Amit Sharma's Pharmaceutical Production Resume

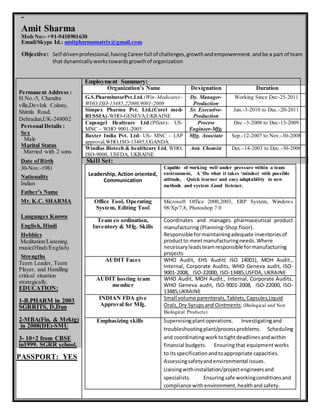

- 1. - Amit Sharma Mob No:- +91-9410901630 Email/Skype Id.: amitpharmamatrix@gmail.com Objective: Self drivenprofessional,havingCareerfull of challenges,growthandempowerment. andbe a part of team that dynamicallyworkstowardsgrowthof organization Permanent Address : H.No.-5, Chandra villa,Devlok Colony, Shimla Road, Dehradun,UK-248002 Personal Details : Sex Male Marital Status Married with 2 sons Date ofBirth 30-Nov.-1981 Nationality Indian Father’s Name Mr. K.C. SHARMA Languages Known English, Hindi Hobbies Meditation/Listening music(Hindi/English) Strengths Team Leader, Team Player, and Handling critical situation strategically. EDUCATION: 1-B.PHARM in 2003 SGRRITS, D,Dun 2-MBA(Fin. & Mrktg) in 2008(DE)-SMU 3- 10+2 from CBSE in1999. SGRR school. PASSPORT: YES Employment Summary: Organization’s Name Designation Duration G.S.PharmbutorPvt.Ltd.(Win–Medicare)– WHO,ISO-13485,22000,9001-2008 Dy. Manager- Production Working Since Dec-25-2011 Simpex Pharma Pvt. Ltd.(Corel med- RUSSIA)-WHO-GENEVA,UKRAINE Sr. Executive- Production Jan.-3-2010 to Dec.-20-2011 Capsugel Healtcare Ltd.(Pfizer)- US- MNC – WHO 9001-2005 Process Engineer-Mfg. Dec.-3-2008 to Dec-13-2009 Baxter India Pvt. Ltd- US- MNC – LSP approval,WHO,ISO-13485,UGANDA Mfg. Associate Sep.-12-2007 to Nov.-30-2008 Windlas Biotech & healthcare Ltd, WHO, ISO-9000, USFDA, UKRAINE Asst. Chemist Dec.-14-2003 to Dec.-30-2006 Skill Set: Leadership, Action oriented, Communication Capable of working well under pressure within a team environment, A ‘Do what it takes ‘mindset with possible attitude, . Quick learner and easy adaptability to new methods and system .Good listener. Office Tool, Operating System, Editing Tool Microsoft Office 2000,2003, ERP System, Windows 98/Xp/7,8, Photoshop 7.0 Team co ordination, Inventory & Mfg. Skills Coordinates and manages pharmaceutical product manufacturing (Planning-Shop floor). Responsible formaintainingadequate inventoriesof productto meetmanufacturingneeds.Where necessaryleadsteamresponsible formanufacturing projects AUDIT Faces WHO Audit, EHS Audit( ISO 14001), MOH Audit., Internal, Corporate Audits, WHO Geneva audit, ISO- 9001-2008, ISO-22000, ISO-13485,USFDA, UKRAINE AUDIT hosting team member WHO Audit, MOH Audit., Internal, Corporate Audits, WHO Geneva audit, ISO-9001-2008, ISO-22000, ISO- 13485,UKRAINE INDIAN FDA give Approval for Mfg. Small volume parenterals,Tablets,Capsules,Liquid Orals,Dry Syrupsand Ointments. (Biological and Non Biological Products) Emphasizing skills Supervisingplantoperations. Investigatingand troubleshootingplant/processproblems. Scheduling and coordinatingworktotightdeadlinesandwithin financial budgets. Ensuringthat equipmentworks to itsspecificationandtoappropriate capacities. Assessingsafetyandenvironmental issues. Liaisingwithinstallation/projectengineersand specialists. Ensuringsafe workingconditionsand compliance with environment, healthandsafety.

- 2. JOB PROFILE TILL TODAY( MANUFACTURING) : 1. Manufacturing & packing of Oral solid/liquid dosage form-Tabs, Caps, Dry Syrups &Oral Fluids ( 5 years) 2. Manufacturing & packing Topical preparations-External Liquid, Ointments and creams.(2 years) 3. Manufacturing, filling, sterilization & packing of sterile preparation - SVP/LVP.(3+1 years) 4. Manufacturing, filling, gasing, leak test and packing of Aerosols.(1 year) JOB RESPONSIBILITYWITH ABOVE PROFILE 5. Responsible for preparing Production plans as per monthly plans received. 6. Responsible for job allocation of Supervisors section wise for supervising all unit operations. 7. Responsible for indent of change parts for the Production equipments and advising Engineering department for procuring spares time to time. 8. Responsible for coordinating with Warehouse, Quality control and Quality Assurance for daily follow ups for material, analysis and documentation respectively. 9. To ensure that the products are produced and stored according to the appropriate documentation in order to obtain the required quality. 10.To approve the instructions relating t o Production operations including the in-process controls and to ensure their strict implementation. 11.To ensure that the Production Records are evaluated and signed by a designated person before they are made available to the QA Department. 12.To check the maintenance of the department, premises and equipment. 13.To do and ensure the appropriate process validations and calibrations of control equipments. are performed and recorded and the reports made available. 14.Implement New System and Technologies as required.May train new staff members in process and procedures. Work with project team members to analyze their requirements Project Undertaken A - IN CAPSUGEL HEALTHCARELTD 1. Technology transfer – Value in Process(recuperation of Hard gelatin capsule shells) and systemup gradation - 15 days – CHINA –SUZHOU Plant( Successfully Implemented in India within Time framed-3 months ). 2. Machine Mechanic – Gelatin Tanks washing and cleaning M/C commissioning Mr. Gary from Belgium Plant 3. Leadership Project- Gelatin Batch Manufacturing process training to employees, who don’t have exposure to SCADA( 1 Month). B - In BAXTER INDIA PVT.LTD. 1. PRODUCTIVITYIMPROVEMENT: Part ofTeam to increase Dialysis soln. Ringer lactate soln. Batch size from 25KL to 30 KL. Successful trial batches taken & implementation. C - In ATLAS LABS. AND PHARMACEUTICALS: 1. MACHINE COMMISIONING: Tablet section, Ointment section, Capsule section with QA dept.

- 3. TRAININGS 1- EHS 2- Process flow- From URS to User end -Capsugel 3- GMP Aspects ( CALGS) 4- QA Aspect ( CALGS) 5- Leadership in Action Achievements 1-Successful implementation of Tech. Transfer from Capsugel – Suzhou – China to Capsugel- India Plant of Empty Hard Gelatin capsule Recuperation. 2-Represents Production during WHO- GENEVA pre-audit and clear that audit with 01 minor point in SIMPEX Pharma Pvt. Ltd.(COREL –MED). 3-On the go, from project to production, first taking pilot batches and then final production. 4- Got man of the match in Cricket tournament final match of 5 institutes and we won that Trophy Declaration: I hereby to confirm that all Information given in my Resume are true and Authenticate through my Knowledge. THANKING YOU DATED 10/07/15 PLACE: Rudrapur .Uttarankhand (AMIT SHARMA)