Recommended

More Related Content

Similar to SI58_SKETCHES_EVAL

Similar to SI58_SKETCHES_EVAL (20)

Design, Application & Installation of Custom Clamps - July

Design, Application & Installation of Custom Clamps - July

Design, Application & Installation of Custom Clamps - March

Design, Application & Installation of Custom Clamps - March

Pipe Clamp Design, Application & Installation - November

Pipe Clamp Design, Application & Installation - November

Design, Application & Installation of Pipe Clamps Webinar

Design, Application & Installation of Pipe Clamps Webinar

Spencer Turbine - Vacuum and Low Pressure Air Tubing

Spencer Turbine - Vacuum and Low Pressure Air Tubing

Pipe line activities To know about fabrication and modifications work Instal...

Pipe line activities To know about fabrication and modifications work Instal...

More from Kevin Wilson

More from Kevin Wilson (20)

SI58_SKETCHES_EVAL

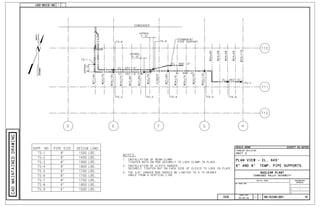

- 7. BILL OF MATERIAL Evaluator: Kevin Wilson – Field Engineer Date: 9/6/11 Unit: 2 Building: Turbine Elevation: 649’ Description of Material Order: Material for temporary support of 6” & 8” pipe between Col. Rows T10 & T11 & D & H. Materials: Item No. Req’d Description 1 6 Adjustable Clevis Hanger, Anvil Fig. 260 for 8” Pipe, Plain Finish 2 16 ¾” Flat Washer, Mat’l: F436 3 24 ¾” Heavy Hex Nut, Mat’l: A563 4 8 ¾” Fully Threaded Round Bar, 16 Ft. Lg., Mat’l: A36 (Cut as Required) 5 5 Universal Beam Clamp, Anvil Fig. 292, Size 4 for ¾” Rod, Plain Finish 6 3 Universal Beam Clamp, Anvil Fig. 292, Size 5 for ¾” Rod, Plain Finish 7 1 Standard Riser Clamp, Anvil Fig. 40 for 8” Pipe, Mat’l: Carbon Steel, Plain Finish 8 2 Adjustable Clevis Hanger, Anvil Fig. 260 for 6” Pipe, Plain Finish 9 16 Rod Coupling, Anvil Fig. 135, for ¾” Rod, Straight, Plain Finish

- 8. FIELD ENGINEERING EVALUATION – SI58 Page 1 of 1 Evaluator: Kevin Wilson – Field Engineer Date: 8/24/11 Unit: 2 Building: Turbine Elevation: Floor El. 649’ Location: Between Col. Rows “D” and “H” and Col. Rows “T9” and “T11” References: 1. 3BW0404-OO-01 - Mechanical Drains and Vents & Misc. Piping 2. 3BW0404-OO-42 - Mechanical Drains and Vents & Misc. Piping Problem Description: There is an 8” Pipe running from condenser at a location approx. 16’ West of Col. Row “E” to the south and then parallel to Col Row “T11” then thru a penetration in the floor to El. 629’. The pipe has no permanent or temporary supports installed. There are only cables and turnbuckles installed. There is also a 6” pipe that runs parallel to the 8” pipe. The 6” pipe has some permanent supports installed, but it lacks about 3 of them. It is also suspended by cables. Evaluation Summary: The piping is 8” Sch. 120 which weighs 60.63 lbs./lin. ft. The 6” piping is assumed to be Sch. 120 as well and weighs 36.39 lbs/ lin. ft. The loads are calculated based on those assumptions. The loads calculated for each support are shown on SI58_Sketch_1. New supports should be installed as shown on the attached sketches.