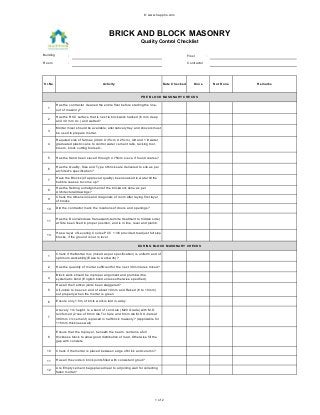

A detailed checklist for Individual Customers who are planning for Bungalow Construction. This document will help you verify your contractors work by providing various check points where you need to inspect the Brickwork or Blockwork masonry. This Quality Control checklist can be used for High Rise Structures also. Visit www.happho.com for more such Quality Control Checklists for Various Construction Works.