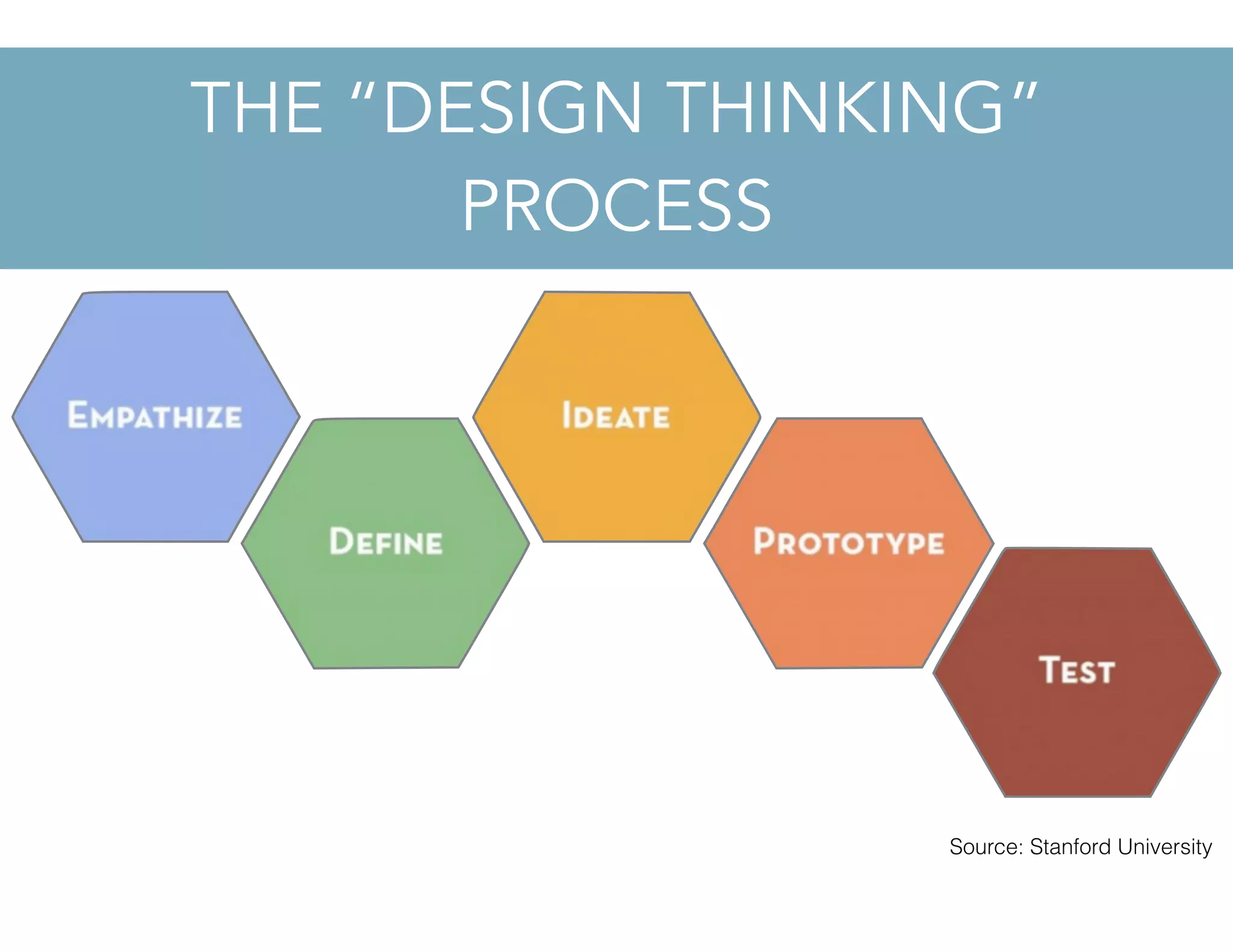

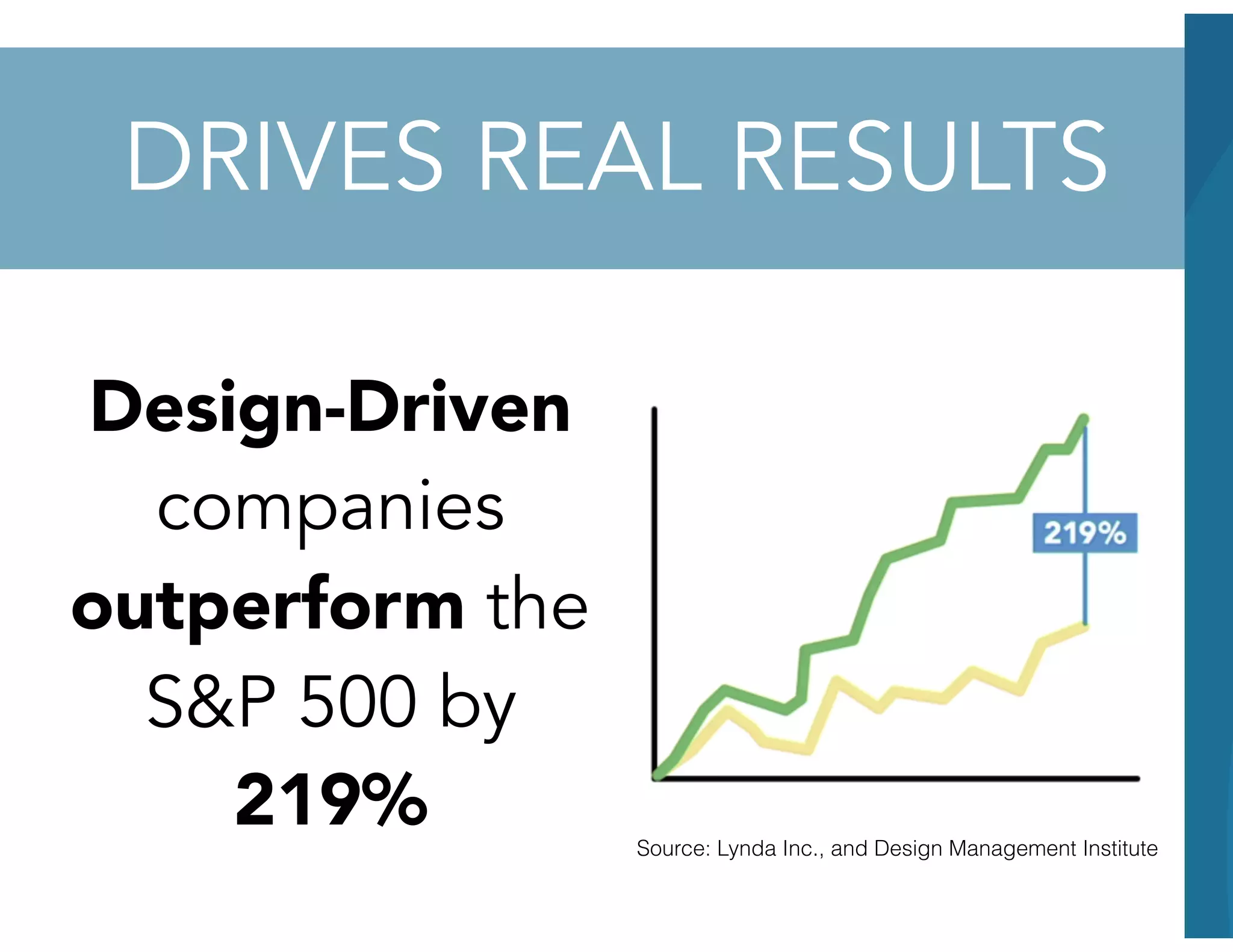

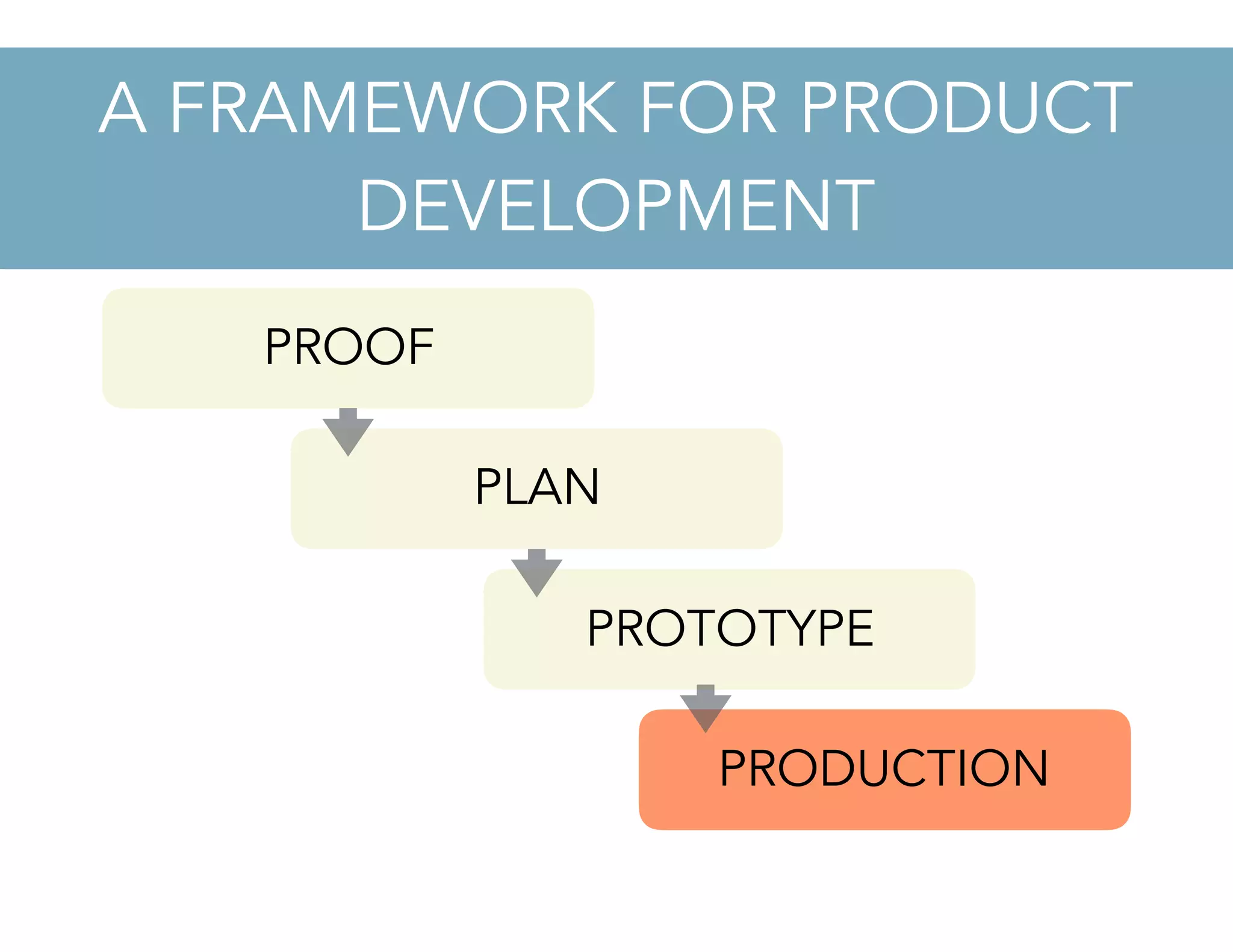

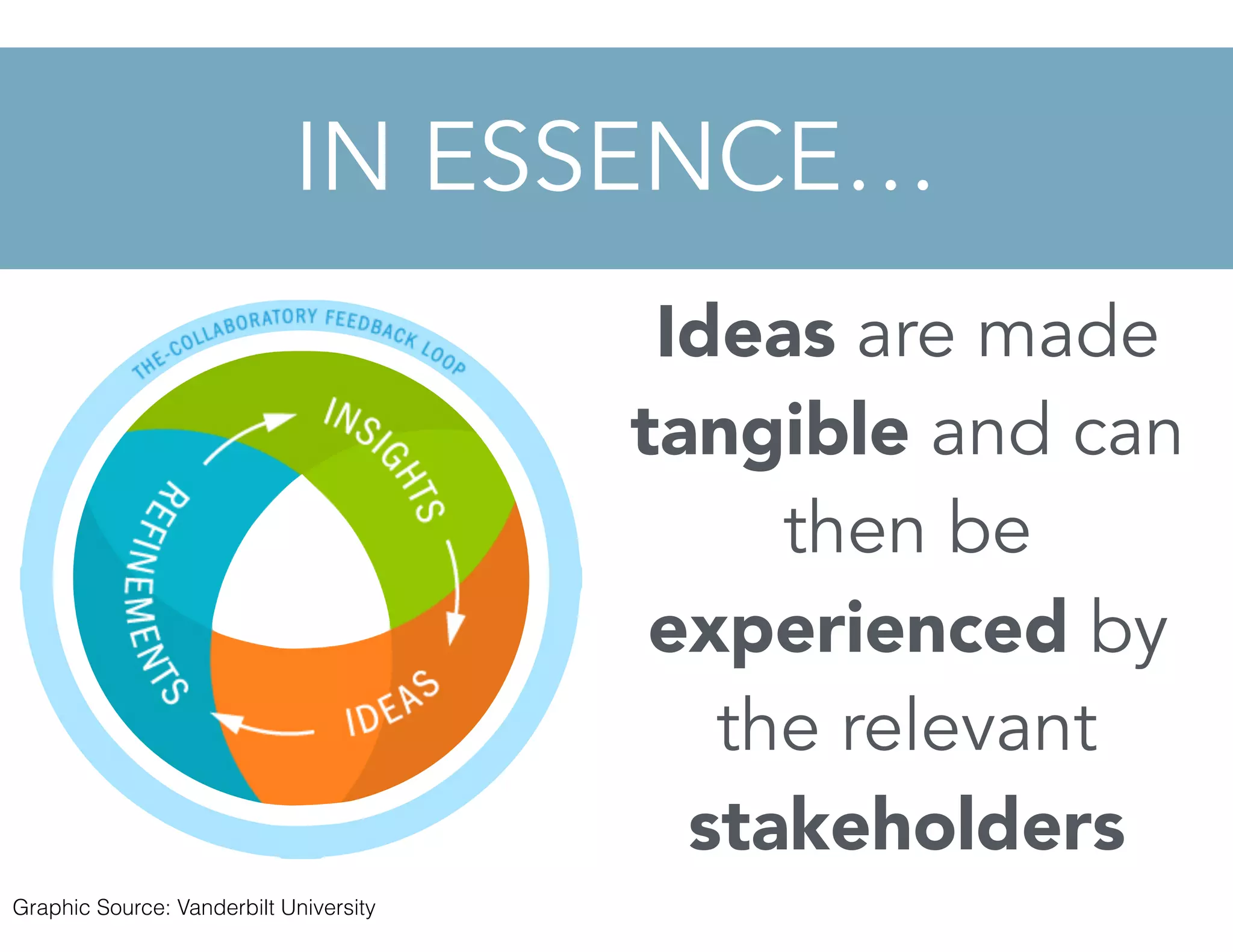

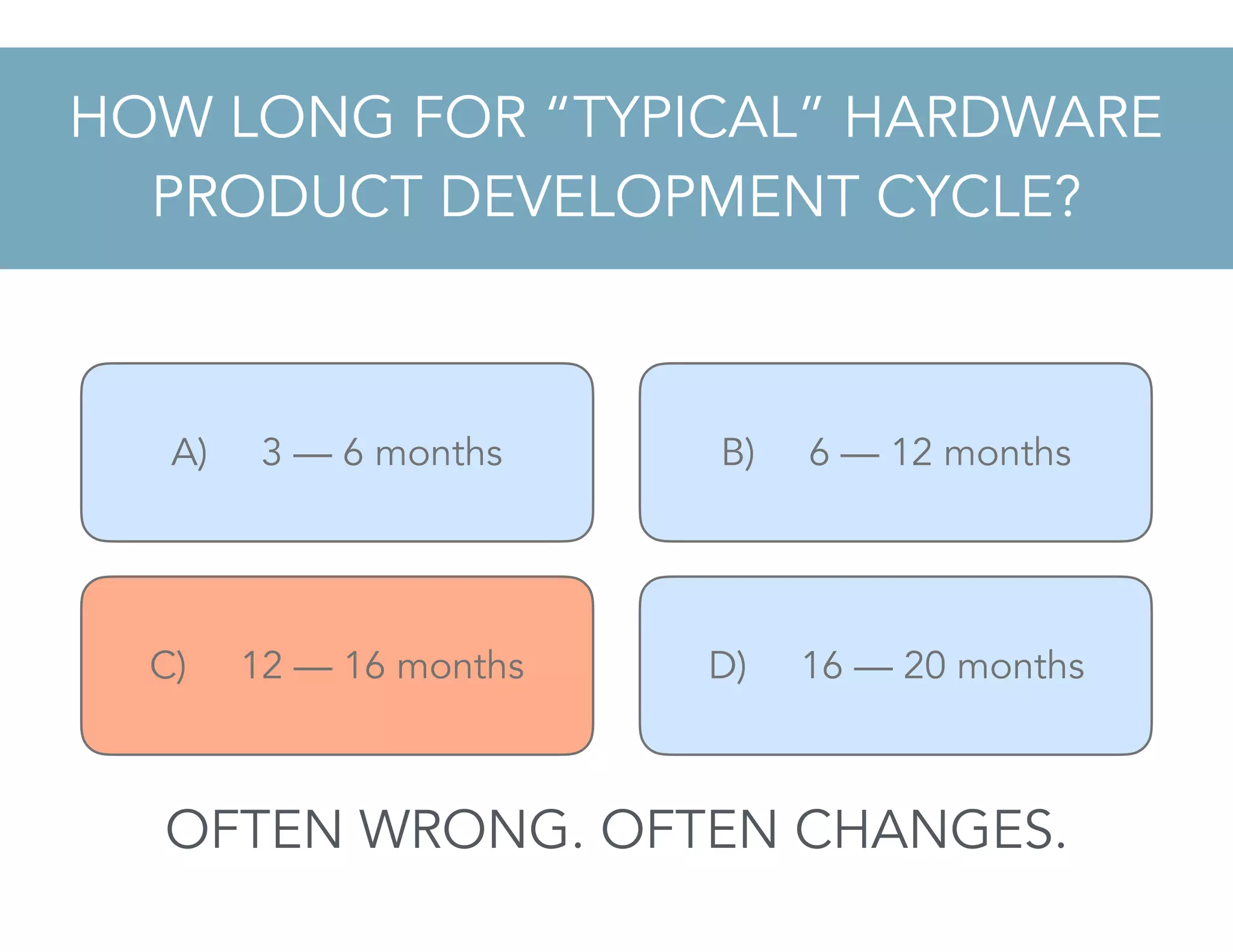

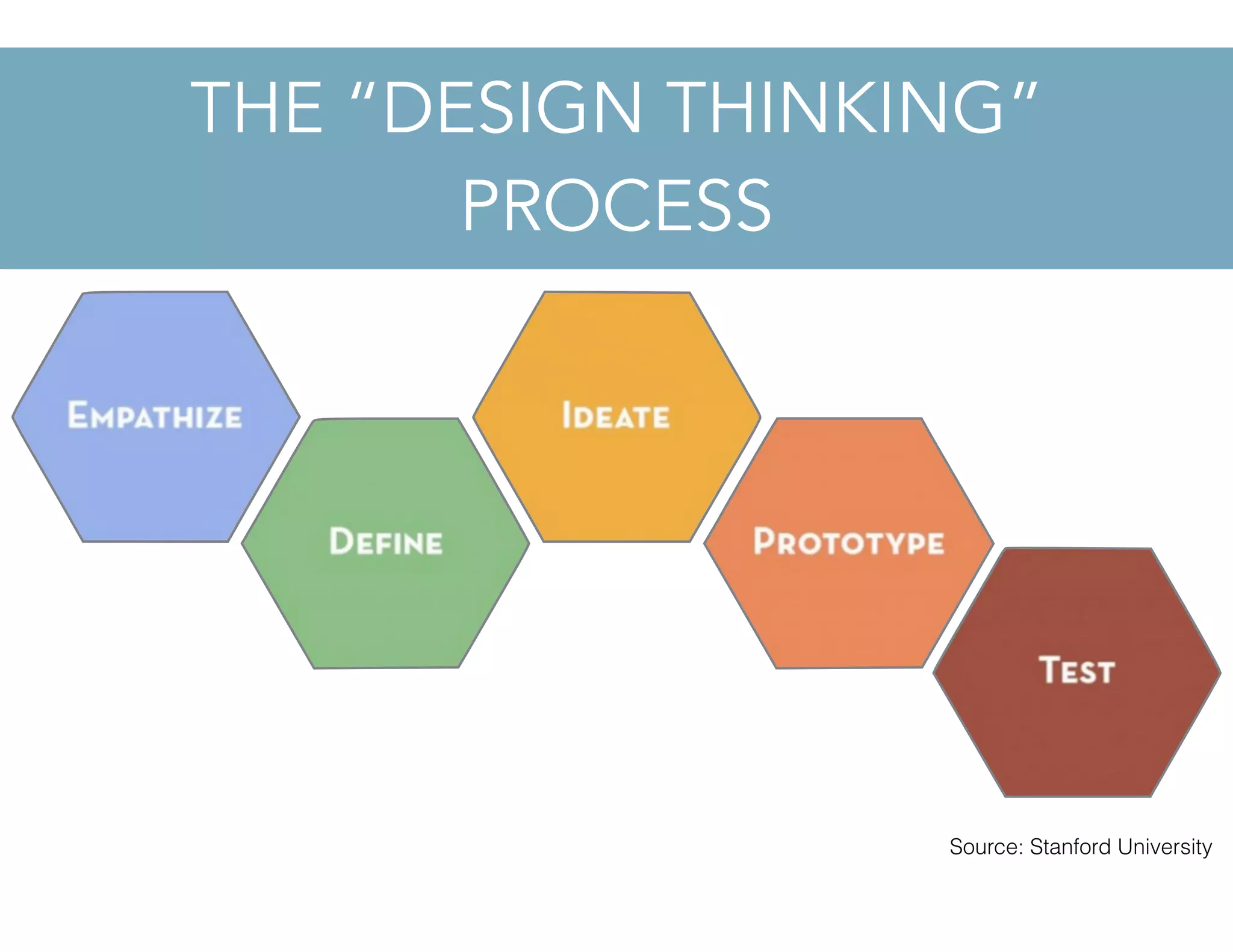

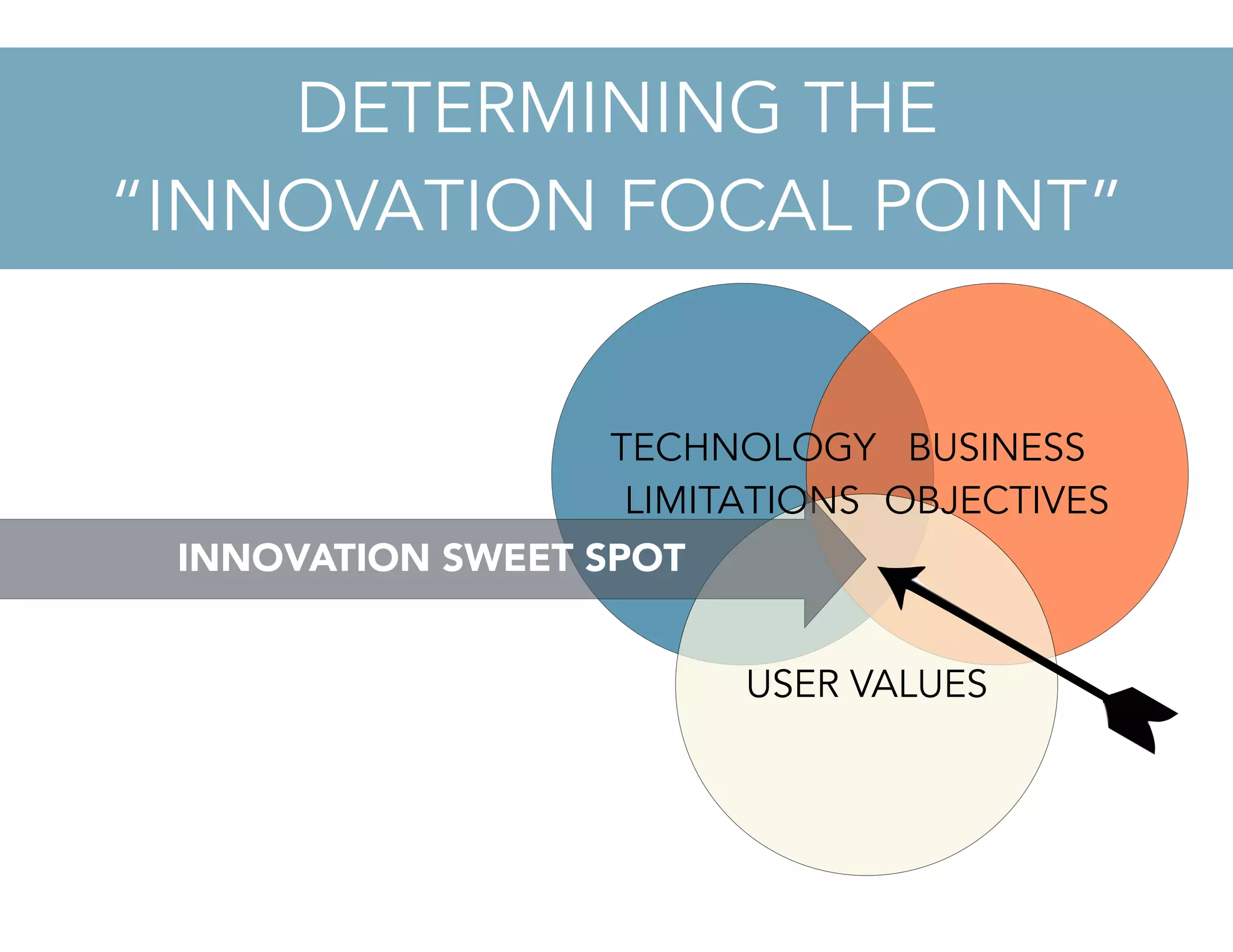

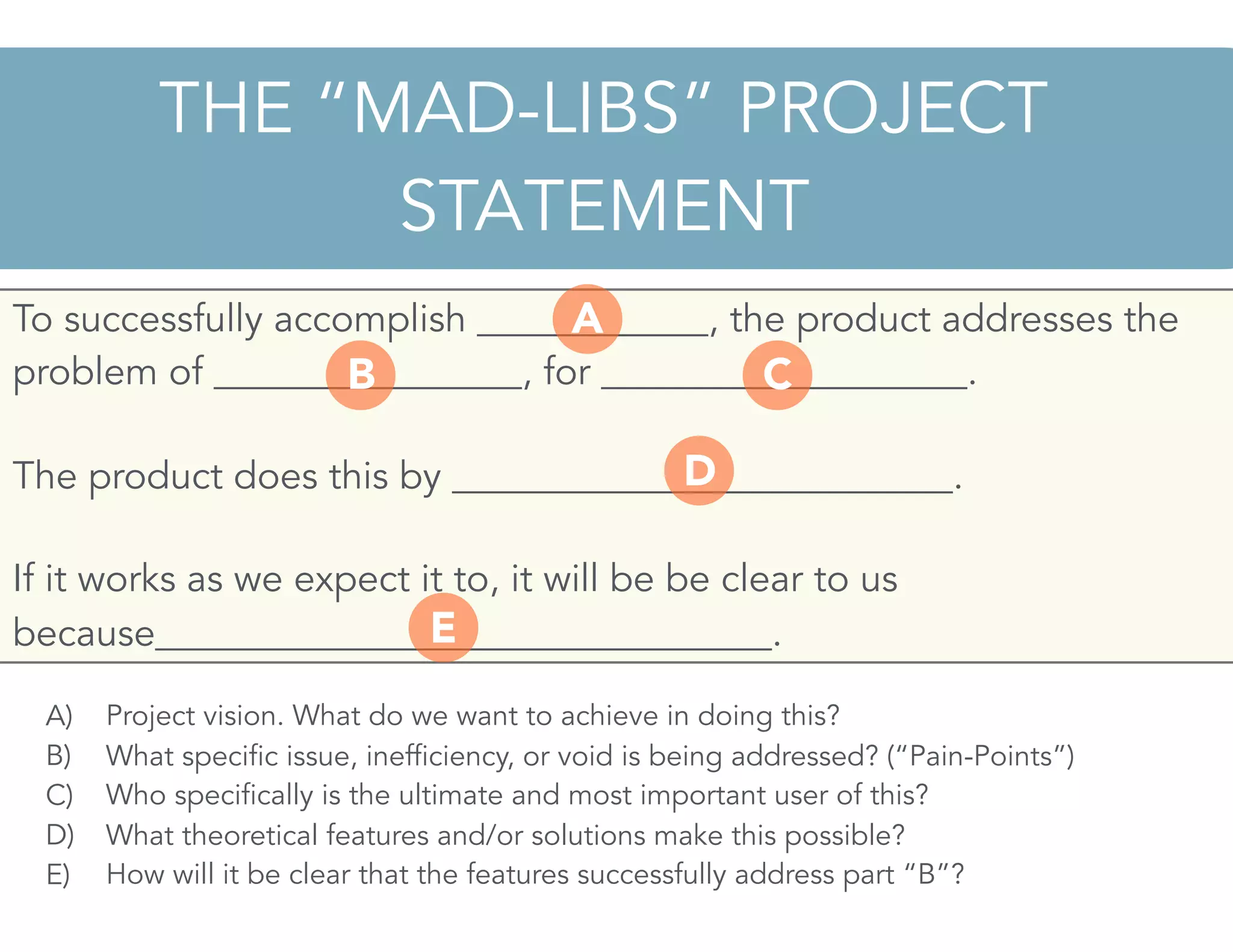

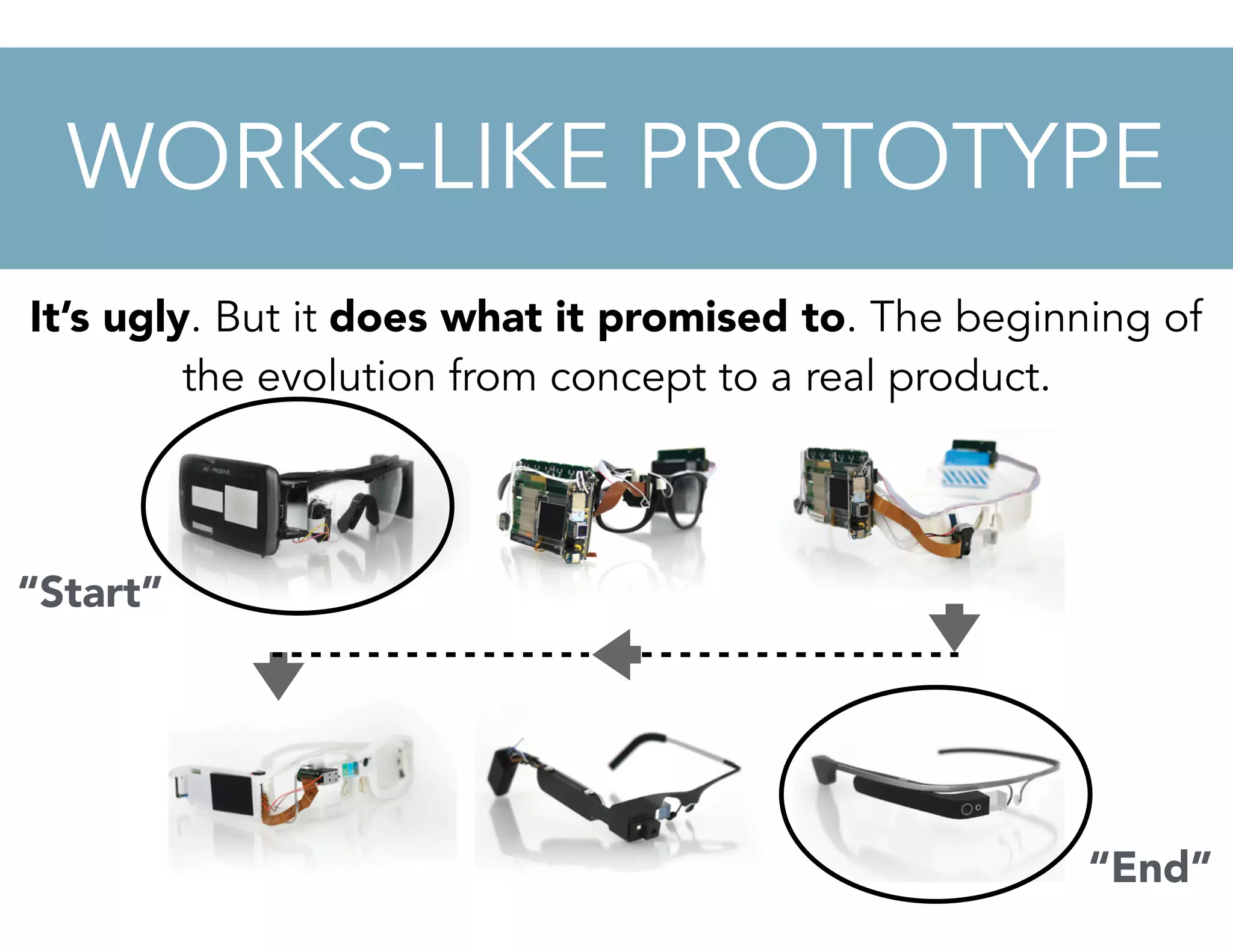

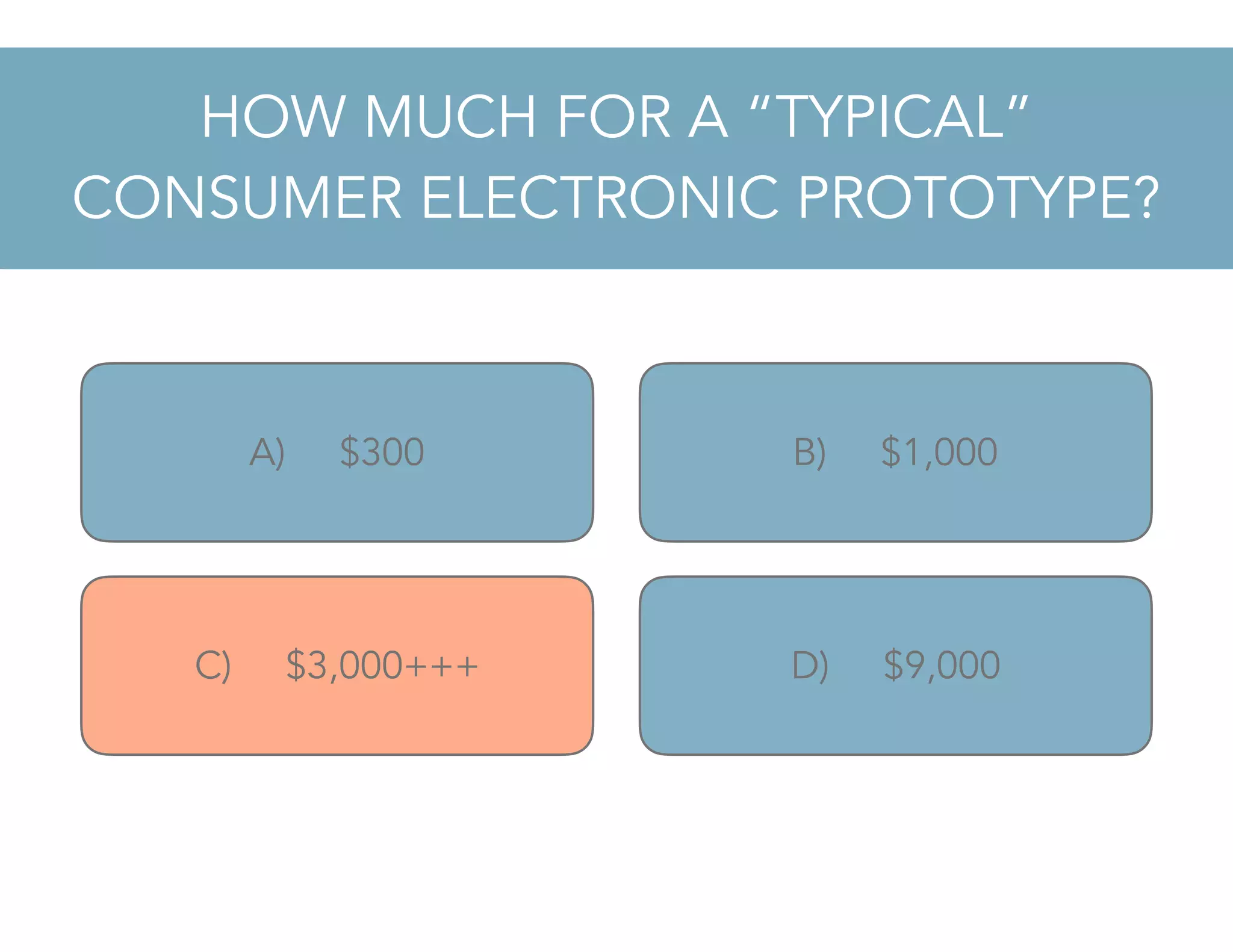

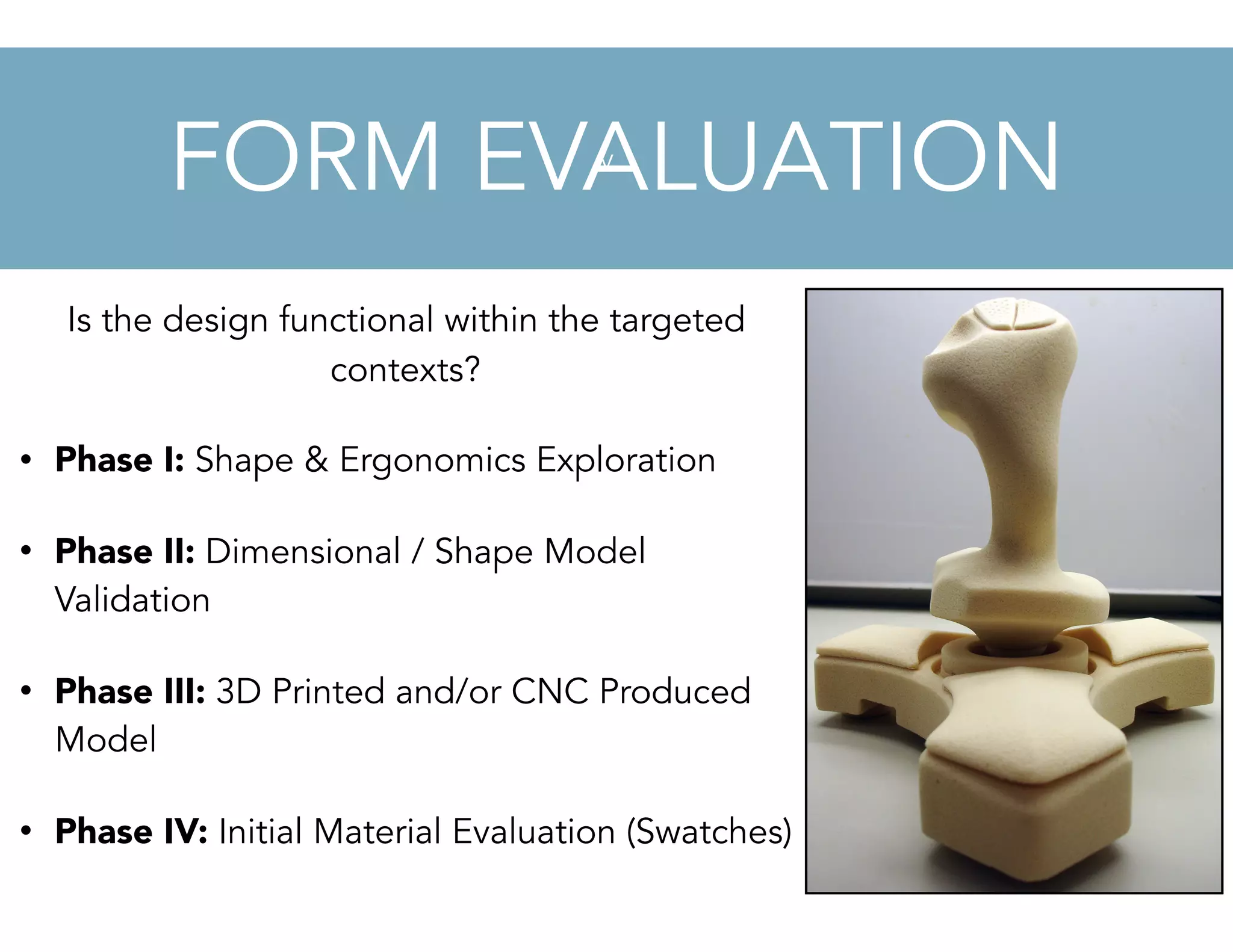

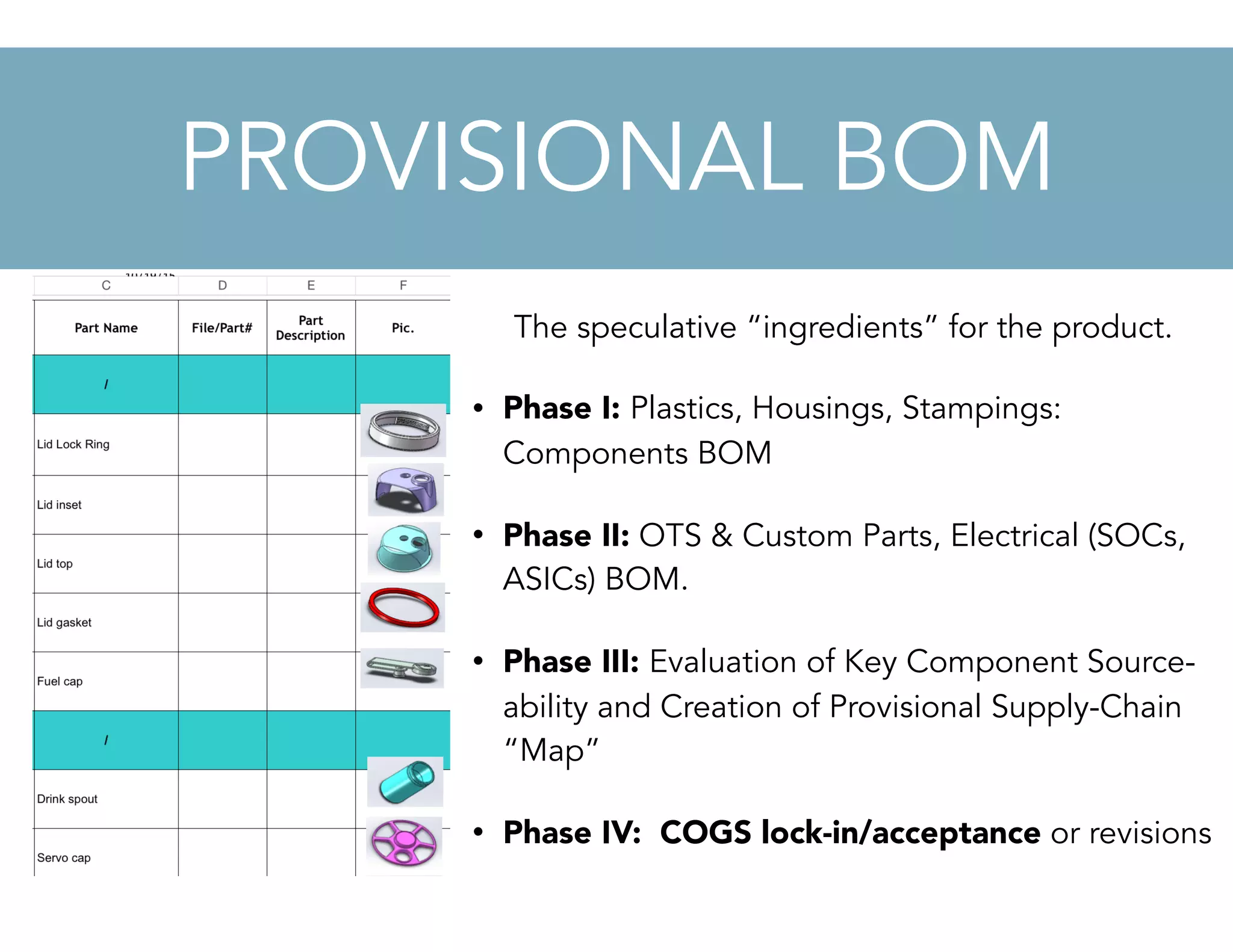

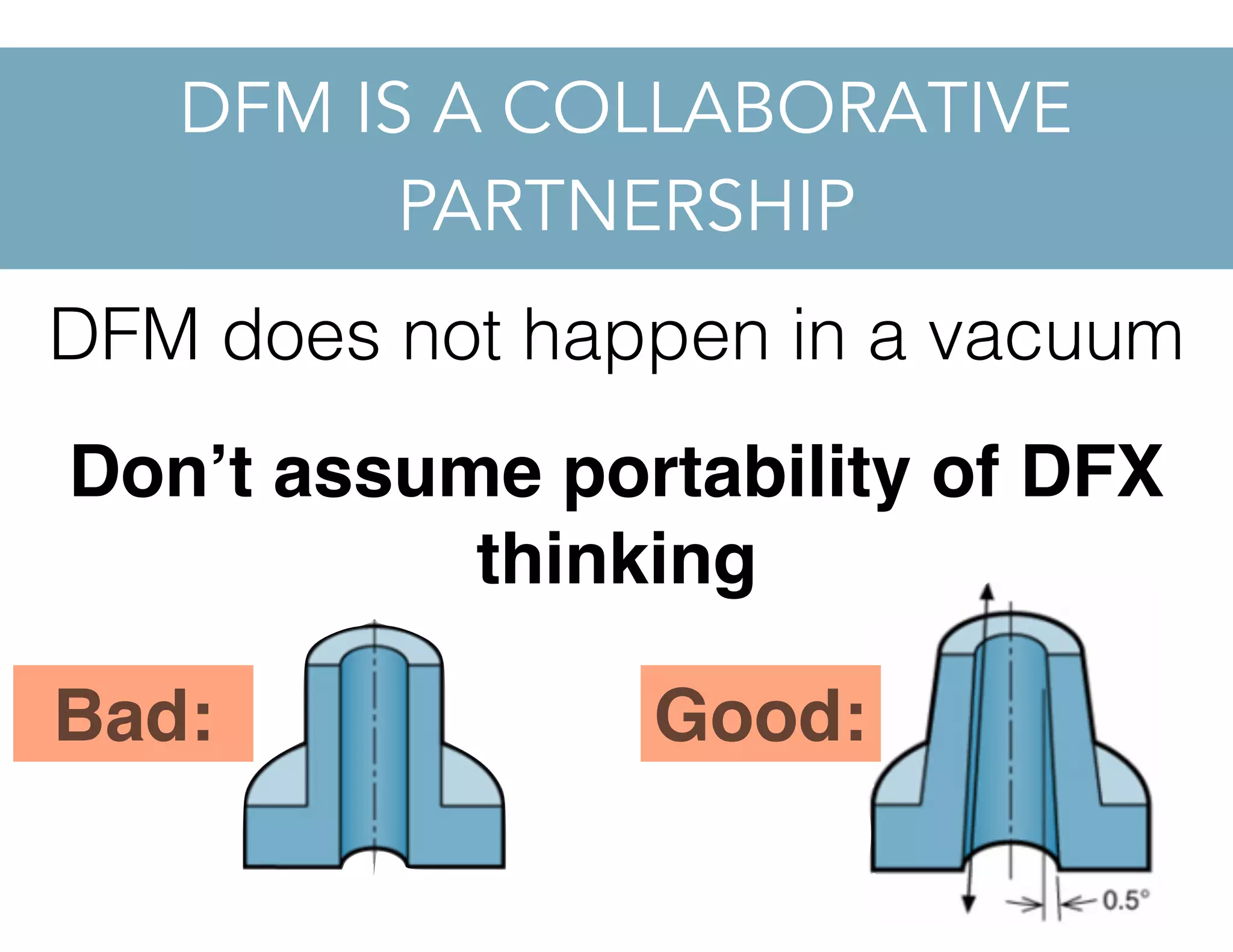

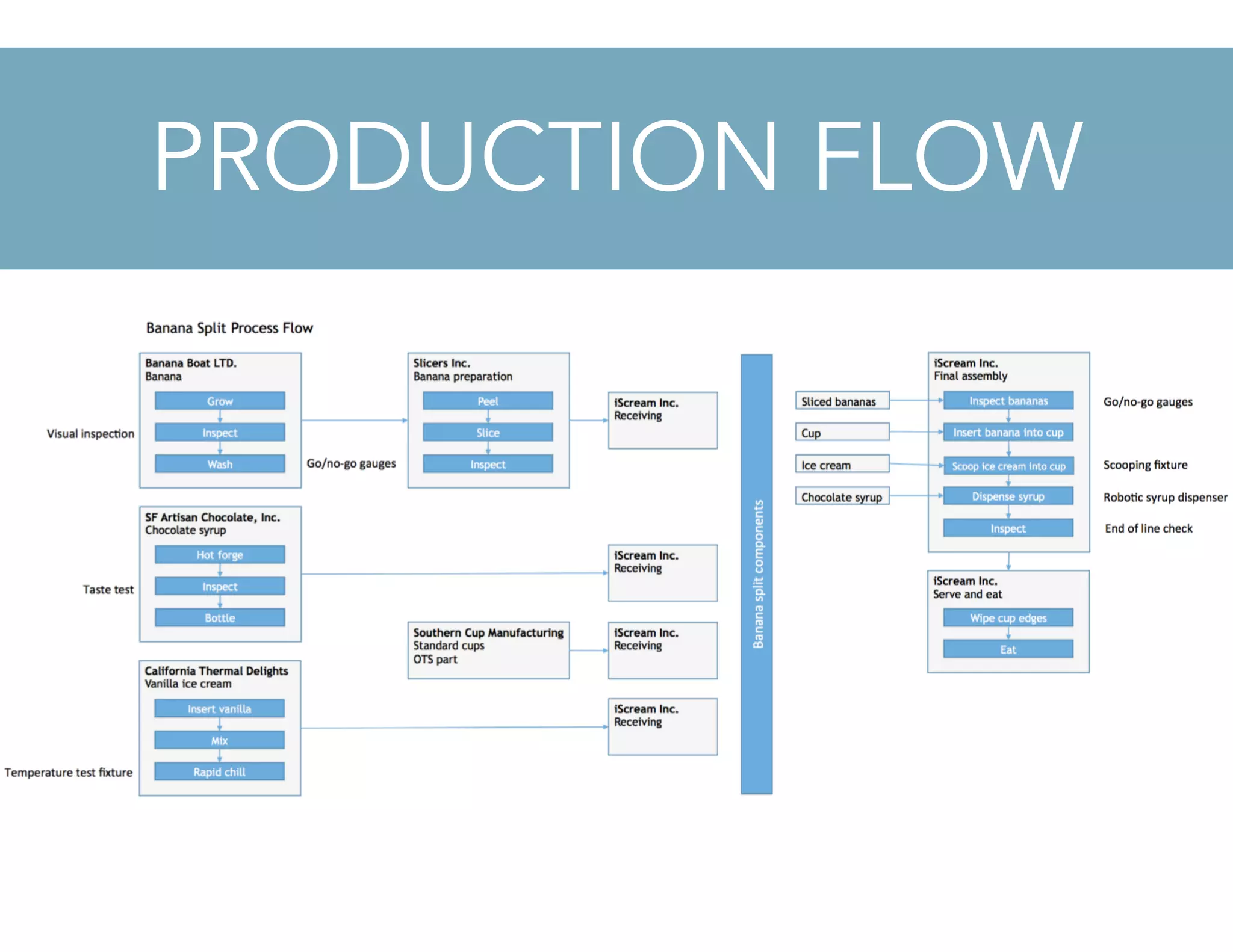

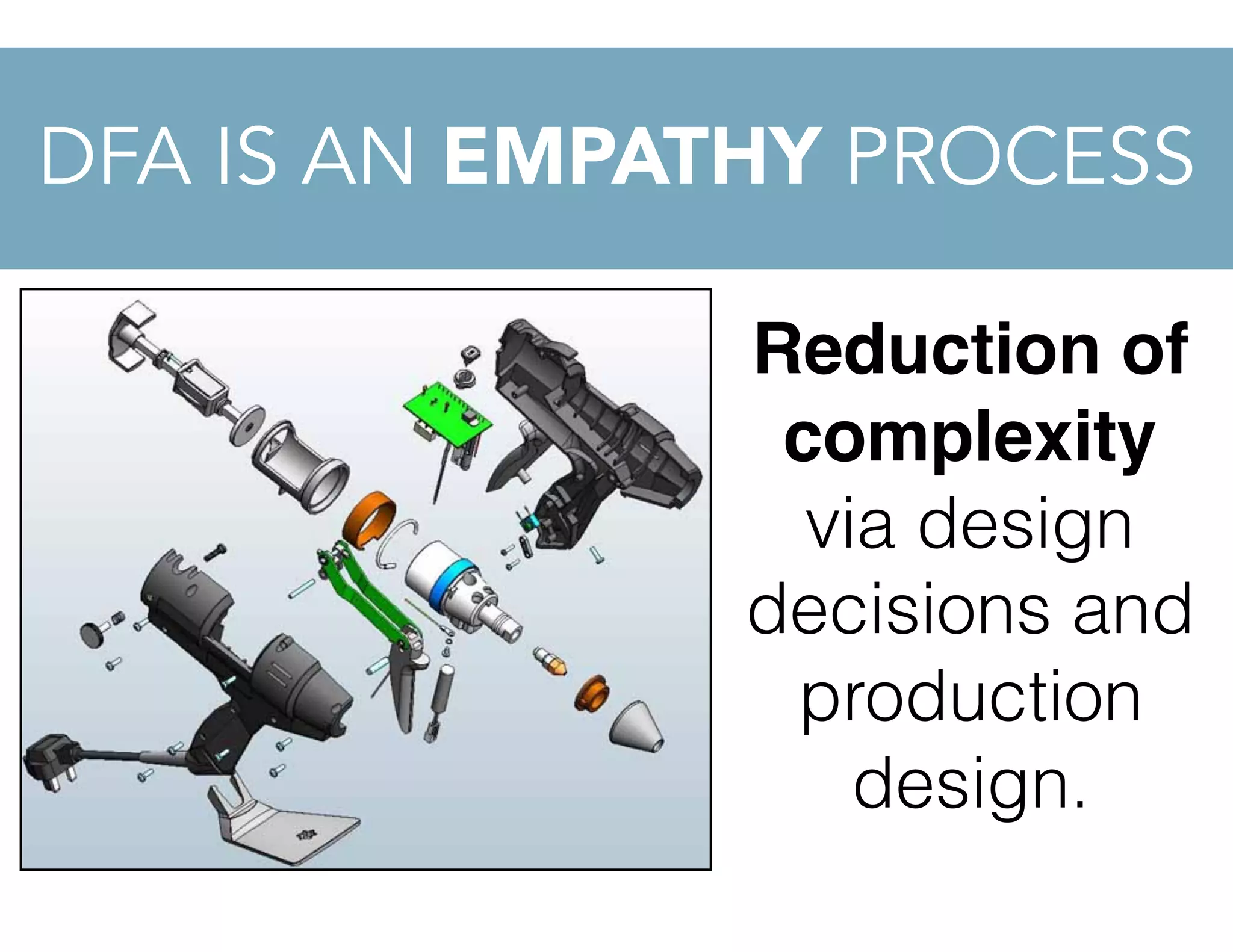

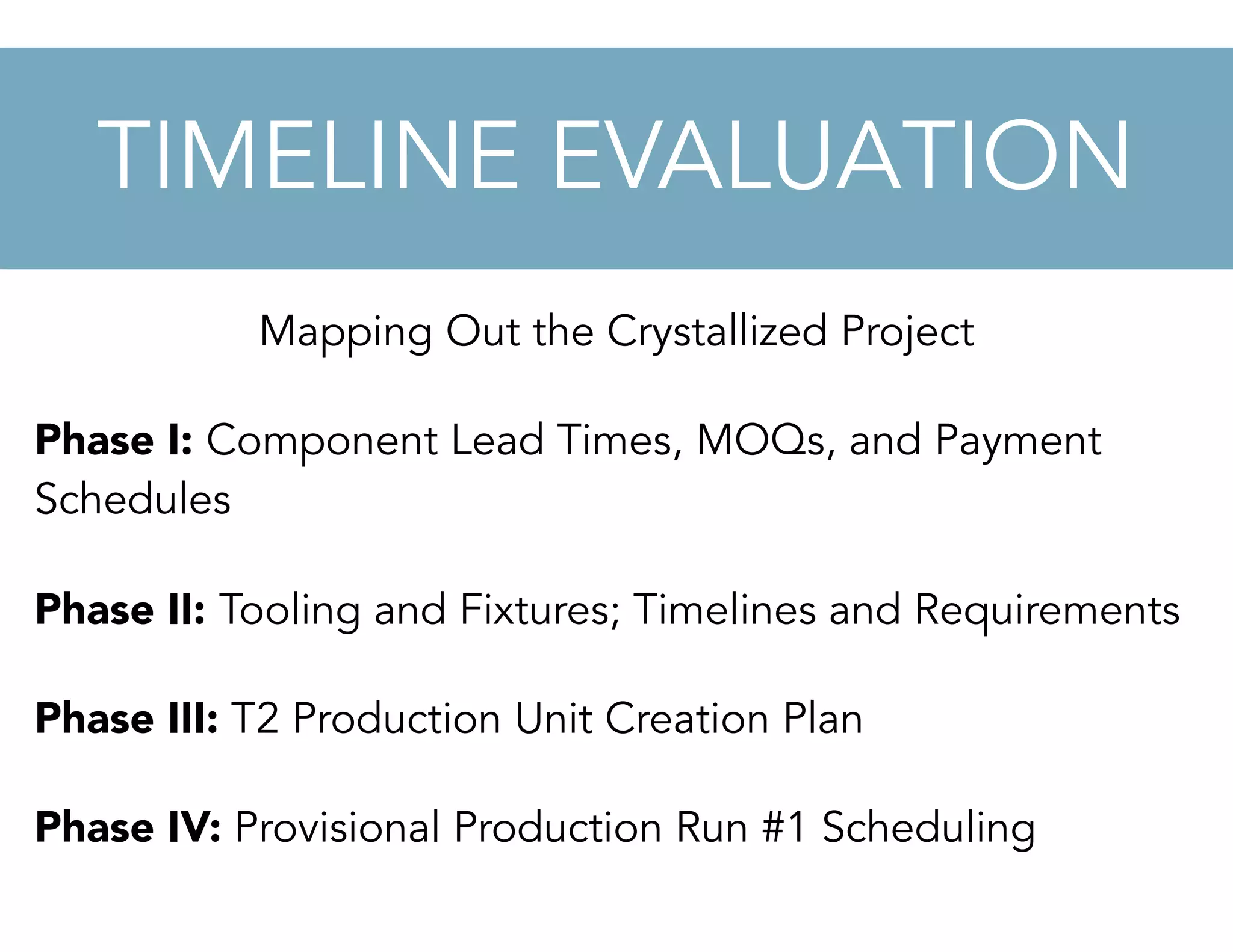

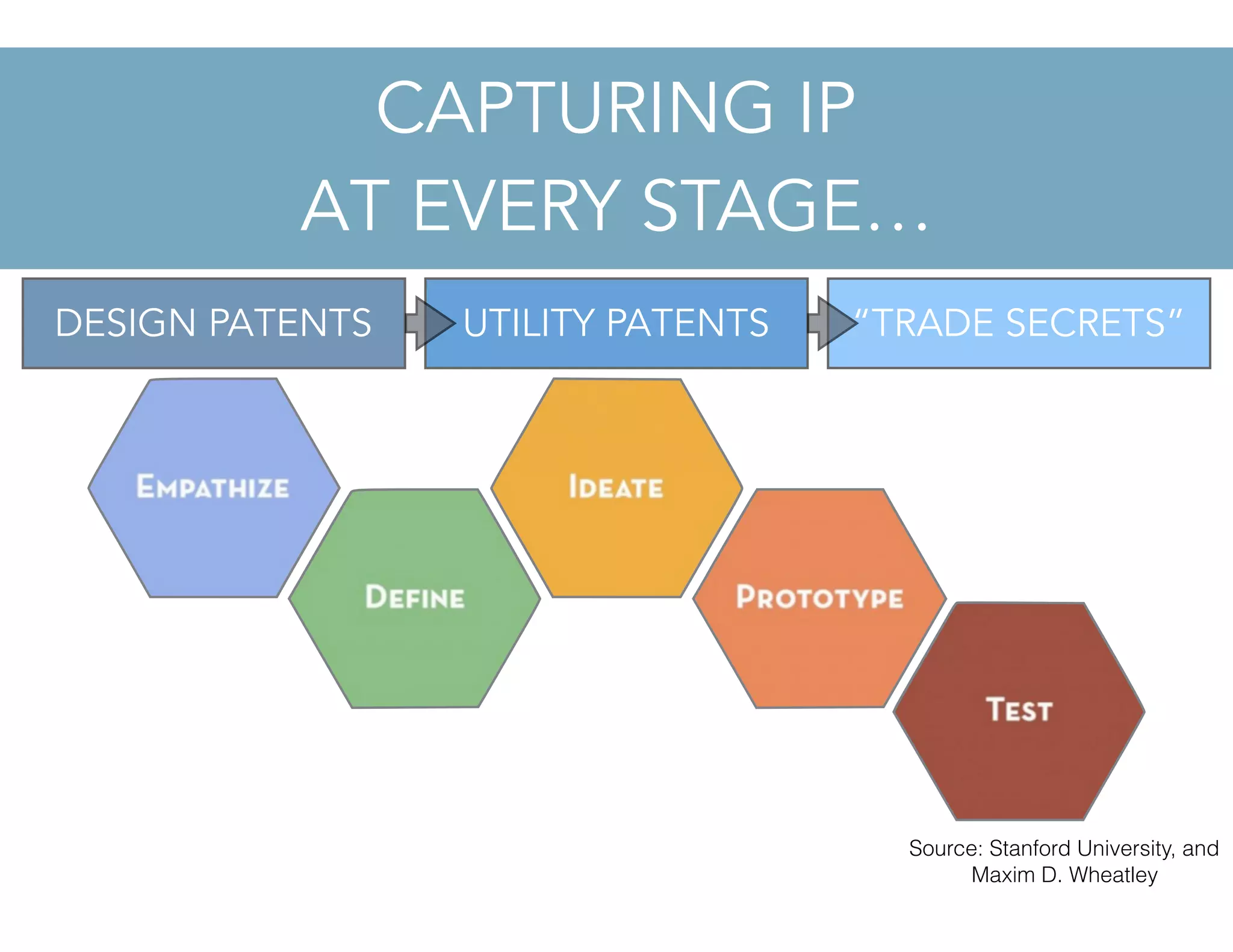

Maxim D. Wheatley outlines the design thinking process and strategies for bringing a product to market, emphasizing the importance of user empathy, iterative prototyping, and stakeholder involvement. He discusses various phases of product development, including user profiling, market analysis, ideation, and validation, while providing practical tools such as a project statement template and testing plans. The document highlights the significance of balancing innovation with market feasibility and the role of crowdfunding in product launches.