Drill Rig Drive Spindle Laser Clad

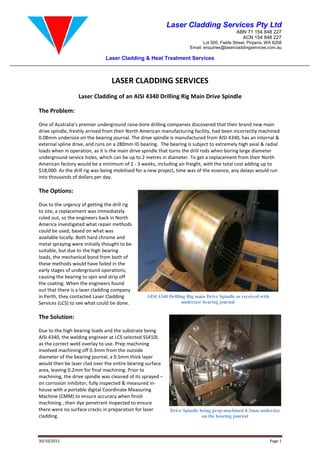

- 1. Laser Cladding & Heat Treatment Services 30/10/2015 LASER CLADDING SERVICES Laser Cladding of an AISI 4340 Drilling Rig The Problem: One of Australia’s premier underground raise drive spindle, freshly arrived from their North American manufacturing facility 0.08mm undersize on the bearing journal. The drive spindle is m external spline drive, and runs on a loads when in operation, as it is the main drive spindle that turns underground service holes, which can be up to 2 metres in diameter. To get a replacement from their American factory would be a minimum of 2 $18,000. As the drill rig was being mobilised for a new project, time was of the essence, into thousands of dollars per day. The Options: Due to the urgency of getting the drill rig to site, a replacement was immediately ruled out, so the engineers back in North America investigated what repair methods could be used, based on what was available locally. Both hard chrome and metal spraying were initially thought to be suitable, but due to the high bearing loads, the mechanical bond from both of these methods would have failed in the early stages of underground operations causing the bearing to spin and strip off the coating. When the engineers found out that there is a laser cladding company in Perth, they contacted Laser Cladding Services (LCS) to see what could be done. The Solution: Due to the high bearing loads and the substrate being AISI 4340, the welding engineer at LCS selected SS410L as the correct weld overlay to use. Prep machining involved machining off 0.3mm from the outside diameter of the bearing journal, a 0.5mm thick layer would then be laser clad over the entire bearing surface area, leaving 0.2mm for final machining. Prior to machining, the drive spindle was cleaned of its sprayed on corrosion inhibitor, fully inspected & house with a portable digital Coordinate Machine (CMM) to ensure accuracy when finish machining , then dye penetrant inspected to ensure there were no surface cracks in preparation for laser cladding. Laser Cladding Services Pty Ltd Lot 500, Fields Email: enquiries@lasercladdingservices.com.au Laser Cladding & Heat Treatment Services LASER CLADDING SERVICES Laser Cladding of an AISI 4340 Drilling Rig Main Drive Spindle One of Australia’s premier underground raise-bore drilling companies discovered that their brand new ly arrived from their North American manufacturing facility, had been incorrectly machined journal. The drive spindle is manufactured from AISI 4340, and runs on a 280mm ID bearing. The bearing is subject to extremely high axial & radial loads when in operation, as it is the main drive spindle that turns the drill rods when boring large diameter underground service holes, which can be up to 2 metres in diameter. To get a replacement from their American factory would be a minimum of 2 - 3 weeks, including air-freight, with the total cost adding up to ,000. As the drill rig was being mobilised for a new project, time was of the essence, any Due to the urgency of getting the drill rig to site, a replacement was immediately the engineers back in North repair methods available locally. Both hard chrome and re initially thought to be suitable, but due to the high bearing loads, the mechanical bond from both of these methods would have failed in the early stages of underground operations, causing the bearing to spin and strip off s found out that there is a laser cladding company in Perth, they contacted Laser Cladding Services (LCS) to see what could be done. and the substrate being AISI 4340, the welding engineer at LCS selected SS410L Prep machining machining off 0.3mm from the outside 0.5mm thick layer the entire bearing surface area, leaving 0.2mm for final machining. Prior to cleaned of its sprayed – inspected & measured in- oordinate Measuring to ensure accuracy when finish dye penetrant inspected to ensure in preparation for laser AISI 4340 Drilling Rig main Drive Spindle as received undersize bearing journal Drive Spindle being prep-machined 0.3mm undersize on the bearing journal Laser Cladding Services Pty Ltd ABN 71 154 848 227 ACN 154 848 227 Lot 500, Fields Street, Pinjarra, WA 6208 enquiries@lasercladdingservices.com.au Page 1 Drive Spindle bore drilling companies discovered that their brand new main , had been incorrectly machined anufactured from AISI 4340, has an internal & The bearing is subject to extremely high axial & radial the drill rods when boring large diameter underground service holes, which can be up to 2 metres in diameter. To get a replacement from their North total cost adding up to any delays would run AISI 4340 Drilling Rig main Drive Spindle as received with undersize bearing journal machined 0.3mm undersize on the bearing journal

- 2. Laser Cladding & Heat Treatment Services 30/10/2015 The Result: The Drive Spindle was prep-machined, laser clad, same day, which allowed the drilling rig to be fully assembled the repair bill coming in at approximately 9% of a replacement spindle client. For more information please visit Laser Cladding Drive Spindle set up to be Laser Clad Completed Laser Clad AISI 4340 Drive Spindle prior to finish machining Laser Cladding Services Pty Ltd Lot 500, Fields Email: enquiries@lasercladdingservices.com.au Laser Cladding & Heat Treatment Services machined, laser clad, finished machined and re-dimensionally che same day, which allowed the drilling rig to be fully assembled and mobilised to site with minimal delay. With the repair bill coming in at approximately 9% of a replacement spindle, it was a successful outcome for the please visit Laser Cladding Services at www.lasercladdingservices.com.au Spindle set up to be Laser Clad Laser Cladding Drive Spindle with SS410L Completed Laser Clad AISI 4340 Drive Spindle prior to finish machining Drilling Rig main Drive Spindle ready to be returned to the customer Laser Cladding Services Pty Ltd ABN 71 154 848 227 ACN 154 848 227 Lot 500, Fields Street, Pinjarra, WA 6208 enquiries@lasercladdingservices.com.au Page 2 dimensionally checked all in the with minimal delay. With , it was a successful outcome for the www.lasercladdingservices.com.au Laser Cladding Drive Spindle with SS410L Drilling Rig main Drive Spindle ready to be returned to the customer