comparative study at bidar mgssk and 2 others

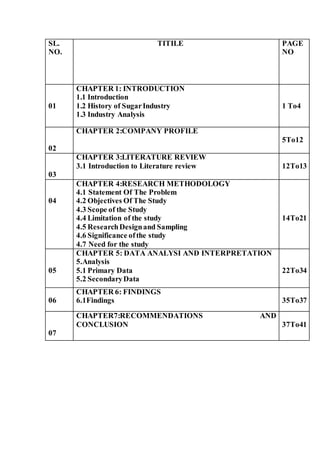

- 1. SL. NO. TITILE PAGE NO 01 CHAPTER 1: INTRODUCTION 1.1 Introduction 1.2 History of SugarIndustry 1.3 Industry Analysis 1 To4 02 CHAPTER 2:COMPANY PROFILE 5To12 03 CHAPTER 3:LITERATURE REVIEW 3.1 Introduction to Literature review 12To13 04 CHAPTER 4:RESEARCH METHODOLOGY 4.1 Statement Of The Problem 4.2 Objectives Of The Study 4.3 Scope of the Study 4.4 Limitation of the study 4.5 ResearchDesignand Sampling 4.6 Significance ofthe study 4.7 Need for the study 14To21 05 CHAPTER 5: DATA ANALYSI AND INTERPRETATION 5.Analysis 5.1 Primary Data 5.2 SecondaryData 22To34 06 CHAPTER 6: FINDINGS 6.1Findings 35To37 07 CHAPTER7:RECOMMENDATIONS AND CONCLUSION 37To41

- 2. Organization Structure In MGSSK pvt ltd Sugar Industry REVA UNIVERSITY MBA 2015-16 Page 2 CHAPTER 1:INTRODUCTION 1.1 Introduction Any operating organization should have its own structure in order to operate efficiently. For an organization, the organizational structure is a hierarchy of people and its functions. The organizational structure of an organization tells you the character of an organization and the values it believes in. Therefore, when you do business with an organization or getting into a new job in an organization, it is always a great idea to get to know and understand their organizational structure. Depending on the organizational values and the nature of the business, organizations tend to adopt one of the following structures for management purposes. Although the organization follows a particular structure, there can be departments and teams following some other organizational structure in exceptional cases. Sometimes, some organizations may follow a combination of the following organizational structures as well. 1.2 History of Sugar Industry Sugar industry is one of the most important agro-based industries in India and is highly responsible for creating significant impact on rural economy in particular and country’s economy in general. Sugar industry ranks second amongst major agro-based industries in India. As per the Government of India’s recent liberalised policy announced on 12th December, 1986 for licensing of additional capacity for sugar industries during 7th five-year plan, there will be only one sugar mill in a circular area of 40 sq km. Also the new sugar mill is allowed with an installation capacity of 2500 TCD ( Tonne Sugar Cane crushed per day) as against the earlier capacity norms of 1250 TCD. Similarly, the existing sugar mills with sugar cane capacity of about 3500 TCD can crush sugar cane to the tune of 5000 TCD with a condition imposed that additional requirement of sugar cane be acquired through increased productivity and not by expansion of area for growing sugar cane. Cane sugar is the name given to sucrose, a disaccharide produced from the sugarcane plant and from the sugar beet. The refined sugars from the two sources are practically indistinguishable and command the same price in competitive markets. However, since they come from different plants, the trace constituents are different and

- 3. Organization Structure In MGSSK pvt ltd Sugar Industry REVA UNIVERSITY MBA 2015-16 Page 3 can be used to distinguish the two sugars. One effect of the difference is the odor in the package head space, from which experienced sugar workers can identify the source. In the production scheme for cane sugar, the cane cannot be stored for more than a few hours after it is cut because microbiological action immediately begins to degrade the sucrose. This means that the sugar mills must be located in the cane fields. The raw sugar produced in the mills is item of international commerce. Able to be stored for years, it is handled as raw material – shipped at the lowest rates directly in the holds of ships or in dump trucks or railroad cars and pushed around by bulldozers. Because it is not intended to be eaten directly, it is not handled as food. The raw sugar is shipped to the sugar refineries, which are located in population centers. There it is refined to a food product, packaged, and shipped a short distance to the market. In a few places, there is a refinery near or even within a raw-sugar mill. However, the sugar still goes through raw stage. The principle by-product of cane sugar production is molasses. About 10 – 15% of the sugar in the cane ends up in molasses. Molasses is produced both in the raw-sugar manufacture and also in refining. The blackstrap or final molasses is about 35 – 40% sucrose and slightly more than 50% total sugars. In the United States, blackstrap is used almost entirely for cattle feed. In some areas, it is fermented and distilled to rum or industrial alcohol. The molasses used for human consumption is of a much higher grade, and contains much more sucrose.

- 4. Organization Structure In MGSSK pvt ltd Sugar Industry REVA UNIVERSITY MBA 2015-16 Page 4 1.3 Industry Analysis In India, sugar is an essential item of mass consumption and the cheapest source of energy, supplying around 10 percent of the daily calorie intake. India i s the second largest producer of sugar (16.3 million ton production in 2008‐09).It howeve r, ranks 15th in export rankings (.23 million ton exports in 2008‐0) as India is the largest c onsumer of sugar in the world. Raw as well as refined sugarprices plunged this year on expectation that output in Brazil and India, the second‐bi ggest producer, will increase. Raw sugar prices declined by 45 percent since the start of th e year 2010 amid hopes that global output will rebound. Four factors determine sugar production in India: Area under sugarcane production (Max. acreage of 4.43 million hectare) Sugarcane yield per hectare (Max. yield of 71.3 tonnes per hectare) The production of sugarcane that is crushed by sugar factories in relation to the tot al sugarcane produced (Max drawl percentage = 69%) Recovery of sugar (Max recovery = 10.48%) Ethanol is being promoted as an alternative to oil. It is commercially viable, clean er fuel but its efficiency is questionable. Ethanol promotion is primarily driven by Brazil which happens to be the largest consumer of ethanol. Incidentally, Brazil pr oduces ethanol directly from the sugarcane unlike many other countries which produce ethanol from molasses (a by‐product after ext raction of sugar from sugarcane). Almost 60% of Brazilian cane crop is diverted t o production of ethanol. Changes to emission norms under Kyoto protocol, increased fiscal incentives from several governments, US bill man dating ethanol use in gasoline, high oil prices are several other factors influencing ethanol production and diverting cane from sugar to ethanol production. In Octobe r 2007, Government of India (GOI) has mandated 5% ethanol blending. India requ ires an estimated 550 million litres of ethanol. GOI has also permitted companies t o produce ethanol directly from sugarcane juice. This will provide companies flexibility to alter the produt mix between sugar and ethanol depending on the relative demand and realisation. The Government of India (GOI) approved the National Policy on Bio‐fuels on December 24, 2009. The bio‐fuel policy encourages use of renewable energy resources as alternate f

- 5. Organization Structure In MGSSK pvt ltd Sugar Industry REVA UNIVERSITY MBA 2015-16 Page 5 uels to supplement transport fuels (gasoline and diesel for vehicle) and proposes target of 20 percent bio‐fuel blending (bio‐diesel and bio‐ethanol) by 2017. Presently, the government is unable to implement compulsory blending of 5 pe rcent ethanol in petrol (gasoline) due to the short supply of sugar molasses in 2009/10 and 2008/09 because of overall low sugarcane crop production in India. Consequently, India i mported about 280 million litres of ethanol in CY 2009 to meet the demand for industrial and potable liquor production. With a bumper sugarcane and sugar production outlook for 2010/11, the government is likely to renew its focus and implement the mandatory 5 percent ethanol blending in petrol. Industry source s report that the government is likely to take a decision on the purchase price of ethanol fo r the Ethanol Blending Program (EBP). Commercial production of biodiesel in India is very small and its utilization is mostly con fined to the unorganized sector. The government’s ambitious plan of producing sufficient bio‐diesel by 2011/12 to meet its mandate of 20 percent diesel blending is unrealized due to a lack of sufficient jatropha seeds to produce bio‐diesel.Advanced bio‐fuels in India are still at the research stage and it will take time before commercial production becomes eco nomically viable.

- 6. Organization Structure In MGSSK pvt ltd Sugar Industry REVA UNIVERSITY MBA 2015-16 Page 6 CHAPTER 2:COMPANY PROFILE Company Profile India is one of the largest producers of sugar in the world. It has large number of sugar manufacturers located through out the country Mgssk Ltd : The MAHATHMA GANDHI SAHAKAR SAKARE KARKHANE HUNAJI LTD was established in the year 2003 under dynamic leadership of Dr. bhimanna khandre. The factory started on the basis of co-operative society system. The company has more than 300 employees including administration and technical experts. Human resources being the most important asset of the factory, all the efforts are made to enhance the motivational level and efficiency of the employees. Objectives Of The Company: The objectives of the company is to encourage proper development of agricultural industries among members on co-operative lines by introducing the principles of co- operatives and joint forming methods with a view to secure the advantages of modern large scale agricultural to the owner or tenant cultivators of land. To teach the members improved methods of cultivation of sugar cane and supply seed ,material, implements etc. ,for growing sugar cane and other crops to promote agriculture and industrial education among members. To raise the share capital and to borrow capital necessary either on the security of the property of the society or without such security from the co-operative societies or from government. Or from financial institution like the industrial financial co-operation of India. The life insurance corporation of the India, scheduled banks etc. for the purpose of the societies. To enter into contract with co-operative societies and with the outside persons for the purchase and sale of goods and to appoint agents on salary or commission basis for such purchases or sales. To give members advances on the security of sugar cane and loans in kind for the raise of crops and with the development of agriculture with prior permission of the director of sugar and additional registrar of the co-operative societies, Bangalore.

- 7. Organization Structure In MGSSK pvt ltd Sugar Industry REVA UNIVERSITY MBA 2015-16 Page 7 To install machinery for utilization of byproducts and to buy raw materials and sell finished products in the course of utilizing and marketing the products. INFORMATION AT A GLANCE 1.Resistration No : DSK/LGL/RGN/12/91-92. Dated : 08-04-1991 2. Licence No : LI 175(1994)23/3/94 3. Crushing Capacity : 2500 TCD-expended up to 3500 TCD With 13 MW Co-generation. 4. Office addrss : Mahatma Gandhi Sahakara Sakkare Karkhane (N),Hunji(A), Taluka: Bhalki, Bidar Dist. Karnataka 5. Factry at : Hunaji(A) Bhalki Taluka, Bidar Dist. 6. Phone : 08484-265779, 265498(Fax) 7. E-Mail_ID : mgsskltdbhalki@yahoo.co.in 8. Internal Auditor : KK.Attal & Associates Bidar, Chartered Accountants. 9. Co Generation Consultance : PTS BIO-POWER Pvt Ltd. Bangalore 10. Financial Assistance : Governament of Karnataka 11. KST : 60303049, 8-7-2004 12. CST : 60353041, 8-7-2004 13. Sugar Code No. : 54701. 14. TIN NO. : 29420257995

- 8. Organization Structure In MGSSK pvt ltd Sugar Industry REVA UNIVERSITY MBA 2015-16 Page 8 Nature Of Business CarriedSugar Production : The Plant Is Capable Of crushing about 3,500tones per day and would be producing export quality crystal white sugar the latest techniques in the country. The factory has got one of the most advanced technologies in India. Robust and reliable equipment of latest design high efficiency and low power Consumption have been installed for continuous operation all around the year. Due to abundant cane available in the area of operation, a minimum duration for the season is of 6 to 7 months which is assured i.e. to say about 6,53,043 lake tones of sugarcane was crushed during the last season to produce around 6,46,500 lake quintals of sugar. When this is done, the turn over of the company right from the beginning would be Rs.120 cores. Power Generation: The company ha undertaken to establish a mega project to generate power using non conventional energy fuel i.e. Bagasse which is a by product coming pout of sugarcane and available in plenty location employing very high pressure 967 (ate) and high efficiency boiler and turbo generator sets. About 4.5 MW POWER IS GENERATED DURING THE SEASON AND WILL Be used for captive consumption. By–Products: THE company has ambitious plans to utilize various by – products in a systematic way as follows. Bagasse: Power generation Paper production Particle board Cattle feed and furniture Molasses : Butanol Yeast Industrial Alcohol High Protein Molasses

- 9. Organization Structure In MGSSK pvt ltd Sugar Industry REVA UNIVERSITY MBA 2015-16 Page 9 Filter Cane: Manure Refined Wax Vision-Mission Policy Vision : The setting up of the sugar factory in HUNAJI(H) that would enable to create employment opportunity in rural areas to the unemployed specially the weak and backward section of that community not in the sugar unit in HUNAJI(H) but also in the ancillary units enabling them to increase their purchasing power and consequent leading to higher living standards Mission: Production of white crystal sugar to meet the increased demand for domestic consumption Co-generation of 4.5 MW power for its own use. Quality Policy : Providing good quality seed material and other input Providing training in sugarcane cultivation etc. Area Of Opration : Its area of operation is extended up to 40 kms. Of radius from the factory site. Bidar Bhalki Hallikhed Kamal Nagar Achievements : In the year 2008-09 Cane crushed 633043 Metric Tone, Sugar Bagged 461960 Quintals, Recovery 10.71%. In the year 2009-10 Cane crushed 197341 Metric Tone, Sugar Bagged 187305 Quintals, Recovery 9.57%. In the year 2010-11 Cane crushed 339779 Metric Tone, Sugar Bagged 325030 Quintals, Recovery 9.57%.

- 10. Organization Structure In MGSSK pvt ltd Sugar Industry REVA UNIVERSITY MBA 2015-16 Page 10 Ownership Pattern : The MGSSK Ltd: Company is a co- operative society in which the boards of directors are elected by shareholders. Among the directors one will be the chairman and another will be the vice – chairman. Their term is 3 years. Chairman will be elected from the board of directors every year. Chairman and board of directors will decide the policy matters of the factory. Managing director will be appointed by govt. of Karnataka. The chairman will be the chief executive Administration Department :- Administration department is the main department in the organization in their is total number of 71 employees working in this department MGSSK Ltd is dividend into 8 sections and they are as fallows. Share sections. Time and labor welfare. Purchase section. Store section. Telephone operating. Sales section. Securities. Account and cash Share section –The share section is one of the important sections because more than half of the total authorized capital is collected from share holders according to low the factories authorized share capital is Rs 20 cores at present the number of share holders are 15641 and capital collected format the share holders is Rs 88.2.64 lakes Factory issues manly 5 types of shares. A - class - Producer member. B - class - Government. C - class - Non-Growers or ordinary member. D - Class - Co-Operative societies. E - Class - Nominal members. Share value The face value of the each share 250 Rupees shares Admission fee – 10 Rupees Share fee Rupees Total share value – 265 Rupees a sum of Rs.250 shall be payable on application the balance shall be calls in installments fixed by the BOD.

- 11. Organization Structure In MGSSK pvt ltd Sugar Industry REVA UNIVERSITY MBA 2015-16 Page 11 Recording of Information:- All the day to day transactions are recorded promptly in journal and posted to ledger at the end of the year these records are used to prepare financial statement the main financial statement prepared are balance sheet. Profit and loss account. Fund flow statement and cash flow Statement records like tax payment. Shift - 06am To 2pm Shift - 02pm To 10pm Shift - 10pm To 06am Finance department: - Company was able to get the working capital finance to the extent of Rs, 42.52 cores. The bankers of the company have expended their fullest co-operation in gander leasing working capital requirement which enable the company to make payments. Of cane bills of the formers the company has paid Rs.700 MT as first installment for the cane supply during the year the finance department of the company hosts highly talented, qualified. Finance idling pay role calculation and crediting salaries, maintaining complete books of the accounts and internal auditing. LOCATION DETAILS : MAHATHMA GANDHI SAHAKARA SAKARE KARKHANE HUNAJI(H) TQ, BHALKI DIST,BIDAR KARNATAKA INFRASTRUCTURE FACILITY: Facility for Employees: Bonus is 8.33% based on the worker’s salary. Quarters, hospital etc. Facility and allowances are given. Canteen facility is made available to the employees. Promotion facilities available Permanent workers get one increment every year.Factory provides two pair of uniforms and one pair of shoes every two years to the workers.

- 12. Organization Structure In MGSSK pvt ltd Sugar Industry REVA UNIVERSITY MBA 2015-16 Page 12 BORD OF DIRECTOR’S LIST SI.NO NAME DESIGNATION 01 Dr. Bhianna S. Khandre Chairman 02 Sri. Amarkumar B. Khandre Voice-Chairman 03 Sri. Jaivantrao H.Patil Director 04 Sri. Vaijinathrao M.Patil Director 05 Sri. Baburao J.Patil Director 06 Sri. Baburao S. Tumba Director 07 Sri. Manoharrao V.Nittur Director 08 Sri. Shravanakumar M. Gayakwad Director 09 Sri. Liyakhatali Ahamadali Director 10 Sri. Sangareddy S.Gonde Director 11 Smt. Surekha B.Shetkar Director 12 Smt. Nalini S. Patil Director 13 Sri. Shivakumar A.Mallasure Director 14 Sri. Vijaykumar K. Lingoji DCC Bank Nominee Director 15 Sri. J.C.Para Managing Director

- 13. Organization Structure In MGSSK pvt ltd Sugar Industry REVA UNIVERSITY MBA 2015-16 Page 13 FIG (A) shows the organization stracture of sugar industry

- 14. Organization Structure In MGSSK pvt ltd Sugar Industry REVA UNIVERSITY MBA 2015-16 Page 14 CHAPTER 3:LITERATURE REVIEW 3.1 Introduction to Literature review

- 15. Organization Structure In MGSSK pvt ltd Sugar Industry REVA UNIVERSITY MBA 2015-16 Page 15 A review of the existing studies on sugar industries in general regarding the available literature on sugar industry in India are to be related to production, procurement, pricing policies and marketing aspects of sugarcane. Review of literature is concerned to the study of previous research work in the field of chosen research problem. This is one of the most important components in the research process, which introduce the researcher to research gaps as well as to the research process. In order to get familiarity with the research process and to understand the research gaps in the chosen research problems about 100 research articles, 12 Ph. D thesis and 5 M. Phil dissertations were reviewed and the reviewed literature is presented under the following heads, viz., sugar industry in India and abroad, co-operative sugar sector in India, cost and operational analysis of sugar factories, financial analysis of sugar factories, human resources in sugar factories and in sugarcane fields, sugarcane and sugarcane cultivation. The Sugar Enquiry Commission: Appointed by Government of India it studies the trends in the sugar production, sugar policy, problems of sugar cane development, pricing and distribution policy of sugar and sugarcane and licensing policy. However the report of the sugar enquiry Commission did not touch the cost management factors in sugar industry in general and specifically co-operative sugar industries G.S.Kamat: Reviewed the management aspect of the co-operative enterprises. And studied the co-operative sugar factories in Maharashtra state in 1965.it covers the problems relating to finance, raw materials and personnel. The conclusion of the study is that the co- operative sugar factories could play an important role in rural development if they managed properly. V L Dutt: Conducted a study on problems and prospects of sugar industry and urged state Government to earmark the entire purchase tax for intensive cane development Sri. L. Kumar: Studied the cost structure of sugar industry and recommended for the policy of partial decontrol restoration in 1980. S. Pruthi:

- 16. Organization Structure In MGSSK pvt ltd Sugar Industry REVA UNIVERSITY MBA 2015-16 Page 16 (1995) studied the history of sugar industry in India. The study focused on history of sugar, sugar making in ancient and medieval India, during British period and after independence till 1992. The consolidated chronological write up backed by secondary data, which was collected from the Government records and books. The study concluded with remarkable findings that the English trader brought sugarcane at Agra and Luknow to meet the growing sugar needs of the British Empire; the manufacturing of sugar was intensified by the East India Company; dominance of small size units in the initial phase of the growth of the sugar industry and the existence of major regional difference in the size of sugar mills in India; and after the independence the growth of sugar industry was adversely affected by a variety of factors such as control, cane price, quota, duty and sugar politics. M.L.K. Dagde" (2001) has proposed a new concept of right sizing of manpower in sugar industry and advocated that without restructuring, right sizing, down sizing or optimising Indian sugar industry may be private or co-operative sector would not survive. Right sizing of manpower does not mean reduction in manpower but does mean right person at right place at right time; avoiding duplication of work force; and reduction in salary and wage bills. The study proposed a model based on the manpower requirement stated by the various authorities/institutions based on the crushing capacity of sugar factories.

- 17. Organization Structure In MGSSK pvt ltd Sugar Industry REVA UNIVERSITY MBA 2015-16 Page 17 CHAPTER 4:RESEARCH METHODOLOGY

- 18. Organization Structure In MGSSK pvt ltd Sugar Industry REVA UNIVERSITY MBA 2015-16 Page 18 RESEARCH METHODOLOGY : The present paper is based on secondary data which is collected from selected Co- operative sugar factories of Bidar district in Karnataka state. Following reports are collected for study. 1. MIS Reports 2. Daily Manufacturing Reports. 3. Annual Technical Reports. 4. Cane Manufacturing. 5. Audit Reports. 6. Cost and Management accountant Journal. 7. Cost Accounting Standard which are issued by ICWAI 8. Records of Co-operative Sugar Factories 9. Manufacturing account, Cost sheet. 10. Unstructured interviews conducted with special officer, Cane Inspector, Field Officer, Executives, workers, Farmers and Leader of farmer association. 11. It is an empirical research in which the researcher has analyzed the cost of production. The percentage method has been used to analyze the cost elements. The secondary data which was compiled from three selected co-operative sugar mills for the period 2005-06 to 2014-15 has been used for analysis. 4.1 Statement Of The Problem: The cooperative sector plays an important role in the Indian sugar industry. Co- operative sugar factories are the processing unit established by the farmer in the 103 rural area. The capital is collected from the farmers for their economical and social development. It is established as per the co-operative norms and rules. These co-operative sugar factories have created ample opportunities for employment in rural area. Today co- operative sugar mills are facing many problems like competitive environment, cyclic nature of the industry, high support price payable to farmers, inadequate working capital, low yield of sugarcane outdated machinery in old co-operative sugar factory, competition with Gur and Khandsari industry. Sugar export policy was unstable, more government regulations, high cost of production etc. because of this problems the working of many

- 19. Organization Structure In MGSSK pvt ltd Sugar Industry REVA UNIVERSITY MBA 2015-16 Page 19 sugar factories is not comfortable. This is therefore, the right time to launch some by- product industry to make the sugar industry financial viable. The dynamic leadership given by some progressive co-operative sugar factories in this direction has encouraged many more co-operative sugar factories to set up such by- product industries. Because of importance of by-products of the sugar industry the researcher selected research problem, “An Analytical study of By-products of sugar industry with reference to Kolhapur Districts” 4.2 Objectives Of The Study: Researcher has conducted research work on the basis of set objectives, the specific objectives are as follows:- 1. To know the growth and development of sugarcane By-products industries and their ancillaries. 2. To examine the financial position of the co-operative sugar factories and its departments of By-products. 3. To stud the functional areas like production, marketing, finance and Human Resource of by-products production in the sample units. 4. To know the financial liability of the by-products in sample sugar factories 5. To suggest product mix model to sample sugar factories. 6. To draw conclusion and suggest appropriate suggestion, if necessary. 4.3 Scope of the Study: To evaluate the cost management practice adopted by the Co-operative sugar factories of Bidar District in Karanataka, the following factories are taken in to consideration. 1. Mahatma Gandhi Sahakar Sakkare Karkhane Limited, Donagapur, Bhalki. (MGSSK) Ltd. 2. Bidar Sahakar SakkareKarkhane Limited Hallikhed (B),Bidar. (BSSK) Ltd. 3. NaranjaSahakarSakkareKarkhane Limited, Imampur, Janwada, Bidar. (NSSK) Ltd. 4. Mahatma Gandhi Sahakar SakkareKarkhane Limited, Donagapur, Bhalki. (MGSSK) Ltd 4.4 Limitation of the study:

- 20. Organization Structure In MGSSK pvt ltd Sugar Industry REVA UNIVERSITY MBA 2015-16 Page 20 The present study covers the sample sugar factories in Bidar District. The selected subject has following limitation. The study relates the selected five co-operative sugar factories in the Bidar District only. The researcher studied the functional areas like production, financial, marketing and human resource in relation to the sugar factories and its by-products developments. This study does not necessarily cover all these technical aspect of sugar factories. The period of the study is of only seven years i.e. from 2005-06 to 2012-13. Therefore time factor is the limiting factor. The conclusions drawn in this study are based on the data made available by these sugar factories. Use of statistical tools and technique has its own limitation 4.5 Research Design and Sampling: a) Sampling Design: It consists of selection of the study area and selection of the sample sugar factories. Selection of the study Area: India has emerged as one of the largest production of sugarcane and sugar in the world with highest number of sugar factories. In India, Karnataka is one of the major sugars producing State in the country and in Karnataka; Bidar District in particular, became a potential sugarcane belt area. Sugarcane occupies an important place in the economy of the district it is the most important cash crop of the District. The District as such as in the top on many indicators such as number of sugar factories, crushing capacity, cane crushed, cane recovery, Sugarcane by-product industries, etc. Bidar is the home district of the researcher, located in peninsular part of India of North-Karnataka; it was chosen on convenient bases as the study area for the purpose of the present investigation. Selection of Sample Co-operative Sugar Factories in the Study Area. The total numbers of sugar factories in Bidar District are 10 Out of 07- sugar factories in co-operative sector. Researcher is selected 5 (30%) co-operative sugar factories. It is also considered that geographical location, area, size, age, crushing

- 21. Organization Structure In MGSSK pvt ltd Sugar Industry REVA UNIVERSITY MBA 2015-16 Page 21 capacity, nature of production of by-products etc. The use of convenience sampling method was taken up for selection of the sugar factories. Map No.3.1 Map shows location of Karnataka

- 22. Organization Structure In MGSSK pvt ltd Sugar Industry REVA UNIVERSITY MBA 2015-16 Page 22 4.6 Significance ofthe study: In other countries sugar is a by-product, but in India sugar is the main product produced by sugar mills. India is producing large quantity of sugar because of our own needs, but now a day’s only sugar production is not production is not profitable for sugar mills. Sugar industry needs to increase their capacity in by products like alcohol, ethanol co-generation etc. This could be possible only through fuller and better utilization of the by-products and alternative produce, so that the higher value products are manufactured from them and sugar industry derives maximum benefit from the sugar crop. The ultimate prosperity of the Indian sugar industry depends upon diversification intonumerous avenues based on the by-products of the sugar industry. The following are reason for setting up by-product industries in India. To improve the general economy of the sugar industries and to make them financially viable. To improve the economic status of sugarcane growers and workers by way of paying higher prices for sugarcane crop. • To create more employment opportunities in the rural areas by setting up industries based on sugarcane by- products. Judiciously utilizing sugarcane crop residues and industrial effluents to produce value-added products and minimize pollution hazards. Biomass has always been an important energy source for the country considering the benefits it offers. It is renewable, widely available, carbon neutral and has the potential to provide significant employment in the rural areas. Biomass is also capable of providing firm energy. For efficient utilization of biomass, bagasse based cogeneration in sugar mills and biomass power generation have been taken up under biomass and cogeneration program me. Sugar industry has been traditionally practicing cogeneration by using bagases as a fuel. With the advancement in the technology for generation and utilization of steam at high temperature and pressure, sugar industry can produce electricity and steam for their own requirement. Ethanol which is an alternatives fuel for automobile vehicle is produced from sugarcane molasses. The bio-ethanol blending program me reduce India’s dependence of fossil fuel import, it also ensures that the nation moves towards energy efficiency. It also has other very important advantages of being the best oxidant which helps burn the petrol better when blended with it thereby reducing environmental pollution that fossil fuel are infamous for.

- 23. Organization Structure In MGSSK pvt ltd Sugar Industry REVA UNIVERSITY MBA 2015-16 Page 23 The Government of India realized the benefits of fuel ethanol use in India with the fast growing sugar industry. India being the second largest sugarcane producer in the World, it accepted that there is a huge potential of production and availability of the fuel ethanol. It was accepted by the Government in 2006, that a mandatory 5% ethanol blending with petrol (EBP) program me would directly benefit the sugarcane farmers by assuring the sugar industry a stable and reasonable return for the molasses and then passing a significant part of the same to the farmers. 4.6 Hypotheses of the study: 1. Co-operative sugar factories are suffering from the losses due to high cost of production and low productivity in relation to by-product units. 2. Low level of efficiency is found at various By-product departments. 3. The functional areas of management like production, marketing, finance and HR are weak in the by-products sample units 4. By-Products production mix is not up to the mark in sample units. 4.7 Need for the study The study is very helpful and gives needed suggestion to improve in the existing cost management philosophy .There is suitable cost management policies are needed in co-operative industries. There is a need for effective cost management Concept development and co-operative sugar industries yet to develop systematic and objective oriented cost management policies and practices. The present study which attempts to analyze the cost management policies and practices in co-operative sugar industry of Bidar district in Karnataka state. Areas of cost reduction 1.Physical parameters 1. Cane planning 2. Good sugar cane varietal mix 3. High sugar variety and high yield variety 4. Cultivation of sugar cane near factory building avoids transportation cost. 5. Raw material supply time should not cross 24 hours.

- 24. Organization Structure In MGSSK pvt ltd Sugar Industry REVA UNIVERSITY MBA 2015-16 Page 24 2.Crushing 1. Crushing should be arranged in such way that 80% sugar cane crushed in peak period i.e. (December to March)crushing should be achieved at least its installed capacity. 3.Down time. Down time stoppage will occur in following reason 1) Want cane 2) Engineering problems. 3) General periodical cleaning 4) Other reasons. The deduction of down time will enhance the productivity generally permitted down time in Karnataka is 8% 4. Total losses the permitted norm for the total loss of sugar is 1.80% 1) Loss in Bagasse : 0.60 2) Loss in Pressumd : 0.05 3) Loss in Molasses: 1.10 4) Unknown Loss: 0.05 5) Total: 1.80 . 5. Cane cost Increasing in the recovery % by reducing the total loss will ensure reduction of unit cost of production. Here the Purchase tax and Cane Cess will not be avoidable. But we can control the transport charges which could be reduced by the area of production ofsugarcane near to factory. 6. Conversion cost. Fuel, oil, lubricants and power can be reduced by preventive majors, basically now days all sugar mills produce power for their consumption. Still need to use most appropriate use of power it should be put off when machine is not in use all the department of the factory should use LED lighting in factory premises which is required that much power should be consumed and reaming power should be sold.

- 25. Organization Structure In MGSSK pvt ltd Sugar Industry REVA UNIVERSITY MBA 2015-16 Page 25 7. Repairs and maintenance: 1. Quality spare parts should be installed 2. Necessary technical up gradation of machinery should be done in time. 3. Opinion of Export should be taken about machinery life, and quality of work. 8. Administration Cost reduction. 1. Overtime should be avoided to possible extent 2. Salary and wages should be paid on scientific basis neither more nor less. 3. Free medical facilities should be provided. 4. Rent should be fixed according to Rent Control Act wherever possible. 5. Staff is the back bone of any organization enough care should be taken providing all amenities to staff. 6. Avoid unnecessary expenses each and every paisa outgoing or incoming should be accounted and most of the payment should be made account pay crossed cheque only

- 26. Organization Structure In MGSSK pvt ltd Sugar Industry REVA UNIVERSITY MBA 2015-16 Page 26 CHAPTER 5: DATA ANALYSIS AND INTERPRETATION 5.Analysis

- 27. Organization Structure In MGSSK pvt ltd Sugar Industry REVA UNIVERSITY MBA 2015-16 Page 27 In India, sugar is an essential item of mass consumption and the cheapest source of energy, supplying around 10 percent of the daily calorie intake. India is the seco nd largest producer of sugar (16.3 million ton production in 2008‐09).It, however, ranks 1 5th in export rankings (.23 million ton exports in 2008‐09) as India is the largest consume r of sugar in the world. Raw as well as refined sugar prices plunged this year on expectati on thatoutput in Brazil and India, the second‐biggest producer, will increase. Raw sugar p rices declined by 45 percent since the start of the year 2010 amid hopes that global output will rebound. Four factors determine sugar production in India: Area under sugarcane production (Max. acreage of 4.43 million hectare) Sugarcane yield per hectare (Max. yield of 71.3 tonnes per hectare) The production of sugarcane that is crushed by sugar factories in relation to the tot al sugarcane produced (Max drawl percentage = 69%) Recovery of sugar (Max recovery = 10.48%) Ethanol is being promoted as an alternative to oil. It is commercially viable, cleaner fu el but its efficiency is questionable. Ethanol promotion is primarily driven by Brazil whic h happens to be the largest consumer of ethanol. Incidentally, Brazil produces ethanol dir ectly from the sugarcane unlike many other countries which produce ethanol from molass es (a by‐product after extraction of sugar from sugarcane). Almost 60% of Brazilian cane crop is diverted to production of ethanol. Changes to emission norms under Kyoto protoc ol,increased fiscal incentives from several governments, US bill mandating ethanol use in gasoline, high oil prices are several other factors influencing ethanol production and diver ting cane from sugar to ethanol production. In October 2007, Government of India (GOI) has mandated 5% ethanol blending. India requires an estimated 550 million litres of ethan ol.GOI has also permitted companies to produce ethanol directly from sugarcane juice. Th iswill provide companies flexibility to alter the product mix between sugar and ethanol de pending on the relative demand and realisation. The Government of India (GOI) approved the National Policy on Bio‐fuels on De cember 24, 2009. The bio‐fuel policy encourages use of renewable energy resources as alt ernate fuels to supplement transport fuels (gasoline and diesel for vehicles) and proposes a target of 20 percent bio‐fuel blending (bio‐diesel and bio‐ethanol)by 2017.

- 28. Organization Structure In MGSSK pvt ltd Sugar Industry REVA UNIVERSITY MBA 2015-16 Page 28 Presently, the government is unable to implement compulsory blending of 5 perce nt ethanol in petrol (gasoline) due to the short supply of sugar molasses in 2009/10 and20 08/09because of overall low sugarcane crop production in India. Consequently, India imp orted about 280 million litres of ethanol in CY 2009 to meet the demand for industrial and potable liquor production. With a bumper sugarcane and sugar production outlook for201 0/11, the government is likely to renew its focus and implement the mandatory 5 percent ethanol blending in petrol. Industry sources report that the government is likely to takeade cision on the purchase price of ethanol for the Ethanol Blending Program (EBP). Commercial production of biodiesel in India is very small and its utilization is mo stly confined to the unorganized sector. The government’s ambitious plan of producing su fficient bio‐diesel by 2011/12 to meet its mandate of 20 percent diesel blending is unreali zed due to a lack of sufficient jatropha seeds to produce bio‐diesel. Advanced bio‐fuels in India are still at the research stage and it will take time before commercial production bec omes economically viable. 5.1 Primary Data : The primary data the researcher has been visited to all sample sugar factories as well as through discussion and observations. The researcher interview of the officials and management, by-product department heads, were organized discussion and observations Primary data has also been obtained through other methods like observation and field survey. The data about production performance, financial, marketing, and H.R. etc. it has been related with sample sugar factories and its by-products departments. 5.2 Secondary Data:

- 29. Organization Structure In MGSSK pvt ltd Sugar Industry REVA UNIVERSITY MBA 2015-16 Page 29 The researcher has collected secondary data from Annual reports, books and published literature of the sample sugar factories. For theoretical background researcher has made use of textbooks related of the sugar industry and by-products industries. Other necessary data is collected from:- Various Annual reports from the related sugar industry. Reports of Mahatma Gandhi Sahakar Sakkare Karkhane Kanaji. North- Karnataka. Reports of ethanol producers Association. Report of co-cogeneration producers. Books and Magazines etc. Published and unpublished research work. The Internet. Karnataka has produced the highest ever sugar production in its history and as on 15th April, 2014, it has produced 40.5 lakh tons of sugar. In the previous season, Karnataka had produced 33.5 lakh tons, but it has closed its crushing operation by now. As compared to that, 19 sugar mills continue to crush sugarcane this year.

- 30. Organization Structure In MGSSK pvt ltd Sugar Industry REVA UNIVERSITY MBA 2015-16 Page 30 Table No:1 Basic imformation of Indian Sugar Industry Particulars 2008- 09 2009-10 2010-11 2011-12 2012-13 2013-14 No of factories in operation 488 490 507 529 526 509 Cane acreage (hectors) 4415 4175 4885 5100 5279 5341 Sugar cane production (lakha Tons) 2850 2923 3424 3538 3544 3456 Molasses Production( Tons) 6542 8400 10970 11824 11744 10881 Sugar crushing capacity in percentage It is clear from above figure that, 48%. of sugar cane crushed by private sector, 47% by co-operative sector and remaining 5% by the Government sector.

- 31. Organization Structure In MGSSK pvt ltd Sugar Industry REVA UNIVERSITY MBA 2015-16 Page 31 Basic information about sugar production in Karnataka Particulars Rs/kg Sugarcane price payable for SS 2013-14 (Rs/quintal) 290 (Per Quintal) Recovery Rate 11 Sugarcane price per kg of sugar produced (Rs/kg) 26.40 Conversion cost from Sugarcane to raw sugar (Rs/kg) 3.50 Total cost of raw sugar production (Rs/kg) 29.90 Conversion cost from raw to white sugar (In Rs/kg) 2.50 Total cost of production for white sugar (Rs/kg) 32.40 Domestic ex-mill sugar price (Rs/kg) 26.10-26.60 Sweetness of sugar is not to the former or growers of sugar cane in Karnataka expected rate at which they are producing cost are not paid by the factories in time .this study is concern here how to minimize sugar manufacturing cost from factory point of view .The success of any industry or sugar manufacturing organization depend on to enhance the selling price do not decrease cost per unit manufacturing cost .but long run increasing in selling price not hold good in competitive environment so we need to survival in cut thought competition just control the cost than next step is reduce per unit cost without reducing quality. Here quality should be maintained but unit or single output cost per unit (marginal cost per unit) should be reduced possible extent using best and latest cost management techniques applied in production process. A Brief Profile of Selected Sugar Factories of Bidar District in Karnataka State: 1. . Mahatma Gandhi Sahakar Sakkare Karkhane Limited,. (MGSSK) This factory was started in the year 2003 at Donagapur, village near Bhalki taluka of Bidar district. Raw Materials: Sugarcane Installed Capacity: 2,500 Tonnes Crushing Daily (TCD) of Sugarcane. The people of Bidar District particularly the Agriculturists and Sugarcane growers are fully supporting, as their dream was came true reality. From the Co-generation unit of the sugar factory it is producing 8 MW of power per day since six years and planning to extend it to 14 MW power generation per day, to ease the power

- 32. Organization Structure In MGSSK pvt ltd Sugar Industry REVA UNIVERSITY MBA 2015-16 Page 32 situation in the State the company utilizing the 4 MW power and selling about 4 MW power to state Electricity Board. Capacity Tone cane Crushed per day 3500 TCD. 2. Bidar Sahakar Sakkare Karkhane Limited. (BSSK) The Bidar co-operative sugar factory Hallikhed was established in the year 1961- 62 under the dynamic leadership of Mr. Gurupadappa and M. Kheny. The factory started on the basis of Co-operative society system. It Estimated cost of project was 3 cores and this occupies the area around 168 acres and its crushing capacity was 1250 TCD in 1969, in the year 1991-92 It was increased to 2000 TCD. Now it is 3500TCD. This factory is located near Karanja River and it is 30 km away from Bidar and just 4 km away from the Hallikhed. The Factory has more than 1000 employees including administrator and technical experts, human resources being the most important asset of the factory. 3. NaranjaSahakarSakkareKarkhane Limited,. (NSSK). This factory was started in the year 2000 at Imampur, village near Janwada,Bidar district with a record period of 18 months. The people of Bidar District particularly the Agriculturists and Sugarcane growers are fully supporting, as their dream was came true reality. From the Co-generation unit of the sugar factory it is producing 8 MW of power per day since six years and planning to extend it to 14 MW power generation per day, to ease the power situation in the State the company utilizing the 4 MW power and selling about 4 MW power to state Electricity Board. Capacity Tone cane Crushed per. Chart.1

- 33. Organization Structure In MGSSK pvt ltd Sugar Industry REVA UNIVERSITY MBA 2015-16 Page 33 Cost Components of Co-operative Sugar mill (MGSSK) See Table -1 Source annual reports of Co-operative sugar factory It is clear from above figure 61% is cane cost,12% is Depreciation cost,11% is interest cost,10% is total conversion cost ,4% is selling , administration cost 2% is salaries ,wages , repairs and maintenance cost in total cost.

- 34. Organization Structure In MGSSK pvt ltd Sugar Industry REVA UNIVERSITY MBA 2015-16 Page 34 Table1. Cost Components of Co-operative Sugar mill (MGSSK.LTD)(Rs.In Lakhs S.no Year CaneCost TotalConversioncost Salariesandwages Depreciation RepairsandMaintenance Interest SellingandAdministration Expenses Totalcostofproduction Canecost%totalcost Totalconversioncost% totalcost Salariesandwages%to totalcost Depreciation%tototalcost RepairsandMaintenance %tototalcost Interest%tototalcost SellingandAdministration expenses%tototalcost percentage 1 2004-05 247.5 110.9 9 1.68 838.30 0.77 405.1 4 83.53 1687.47 14.64 6.58 0.10 49.6 8 0.05 240 1 4.95 100. 00 2 2005-06 1719. 25 95.26 45.07 436.57 2.53 389.1 3 135.4 7 2823.28 60.90 3.37 1.60 15.4 6 0.09 137 8 4.80 100. 00 3 2006-07 2269. 12 131.2 8 68.44 387.5 32.8 6 339.0 3 311.4 8 3539.71 64.10 3.71 1.93 10.9 5 0.93 9.58 8.80 100. 00 4 2007-08 2437. 96 337.8 1 101.9 4 648.27 0.85 466.0 3 520.9 7 4513.83 54.01 7.48 2.26 14.3 6 0.02 10.3 2 11.5 4 100. 00 5 2008-09 2518. 70 168.3 2 141.4 1 282.27 4.12 436.7 7 33.33 3584.92 70.26 4.70 4.70 3.94 7.87 0.11 0.11 12.1 8 0.93 100. 00 6 2009-10 7835. 45 1268. 60 153.0 6 267.52 33.3 3 280.8 2 75.81 9914.59 79.03 12.8 1.54 1.54 12.8 0 0.34 2.83 0.76 100. 00 7 2010-11 6114. 45 2312. 67 293.2 8 307.51 31.6 9 701.0 4 347.4 5 10108.09 60.49 22.8 8 2.90 3.04 0.31 6.94 3.44 100. 00 8 2011-12 8625. 49 1659. 81 276.4 9 376.10 137. 44 1089. 24 319.1 6 12483.73 69.09 13.3 0 2.21 3.01 1.10 8.73 2.56 100. 00 9 2012-13 1187 8.85 1485. 31 277.5 1 544.88 19.3 7 1257. 09 389.2 7 15852.28 74.93 9.37 1.75 1.75 3.4 0.12 7.93 100. 00 10 2013-14 8540. 63 1469. 68 305.7 6 497.39 96.9 4 1602. 34 378.4 5 12891.19 66.25 11.4 0 2.37 3.86 0.75 12.4 3 2.94 100. 00 Avg 61.3 7 9.5 6 2.0 6 11. 44 0.3 8 10. 87 4.3 2 100 .00

- 35. Organization Structure In MGSSK pvt ltd Sugar Industry REVA UNIVERSITY MBA 2015-16 Page 35 Chart.2 Cost components of Co-operative Sugar mill (BSSK). See Table -2 *Source annual reports of Co-operative sugar factory It is clear from above figure 69% is cane cost, 11% is interest cost, 10% is total conversion cost, 1% is selling, administration cost, 9%is salaries, wages, repairs and maintenancecost in total cost.

- 36. Organization Structure In MGSSK pvt ltd Sugar Industry REVA UNIVERSITY MBA 2015-16 Page 36 Table2. Cost Components of Co-operative Sugar mill (BSSK.LTD)Rs.In Lakhs) S.no Year CaneCost TotalConversioncost Salariesandwages Depreciation RepairsandMaintenance Interest SellingandAdministration expenses Totalcostofproduction Canecost%totalcost Totalconversioncost% totalcost Salariesandwages%to totalcost Depreciation%tototalcost Maintenance%tototalcost Interest%tototalcost SellingandAdministration expenses%tototalcost percentage 1 2004-05 1984. 68 354.8 0 391.4 3 44.37 29.5 5 1358. 70 12.95 4176.48 47.52 8.50 9.37 1.06 0.71 32.5 3 0.31 100. 00 2 2005-06 3479. 15 457.5 1 375.6 9 38.60 11.8 1 263.2 7 10.23 4636.26 75.04 9.87 8.10 0.83 0.25 5.68 0.22 100. 00 3 2006-07 3479. 15 459.1 7 528.9 1 21.00 32.1 0 411.8 0 11.33 4943.46 70.38 9.29 10.7 0 0.42 0.65 8.33 0.23 100. 00 4 2007-08 2542. 15 726.1 5 727.7 6 24.10 32.7 1 448.8 5 27.15 4528.8 56.13 16.0 3 16.0 7 0.53 0.72 9.91 0.60 100. 00 5 2008-09 2170. 69 594.5 6 718.3 7 25.63 38.5 7 559.1 4 23.44 4130.40 52.55 14.3 9 17.3 9 0.62 0.93 13.5 4 0.57 100. 00 6 2009-10 6794. 74 469.1 0 428.0 2 0.82 30.0 4 583.3 0 17.42 8323.44 81.63 5.64 5.14 0.01 0.36 7.01 0.21 100. 00 7 2010-11 5536. 39 705.1 4 310.3 8 1.02 22.1 7 930.1 3 25.80 7531.03 73.51 9.36 4.12 0.01 0.29 12.3 5 0.34 100. 00 8 2011-12 4589. 29 654.2 5 356.1 2 9.85 21.3 6 452.1 8 16.89 6099.94 75.24 10.7 3 5.84 0.16 0.35 7.41 0.28 100. 00 9 2012-13 9123. 14 1271. 37 783.0 8 8.42 42.5 0 1154. 15 15.18 12397.8 4 73.59 10.2 5 6.32 0.07 0.34 9.31 0.12 100. 00 10 2013-14 7172. 34 905.7 1 475.5 3 3.41 15.1 0 448.8 5 25.10 9046.04 79.29 10.0 1 5.26 0.04 0.17 4.96 0.28 100. 00 Avg 68.49 10. 41 8.8 3 0.3 8 0.4 8 11. 10 0.3 2 100 .00

- 37. Organization Structure In MGSSK pvt ltd Sugar Industry REVA UNIVERSITY MBA 2015-16 Page 37 Chart.3 Cost components of Co-operative Sugar mill (NSSK). See Table -2 It is clear from above figure 57% is cane cost,15% is interest cost,13% is total conversion cost ,5% is selling and administration cost ,5%issalaries ,wages cost , 4% is depreciation cost ,1% is repairs and maintenance cost in total cost.

- 38. Organization Structure In MGSSK pvt ltd Sugar Industry REVA UNIVERSITY MBA 2015-16 Page 38 Table3. Cost Components of Co-operative Sugar mill (NSSK.LTD)(Rs.In Lakhs) S.no Year CaneCost TotalConversioncost Salariesandwages Depreciation RepairsandMaintenance Interest SellingandAdministration expenses Totalcostofproduction Canecost%totalcost Totalconversioncost% totalcost Salariesandwages%to totalcost Depreciation%tototalcost Maintenance%tototalcost Interest%tototalcost SellingandAdministration expenses%tototalcost percentage 1 2004-05 4125. 23 589.2 5 350 44.37 45 1358. 70 12.95 4176.48 56.73 8.10 4.81 6.30 0.62 17.1 2 6.30 100. 00 2 2005-06 7814. 26 580.1 2 375 38.60 42 263.2 7 10.23 4636.26 69.16 5.13 3.32 4.33 0.37 12.5 0 5.19 100. 00 3 2006-07 5139. 1 459.1 7 400 21.00 50 411.8 0 11.33 4943.46 58.68 6.77 4.57 6.59 0.57 14.9 9 7.84 100. 00 4 2007-08 4974. 56 9458 450 24.10 45 448.8 5 27.15 4528.8 55.86 9.28 5.05 6.09 0.51 15.1 7 8.04 100. 00 5 2008-09 3802. 9 594.5 6 500 25.63 40 559.1 4 23.44 4130.40 51.27 10.7 8 6.74 5.96 0.54 17.0 5 7.66 100. 00 6 2009-10 4852. 12 469.1 0 525 0.82 45 583.3 0 17.42 8323.44 27.80 54.1 9 3.01 2.58 0.26 9.43 2.74 100. 00 7 2010-11 6590. 25 705.1 4 550 1.02 50 930.1 3 25.80 7531.03 61.33 9.72 5.12 3.43 0.47 16.4 3 3.50 100. 00 8 2011-12 6489. 12 654.2 5 650 9.85 55 452.1 8 16.89 6099.94 59.36 9.38 5.95 3.46 0.50 16.8 8 4.48 100. 00 9 2012-13 1206 7.1 1271. 37 800 8.42 100 1154. 15 15.18 12397.8 4 66.72 8.48 4.42 1.78 0.55 13.6 5 4.40 100. 00 10 2013-14 8214. 23 1531. 76 725 283.83 90 3688. 45 537.5 4 15070.8 1 54.50 10.1 6 4.81 1.88 0.60 24.4 7 3.57 100. 00 Avg 56.14 13. 20 4.7 8 4.2 4 0.5 0 15. 77 5.3 7 100 .00

- 39. Organization Structure In MGSSK pvt ltd Sugar Industry REVA UNIVERSITY MBA 2015-16 Page 39 ESTIMATED BUDGET INCOME FOR THE YEAR 2015-16 IN MAHATMA GANDHI SAHAKAR SAKKARE KARKHANE(N),BHALKI SL.NO. PARTICULARS AMOUNT 01 Sugar Sales(4,75,000 Qtls* Rs.2400) 11400.00 02 Molasses Sales(20,000 Mts* Rs.4500) 900.00 03 Bagasses Sales(25000 Mts*Rs.800) 200.00 04 Power Sales(70000 Units* 180 Days* Rs.3.67) 462.42 05 Other Income/Bagasses/Scrap etc, 163.00 TOTAL 13125.42 01 Total Estimated Budget income for the year2015-16 13125.42 02 Total Estimated Budget Expenditure for the year2015-16 17421.00 03 Total Estimated Budget(+)Surplus/(-)Deficit -4295.58

- 40. Organization Structure In MGSSK pvt ltd Sugar Industry REVA UNIVERSITY MBA 2015-16 Page 40 Results and interpetation : The above study highlights various aspects of cost elements. 1. Basically in sugar industry cane cost is the major component of cost of production i.e. 50% to70%. 2. MGSSK Ltd,BSSK.Ltd and NSSSK.Ltd cane cost to total cost is 61%, 69% and 57% respectively. 3. Important cost item is conversion cost it constitute 10% to15%. 4. MGSSK Ltd, BSSK.Ltd and NSSSK.Ltd conversion cost to total cost is 10%,10% and 13% respectively. 5. Another major cost item in sugar production is interest paid it constitute 10% to15%. 6. MGSSK Ltd, BSSK.Ltd and NSSSK.Ltd.Interest cost to total cost is 11%, 11% and 15% respectively. 7. Salary and wages another important cost component 2% to10%. 8. MGSSK Ltd, BSSK.Ltd and NSSSK.Ltd. Salary and wages cost to total cost is 2%, 9 % and 5% respectively. 9. Depreciation also play vital role in cost structure 12%,1% and 4% in total cost of MGSSK Ltd, BSSK.Ltd and NSSSK.Ltd respectively. 10. Selling and administration overhead also part of cost of production it constitute to total cost is 4%, 1% and 5% of MGSSK Ltd, BSSK LLtd and NSSSK.Ltd respectively.

- 41. Organization Structure In MGSSK pvt ltd Sugar Industry REVA UNIVERSITY MBA 2015-16 Page 41 CHAPTER 6: FINDINGS 6.1Findings:

- 42. Organization Structure In MGSSK pvt ltd Sugar Industry REVA UNIVERSITY MBA 2015-16 Page 42 Bio‐fuel Policy: India’s bio‐fuel policy is comprehensive and gives a broad outline to all the major areas that need attention. These guidelines have to be translated into a bio‐fuel program a nd a series of projects to reap the potential benefits. Given the vast differences in the econ omic performances and cross‐sectoral implications of ethanol and biodiesel, the bio‐fuel p olicy can serve better if these two sectors are dealt with separately. Potential for Producing Bio‐fuels: Simple natural resource accounting shows that 20% blending of ethanol with petro l can be achieved by 2017, only if sugar cane juice is converted to ethanol to supplement molasses ethanol. Sweet sorghum (SS) and tropical sugar beets (TSB) are still at the initia l stage of development and face major technological and financial constraints. About 32 million hectares of wasteland are required for biodiesel production together with yield im provements to meet a 20% blending target with petroleum diesel. However, it is unlikely that India can achieve the 20% blending target by 2017 given the current infant stage of the biodiesel industry in the country. Food Security: At the current level of productivity, a 20% blending of sugar cane based ethanol cannot be achieved without affecting the food sector. SS and TSB will also comp ete with the food sector for land and water. However, molasses based ethanol blending do es not have any impact on the food sector. If confined to wastelands and using only limite d irrigation during the establishment phase of the crops, biodiesel production will not hav e any adverse impact on the food sector. Technological Constraints: Thesugarcane sector is well organized and there are no major technological or oth er constraints, which prevent meeting the blending targets. The SS and TSB supply chains are yet to be fully developed and they face a major bottleneck at the juice extraction seg ment of the supply chain making juice extracting units financially unattractive. In contrast to sugarcane, the biodiesel supply chain is in its infancy and understanding the agronomy development of nurseries and plantations with high yielding varieties are major constrain Impact on Water:

- 43. Organization Structure In MGSSK pvt ltd Sugar Industry REVA UNIVERSITY MBA 2015-16 Page 43 Sugarcane is a water intensive crop but if confined to existing sugarcane lands or to molasses based ethanol, ethanol production will not add to the irrigation water demand. Biodiesel crops most likely will not add to the water problems if confined to limited irriga tion in the early tage of the crop establishment. Environmental Impacts: Both ethanol and biodiesel crops have limited negative environmental impacts which can be easily mitigated using available technologies and regulatory measures.Copa red to ethanol, biodiesel crops have a number of positive environmental effects and their carbon benefit potential is also large. There are no foreseeable negative social impacts of biodiesel. Financial Feasibility ‐ Ethanol: Ethanol production is not profitable under the administr atively determined price of Rs21.5/liter.The recent price revision may provide adequate profits to producers. Financial Feasibility ‐ Biodiesel: Biodiesel production is also not financially feasible un der the current pricing mechanism. The current administratively determined price of Rs26 .5/liter needs to be revised to provide financial incentives along the supply chain. Economic Feasibility Ethanol: Molasses based ethanol is economically feasible at the current price of oil and inc reases of oil prices make molasses based ethanol economically more attractive. The diver sion of ethanol from current uses in industry and as potable alcohol is not economically vi able. The cost of sugarcane juice based ethanol exceeds the social benefits, hence, sugar c ane juice ethanol is not economically justifiable. Higher oil prices do not make sugarcane juice based ethanol economically attractive. Therefore, sugarcane based ethanol will not b e economically viable even in the future. Alternative feed stocks such as TSB and SS are not economically feasible at current oil prices.Thereforethe ethanol sector should revise it s national targets to an economically beneficial target ‐ up to 5% blending only using mol asses ethanol. Economic Feasibility Biodiesel:

- 44. Organization Structure In MGSSK pvt ltd Sugar Industry REVA UNIVERSITY MBA 2015-16 Page 44 Both jatropha and pongamia provide acceptable economic returns at current oil pri ces, and an increase in the price of diesel makes biodiesel economically more attractive. E mployment generation and CDM benefits are also significant in the case of biodiesel. Therefore, the expansion of biodiesel production is socially desirable and the resul ts of this report support an aggressive program for biodiesel in India. Economy Wide Impact of Biodiesel: The Indian general equilibrium model, with only biodiesel interventions, shows th at biodiesel could provide India with an opportunity to enhance economic growth and the well‐being of rural populations. The national bio‐fuel program has the potential to create a significant number of jobs with substantial real wage increases; hence, it is a potential a venue for poverty reduction within an inclusive growth policy framework. The negative effect of the program, i.e. higher fiscal deficits, seems not to dampen the growth effect. I contrast, the 20% ethanol blending does not add much value to the economy.

- 45. Organization Structure In MGSSK pvt ltd Sugar Industry REVA UNIVERSITY MBA 2015-16 Page 45 CHAPTER 7: RECOMMENDATIONS AND CONCLUSION

- 46. Organization Structure In MGSSK pvt ltd Sugar Industry REVA UNIVERSITY MBA 2015-16 Page 46 7.1 Recommendations 1. Supply of clean and good quality sugar cane should be taken in put. 2. Cost management should be culture need to concentrate on grass root level approach not top levelapproach. 3. Need tool for Comprehensive & Sustained Cost Management Approach. 4. TQM (Total Quality Management) should be adopted for reducing cost of manufacturing. 5. Benchmarking should be followed in process costing inter factory. 6. Avoid too distance cane from factory for reducing transport cost and cane cost all three factories cane cost to total cost is within set limit only but comparatively BSSK Ltd cane cost 69% it is high reason for same it is the old factory in the district and area of operation is whole district transport cost will be more 7. Conversion cost is in set limit but can be minimized using new machinery. 8. NSSK Ltd paid more interest i.e. 15% they can avoid interest minimizing the private debt. 9. Salary and wages in case of BSSK Ltd is more i.e. 9% of total cost comparatively try to reduce it for possible extent avoid overtime and bonus to employee. 10. Depreciation play vital role cost of production in case of MGSSK Ltd it is 12% more amt they should decrease to 10% and BSSK Ltd and NSSK Ltd actual depreciation in total cost is 1% and 4% respectively at least they should maintain 10%. 11. Selling and administration expenses of MGSSK Ltd and NSSK Ltd is 4% and % 5 respectively it should be decrease to possible extent because it is more compared to BSSK Ltd.(BSSK Ltd selling and administrative cost to total cost is i.e. 1%). 12. Reduction in down time and total loss it should not cross 1.80% as industry norms fixed. 13. Administrative cost should be minimized possible extent 14. Increase the recovery of sugar from sugar cane using new machinery or new technology

- 47. Organization Structure In MGSSK pvt ltd Sugar Industry REVA UNIVERSITY MBA 2015-16 Page 47 15. Batter utilization of By Product and Joint Product more power should be generated and it should be sold 16. Install ABC inventory technique in material management department Conclusion Performance of Co-operative sugar mills is very poor when compared to international sugar industry this is basically sugar mills do not have effective cost control techniques it is better to adopt ABC (Activity Based Costing) techniques to apportion of overhead and also need to install advance machinery to get high quality sugar in less time as well as less cost most of the sugar factories are not proper utilizing the By product and joint product like ethanol, molasses, and bagasse’s ethanol can be used with petrol so sugar factories of Karnataka should adopt a long run plan to effective cost management

- 48. Organization Structure In MGSSK pvt ltd Sugar Industry REVA UNIVERSITY MBA 2015-16 Page 48 BIBLIOGRAPHY 1. www.sugarindustry.com 2. www.indianfoline.com 3. www.kar.nic.in/policynote 4. www.affa.gov.au