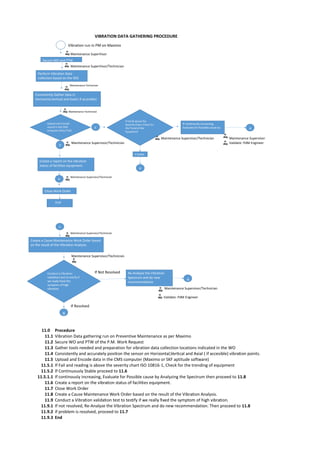

Process flow chart vibration data gather

•

2 likes•598 views

Report

Share

Report

Share

Download to read offline

Recommended

Recommended

More Related Content

Featured

Featured (20)

Product Design Trends in 2024 | Teenage Engineerings

Product Design Trends in 2024 | Teenage Engineerings

How Race, Age and Gender Shape Attitudes Towards Mental Health

How Race, Age and Gender Shape Attitudes Towards Mental Health

AI Trends in Creative Operations 2024 by Artwork Flow.pdf

AI Trends in Creative Operations 2024 by Artwork Flow.pdf

Content Methodology: A Best Practices Report (Webinar)

Content Methodology: A Best Practices Report (Webinar)

How to Prepare For a Successful Job Search for 2024

How to Prepare For a Successful Job Search for 2024

Social Media Marketing Trends 2024 // The Global Indie Insights

Social Media Marketing Trends 2024 // The Global Indie Insights

Trends In Paid Search: Navigating The Digital Landscape In 2024

Trends In Paid Search: Navigating The Digital Landscape In 2024

5 Public speaking tips from TED - Visualized summary

5 Public speaking tips from TED - Visualized summary

Google's Just Not That Into You: Understanding Core Updates & Search Intent

Google's Just Not That Into You: Understanding Core Updates & Search Intent

The six step guide to practical project management

The six step guide to practical project management

Beginners Guide to TikTok for Search - Rachel Pearson - We are Tilt __ Bright...

Beginners Guide to TikTok for Search - Rachel Pearson - We are Tilt __ Bright...

Process flow chart vibration data gather

- 1. VIBRATION DATA GATHERING PROCEDURE Vibration run in PM on Maximo Maintenance SuperVisor Maintenance SuperVisor/Technician Maintenance Technician Maintenance Technician Maintenance Supervisor/Technician Maintenance Supervisor Maintenance Supervisor/Technician Validate: PdM Engineer Maintenance Supervisor/Technician Maintenance Supervisor/Technician Maintenance Supervisor/Technician If Not Resolved Maintenance Supervisor/Technician Validate: PdM Engineer If Resolved 11.0 Procedure 11.1 Vibration Data gathering run on Preventive Maintenance as per Maximo 11.2 Secure WO and PTW of the P.M. Work Request 11.3 Gather tools needed and preparation for vibration data collection locations indicated in the WO 11.4 Consistently and accurately position the sensor on Horizontal,Vertical and Axial ( if accesible) vibration points. 11.5 Upload and Encode data in the CMS computer (Maximo or SKF aptitude software) 11.5.1 If Fail and reading is above the severity chart ISO 10816-1, Check for the trending of equipment 11.5.2 If Continuously Stable proceed to 11.6 11.5.1.1 If continously increasing, Evaluate for Possible cause by Analyzing the Spectrum then proceed to 11.8 11.6 Create a report on the vibration status of facilities equipment. 11.7 Close Work Order 11.8 Create a Cause Maintenance Work Order based on the result of the Vibration Analysis. 11.9 Conduct a Vibration validation test to testify if we really fixed the symptom of high vibration. 11.9.1 If not resolved, Re-Analyze the Vibration Spectrum and do new recommendation. Then proceed to 11.8 11.9.2 if problem is resolved, proceed to 11.7 11.9.3 End Secure WO and PTW Perform Vibration Data collection based on the WO Consistently Gather data in Horizontal,Vertical and Axial ( if accesible) Upload and Encode record in the CMS computer (Pass/ Fail) F P if Fail & above the Severity Chart, Check for the Trend of the Equipment If continously increasing, Evaluate for Possible cause by If Stable P A Create a report on the vibration status of facilities equipment. End A Create a Cause Maintenance Work Order based on the result of the Vibration Analysis Close Work Order B Conduct a Vibration validation test to testify if we really fixed the symptom of high vibration B Re-Analyze the Vibration Spectrum and do new recommendation A