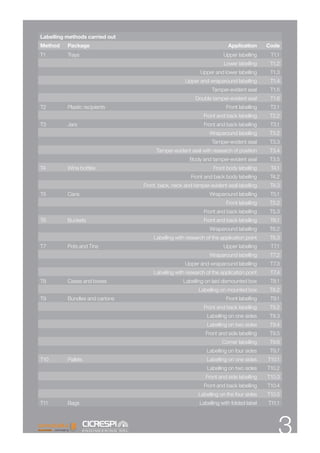

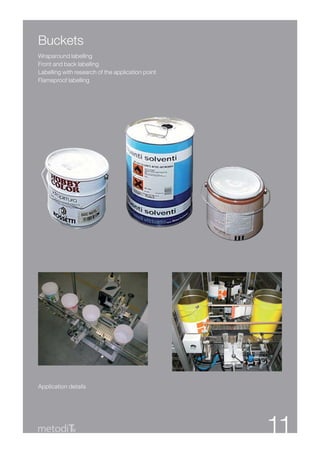

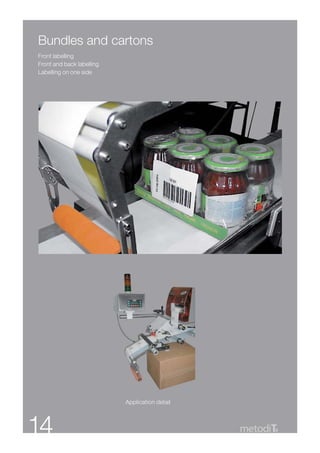

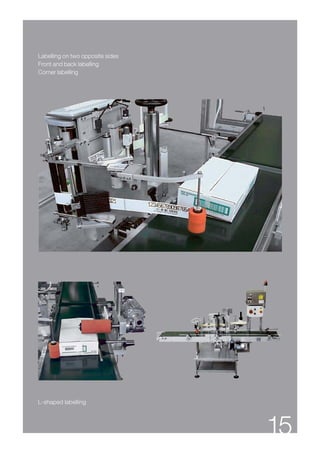

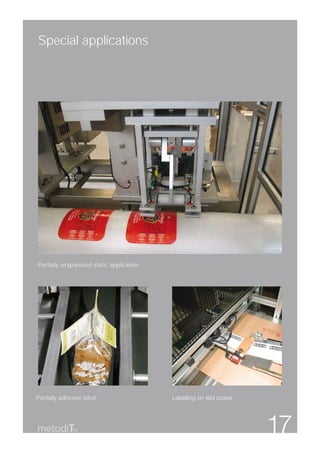

The document outlines various industrial labeling solutions that provide automatic, precise, and high-speed application of self-adhesive labels across multiple industries including food, beverage, cosmetics, and pharmaceuticals. It details different labeling methods, applications on various packaging types, and integrates automated systems for identification and quality control. Additionally, it highlights the company's commitment to customer service and technical support.