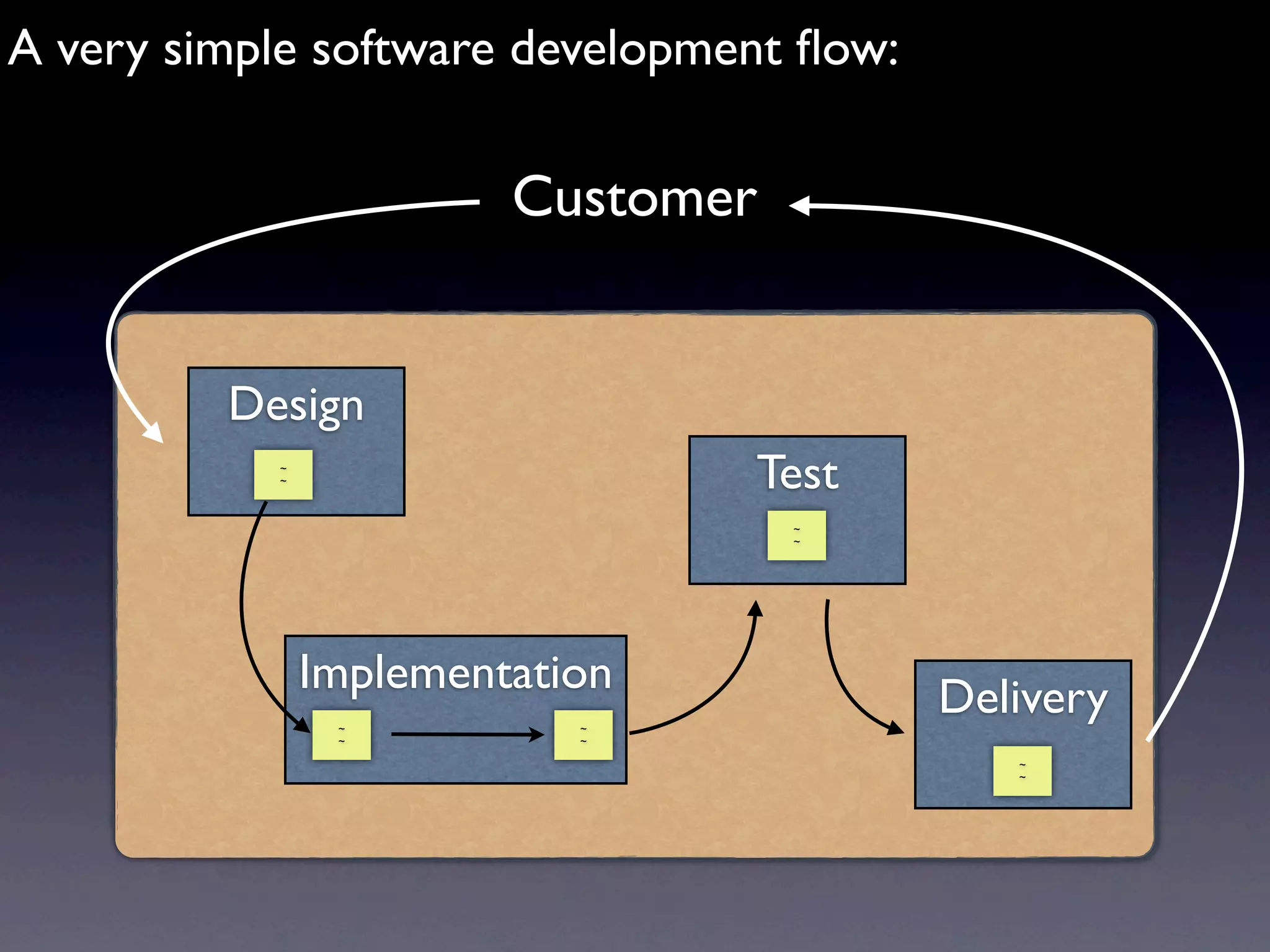

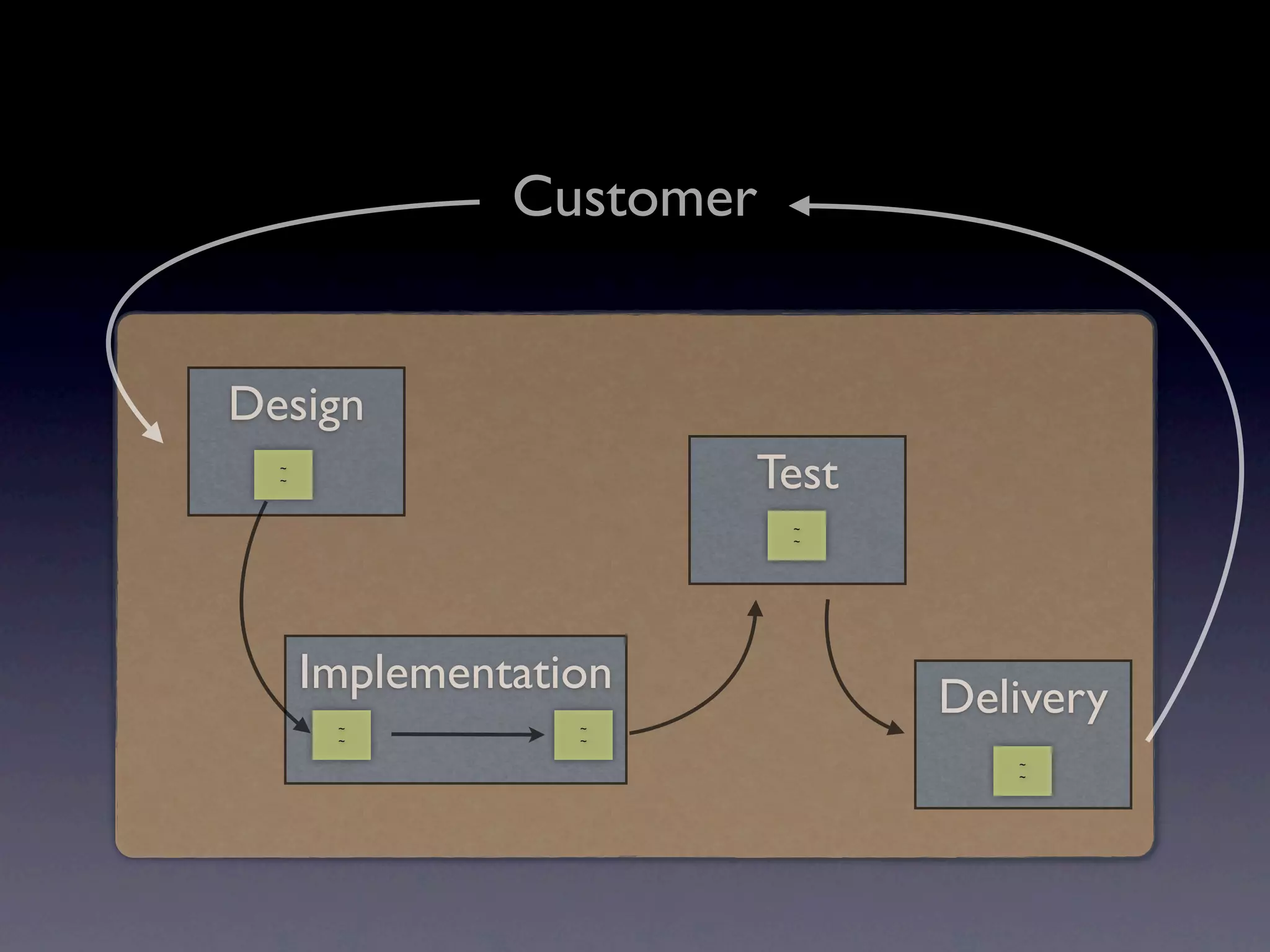

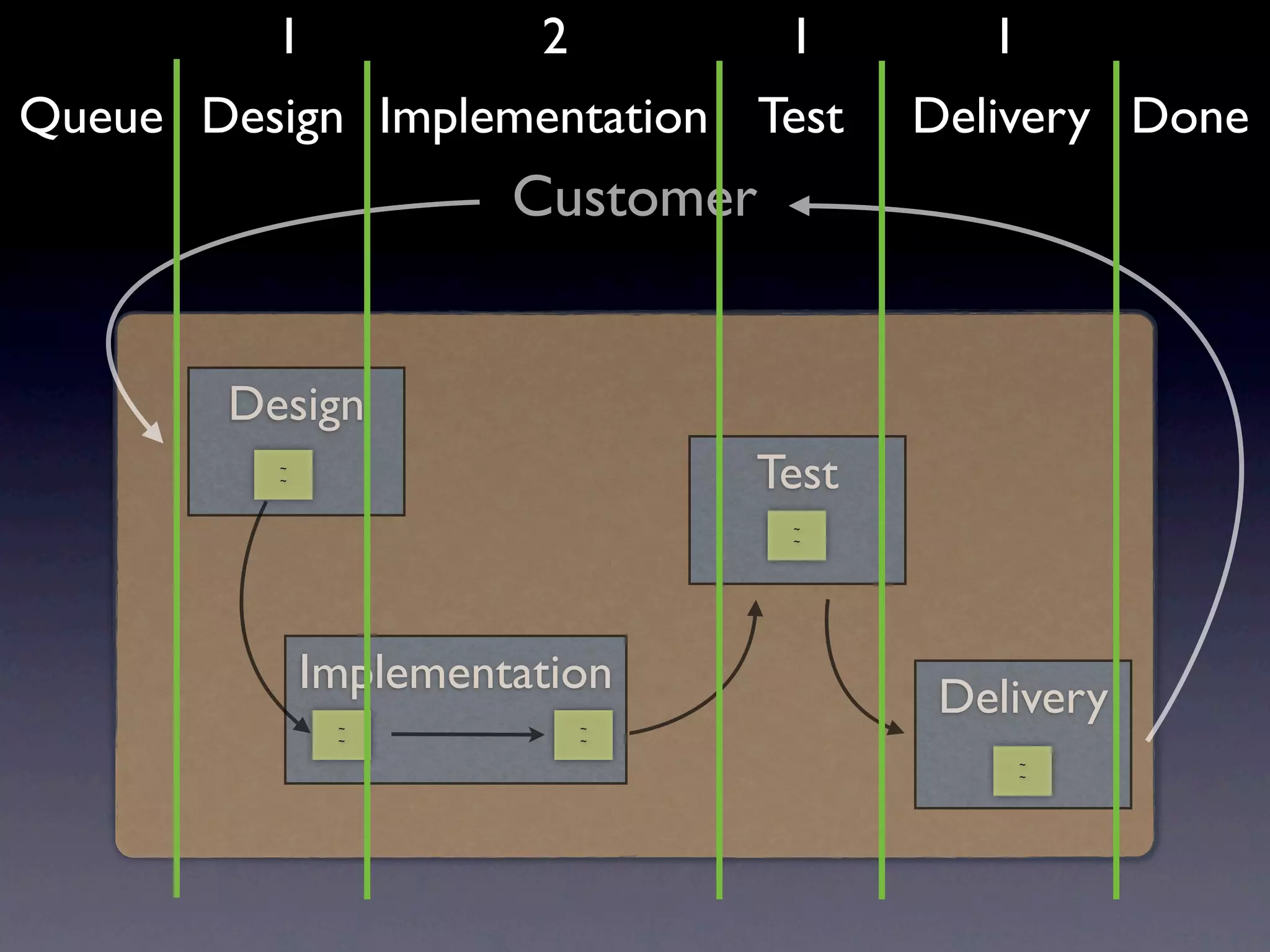

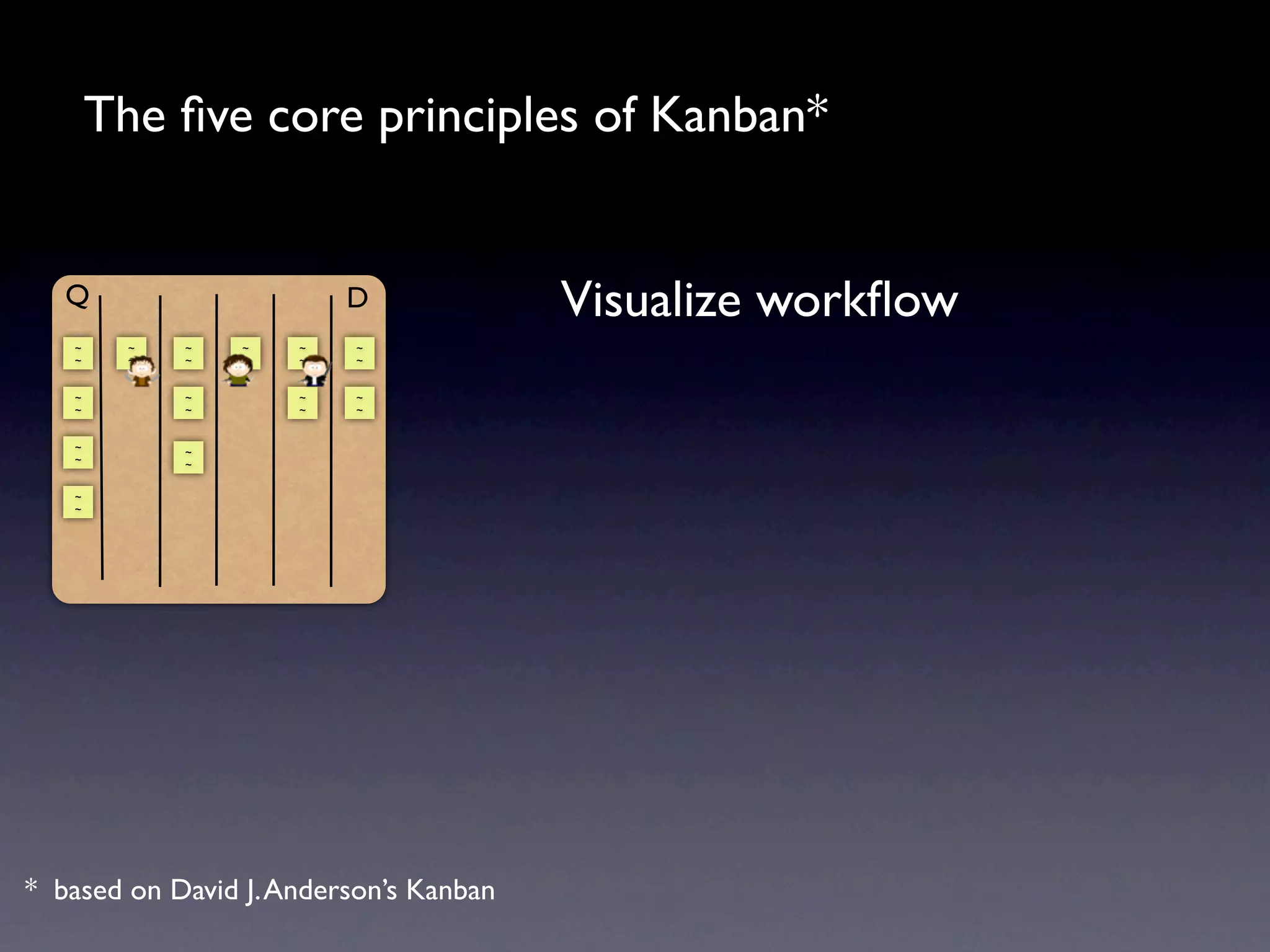

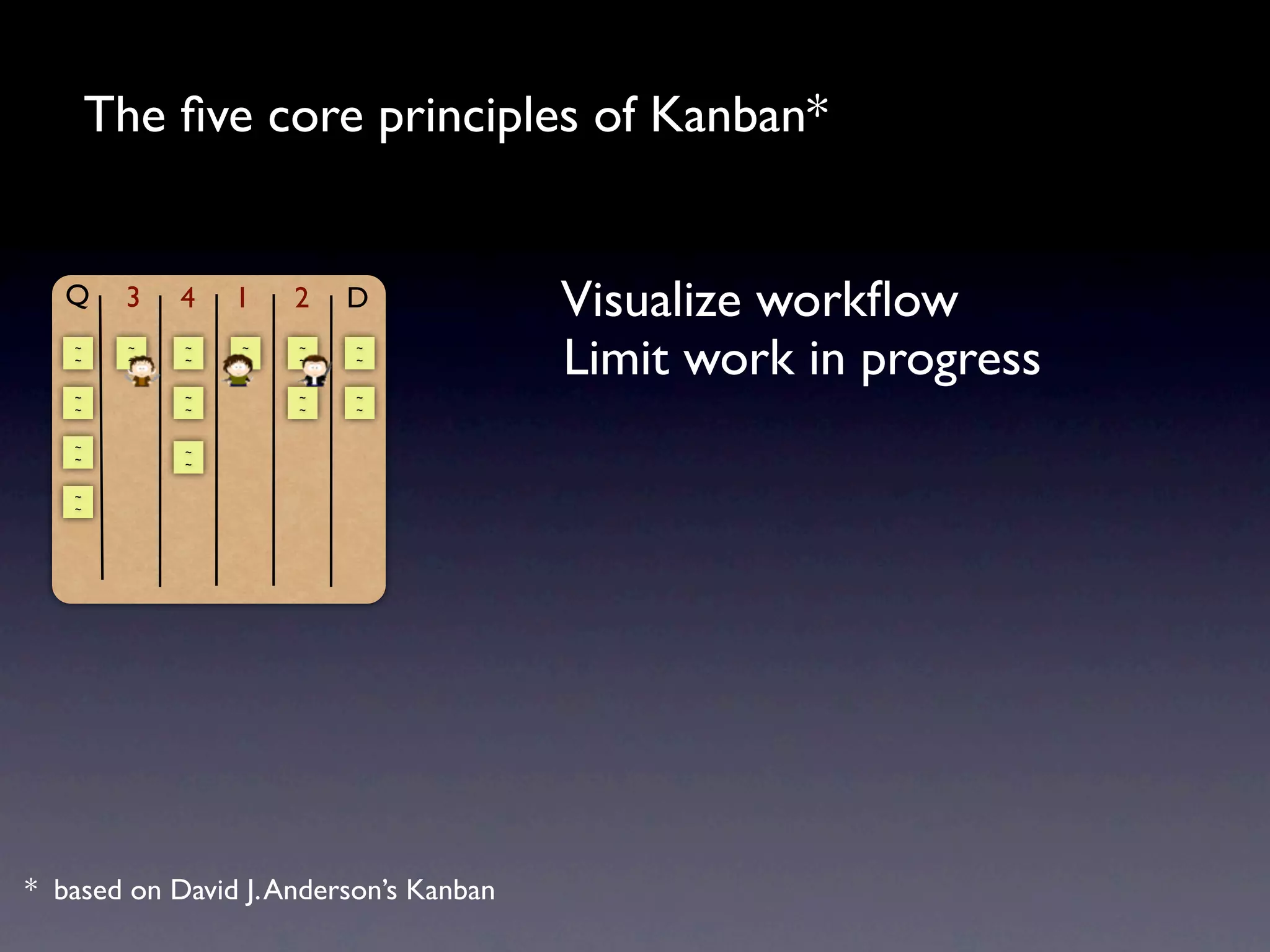

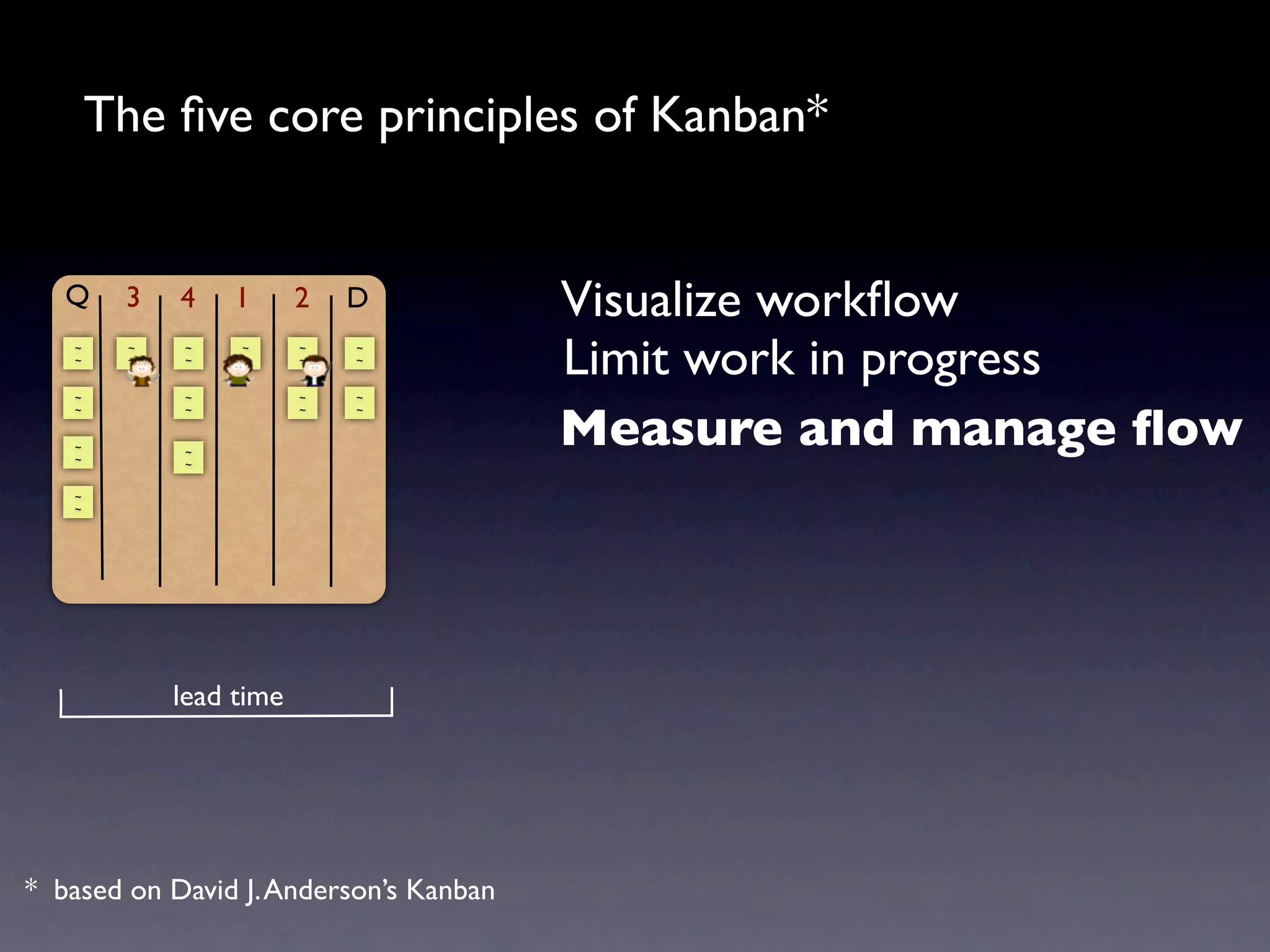

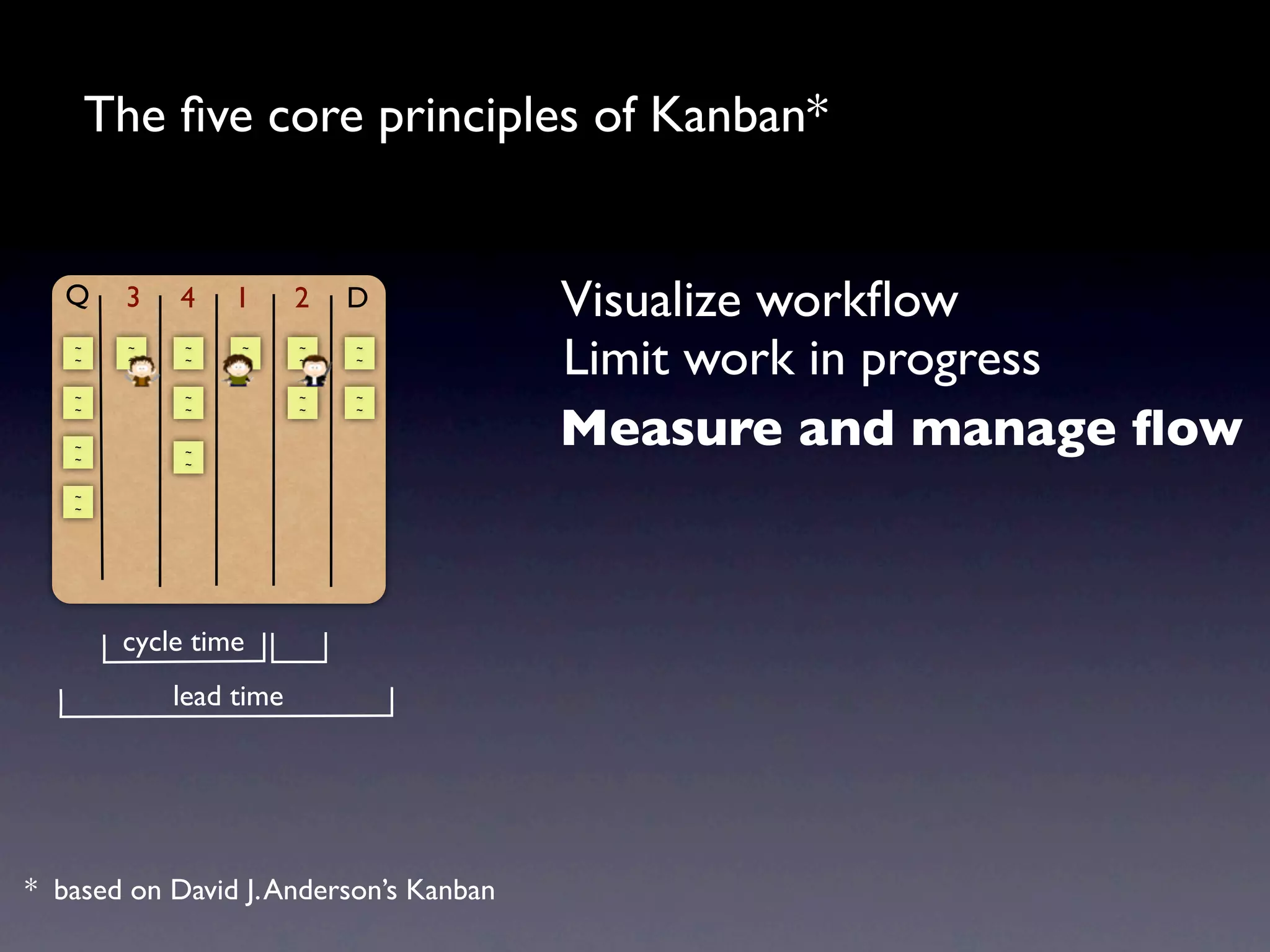

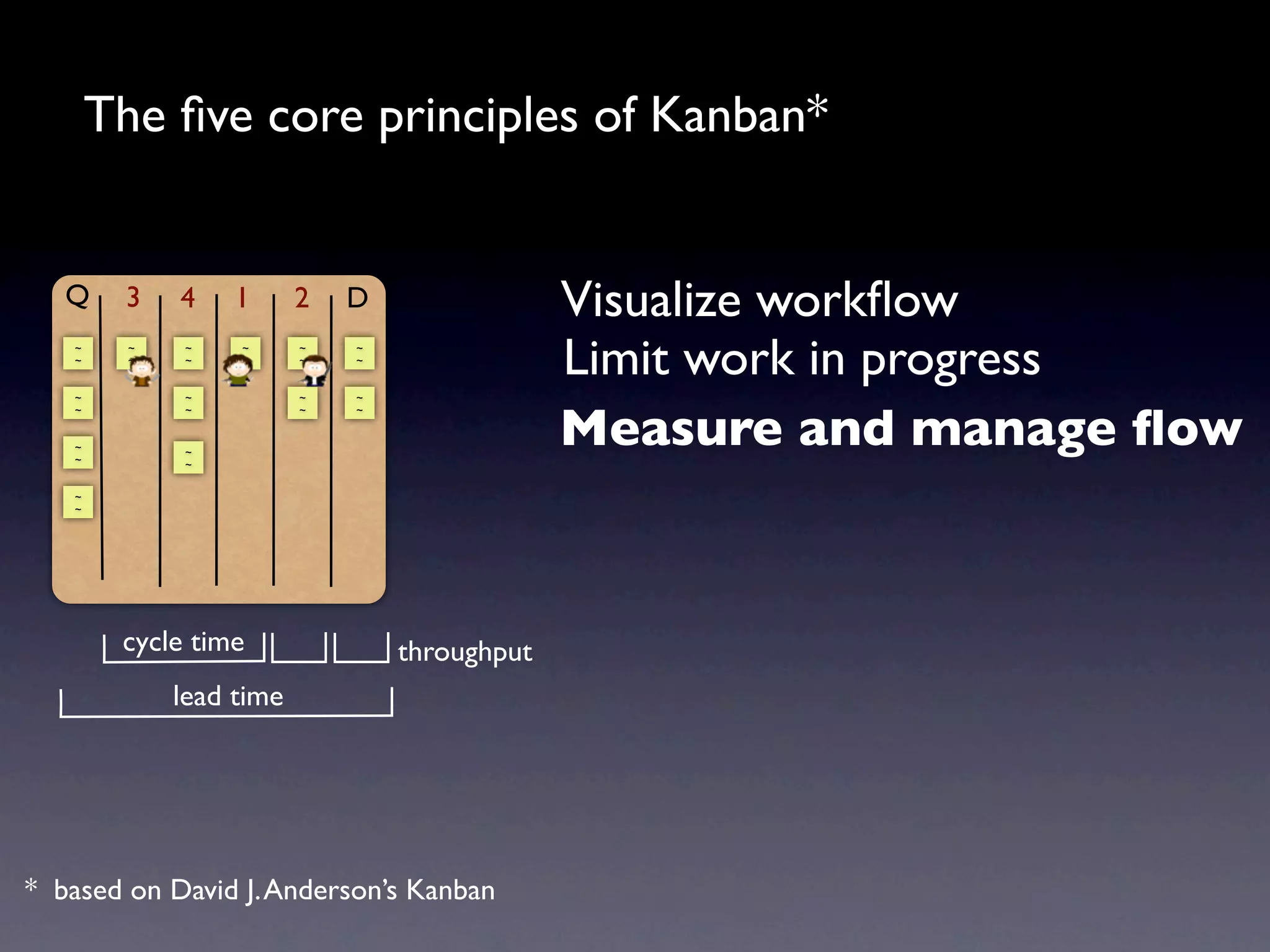

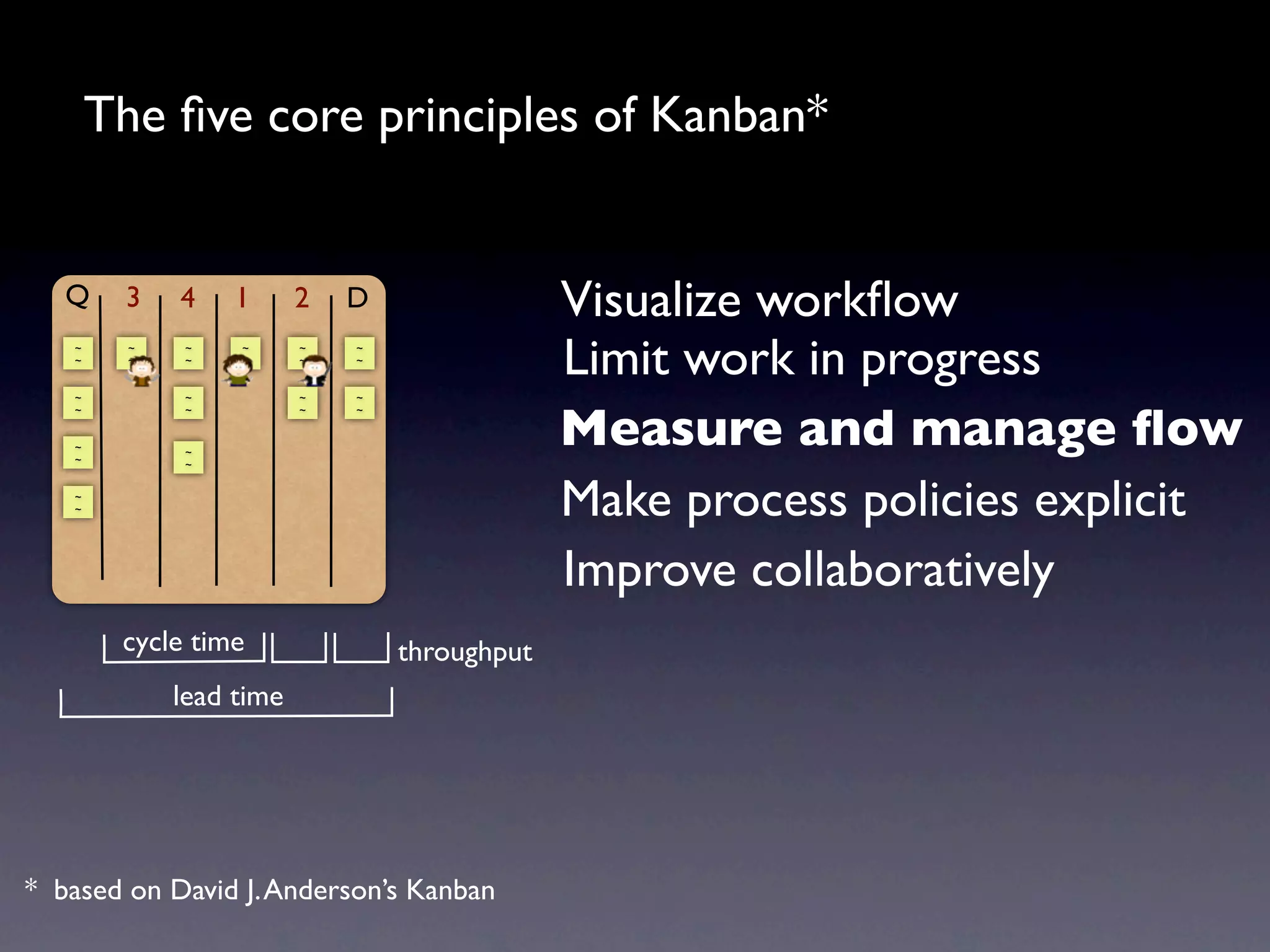

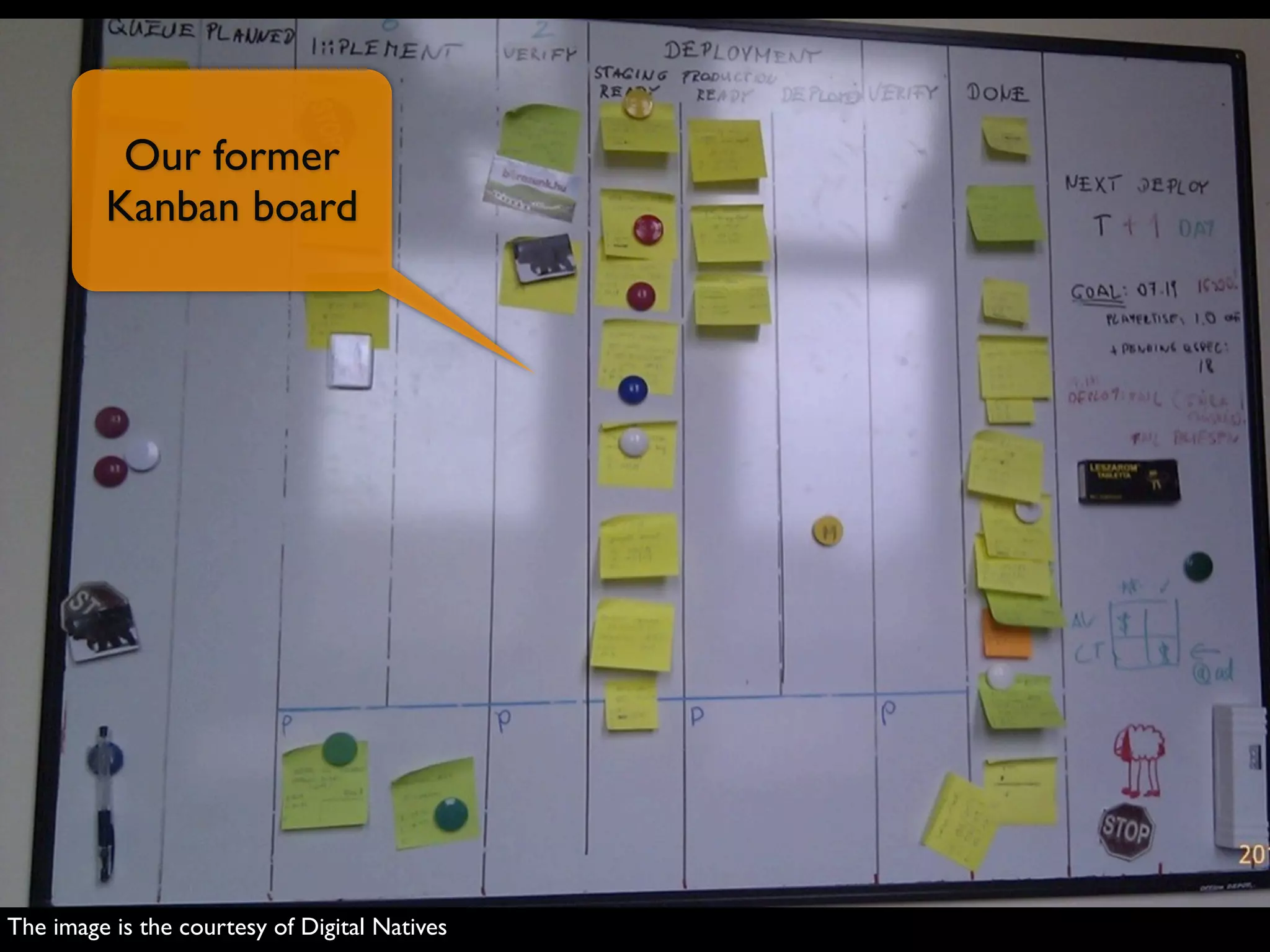

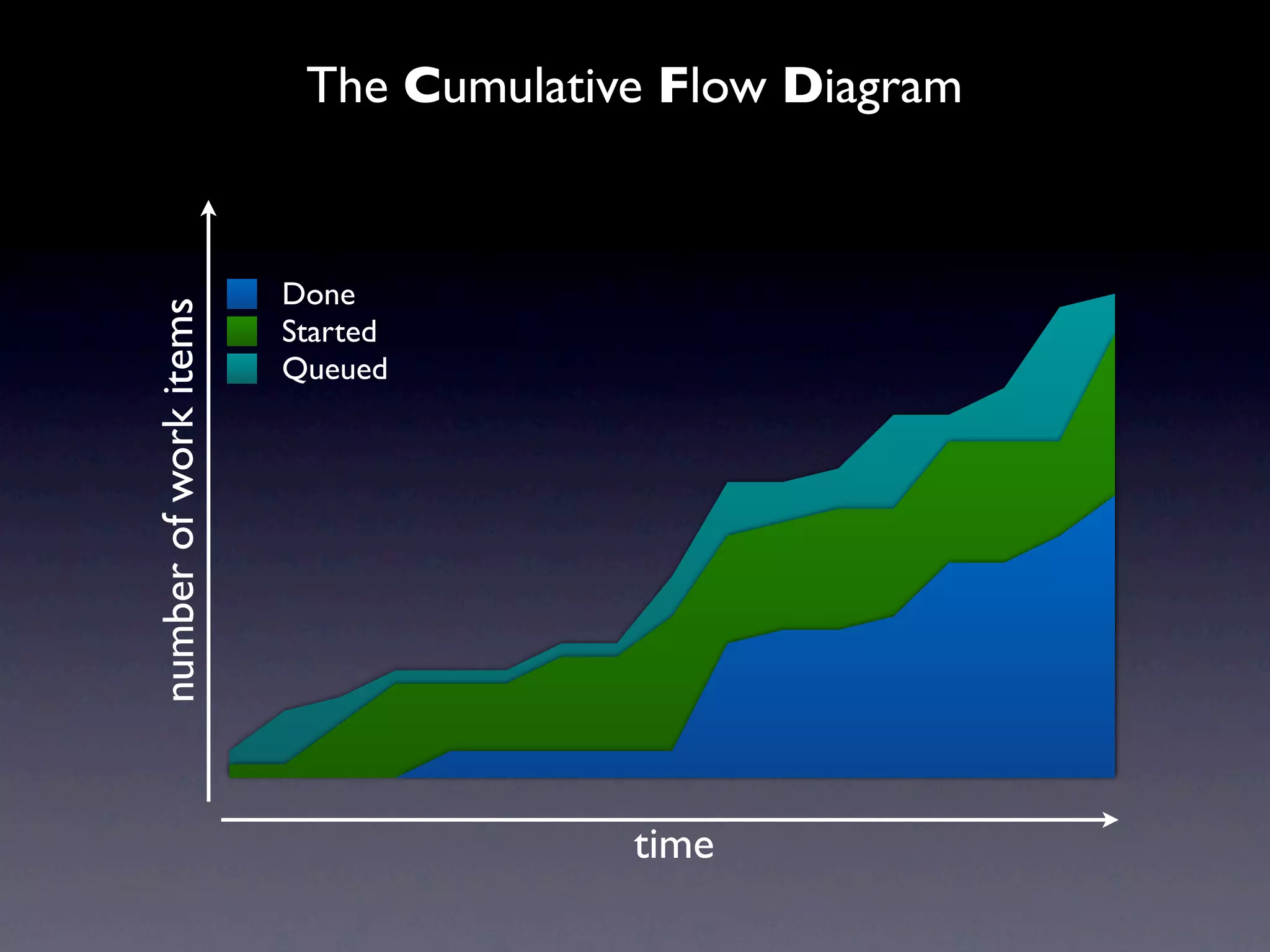

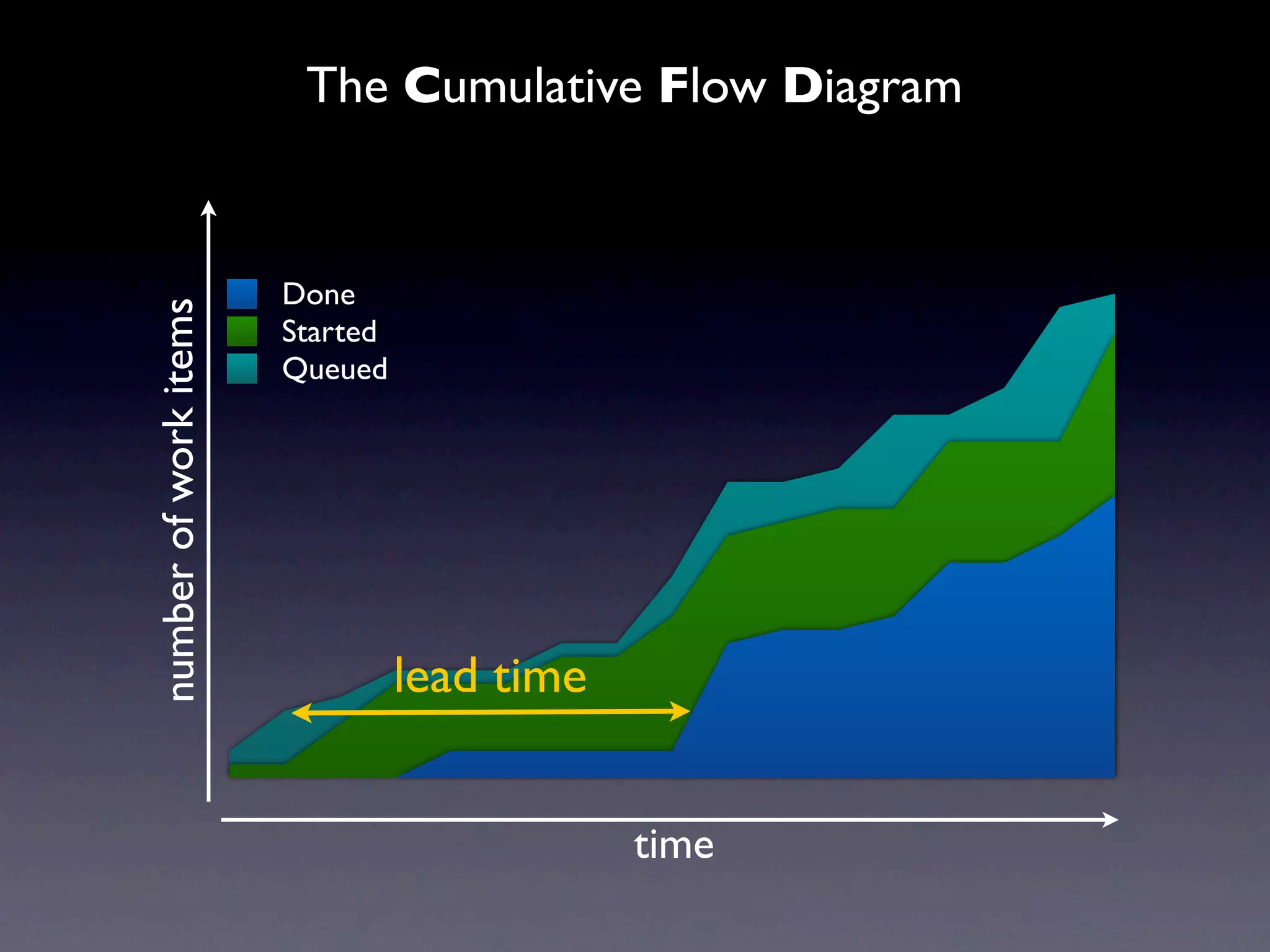

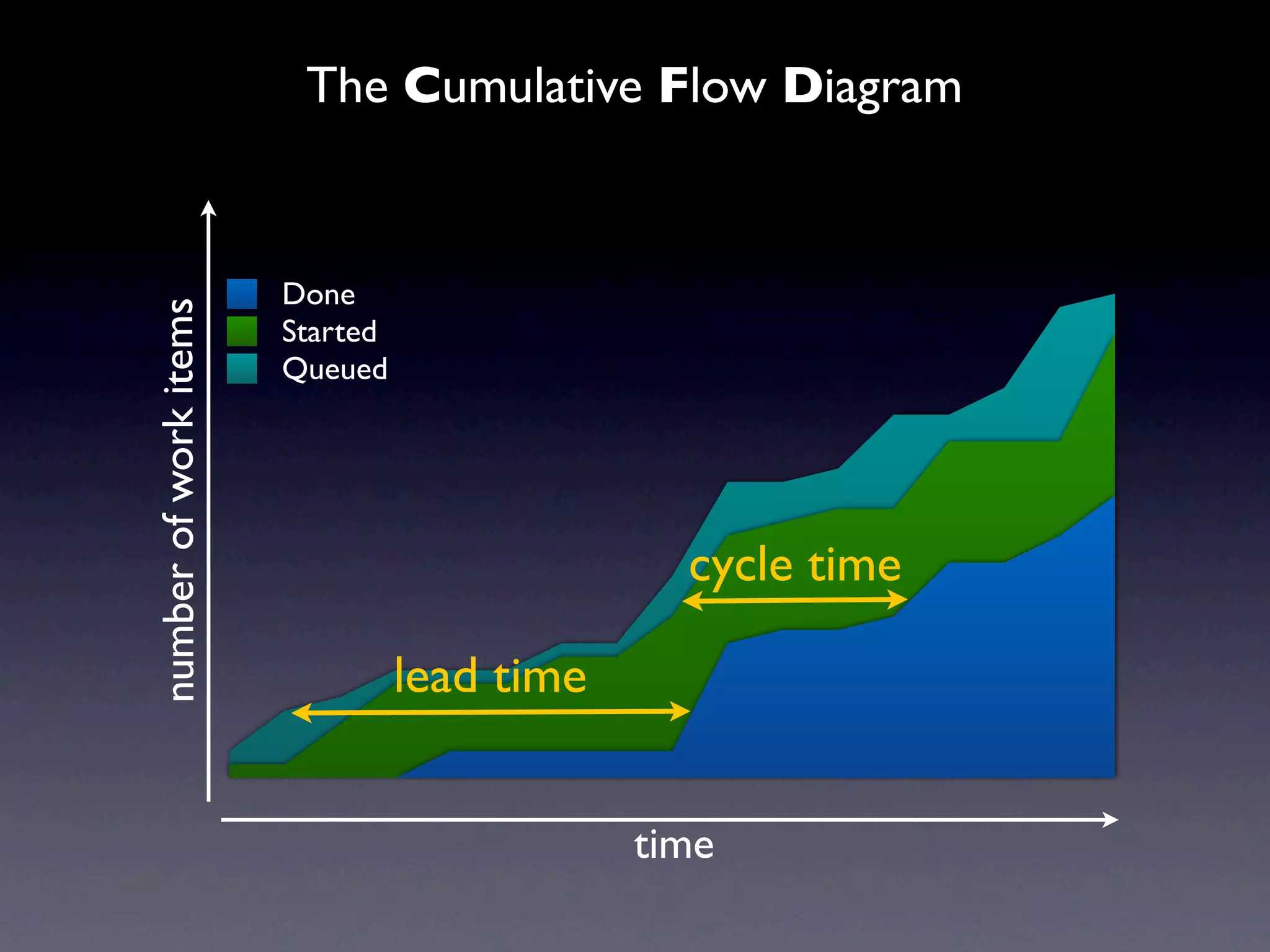

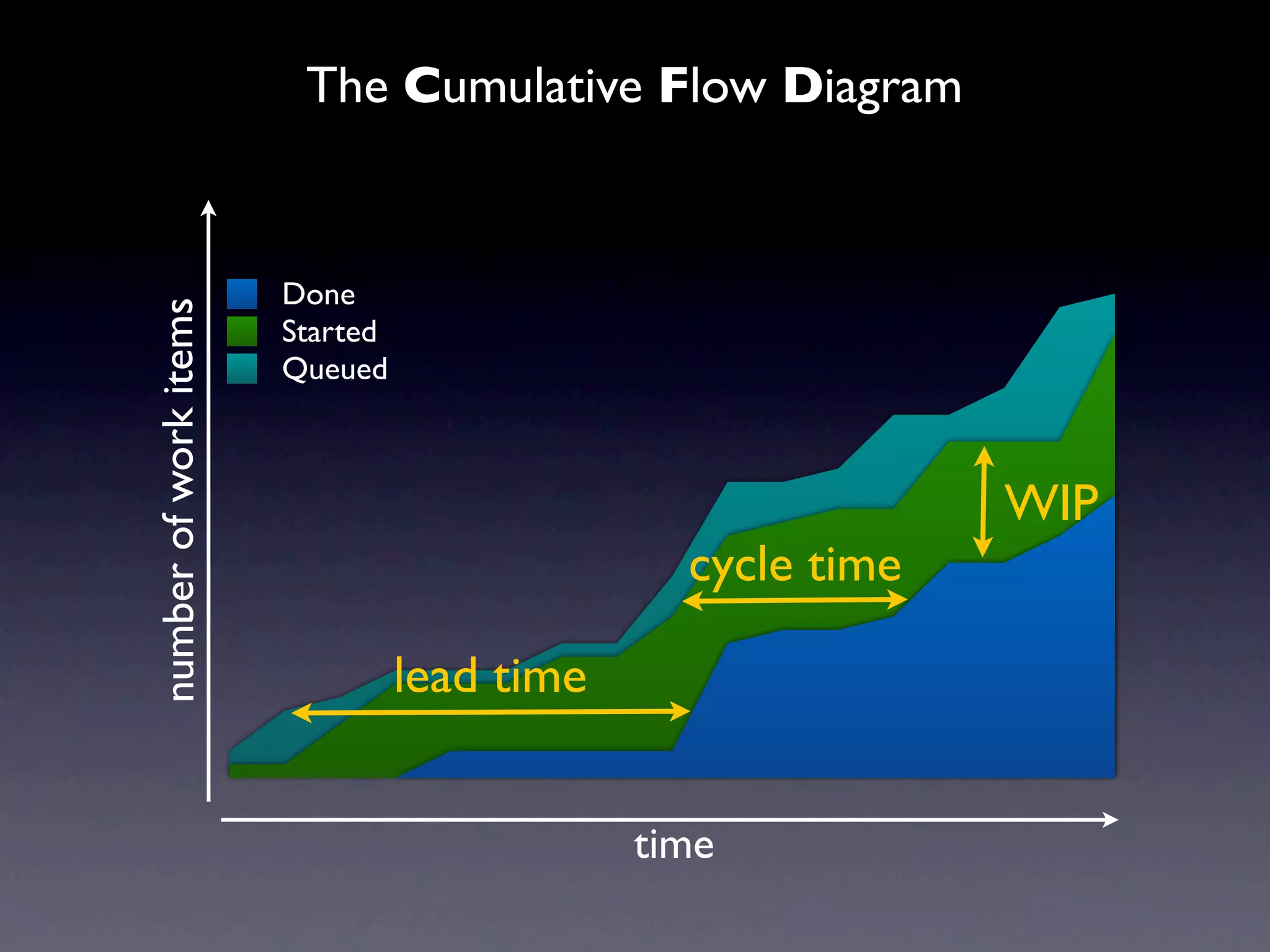

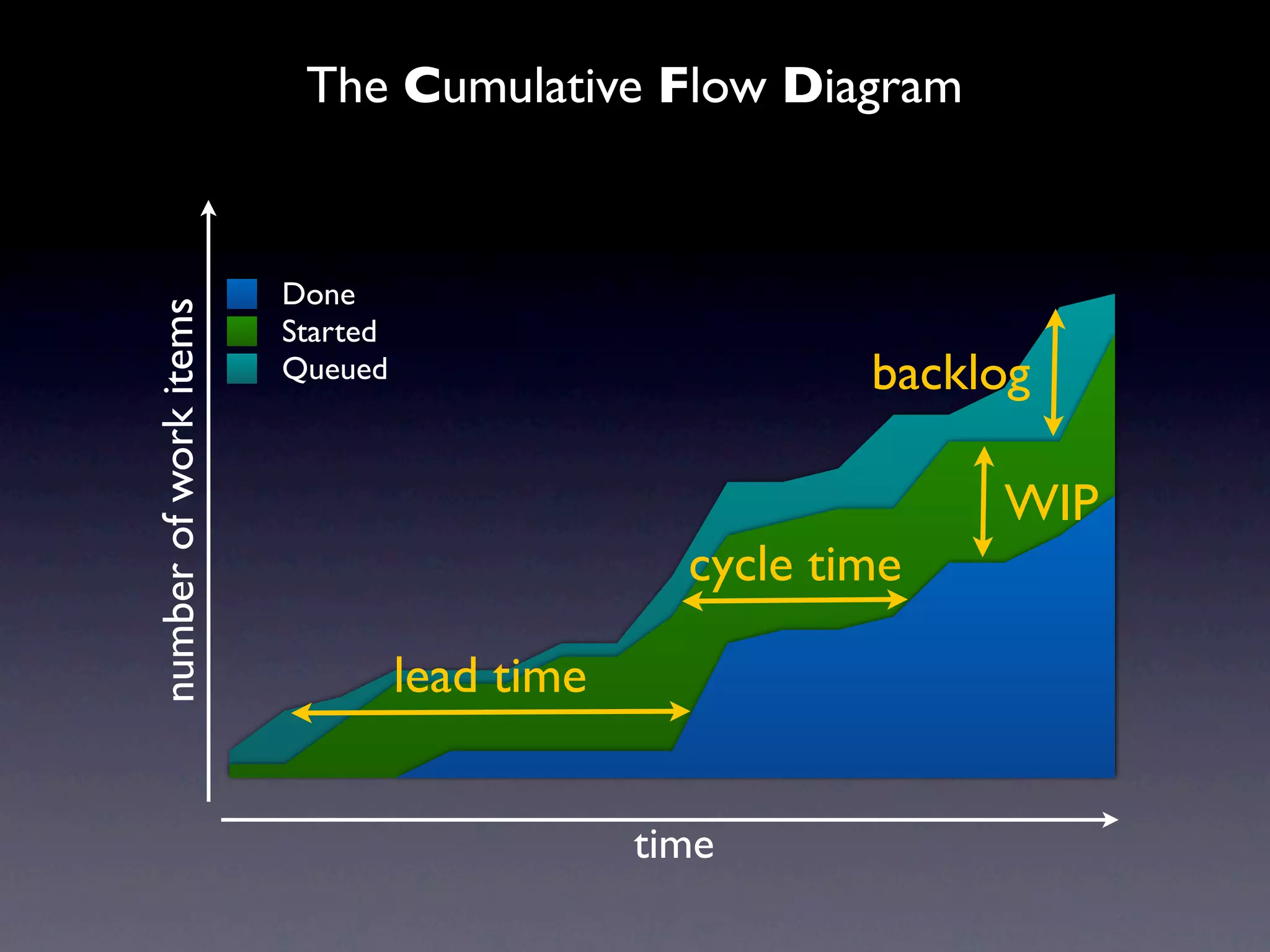

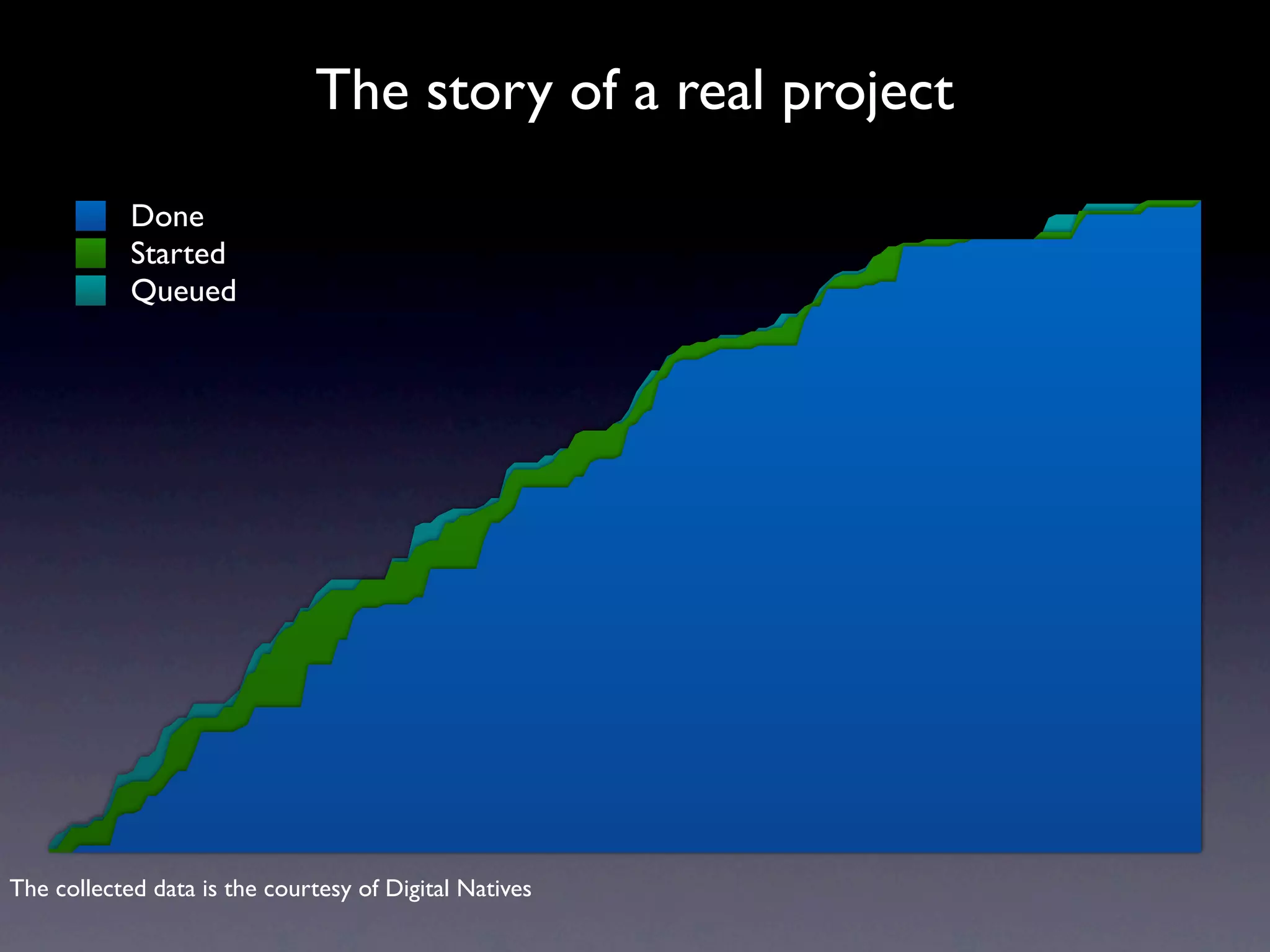

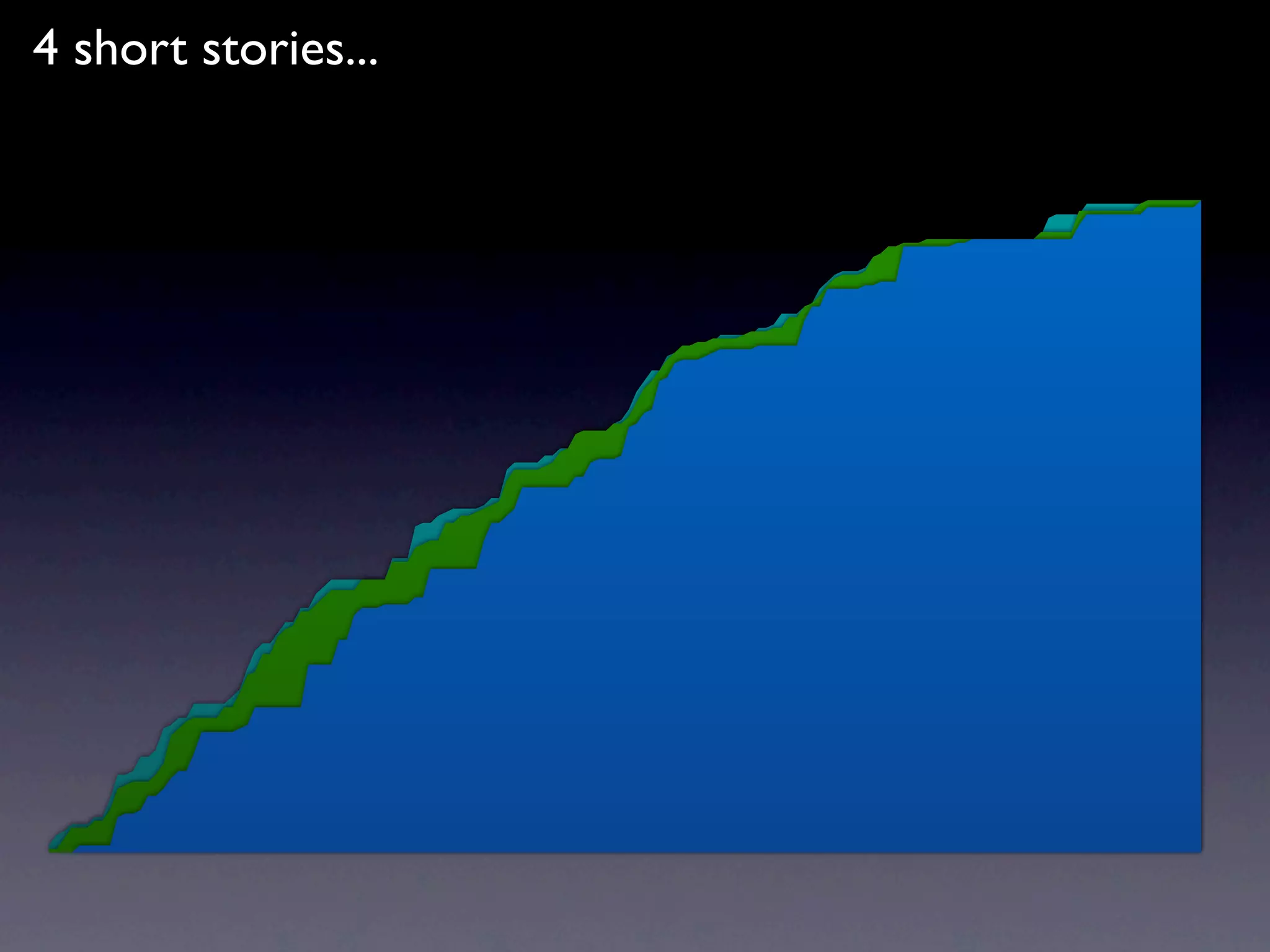

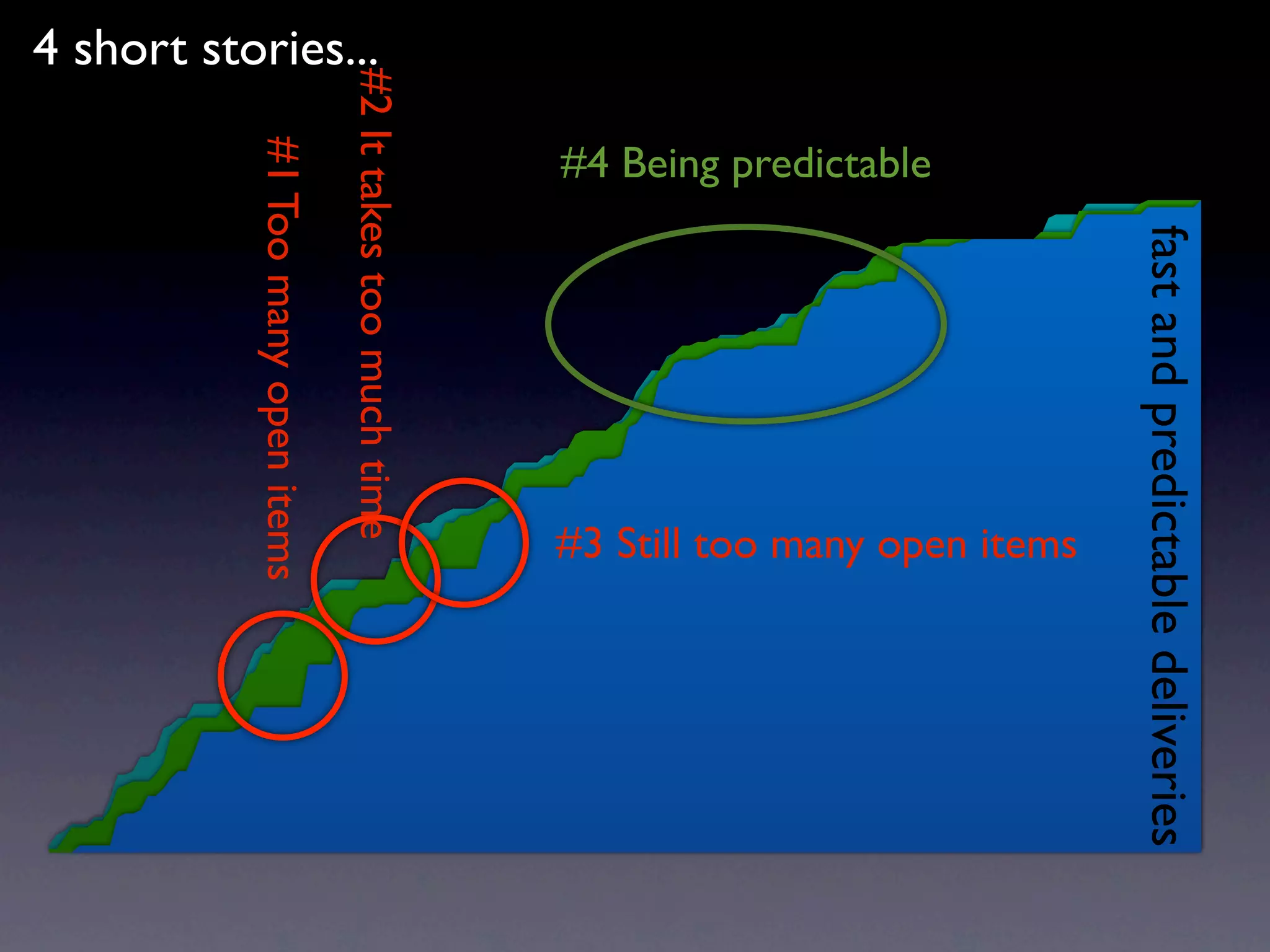

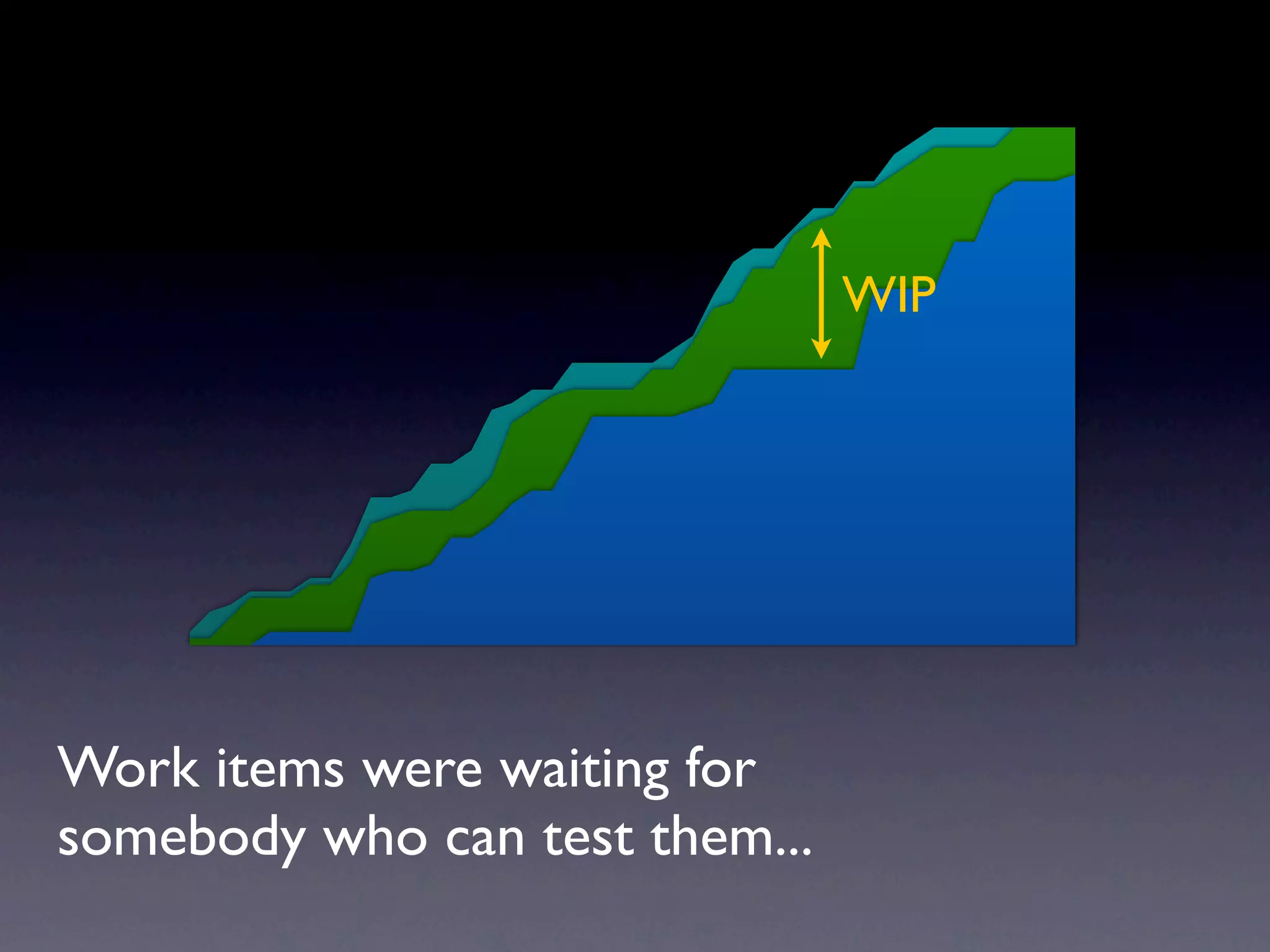

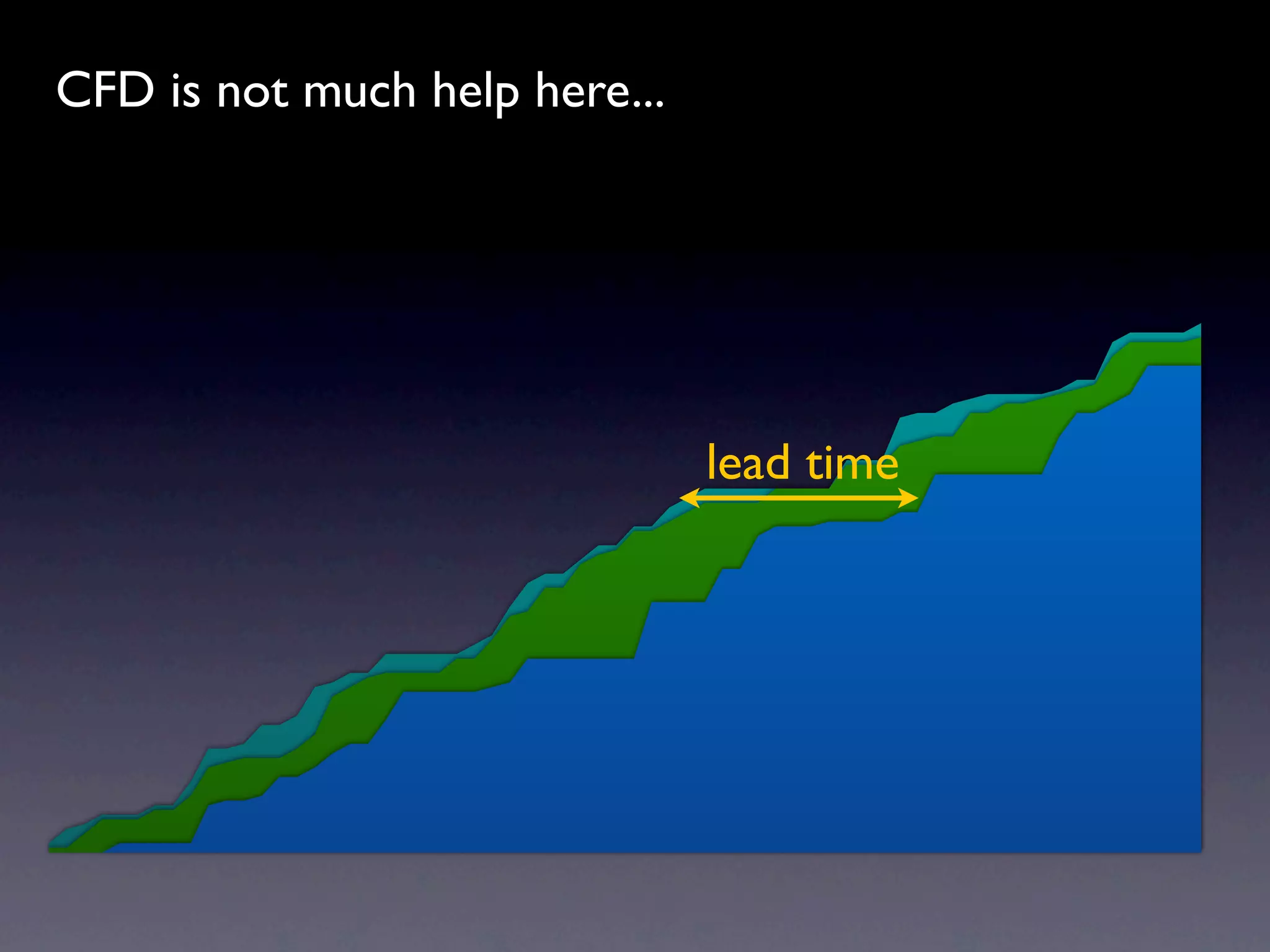

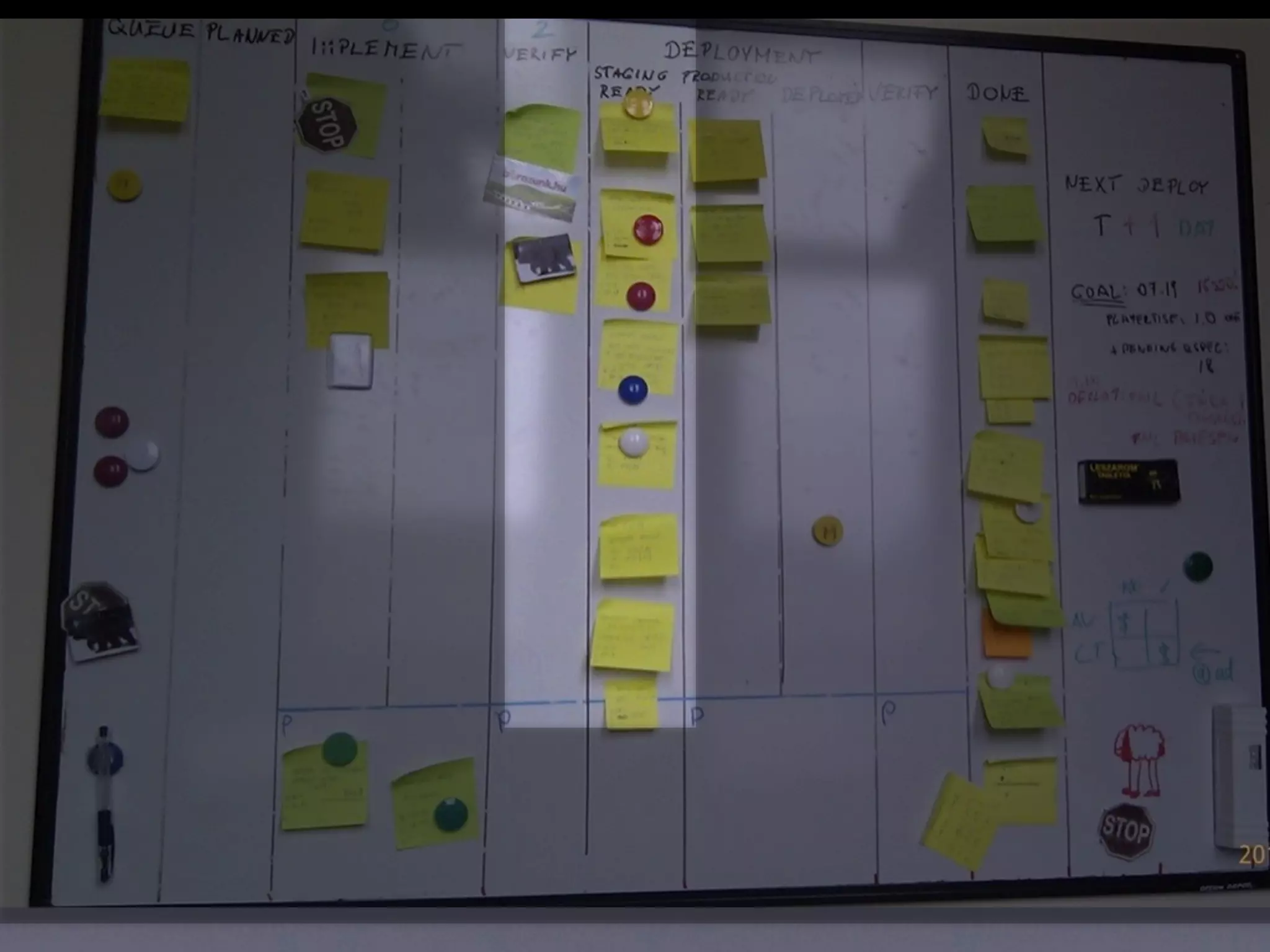

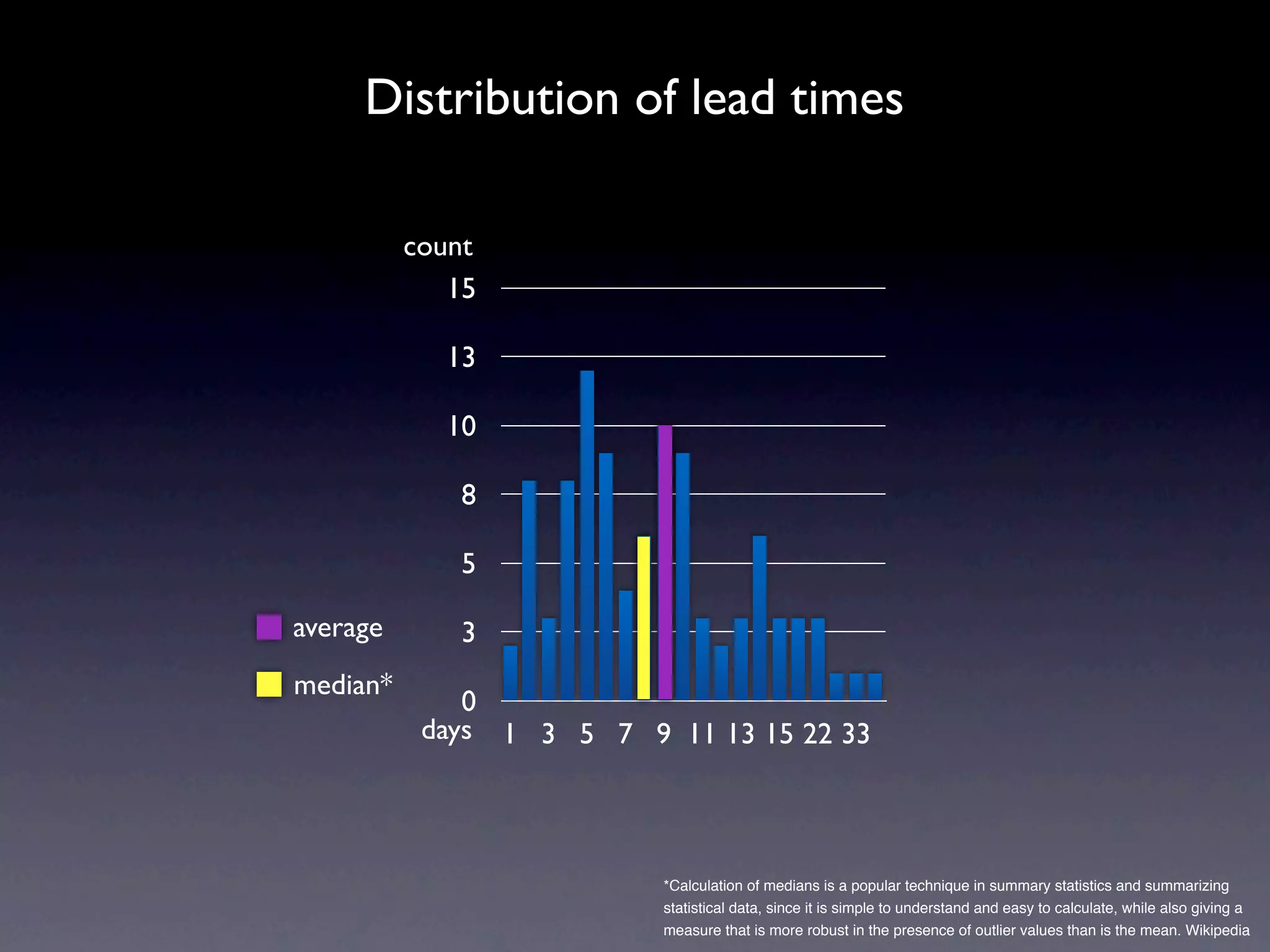

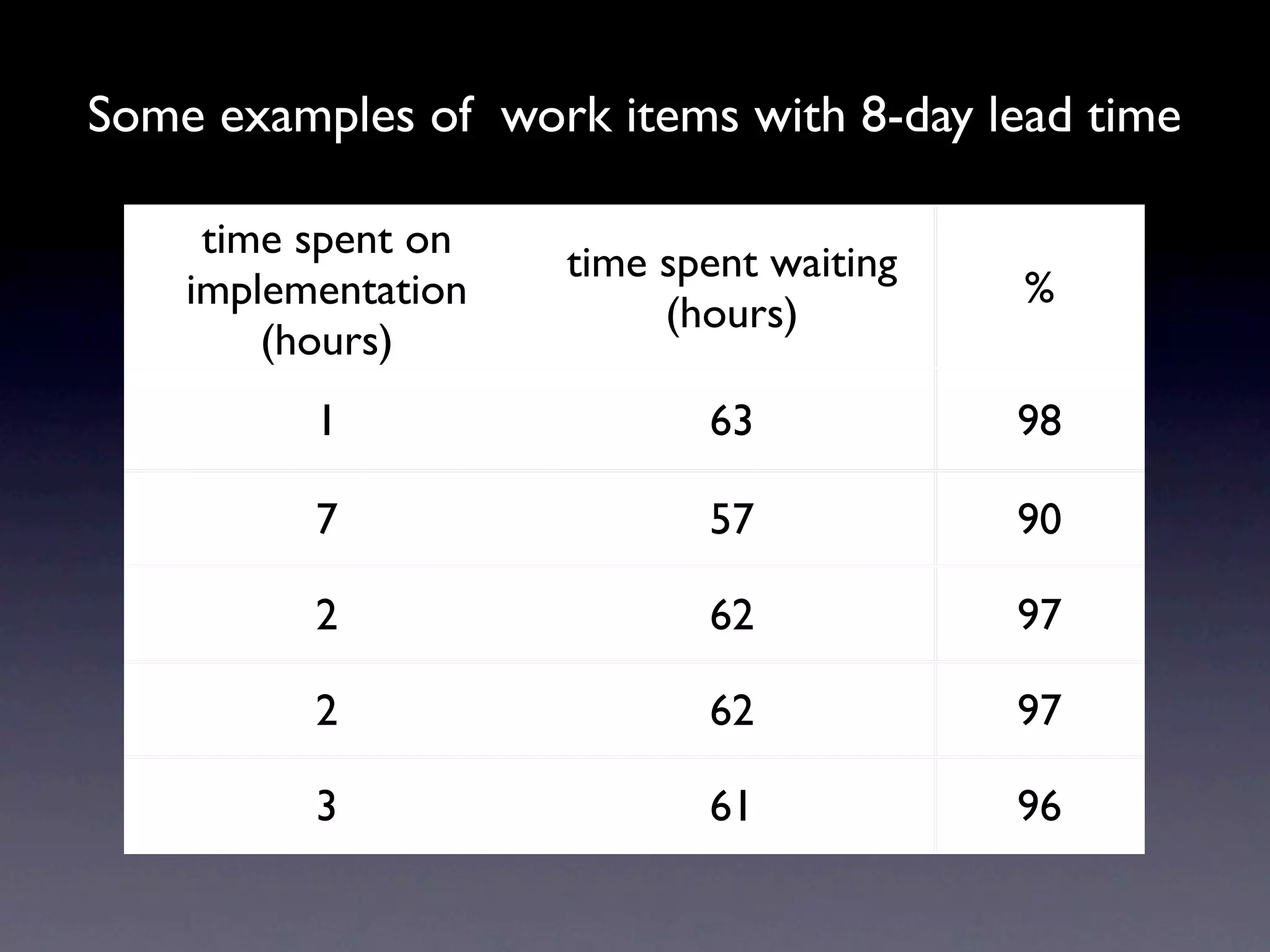

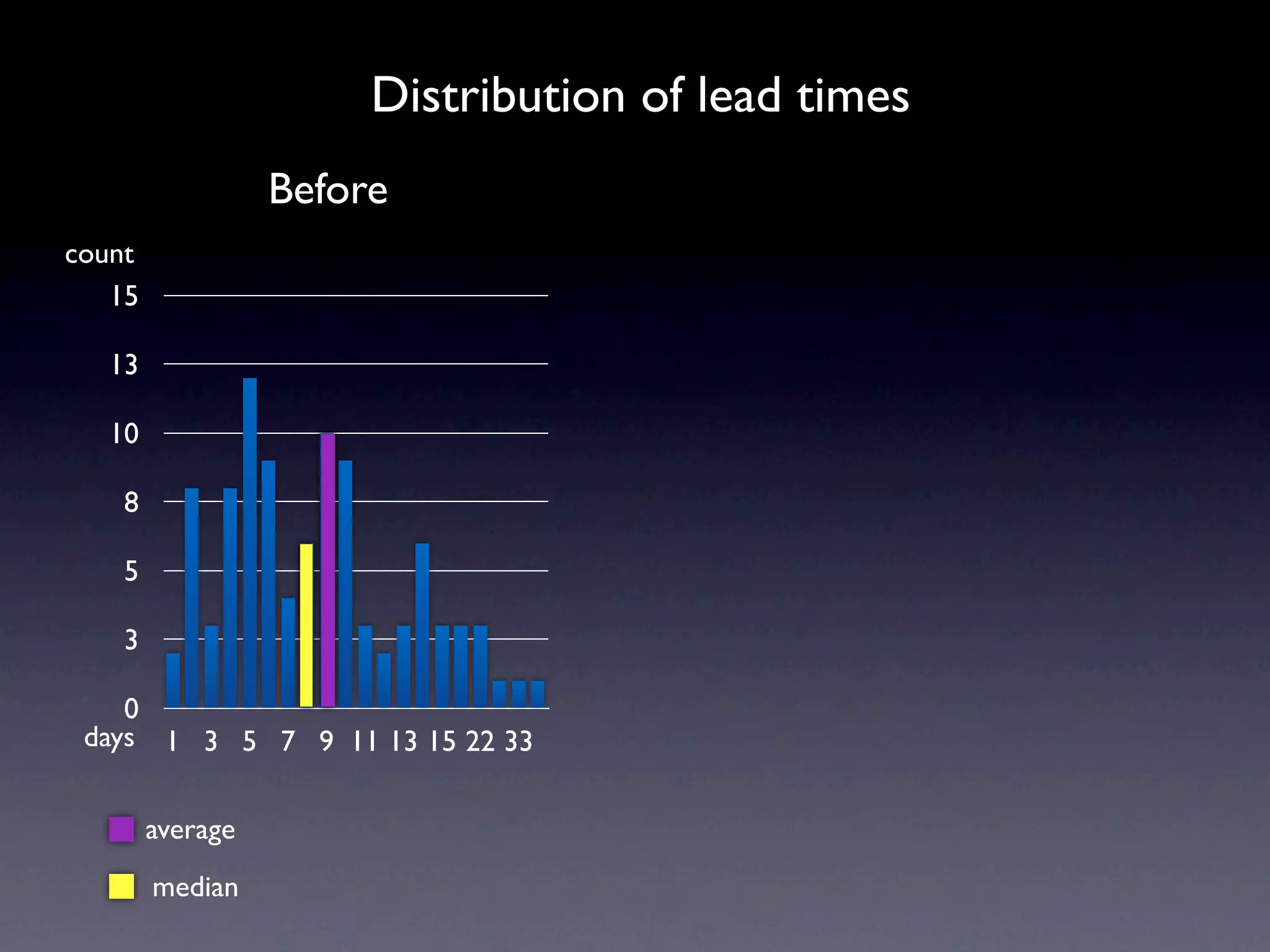

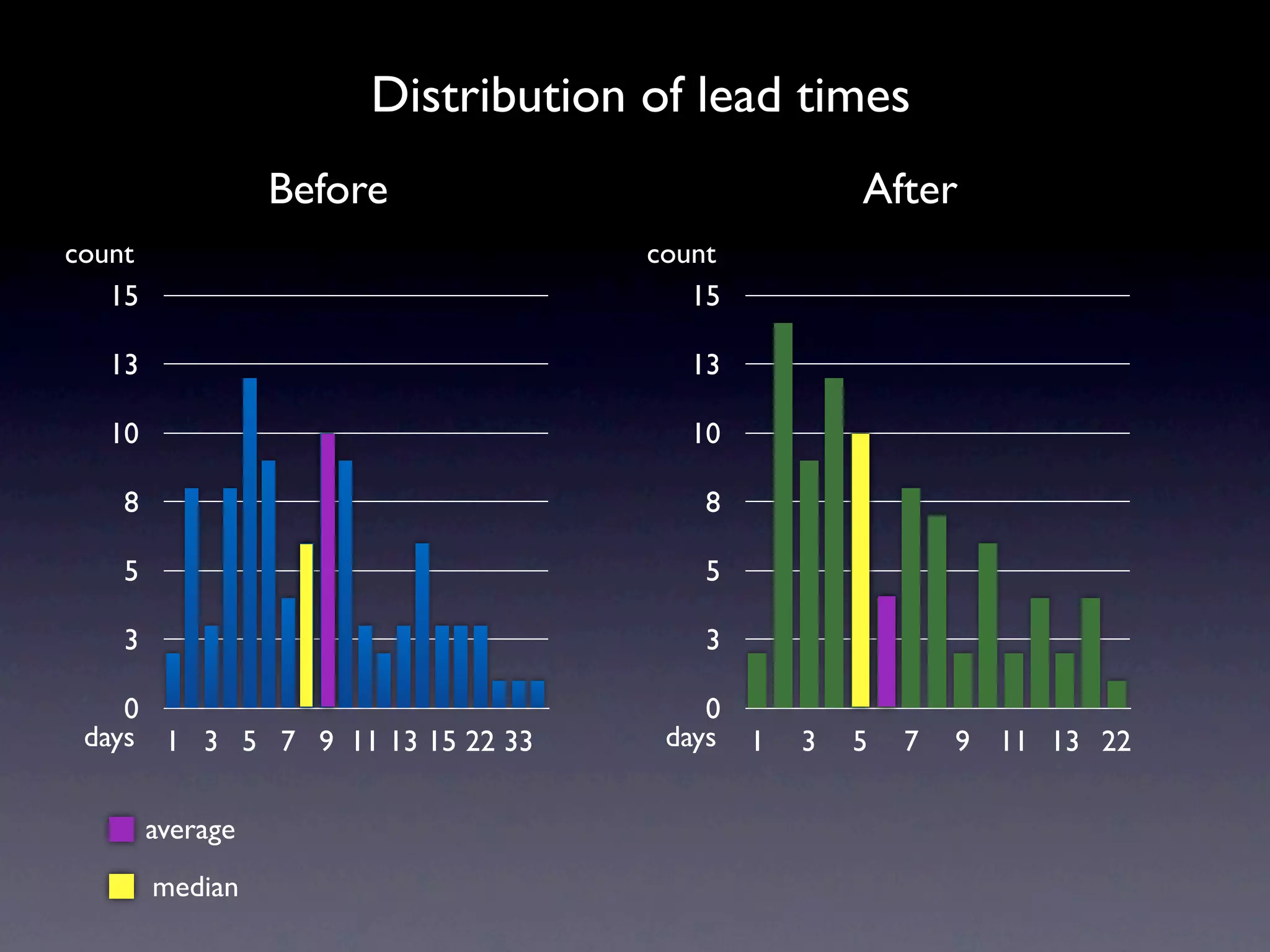

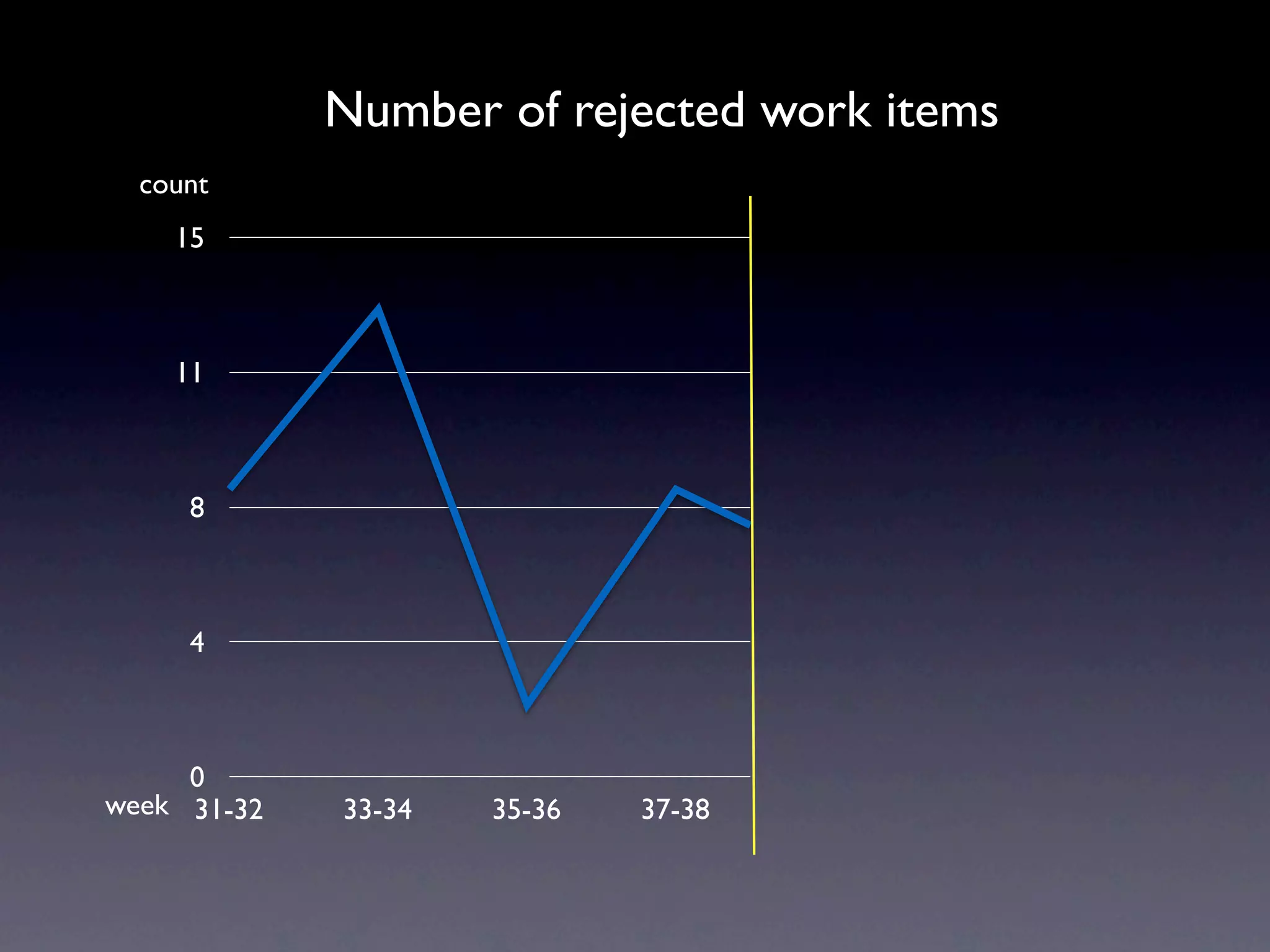

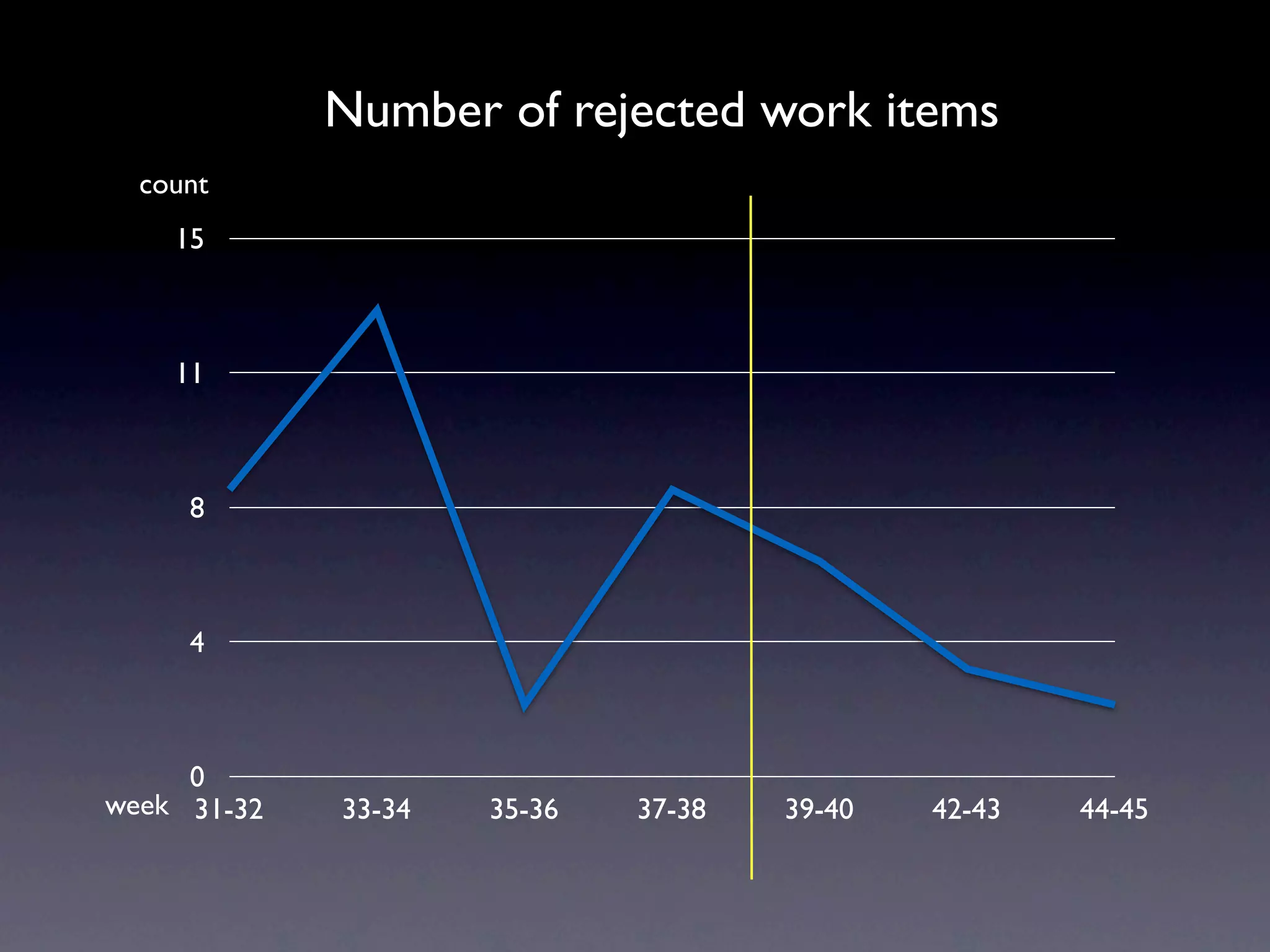

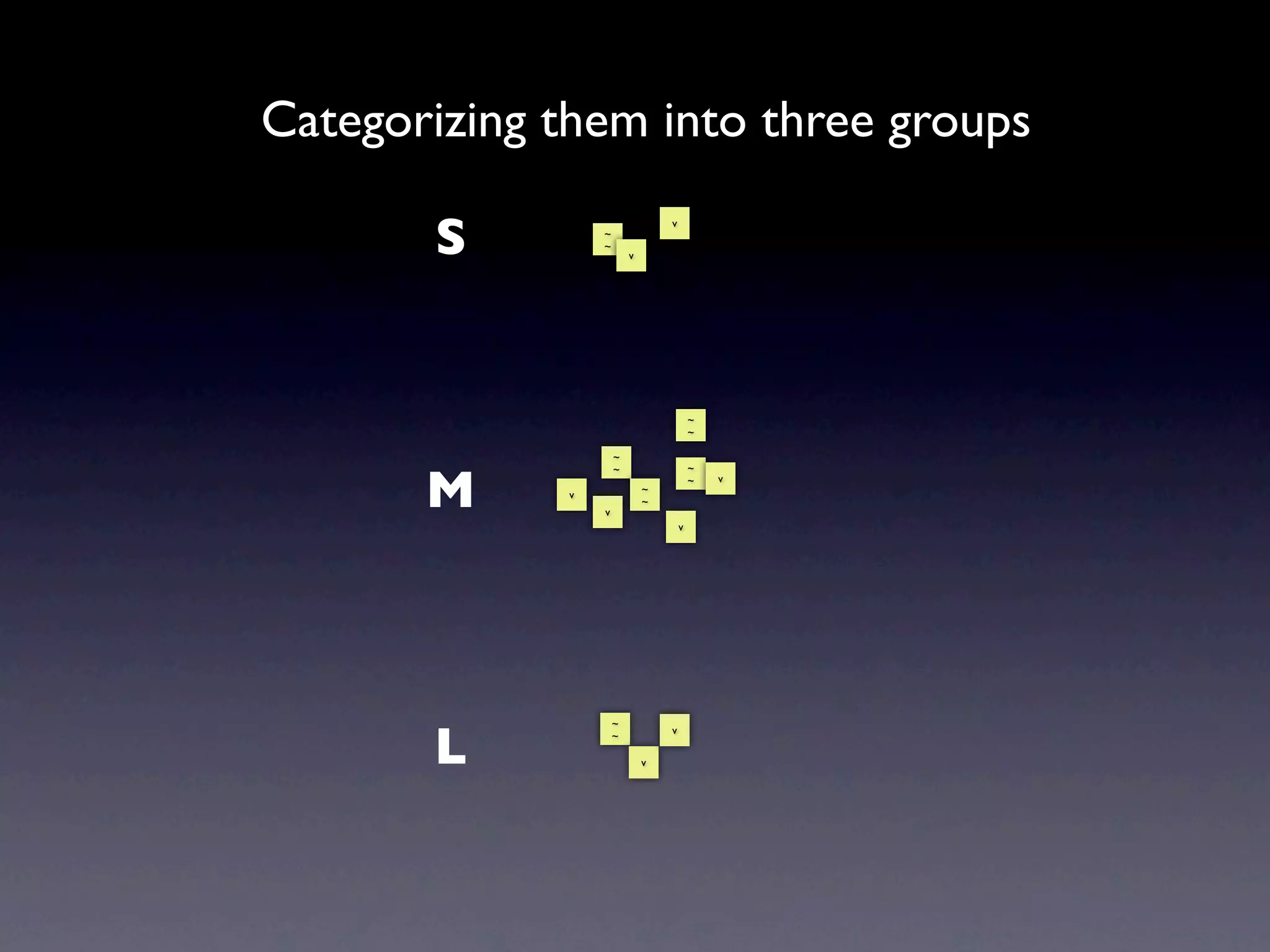

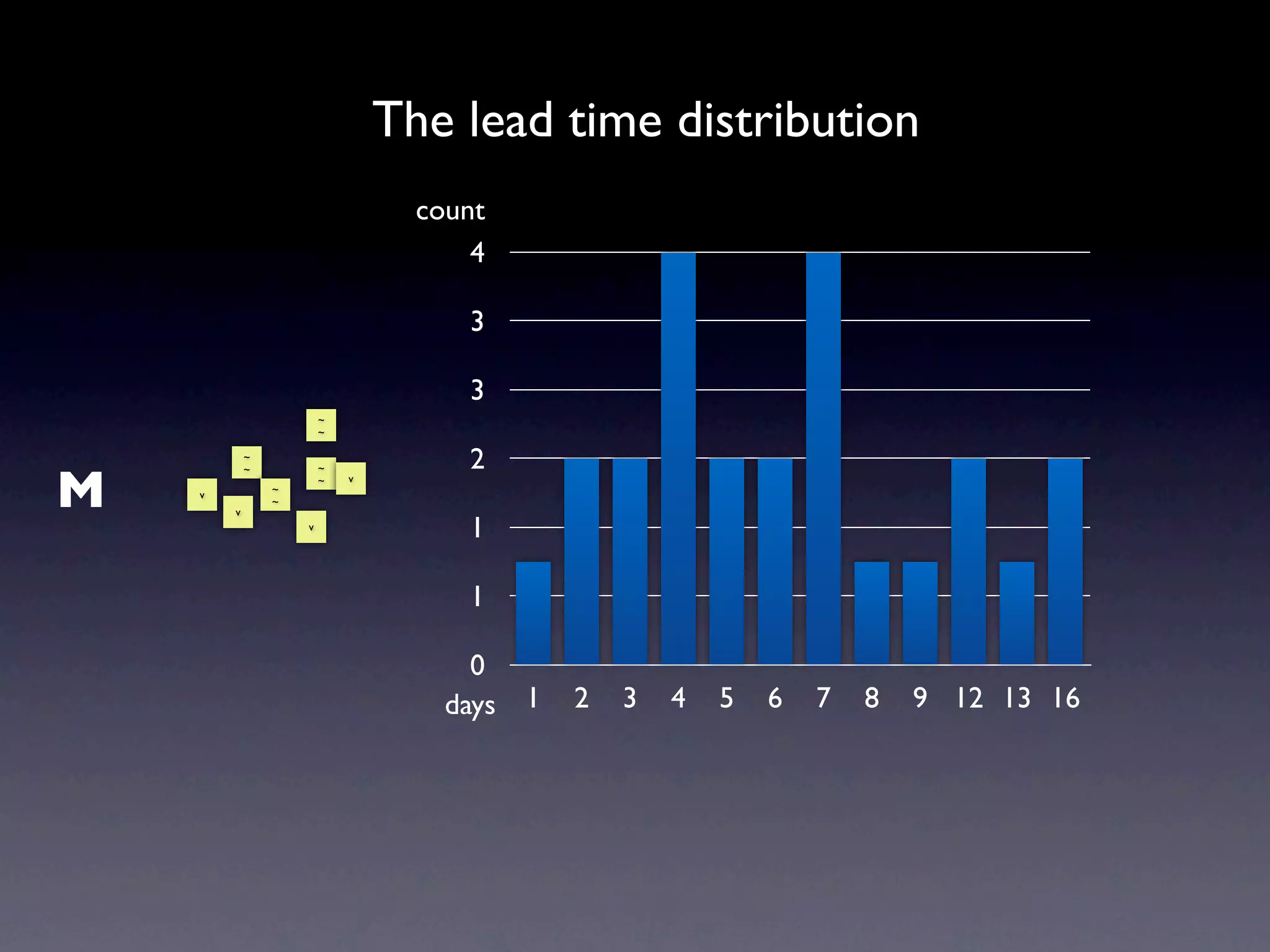

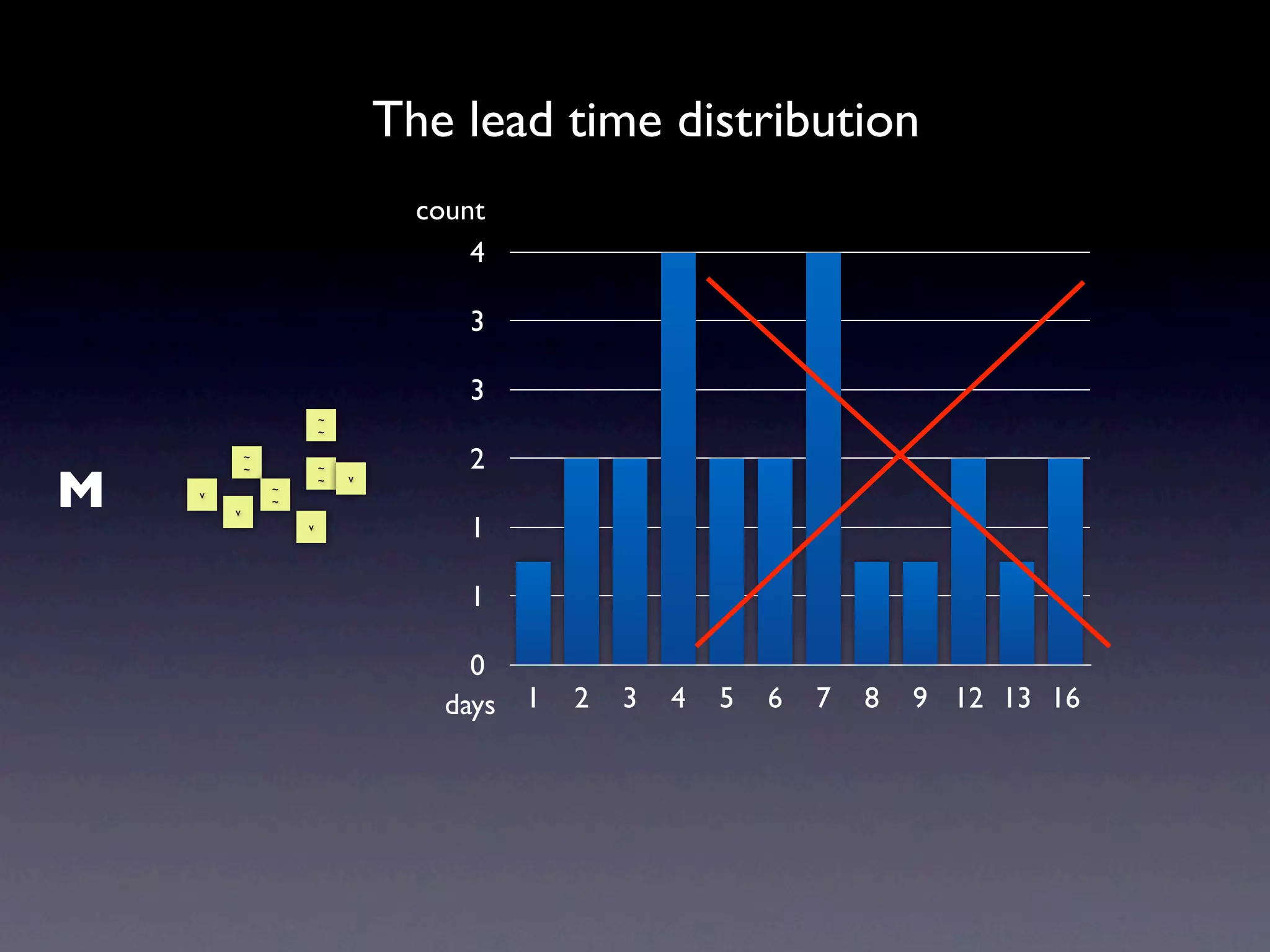

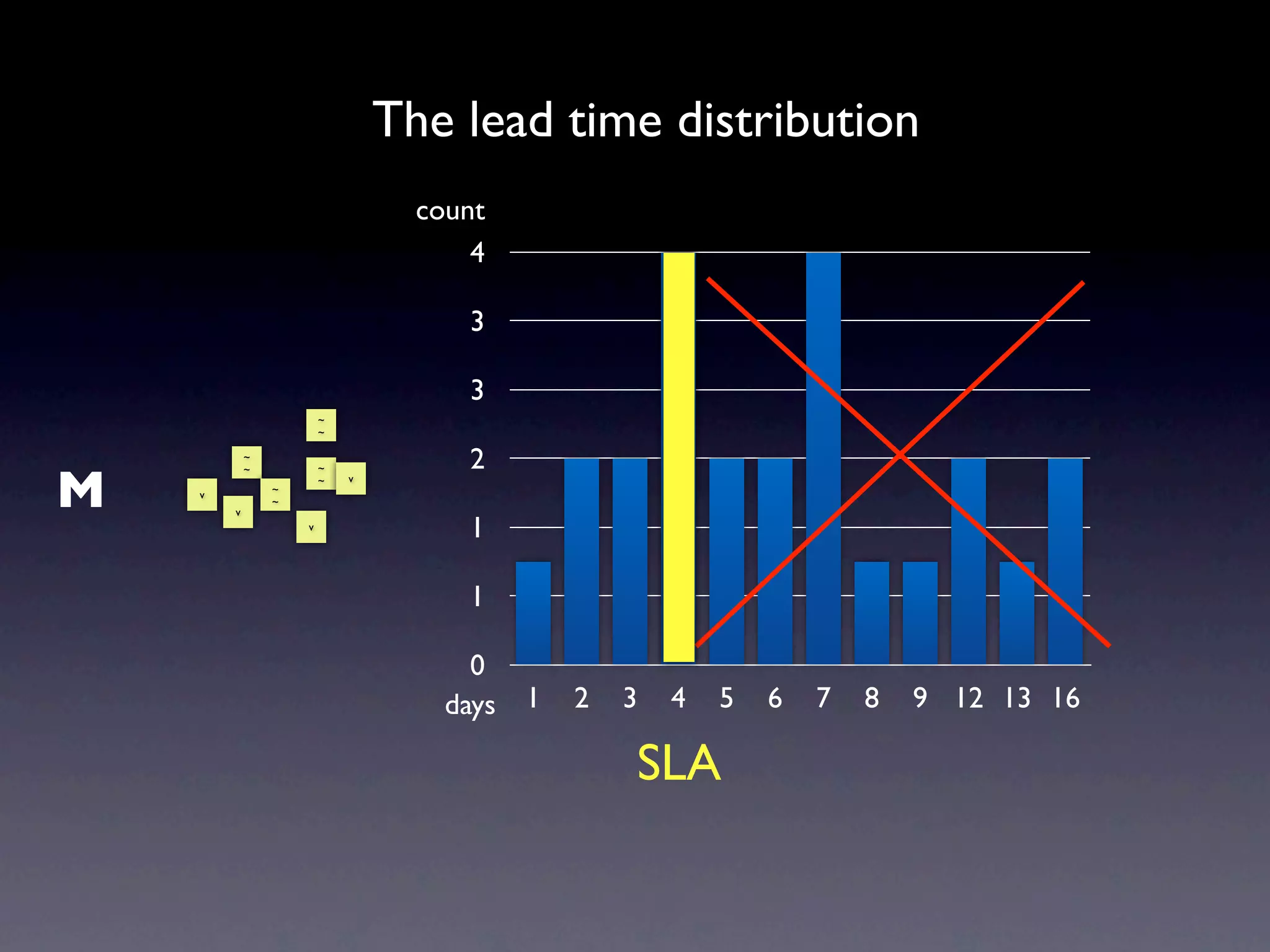

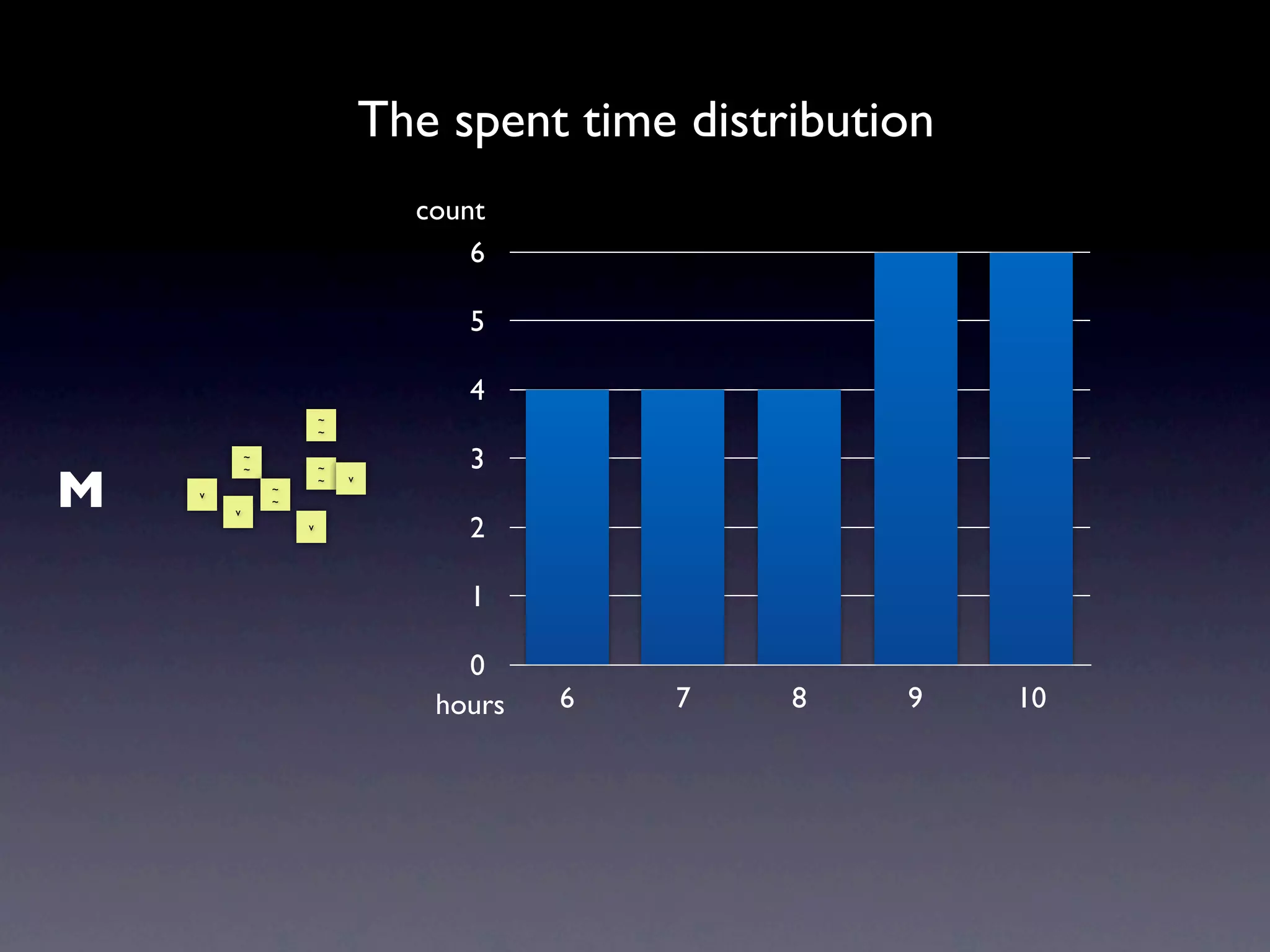

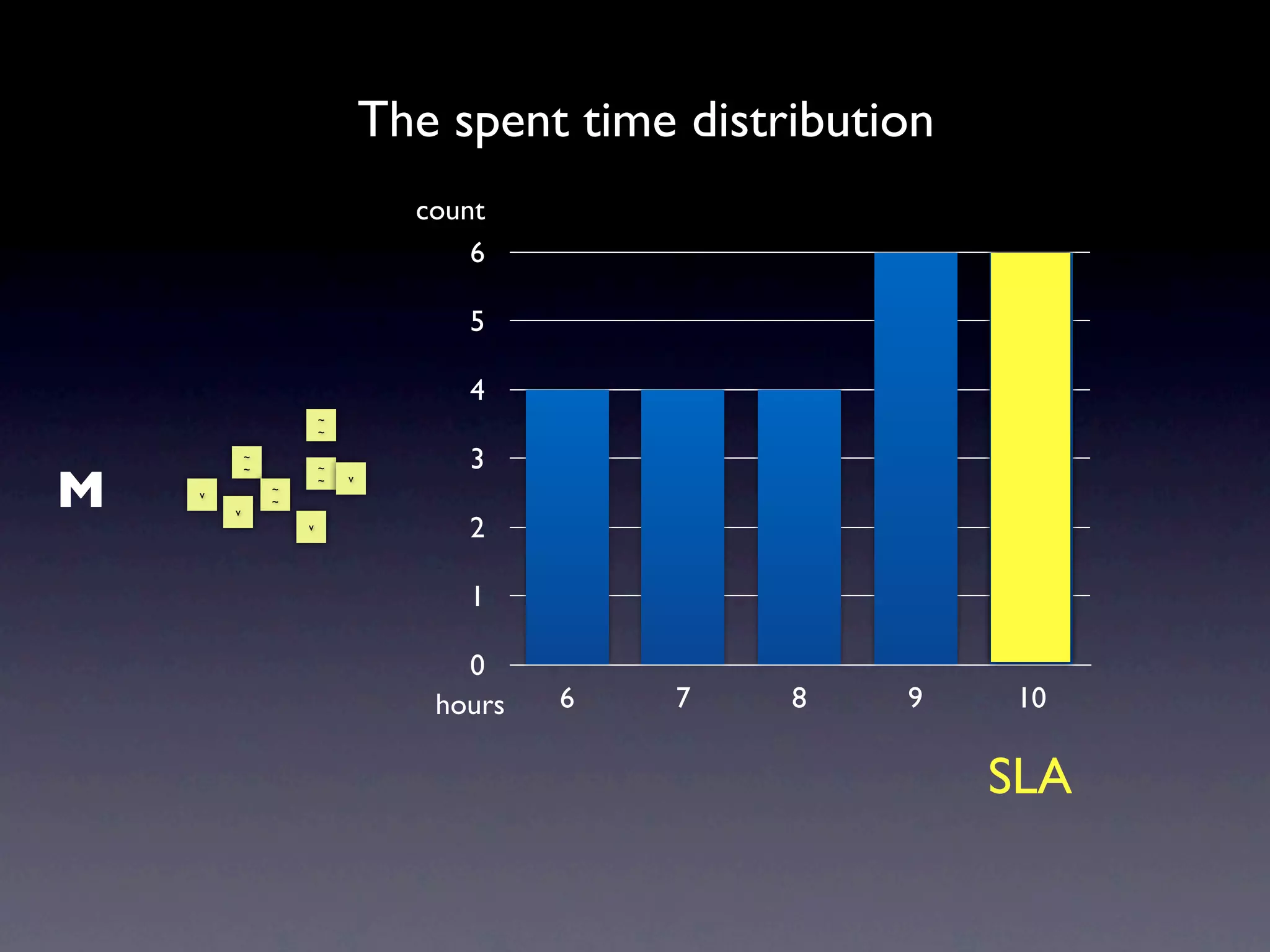

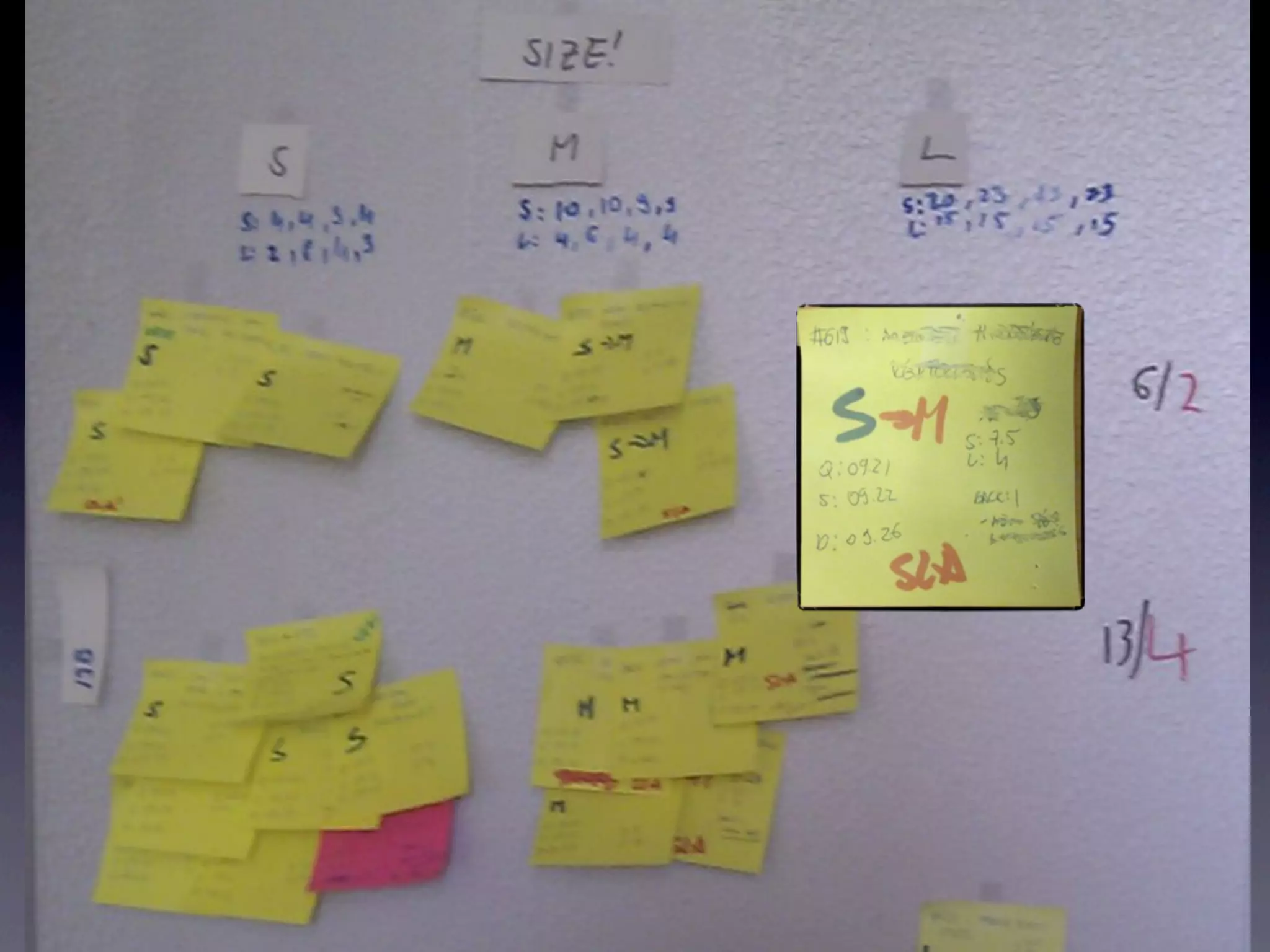

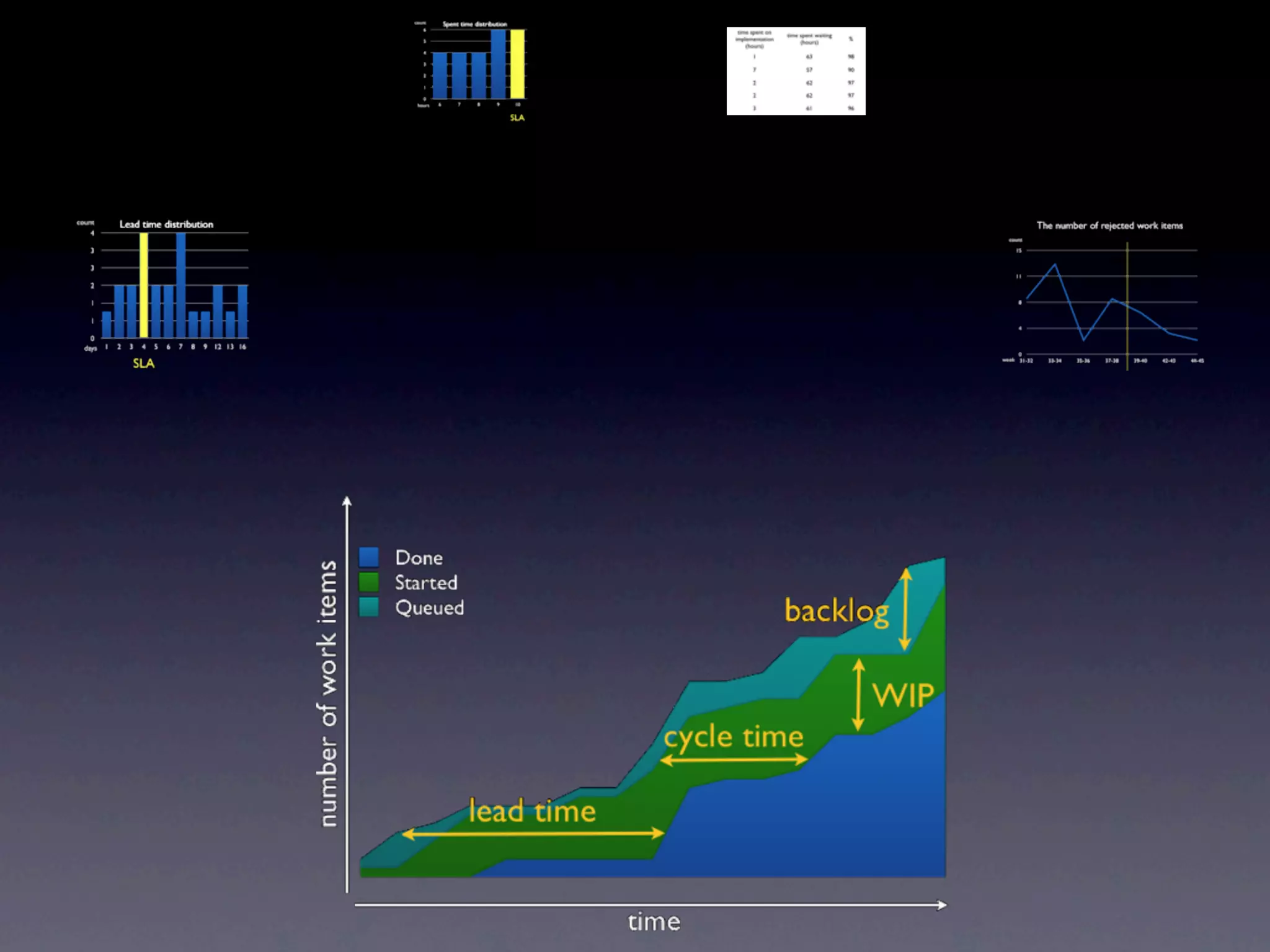

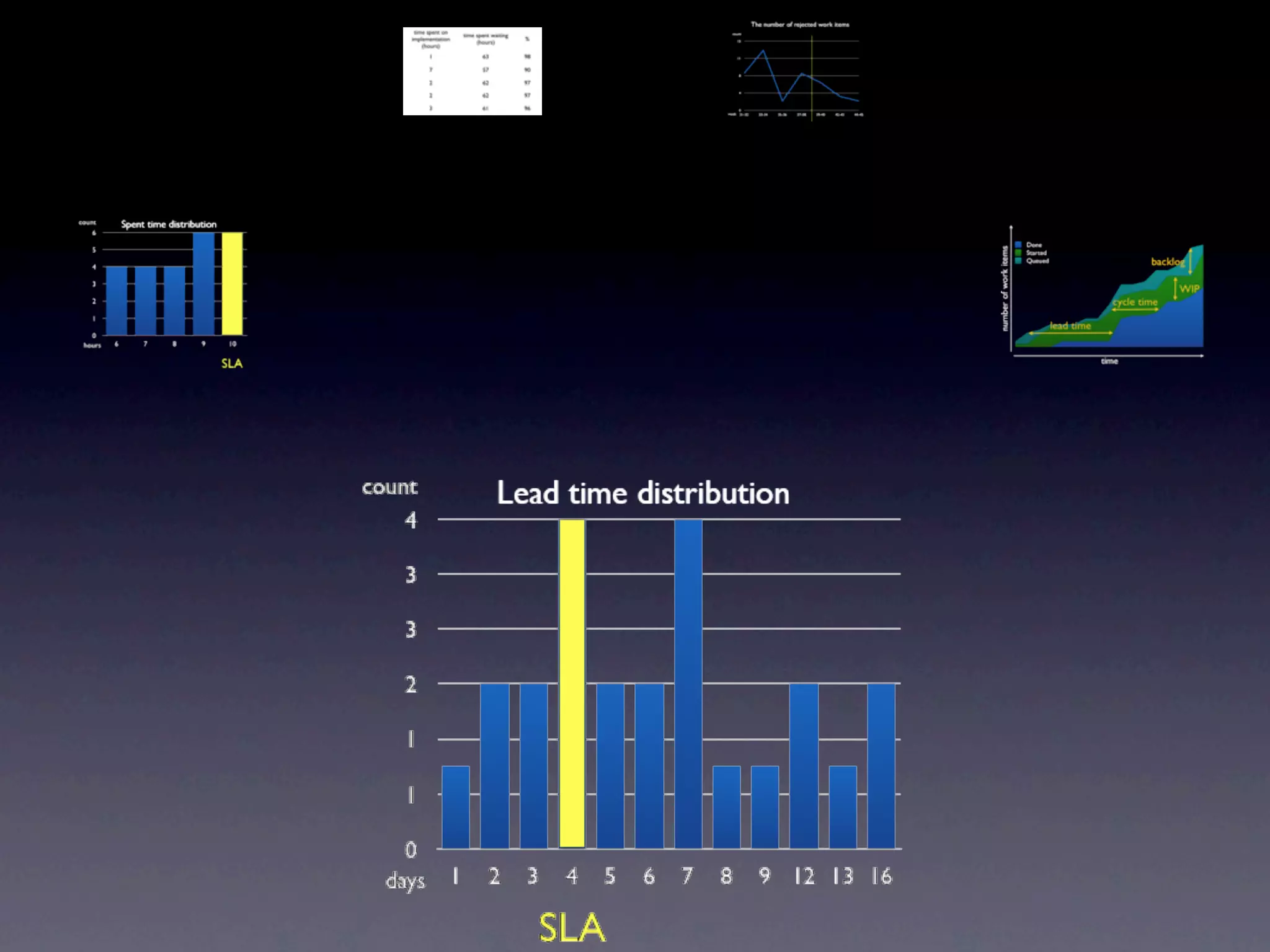

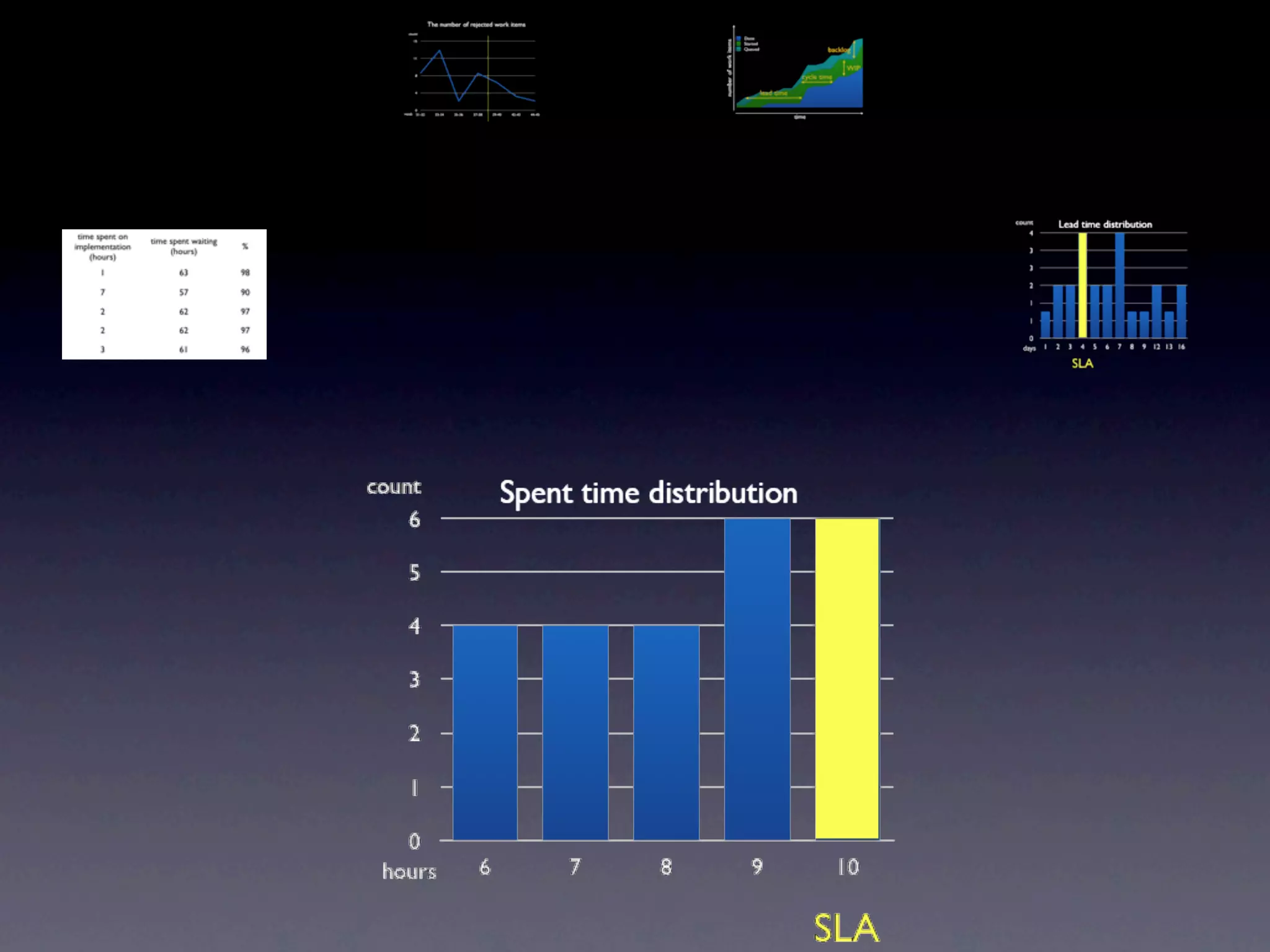

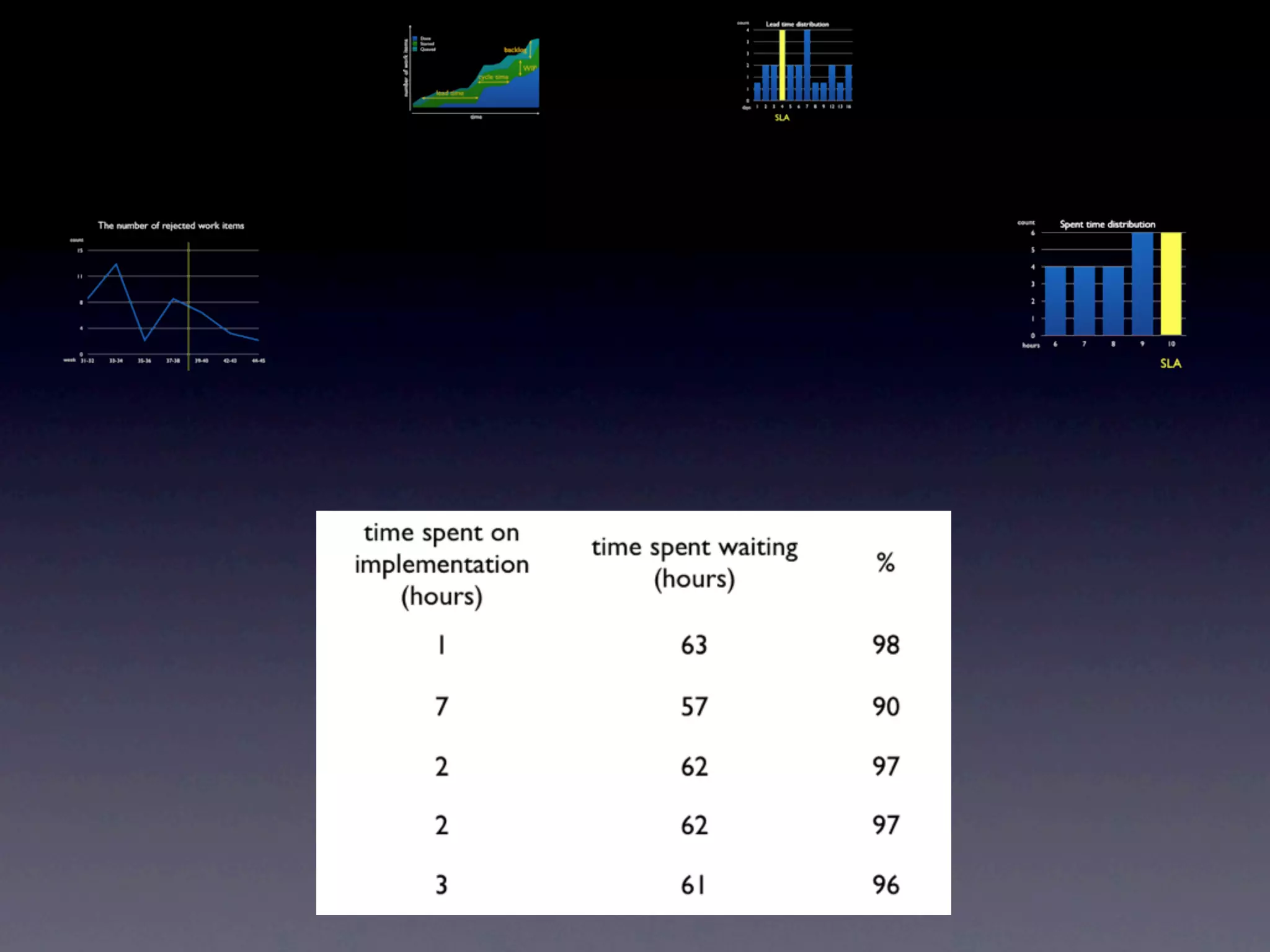

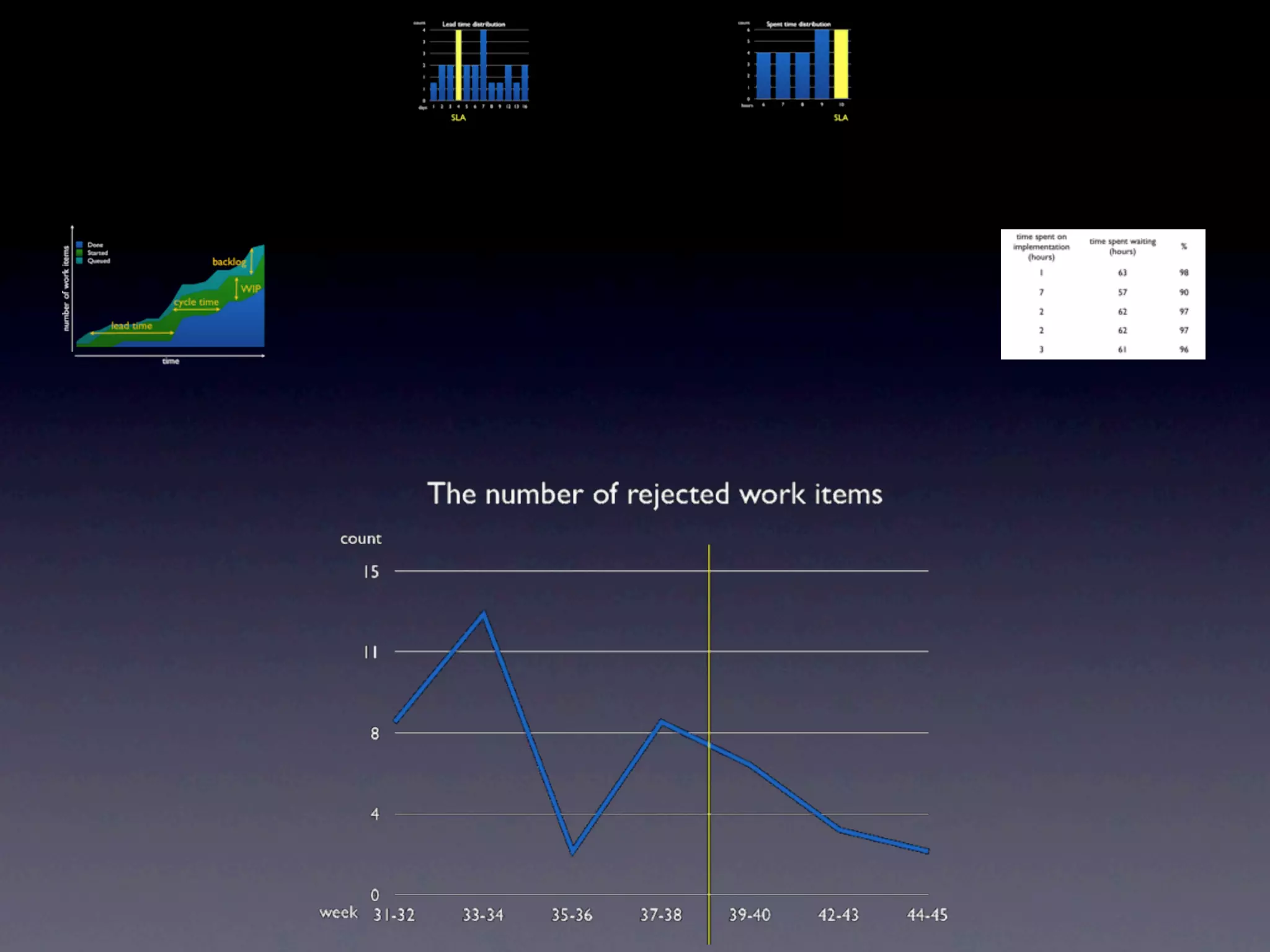

The document discusses using Kanban principles to measure and manage workflow. It provides examples of how understanding workflow flow can help deliver products faster and more predictably by visualizing the process, limiting work-in-progress, and measuring metrics like lead time, cycle time and throughput. Specific strategies discussed include using a Kanban board to manage workflow, collecting data in a cumulative flow diagram to calculate metrics, and identifying bottlenecks and waste through analysis of that data.