The African Milling School

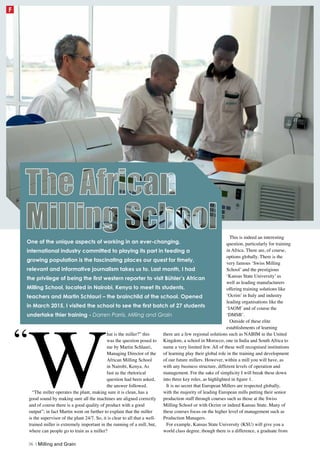

- 1. W hat is the miller?” this was the question posed to me by Martin Schlauri, Managing Director of the African Milling School in Nairobi, Kenya. As fast as the rhetorical question had been asked, the answer followed. “The miller operates the plant, making sure it is clean, has a good sound by making sure all the machines are aligned correctly and of course there is a good quality of product with a good output”; in fact Martin went on further to explain that the miller is the supervisor of the plant 24/7. So, it is clear to all that a well- trained miller is extremely important in the running of a mill, but, where can people go to train as a miller? This is indeed an interesting question, particularly for training in Africa. There are, of course, options globally. There is the very famous ‘Swiss Milling School’ and the prestigious ‘Kansas State University’ as well as leading manufacturers offering training solutions like ‘Ocrim’ in Italy and industry leading organisations like the ‘IAOM’ and of course the ‘DMSB’. Outside of these elite establishments of learning there are a few regional solutions such as NABIM in the United Kingdom, a school in Morocco, one in India and South Africa to name a very limited few. All of these well recognised institutions of learning play their global role in the training and development of our future millers. However, within a mill you will have, as with any business structure, different levels of operation and management. For the sake of simplicity I will break these down into three key roles, as highlighted in figure 1. It is no secret that European Millers are respected globally, with the majority of leading European mills putting their senior production staff through courses such as those at the Swiss Milling School or with Ocrim or indeed Kansas State. Many of these courses focus on the higher level of management such as Production Managers. For example, Kansas State University (KSU) will give you a world class degree, though there is a difference, a graduate from One of the unique aspects of working in an ever-changing, international industry committed to playing its part in feeding a growing population is the fascinating places our quest for timely, relevant and informative journalism takes us to. Last month, I had the privilege of being the first western reporter to visit Bühler’s African Milling School, located in Nairobi, Kenya to meet its students, teachers and Martin Schlauri – the brainchild of the school. Opened in March 2015, I visited the school to see the first batch of 27 students undertake thier training - Darren Parris, Milling and Grain “ 36 | Milling and Grain F

- 2. KSU will be highly educated and will be learning about the running of a mill at the very highest level of management and often though not always, will have worked only a limited time in a mill. They will no doubt talk about purifiers etc. and often they may only experience the majority of the practical applications on paper or during an internship at a mill, regardless, the goal is often mill management. With the African School of Milling (AMS), it was clearly evident to me that all of the students currently work in a mill and the majority have worked in a mill for many years. They attend the AMS to hone their skills and to learn many new things about the better practice within the mill. As I mentioned before, there are a few other establishments that focus on training the mill worker to become a professional miller, but again there are some obstacles, for example, the school in Morocco is primarily in French, the Indian School is catering for the Indian market and geographically is not logistical for African Millers, which is also the issue with the Swiss Milling School and KSU etc. as is the cost of both travel, accommodation and the courses themselves. Therefore, it was evident to me that the African Milling School (AMS) filled a very special and desperately required niche in the African market. Being centrally located in Nairobi in Kenya, the AMS is the only school in its class that caters 100 percent to the English speaking countries of Africa and is 100 percent dedicated in turning experienced mill workers into world recognised professional millers, with further courses planned to educate professional millers to the level of Head Miller. Not to mention the price of just US$4,800 per year which includes lunch and there is help with affordable accommodation sourced by Bühler, so all round it is an affordable solution for African millers, who with professionally trained millers on their staff will be able to reap a return of one percent to multiple improvement in their annual production, which will more than cover the costs of the course within one year. Furthermore, what is obvious in developing countries in Africa is the very same problem that exists in Europe, such as in the UK and France for example. In these countries there is a chronic shortage of trade people such as plumbers, electricians, bricklayers, carpenters and of course, professionally trained millers. If a country wants to develop, which of course the majority of African countries are focussed on doing, then they will need professional trade people and skilled workers. Over the years we see many companies come to countries in Africa, compete for and complete a project in one country then they are gone. Some would describe this as opportunistic, as there is no service or aftersales support available locally. This is, quite frankly where I observed first hand Bühler taking the lead in the marketplace. Talking further with Martin AMS - African Milling School AMS –African Milling School SMS - Swiss Milling School KSU - Kansas State University DMSB - IAOM - OCRIM MILLER Proffesional Miller PRODUCT MANAGER Figure 1 HEAD MILLER Supervisor May 2015 | 37 F

- 3. Schlauri, Managing Director of the African Milling School, he went on to explain, “I started dreaming of having an African Milling School five years ago, apart from the fact that I myself am a trained miller, I pride myself on my communication with many customers that I have built excellent relationships with over many years. Listening to their needs was key. I was consistently receiving strong messages that many of our customers at Bühler wanted to build more new mills, but they were restricted, as they did not have the skilled staff to operate them, they all are entrepreneurs and all wanted to expand their businesses.” Commitment to Africa “Building this centre cements Bühler’s commitment to Africa, as it is not just a state of the art mini mill for training purposes with modern classrooms, highly qualified teaching staff, sophisticated laboratory and onsite catering” Martin continued, “It is much, much more than this, it is a complete service centre with 10 fulltime engineers with facilities onsite to carry out roll re-grinding, re-fluting etc. as well as our staff on the road who are on hand to deal with any technological challenges but as well as mechanical and electrical issues, it is a complete package, giving piece of mind to all our customers.” And this is not the only establishment Bühler has in Africa and the Middle East; I noted they have split the region Middle East & Africa into five sub- regions. With over 500 permanent staff they have offices in South Africa, East Africa, North and West Africa as well as Middle East and Central-Eurasia. With full time employees on hand to help their customers grow and develop their businesses. Talking further with Martin, he went on to explain “You must understand Darren, working at Bühler is fascinating and inspiring as it is not just flour milling, we have feed milling, pasta technology, rice milling and also coffee and cocoa processing. Africans love rice and this is growing in popularity and many African Governments give support to develop the agroindustry.” Continuing, “So this is why Bühler has a solid base. We have many customers that want to diversify their milling opportunities and we not only have the equipment solutions, we can offer the after-sales service and training as well. In the lab there was all the latest equipment from companies such as Perten and Brabender to name but a few. Martin was quick to point out that he was extremely grateful to all the companies that had contributed to some of the cost in supplying AMS with the latest equipment for students to use. In the lab there was all the latest equipment from companies such as Perten and Brabender to name but a few. Martin was quick to point out that he was extremely grateful to all the companies that had contributed to some of the cost in supplying AMS with the latest equipment for students to use. 38 | Milling and Grain F

- 4. First impressions Having made my way via Turkey and the TUSAF conference in Antalya to Kenya and Bühler’s African Milling School, my first impressions of the school were of the awe inspiring compound in which it is located with high walls, guard and large electronic gate. Once I was checked through and made my way to the reception I met with Martin Schlauri and had the initial introduction as I have detailed above. It was then the grand tour. Of the two beautifully built buildings in the Bühler compound, I first visited one housing the service centre, where I witnessed the rolls from many mills all over Kenya, with Bühler staff busy re-grinding and re-fluting them. It was a privilege to be the first western reporter to go behind the scenes of Bühler’s new modern service centre. From here we stepped out in to the 30-degree heat and walked across the carpark with the flags flying proudly for Switzerland, Kenya, the African Milling School and Bühler. On entering the school for the first time it was evident of the high quality build and attention to detail at every turn. This was no more evident than when I entered the training mill, a mill designed for all their customer’s needs, and most extraordinary was the fact that this was a Maize mill and a Wheat mill, both integrated, and on May 2015 | 39 F Brabender® GmbH&Co.KG · www.brabender.com Our key measurement result: The satisfaction of our customers. For over 90 years, we have been developing innovative measurement and control systems that deliver precise values to the food and chemicals industries. For Brabender® , human values are just as important as empirical ones.That is why the satisfaction of our customers is a cornerstone of our business.We want to continuously increase the satisfaction value (SV), by putting a smile on your face. Delighting our customers is what drives our company. SV Image_AZ_190x132_E_RZ.indd 1 17.04.2015 08:47:28

- 5. talking with Martin he commented, “I am not aware of another mill that does this.” You can see from the images in this feature, that the pipe work is really a work of art, and in many ways this pipe work sums up the ultimate learning goal, as when the students leave and they understand this, they are a real miller. Walking through the full scale training mill there were cleaning equipment, rollers, sieves and sifters, there was even a feed mill with a conditioner, a pellet press and a cooler. The mill was clinically clean and very open plan affording suburb space to work, teach and practice, it really is what every milling school would dream of. All the machines I inspected were exactly the models sold to customers with no modifications whatsoever. So, the students are really training on what they will end up using. They even have a small grinding mill to practice on before moving onto the larger mill, it was very impressive. And that is not just my opinion. Meeting up with the 27 students, a completely full class, I was blown away by their enthusiasm to learn and the detail into which they went during the lectures. In this, the very first class of the AMS 2015, there were 27 students of nine different nationalities from 14 different mills, a really international group of students. On entering the modern well equipped classroom for the first time, I was greeted by Stephan Lutz the teacher, going into some significant detail, and 40 | Milling and Grain F

- 6. in the limited time I spent in the classroom, it was clear the whole group were following every word of Stephan and asking quite challenging questions. Being the first group of students to go through the AMS, there was an evident sense of pride that was clearly visible on the students faces, and being in the fourth week of the first four week module of the course, there was immense excitement from the students about returning to their mill for 8 to 16 weeks so they could start to implement what they have learnt before they returned for the second four week module. This management of the modules is one of the fantastic aspects of the whole course. This is split into six, four-week modules over a two-year period. In the first year they will spend, for example, four weeks in February, May and October covering such topics as, but not limited to: • Cereal Science such as cereal varieties • Grain Intake / Storage such as machines for pre-cleaning, flow sheets for grain intake/storage and conveyers • Cleaning covering machines for grain cleaning, tempering and conditioning of wheat, flow sheets for cleaning all backed up with daily practical work • Wheat milling learning about all the machines of a mill and their respective flow sheets etc In the second year they will spend, for example, four weeks in March, June and November covering such topics as but not limited to: • Wheat milling which will cover break systems, purification, sifting and practical work in the mill • Maize milling learning about cleaning, degermination, flow sheets and practical work • Finished product sections covering the machines and handling finished products May 2015 | 41 F New Innovative Product EASI-EXTRACT® STERIGMATOCYSTIN, Art No. P125 / P125B R-Biopharm Rhône Ltd. • Block 10 Todd Campus, West of Scotland Science Park, Acre Road, Glasgow • Scotland G20 0XA • www.r-biopharm.com R-Biopharm Rhône Ltd. • first immunoaffinity column on market • use prior to HPLC or LC-MS/MS • improves sensitivity • methods for a range of commodities

- 7. • Quality Control, looking at various methods and practical work in the laboratory • Maintenance, learning about preventative and organising maintenance Whilst I have not covered every topic covered by the milling course, you can clearly see how each class will have an intensive four week module of eight hour days, with a strict one hour lunch provided onsite with all lessons starting in typical Swiss tradition – on time. The mornings are spent in the classrooms, which is where I first met this inaugural class, after which I enjoyed a relaxing lunch with them in the Schools Canteen before the class was split into two for the afternoon activities. Stephan took half of the group for the practical work in the mill, which as well as all the aforementioned machinery also includes learning about conveyors, buckets and silos. Here, I noticed that Bühler had teamed up with Agromatic and the students were being taught about making sure buckets were aligned correctly. Unfortunately, it can be commonplace for buckets to get hot and result in explosions, so again this focus on preventative measures was impressive. I then spent some time with Martin Schlauri in the laboratory with his half of the group, over the four days I spent in Kenya, it was immensely clear that teaching in the Lab was what Martin enjoyed most, it was like watching a conductor of music as he guided each group of students working on their practical experiments. And as an independent reporter that has visited many mills around the globe, it was very impressive to see the quality of the equipment in the AMS laboratory for the students to learn on. There was all the latest equipment from companies such as Perten and Brabender to name but a few. Martin was quick to point out that he was extremely grateful to all the companies that had contributed to some of the cost in supplying AMS with the latest equipment for students to use. On behalf of Martin, I pass his thanks on to all those companies. With all the teachers busy and the students learning, I was free to roam around the school at my own leisure and have included a number of pictures taken throughout the mill. The whole complex has space to expand should the need arise, as I wondered around what in essence was the back garden, there were a number of special trees, planted in traditional African honour of those key people that had made the whole AMS project a success. Whilst the teachers were busy, I met with Jean-Claude Baur, the regional manager for Bühler East Africa, known more affectionately to his colleagues as JC. I received from him a detailed explanation on the economics and ROI that mills would receive by investing US$4,800 dollars for a member of their staff to attend this prestigious milling course. It is agreed by all professionals that a professionally trained miller who has been taught how to align machinery correctly, analyse data and product correctly and is able to create and follow a mill flow chart with optimum efficiency, as well as having the skills to correctly clean and maintain all the machinery can, as a minimum add a two percent value to the mill. Therefore imagine this: - A mill receives 220 tons of grain daily with an 80 percent conversion being – 220 x 0.8 = 176 tons - Imagine the mill is operational for 250 days per year, which would equal – 250 x 176 tons = 44,000 tons - If the price per ton of corn is $350 the turnover of product would be – 44,000 tons x $350 = $15,400,000 per year. - Therefore an uplift of value in 2 percent because of having a trained miller would add value of $15,400,000 x 2 percent =$308,000 By anyone’s calculation this makes the investment of US$4,800 per year for two years US$9,600 worthwhile, even if the added value was only 0.1 percent per year this is still add additional US$15,400. I think it is fair to say that it is no surprise that the course for 2016 is filling up very quickly. They will of course join the returning 27 students from 2015 to complete year two. As a final note, I would like to thank Martin Schlauri for his generous time and detailed explanations and for the free pass to wonder at my own leisure through this very open and transparent school. And a big thank you to the Bühler Management for allowing me to gain as a reporter for Milling and Grain, a unique insight into this wonderful facility. 42 | Milling and Grain F

- 8. Nothing escapes Romer Labs. FIND OUT MORE ABOUT ROMER LABS TESTING SOLUTIONS AND CONTACT: Romer Labs Diagnostic GmbH Technopark 1, 3430 Tulln, Austria Tel: +43 2272 61533 10 Email: office-europe@romerlabs.com www.romerlabs.com AgraStrip® WATEX now GIPSA approved