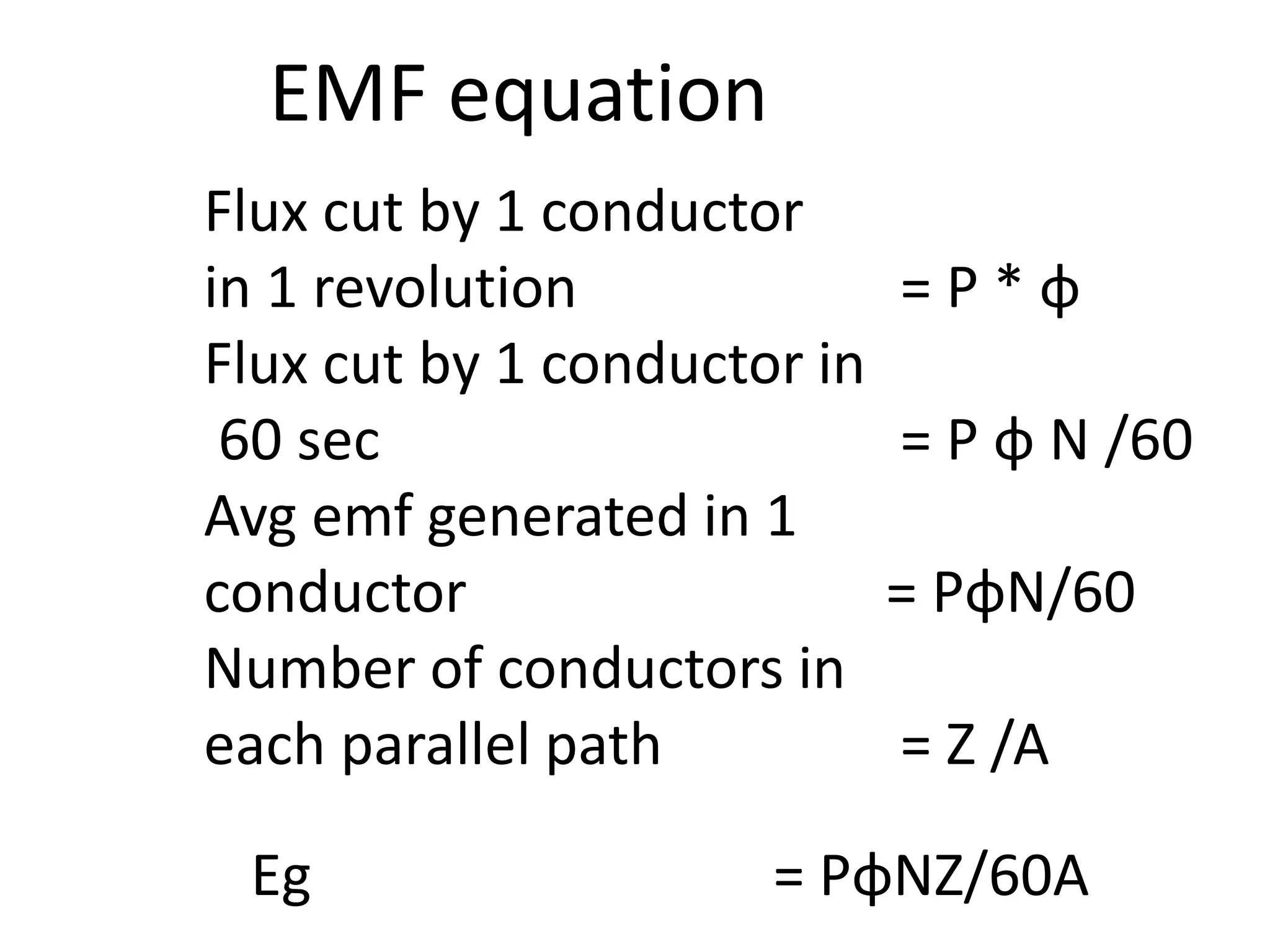

The document provides an overview of DC machines, detailing their construction, components such as yoke, poles, field winding, armature, commutator, and brushes, as well as working principles and applications. It explains the types of DC motors including shunt, series, and compound, along with their operational characteristics and starter types. Key concepts include torque, electromotive force (emf), and specific applications for different motor types in industrial settings.