Ball Valves for Use in Clean Steam Trap

•

0 likes•750 views

Specifically Designed for Pharmaceutical, Biotech, Food, Beverage, Cosmetic and other Sanitary and Clean Processes PBM’s Igenix® line of sanitary valves is ideally suited for pure process applications where dead space within the valve need to be minimized. PBM valves exhibit high performance to accompany the high temperature requirements and temperature swings of steam applications and other elevated temperature applications.

Report

Share

Report

Share

Download to read offline

Recommended

More Related Content

More from CTi Controltech

More from CTi Controltech (20)

Groth Corporation Industrial Product Selection Guide

Groth Corporation Industrial Product Selection Guide

Rupture Disc Products For Industrial Process Safety

Rupture Disc Products For Industrial Process Safety

Flame control products for industrial fluid operations

Flame control products for industrial fluid operations

Integrated Flame Scanner For Commercial and Industrial Combustion Operations

Integrated Flame Scanner For Commercial and Industrial Combustion Operations

Controlling Cavitation in Industrial Control Valves

Controlling Cavitation in Industrial Control Valves

Seven recommendations for bolstering industrial control system cyber security

Seven recommendations for bolstering industrial control system cyber security

Digital valve positioner for industrial process control valves

Digital valve positioner for industrial process control valves

Victory Energy Firetube Boiler for extreme duty - Frontier Series

Victory Energy Firetube Boiler for extreme duty - Frontier Series

Recently uploaded

Navigating Complexity: The Role of Trusted Partners and VIAS3D in Dassault Sy...

Navigating Complexity: The Role of Trusted Partners and VIAS3D in Dassault Sy...Arindam Chakraborty, Ph.D., P.E. (CA, TX)

Call Girls in Netaji Nagar, Delhi 💯 Call Us 🔝9953056974 🔝 Escort Service

Call Girls in Netaji Nagar, Delhi 💯 Call Us 🔝9953056974 🔝 Escort Service9953056974 Low Rate Call Girls In Saket, Delhi NCR

(INDIRA) Call Girl Aurangabad Call Now 8617697112 Aurangabad Escorts 24x7

(INDIRA) Call Girl Aurangabad Call Now 8617697112 Aurangabad Escorts 24x7Call Girls in Nagpur High Profile Call Girls

Booking open Available Pune Call Girls Koregaon Park 6297143586 Call Hot Ind...

Booking open Available Pune Call Girls Koregaon Park 6297143586 Call Hot Ind...Call Girls in Nagpur High Profile

(INDIRA) Call Girl Bhosari Call Now 8617697112 Bhosari Escorts 24x7

(INDIRA) Call Girl Bhosari Call Now 8617697112 Bhosari Escorts 24x7Call Girls in Nagpur High Profile Call Girls

Recently uploaded (20)

Design For Accessibility: Getting it right from the start

Design For Accessibility: Getting it right from the start

XXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXX

XXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXXX

Navigating Complexity: The Role of Trusted Partners and VIAS3D in Dassault Sy...

Navigating Complexity: The Role of Trusted Partners and VIAS3D in Dassault Sy...

Call Girls in Netaji Nagar, Delhi 💯 Call Us 🔝9953056974 🔝 Escort Service

Call Girls in Netaji Nagar, Delhi 💯 Call Us 🔝9953056974 🔝 Escort Service

Cara Menggugurkan Sperma Yang Masuk Rahim Biyar Tidak Hamil

Cara Menggugurkan Sperma Yang Masuk Rahim Biyar Tidak Hamil

(INDIRA) Call Girl Aurangabad Call Now 8617697112 Aurangabad Escorts 24x7

(INDIRA) Call Girl Aurangabad Call Now 8617697112 Aurangabad Escorts 24x7

chapter 5.pptx: drainage and irrigation engineering

chapter 5.pptx: drainage and irrigation engineering

Intze Overhead Water Tank Design by Working Stress - IS Method.pdf

Intze Overhead Water Tank Design by Working Stress - IS Method.pdf

Call Girls Pimpri Chinchwad Call Me 7737669865 Budget Friendly No Advance Boo...

Call Girls Pimpri Chinchwad Call Me 7737669865 Budget Friendly No Advance Boo...

Call Girls Wakad Call Me 7737669865 Budget Friendly No Advance Booking

Call Girls Wakad Call Me 7737669865 Budget Friendly No Advance Booking

Booking open Available Pune Call Girls Koregaon Park 6297143586 Call Hot Ind...

Booking open Available Pune Call Girls Koregaon Park 6297143586 Call Hot Ind...

Double Revolving field theory-how the rotor develops torque

Double Revolving field theory-how the rotor develops torque

(INDIRA) Call Girl Bhosari Call Now 8617697112 Bhosari Escorts 24x7

(INDIRA) Call Girl Bhosari Call Now 8617697112 Bhosari Escorts 24x7

Ball Valves for Use in Clean Steam Trap

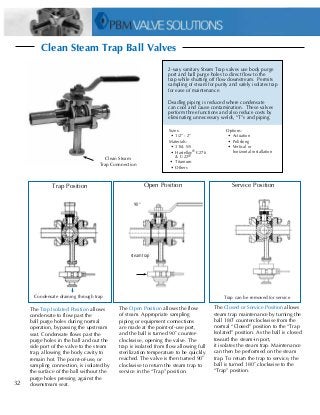

- 1. 32 Service PositionOpen PositionTrap Position steam steam trap Trap can be removed for service steam trap 90° steam trap 180° Condensate draining through trap The Closed or Service Position allows steam trap maintenance by turning the ball 180˚ counterclockwise from the normal “Closed” position to the “Trap Isolated” position. As the ball is closed toward the steam-in port, it isolates the steam trap. Maintenance can then be performed on the steam trap. To return the trap to service, the ball is turned 180˚ clockwise to the “Trap” position. The Open Position allows the flow of steam. Appropriate sampling piping or equipment connections are made at the point-of-use port, and the ball is turned 90˚ counter- clockwise, opening the valve. The trap is isolated from flow allowing full sterilization temperature to be quickly reached. The valve is then turned 90˚ clockwise to return the steam trap to service in the “Trap” position. The Trap Isolated Position allows condensate to flow past the ball purge holes during normal operation, bypassing the upstream seat. Condensate flows past the purge holes in the ball and out the side port of the valve to the steam trap, allowing the body cavity to remain hot. The point-of-use, or sampling connection, is isolated by the surface of the ball without the purge holes pressing against the downstream seat. Clean Steam Trap Ball Valves 2-way sanitary Steam Trap valves use body purge port and ball purge holes to direct flow to the trap while shutting off flow downstream. Permits sampling of steam for purity and safely isolates trap for ease of maintenance. Deadleg piping is reduced where condensate can cool and cause contamination. These valves perform three functions and also reduce costs by eliminating unnecessary welds, “T”s and piping. Sizes: • 1/2” - 2” Materials: • 316L S/S • Hastelloy® C276 & C-22® • Titanium • Others Options: • Actuation • Polishing • Vertical or horizontal installation Clean Steam Trap Connnection