FinalProjectDesignDiary (1)

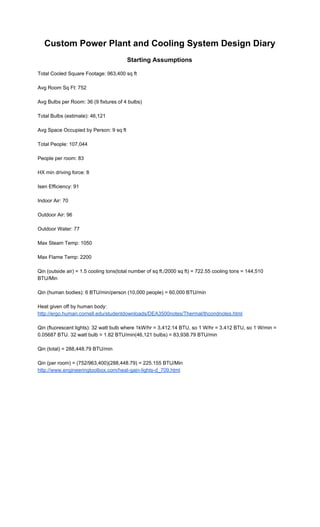

- 1. Custom Power Plant and Cooling System Design Diary Starting Assumptions Total Cooled Square Footage: 963,400 sq ft Avg Room Sq Ft: 752 Avg Bulbs per Room: 36 (9 fixtures of 4 bulbs) Total Bulbs (estimate): 46,121 Avg Space Occupied by Person: 9 sq ft Total People: 107,044 People per room: 83 HX min driving force: 8 Isen Efficiency: 91 Indoor Air: 70 Outdoor Air: 96 Outdoor Water: 77 Max Steam Temp: 1050 Max Flame Temp: 2200 Qin (outside air) = 1.5 cooling tons(total number of sq ft./2000 sq ft) = 722.55 cooling tons = 144,510 BTU/Min Qin (human bodies): 6 BTU/min/person (10,000 people) = 60,000 BTU/min Heat given off by human body: http://ergo.human.cornell.edu/studentdownloads/DEA3500notes/Thermal/thcondnotes.html Qin (fluorescent lights): 32 watt bulb where 1kW/hr = 3,412.14 BTU, so 1 W/hr = 3.412 BTU, so 1 W/min = 0.05687 BTU. 32 watt bulb = 1.82 BTU/min(46,121 bulbs) = 83,938.79 BTU/min Qin (total) = 288,448.79 BTU/min Qin (per room) = (752/963,400)(288,448.79) = 225.155 BTU/Min http://www.engineeringtoolbox.com/heat-gain-lights-d_709.html

- 2. REFRIGERATION CYCLE Within the Room Max Mass Flow Rate for Air: 163.424 lb/min Airspeed: 700ft/min (~7.95 mph) Volumetric Flow (exit): 2100ft^3/min Air Cooling -Enthalpy of entering air @70degrees F = 127.2 -Enthalpy of exiting air @50degrees F = 122.4 -Change in Enthalpy = -4.8 -Mass flow rate = (225.155 BTU/min)/(4.8 BTU/lbm) = 46.91 lbm/min. -Airspeed entering Air Handler: Volumetric Flow Rate =(mass flow rate/molecular weight)RT/P = (46.91/28.97)(10.73)(530)/14.7 = 626.5 cu. ft./min = 208.8 ft/min = 2.373mph -Airspeed exiting Air Handler: Volumetric Flow Rate = (mass flow rate/molecular weight)RT/P = (46.91/28.97)(10.73)(510)/14.7 = 602.795 cu. ft./min = 200.932 ft/min = 2.283mph Process of choosing values We know that s must be constant 1-2 Pressure must be constant 2-3 h must be constant 3-4 Pressure must be constant 4-1 Thus, we will choose a temp/pressure at 1 that gives an s (as a vapor) that can be replicated as a superheated vapor at 2. 3 will have an enthalpy, reached as a sat. liquid at the same pressure as 2. 4 will have the same enthalpy as 3, which will be replicated by having a mixture with the same enthalpy as 3 and pressure as 1. Evaporator -At Position 4 -Quality = 0.2363 -Temperature = 15.37 degrees F -Enthalpy = 37.869 (using h = (1-x)hf + xhg) -Pressure = 30 psi -At Position 1 -Quality = 1 -Temperature = 15.37 degrees F -Enthalpy = 105.32 -Pressure = 30 psi -Entropy = 0.22383 -Change in Enthalpy across Evaporator = (105.32-37.869) = +67.451 BTU/lbm -Mass Flow Rate of R134a = (225.155 BTU/min)/ (67.451 BTU/lbm) = 3.3381 lbm/min Compressor -At Position 1 -Quality = 1 -Temperature = 15.37 degrees F -Enthalpy = 105.32 -Pressure = 30 psi -Entropy = 0.22383

- 3. -At Position 2 -Quality = SH -Temperature = 88.3 degrees F (found using linear interpolation to Produce entropy equal to that found at Position 1) -Enthalpy (ideal)= 116.326 (found using linear interpolation to discover the value at 88.3 degrees) -Pressure = 100 psi -Mass Flow Rate = 3.3381 lbm/min -Entropy (ideal) = 0.22383 Condenser -At Position 2 -Quality = SH -Temperature = 88.3 degrees F -Enthalpy (ideal) = 116.326 -Enthalpy (real) = 117.415 This is derived from the facts that W-ideal = (mass flow rate) (h2-ideal - h1), the isentropic efficiency is 91%, Isentropic Efficiency = W-ide, Efficiency = W-ideal/W-real that W-real = (mass flow rate)(h2-real - h1). W-ideal = 3.3381(116.326 - 105.32) = 36.739. Isentropic Efficiency = 0.91 = W-i/W-r = 0.91 = 37.212/W-r, which gives W-real = 40.373 W-real = (mass flow rate)(h2-real - h1) 40.373 = 3.3381(h2-real - 105.32) H2-real = 117.415 -Pressure = 100 psi -Mass Flow Rate = 3.3381 lbm/min -Entropy (ideal) = 0.22383 -At Position 3 -Quality = 0 --Enthalpy = 37.869 -Pressure = 100 psi -Temperature = 79.12 -At Position 4 -Quality = 0.2363 -Temperature = 15.37 degrees F -Enthalpy = 37.869 (using h = (1-x)hf + xhg) -Pressure = 30 psi NOTES: Across 4-1, 67.451 BTU/lbm are gained Across 2-3, 79.546 BTU/lbm are lost Qin = QL = 225.155 BTU/min Qout = QH = 265.533 BTU/min Air across 7-8 Has same mass flow rate of 49.91 lbm/min as indoors 265.533 BTU/min = (mass flow rate)(Cp)(change in temp) → (46.91)0.24(change in temp) = 265.533 → Change in temp = 23.58532296. Thus, temp @ 8 = 119.585323 degrees F COP: 225.155/40.373 = 5.576 Work required to power one 752 ft^2 room: 40.373 BTU/min = 0.952 hp = 0.7099 kW Work required to power campus: 963,400/752 = 1281.12 rooms. Round up to 1282 Rooms. 40.373(1282)= 51,758.186 BTU/min = 1,220.424 hp = 910.1 kW

- 4. POWER GENERATION: BRAYTON-RANKINE CYCLE Brayton Cycle Given Facts -Across 5-6, Isentropic Compression -Across 6-7, Constant-pressure Heat Addition -7-8,Isentropic Expansion -8-5, Constant-pressure Heat Rejection -Pressure Ratio = rp =P2/P1; the higher this is, the greater the efficiency. Generally ranges from 11 to 16 -Thermal Efficiency = Wnet/Qin; shoot for above 45% (preferably 50%) -Wnet must = 51,758.186 BTU/min Compressor (14:1 Compression Ratio) At Position 5 (Air) -Pressure = 14.7 psi -Temperature = 556 degrees Rankine (96 degrees F) At Position 6 (14:1 Compression Ratio) -Pressure = 205.8 psi -Temperature (ideal) = found using the formula T6/T5 = (P6/P5)^(k-1)/k, with k = 1.4. T6 = T5(P6/P5)^(k-1)/k → T6 = 556(205.8/14.7)^ (1.4-1)/1.4 = 1181.789 degrees Rankine -Change in Enthalpy (Work-ideal): 0.24(1181.789-556) = 150.1894 -Temperature (real) = found knowing that isentropic efficiency is capped at 0.91, and thus Work-real = Work-ideal/0.91 = 165.0433, and since Work-real = Cp(T6r-T5), 165.0433 = 0.24(T6r-556) ---> T6r = 1243.68 Combustion Chamber At Position 6 -Pressure = 205.8 psi -Temperature = 1243.68 At Position 7 -Pressure = 205.8 psi -Temperature = 2660 degrees Rankine -Change in Enthalpy = 0.24 (2660-1243.68) = 339.92 BTU/lbm = Qin = QH Gas Turbine At Position 7 -Pressure = 205.8 psi -Temperature = 2660 degrees Rankine At Position 8 -Pressure = 14.7 psi -Temperature (ideal) → T8 = T7(P8/P7)^((1.4-1)/1.4) = 2660 (14.7/205)^(.4/1.4) = 1251.4586 degrees Rankine -Change in Enthalpy (Work-ideal) = 0.24(2660-1251.4586) = 338.05 -Temperature (real) = found knowing that isentropic efficiency is capped at 0.91, and thus Work-real = Work-ideal(0.91) = 307.625, and since Work-real = Cp(T7-T8r), 307.625 = 0.24(2660-T8r) ---> T8-real = 1378.22723 Total System-Work-net = Work-out-real - Work-in-real = 307.625 - 165.0433 = 142.5817 BTU/lbm -Thermal Efficiency = Work-net/Qin = 142.5817/339.92 = 0.41946 Rankine Cycle

- 5. Given Facts -Across 1-2, Isentropic Compression -Across 2-3, Constant-pressure Heat Addition -3-4,Isentropic Expansion -4-1, Constant-pressure Heat Rejection Max steam temp: 1050 From Position 8 to Position 9 (which has the same temp as 5), the change in enthalpy is 0.24(1378.22723-556) = 197.3345 BTU/lbm, which is the Qin for the Rankine Cycle. 197.3345 BTU/lbm(111.2lbm/min), we get 21,943.5964 BTU/min for Qin. Compressor At Position 1 -Pressure = 14.709 psi -Temperature = 212 degrees F -Specific Volume = 0.01671 -Entropy = 0.31222 -Enthalpy = 180.21 -Quality = 0 At Position 2 -Pressure = 200 psi -Temperature = 212 degrees -Work-ideal, pump = Work-ideal = (spec. vol @1) (P2-P1)(conversion factor) = 0.01671(200-14.709)(.185) = 0.5725 BTU/lbm -Quality = Compressed Liquid -Work-real (pump) = 0.5725/0.91 = 0.62912 BTU/lbm -Enthalpy (real) → Work-real = (h2-real - h1) → 0.62912 = h2-real-180.21 → h2-real = 180.839 BTU/lbm Heat Exchanger At Position 2 -Pressure = 200 psi -Temperature = 212 degrees -Enthalpy = 180.839 BTU/lbm At Position 3 (superheated) -Pressure = 200 psi -Temperature = 550 degrees F -Enthalpy = 1296 BTU/lbm -Entropy = 1.6516 -Change in Enthalpy (h2 to h3) = 1115.161 BTU/lbm = Qh -Quality = SH vapor -Determine Mass Flow Rate: 21,943.5964 BTU/min for Qh / 1115.161 = 19.6775 lbm/min Steam Turbine At Position 3 (superheated) -Pressure = 200 psi -Temperature = 550 degrees F -Enthalpy = 1296 BTU/lbm -Entropy = 1.6516 At Position 4 -Pressure = 14.709 psi -Temperature = 212

- 6. -Enthalpy = Found using quality --> h = (1-x)hf + xhg = (1-0.927)180.21 + 0.927(1150.3) = 1079.48343 BTU/lbm -Entropy = 1.6516 -Quality = x = (entropy - entropy of saturated liquid @ psi/ (entropy of mixture @ psi) = (1.6516 -0.31222)/1.44427 = 0.927 -Work (ideal) Across Turbine = h3-h4 = 1296 - 1079.48343 = 216.517 BTU/lbm -Work (real) Across Turbine = 0.91 (216.517) = 197.03047 BTU/lbm -Work (net) = 197.03047 - 0.62912 = 196.40135 BTU/lbm -Enthalpy (real) = 196.40135 = 1296 - h4-real → 1099.59865 Condenser At Position 4 -Pressure = 14.709 -Temperature = 212 -Enthalpy = 1099.59865 BTU/lbm At Position 1 -Pressure = 14.709 psi -Temperature = 212 degrees F -Enthalpy = 180.21 -Change in Enthalpy (Ql) = 919.38865 -Thermal Efficiency = 1- Ql/Qh = 1-(919.38865/115.161) =0.17556 TOTAL SYSTEM NET OUTPUT For the combined cycle we add the Work-net-Brayton to the product of (Rankine mfr/Brayton mfr)(Work-net-Rankine) → 142.5817 + (19.6775/111.2)(196.40135) = 177.3361 BTU/lbm Thermal Efficiency = Wnet/Qin = 177.3361/339.92 = 0.52 Now, these BTU/lbm figures are in terms of fuel lbm. To get the necessary output, we will divide the total energy needs, rounded up to 57,760 BTU/min, by this Wnet for the Brayton-Rankine cycle. 57,760/177.3361 = 325.71 lbm/min fuel. Now, we need to maintain the ratio of (water mass flow rate)/(fuel mass flow rate), which was originally 19.6775/111.2 = 0.176956. New water mass flow rate = 0.176956(325.71) = 57.64 lbm/min FINAL SPECS -Fuel Mass Flow Rate: 325.71 lbm/min -Total Output: 57,760 BTU/min = 1015.601 kW = 1.0156 MW -Thermal Efficiency: 52% -Coefficient of Performance: 5.576 Cost Analysis: If the Brayton were fueled by Compressed Natural Gas, which has an energy density of 22,268 BTU/lbm, and this design only requires an energy density of 339.92 BTU/lbm, only a ratio of 339.92/22,268 = 0.0153 CNG/Air is needed. Thus, only 0.0153 (325.71 lbm/min) = 4.983363 lbm/min of CNG is needed. Rounding up to 5.0 lbm/min CNG to account for system inefficiencies, and converting to ft^3 → (5.0 lbm/min)(1 ft^3/0.05 lbm) = 100 ft^3/min [drawn from EngineeringToolbox.com, http://www.engineeringtoolbox.com/gas-density-d_158.html]. During one hour of this powerplant’s operation, 1,015.601 kW/hr are produced, consuming 6,000 ft^3 of CNG at an estimated cost of $3.54/1,000 ft^3 [drawn from the US Energy Information Administration, https://www.eia.gov/dnav/ng/hist/n3035us3m.htm], for a total cost of $21.24. This translates to a cost of approximately $0.021 per kW/hr. This is significantly less that the $0.044 per kW/hr that is charged, on average, for industrial uses in Lake Charles [drawn from ElectricityLocal.com http://www.electricitylocal.com/states/louisiana/lake-charles/] Per kW/hr, this represents a cost savings of over 52.27%