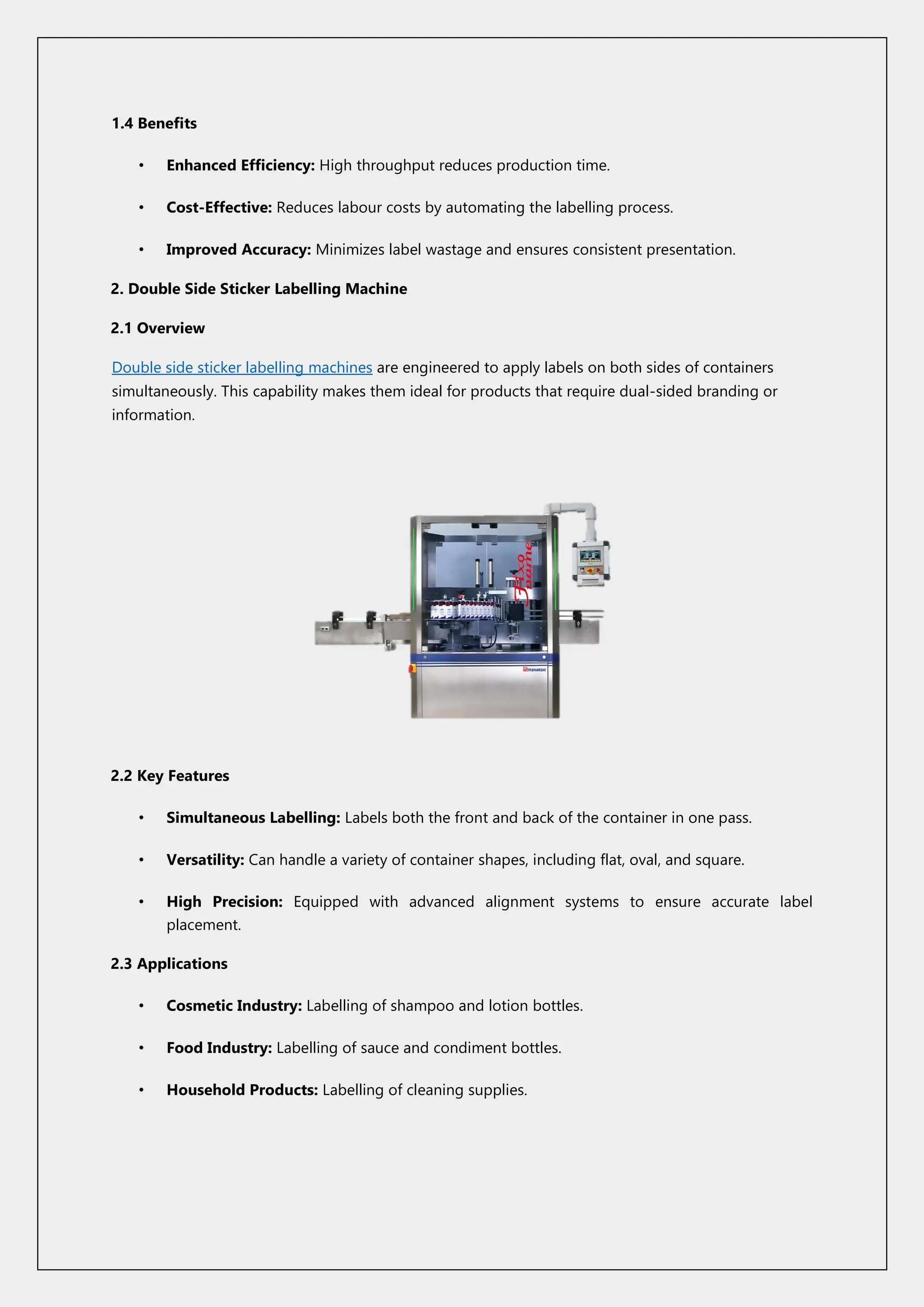

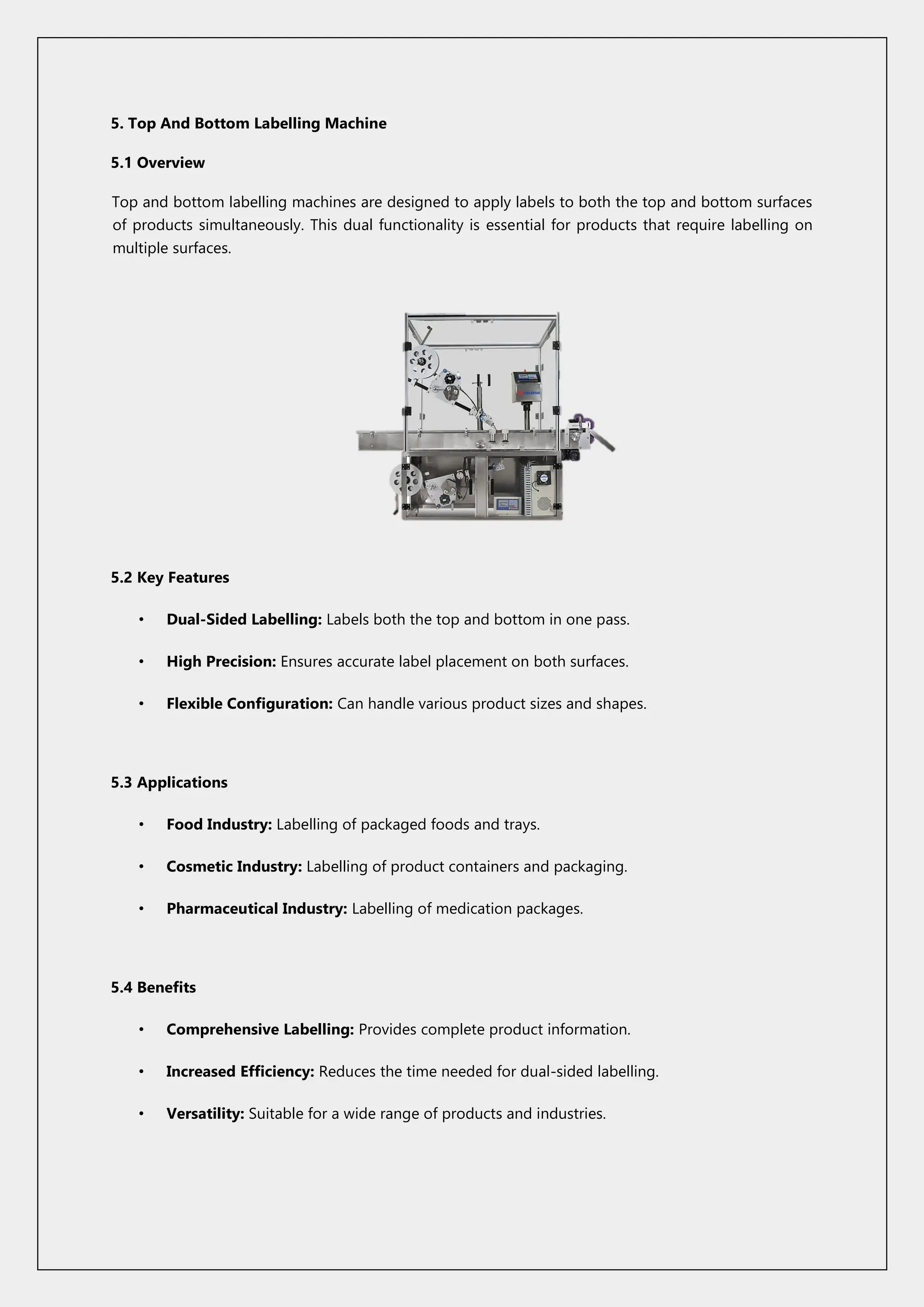

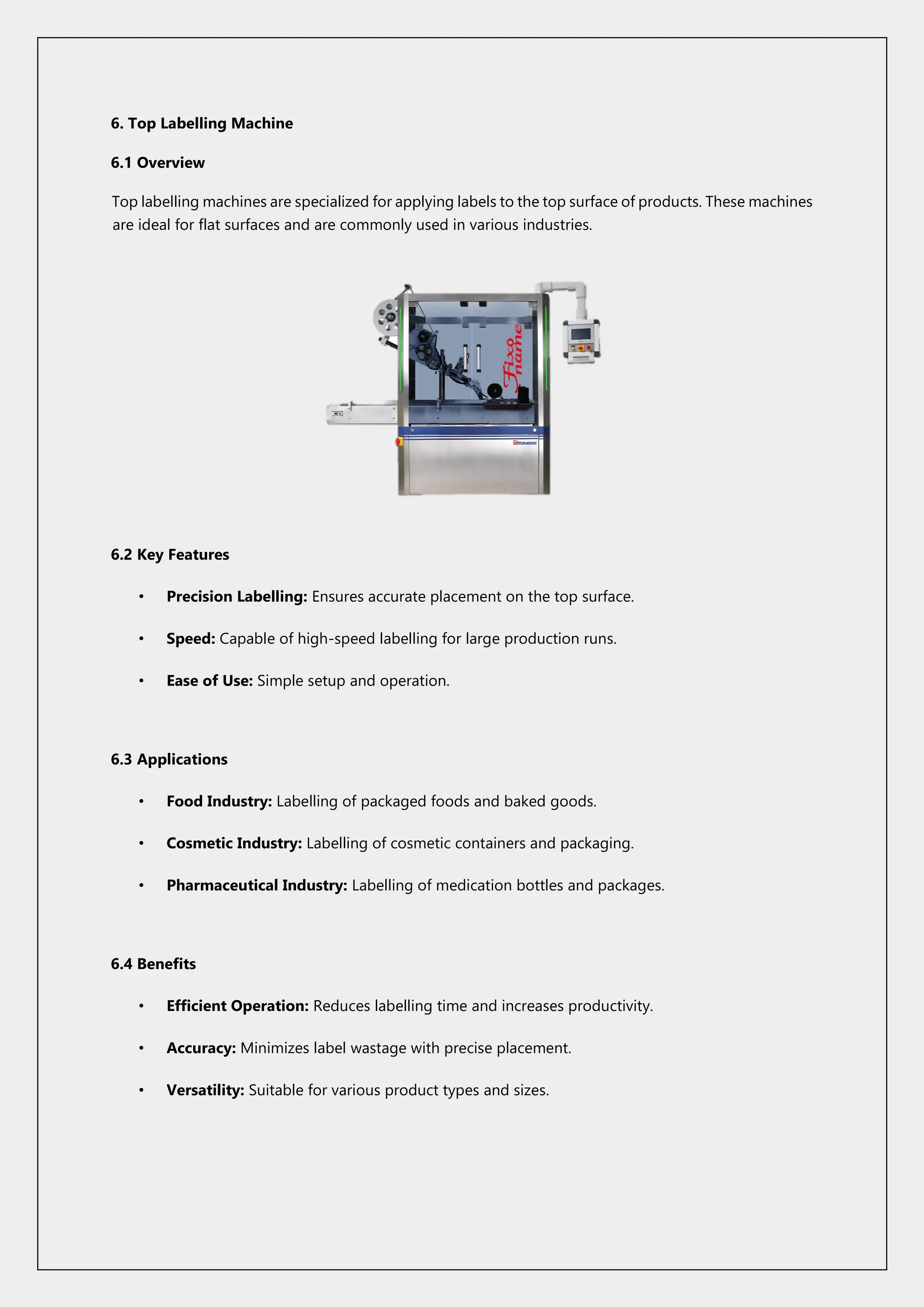

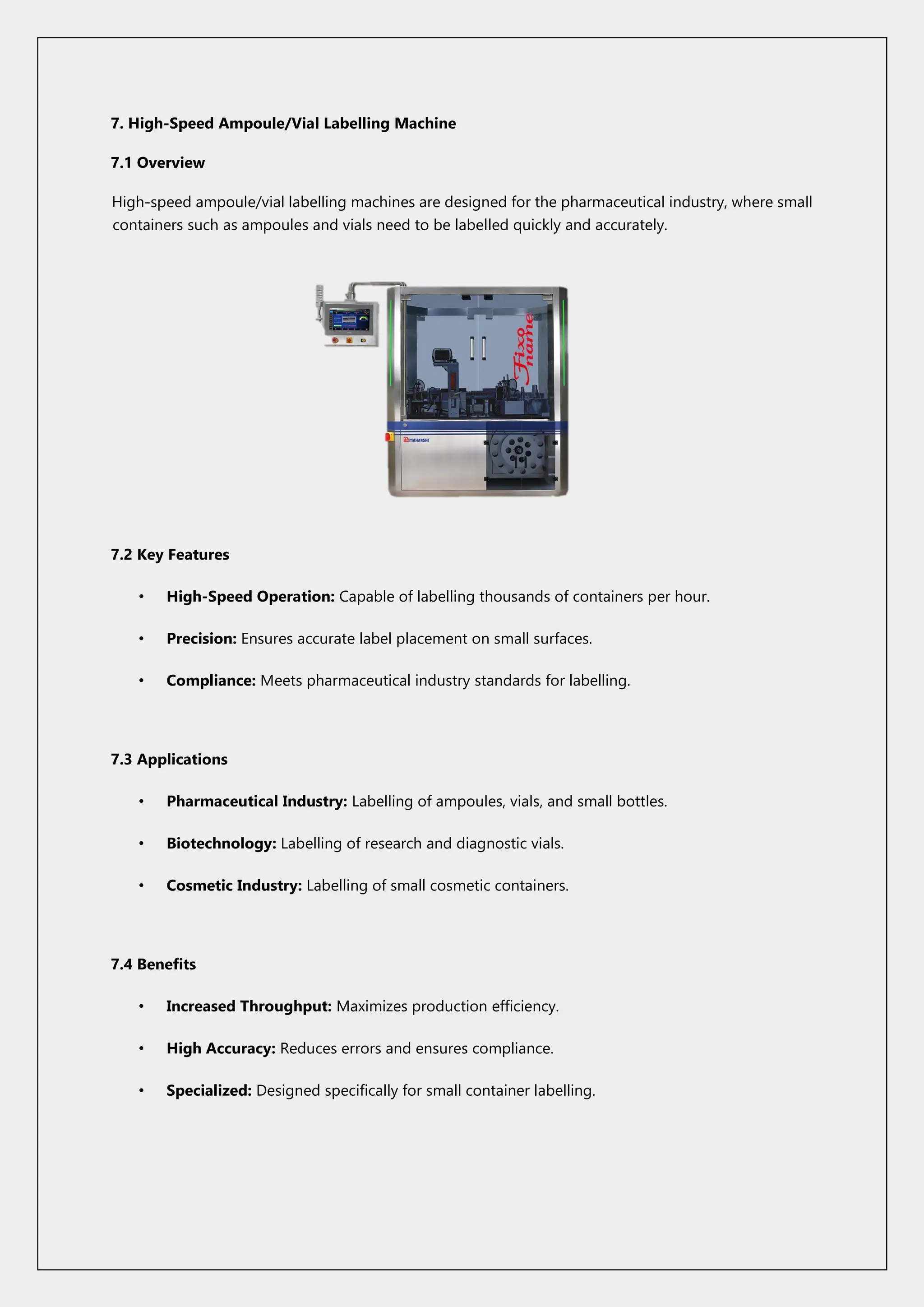

The document provides a comprehensive guide on various types of labelling machines manufactured by Maharshi Udyog, detailing their unique features, applications, and benefits. Key types include rotary, double side, wrap around, stand alone, top and bottom, top, high-speed ampoule/vial, spot wrap around, semi-automatic, security seal, automatic shrink sleeve, tube, and print and apply labelling machines. Understanding these options helps businesses optimize production efficiency, enhance product presentation, and ensure compliance with regulatory standards.