Report

Share

Download to read offline

Recommended

Recommended

More Related Content

What's hot

What's hot (12)

HTR India - Products - Wire Wound Resistors - Silicone Coated Resistors - HFA...

HTR India - Products - Wire Wound Resistors - Silicone Coated Resistors - HFA...

Tech Bulletin DCLEG - 10000 An Overview of Thermal Spray Processes at DCL Eng

Tech Bulletin DCLEG - 10000 An Overview of Thermal Spray Processes at DCL Eng

Viewers also liked

Viewers also liked (8)

Guide to understanding welding procedure specification (wps

Guide to understanding welding procedure specification (wps

Similar to Weld Torch Setting Gauge Improvement

Similar to Weld Torch Setting Gauge Improvement (20)

IRJET- Experimental Investigation on Autogenous Tungsten Inert Gas

IRJET- Experimental Investigation on Autogenous Tungsten Inert Gas

Various approaches to Eliminate MIG Welding and Defects occurring in DT cap F...

Various approaches to Eliminate MIG Welding and Defects occurring in DT cap F...

WQD2011 - INNOVATION - EMAL - Torque measuring device

WQD2011 - INNOVATION - EMAL - Torque measuring device

IRJET-Experimental Study on Flexural Behaviour of Cold Formed Hollow Flanged ...

IRJET-Experimental Study on Flexural Behaviour of Cold Formed Hollow Flanged ...

EXPERIMENTAL OPTIMIZATION OF MILD STEEL ON TIG WELDING

EXPERIMENTAL OPTIMIZATION OF MILD STEEL ON TIG WELDING

Study of Ball Valve and Design of Thickness of Shell and Flange

Study of Ball Valve and Design of Thickness of Shell and Flange

INCREASED PRODUCTIVITY AND SPEED WITH DIGITALLY CONTROLLED SOFTWARE BASED MIG...

INCREASED PRODUCTIVITY AND SPEED WITH DIGITALLY CONTROLLED SOFTWARE BASED MIG...

As-Welded Tube Securing DOM-Like Dimensional Accuracy

As-Welded Tube Securing DOM-Like Dimensional Accuracy

Weld Torch Setting Gauge Improvement

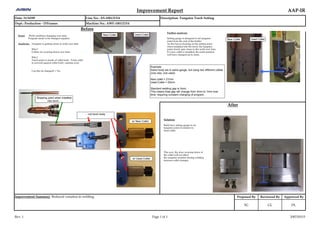

- 1. Improvement Report AAP-IR Further analysis: Issue: Weld condition changing over time. Program needs to be changed regulary Setting gauge is designed to set tungsten point from the end of the holder. Analysis: Tungsten is getting closer to weld over time As this has no bearing on the setting point when installed into the torch, the tungsten Why? point slowly gets closer to the weld over time. Collets are wearing down over time If a new collet is installed, the point position will have changed up to 3mm. Why? Touch point is inside of collet body. Front collet is screwed against collet body, causing wear. Can this be changed? = No. Solution: Build new setting gauge to set tungsten point in relation to front collet. This way, the slow wearing down of the collet will not affect the tungsten position during welding between collet changes. Improvement Summary: Reduced variation in welding. Approved ByReviewed ByProposed By SG GL DL Before After Description: Tungsten Torch SettingDate: 31/10/09 Dept.: Production - D/Frames Line No.: AS-1001/2/3/4 Machine No.: AWE-1001/2/3/4 New Collet Used Collet New Collet Used Collet Stopping point when installed into torch... …not torch body. w/ New Collet w/ Used Collet Example: Same body set in same gauge, but using two different collets (one new, one used) New collet = 21mm Used Collet = 23mm Standard welding gap is 3mm. This means thae gap will change from 3mm to 1mm over time, requiring constant changing of program. Rev: 1 Page 1 of 1 2007/05/15