Technical_Slides_S7-1500_en - Presentación.pdf

- 1. © Siemens AG 2012. All Rights R Indus Safety Integrated The ultimate Plus in Automation

- 2. © Siemens AG 2012. All Rights R MATIC S7-1500 hnical Slides

- 3. © Siemens AG 2012. All Rights R Indus ATIC S7-1500 tioning modular controller SIMATIC S7-400 SIMATIC S7-300 SIMATIC S7-1200 SIMATIC S7-1500 TIA Portal Basic Advanced Micro 2009 2013 V10.5 V11 V12 SIMATIC S7-400 SIMATIC S7-300 SIMATIC S7-200 SIMATIC S7-1500 SIMATIC S7-1200

- 4. © Siemens AG 2012. All Rights R Indus ular controller positioning Resource power I/O Capacity, Program Size, Instruction Speed, Communication Capabilities, … The modular compact controller for solutions in basic discrete and standalone automation SIMATIC S7-1200 The modular controller for system solutions in mid-range to high-end discrete automation SIMATIC S7-400 Logic module for switching and controlling solutions in small- scale automation projects LOGO! Automation (modular) Compact Controller (modular) Controller Logic Module Product Description Application t SIMATIC S7-300

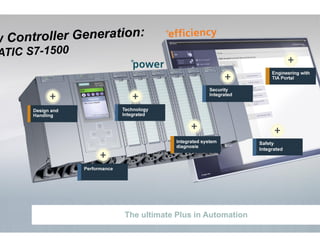

- 5. © Siemens AG 2012. All Rights R Indus ATIC S7-1500 ultimate Plus in Automation Excellent usability to speed up commission and maintenance Integrated system diagnosis to reduce downtime TIA Portal innovations for increased engine efficiency High system performance to increase productivity and flexibility Technology Integrated for perfect integratio drives through motion control functionalities Security Integrated to protect know-how an invest One System for Safety and Standard

- 6. © Siemens AG 2012. All Rights R Indus ATIC S7-1500 ign

- 7. © Siemens AG 2012. All Rights R Indus ATIC S7-1500 rview of Highlights Portfolio One system for machine and plant construction Reduction of modules by >50% for PLCs Reduction of modules by >30% for I/Os

- 8. © Siemens AG 2012. All Rights R Indus ATIC S7-1500 Portfolio standard and safety US T / IE e ace rformance am / memory ype 1511-1PN/ F 35mm 60 ns 150/ 230KB 1 MB 1 1 S7-1511 620/ 830 € 1513-1PN/ F 35mm 40 ns 300/ 450 KB 1,5 MB 1 1 S7-1513 1380/ 1640 € 1516-2PN/DP/F 70mm 10 ns 1/ 1,5 MB 5 MB 1 1 2 S7-1516 3400/ 3760 € …. S7-…. …. S7-…. …. S7-…. Easy PLC selection thanks to an optimized Portfolio

- 9. © Siemens AG 2012. All Rights R Indus ATIC S7-1500 Portfolio standard and safety US T / IE e ace rformance am / memory ype 1511-1PN 35mm 60 ns 150 KB 1 MB 1 1 S7-1511 1.195,00 1513-1PN 35mm 40 ns 300 KB 1,5 MB 1 1 S7-1513 2.640,00 1516-2PN/DP 70mm 10 ns 1 MB 5 MB 1 1 2 S7-1516 …. S7-…. …. S7-…. …. S7-…. Easy PLC selection thanks to an optimized Portfolio

- 10. © Siemens AG 2012. All Rights R Indus ATIC S7-1500 troller Portfolio Standard und Safety US T / IE aces erformance am / Memory oller type 1511-1PN/ F 35mm 60 ns 150/ 230KB 1 MB 1 1 S7-1511 1513-1PN/ F 35mm 40 ns 300/ 450 KB 1,5 MB 1 1 S7-1513 1516-2PN/DP/F 70mm 10 ns 1/ 1,5 MB 5 MB 1 1 2 S7-1516 1515-2PN/ F 70mm 30 ns 500/ 750 KB 2,5 MB 1 1 *S7-1515 2 1517-3PN/DP/F 175mm 1 ns 3/ 4,5 MB 10 MB 1 1 2 *S7-1517 1518- 17 30/ 9 *S7 1511-1PN C 105mm 60 ns 150 KB 1 MB 1 1 *S7-1511C 1511-1PN C 105mm 48 ns 200 KB 1 MB 1 1 *S7-1512C 1 1 Easy Controller selection thanks to an optimized Portfolio delivery release

- 11. © Siemens AG 2012. All Rights R Indus ATIC S7-1500 elivery Release 511 / 1513 PLC-1516 IM 5x PS / PM 6x CM / CP 13x I/Q 2xTM

- 12. © Siemens AG 2012. All Rights R Indus ATIC S7-1500 elivery stage 511 / 1513 CPU-1516 IM 5x PS / PM 6x CM / CP 13x I/Q 2xTM CPUs Interface- module Power- module/supply Communication- module Signal- module Techn mo

- 13. © Siemens AG 2012. All Rights R Indus ATIC S7-1500 rview of Highlights Portfolio One system for machine and plant construction Reduction of modules by >50% for PLCs Reduction of modules by >30% for I/Os Performance Extremely fast backplane bus Extremely fast bit instructions Extremely fast response time (terminal <-> terminal)

- 14. © Siemens AG 2012. All Rights R Indus ATIC S7-1500 mpared bit performance of S7-300/400 and S7-1500 317 DP 315 DP 314 312 319 PN 317 PN 317 DP 315 PN 312 314 1518 1517 1516 1515 1513 417-4 416-3 PN/DP 416-2 414-3 PN/DP 414-3 414-2 414-2 412-1 S7-1500 S7-400 S7-300 FW V3 S7-300 V2.x rformance [ns] 1511 315 DP 1416-3

- 15. © Siemens AG 2012. All Rights R Indus ATIC S7-1500 rview of Highlights Portfolio One system for machine and plant construction Reduction of modules by >50% for PLCs Reduction of modules by >30% for I/Os Performance Extremely fast backplane bus Extremely fast bit instructions Extremely fast response time (terminal <-> terminal) are 32 modules / row modules for U connector and backplane guration ient memory for every application memory via SIMATIC Memory Card

- 16. © Siemens AG 2012. All Rights R Indus 1500 hardware ardware description Module dimensions correspond approximately to S7-300 Significantly faster backplane bus, approx. 40x Terminal-terminal response times < 100 µs* Modules can be assembled in 2 versions U-connector / DIN rail (like S7-300) Up to 32 modules in 1 tier Design of power segments Backplane (like S7-400)* Redundant power supply possible for backplane Up to 39 modules in 3 tiers Hot swapping delivery release

- 17. © Siemens AG 2012. All Rights R Indus S7-300 central: up to 32 modules possible, BUT: additional modules (IMs) required ET 200M distributed: up to 12 modules possible mber of connectable modules increased to 32 Max. 32 I/O modules Space saving due to fewer IMs Cost savings S7-300, ET200M S7-1500 central and E 200MP distributed Up to 32 module can be inserted without additiona S7-1500

- 18. © Siemens AG 2012. All Rights R Indus ATIC S7-1500 engineered with TIA Portal light – Design and Handling d front connector mplified ordering, logistics and stocking ified pin assignment for each component type allows simplified ing and replacement of components beling can be printed in the TIA Portal in later version ring position for user-friendly wiring ables wiring without electrical connection of the plug mplifies wiring for the electrician during wiring the signal lines sy rewiring if needed during operation of the machine Easy setup avoids errors, saves time and costs

- 19. © Siemens AG 2012. All Rights R Indus sability Highlights Ethernet cables can be removed without additional tools Lead-sealing of PLC and display possible – simple protection against unauthorized handling ntegrated DIN rail in S7-1500 section profile or mounting of additional components ATIC S7-1500 dware

- 20. © Siemens AG 2012. All Rights R Indus ATIC S7-1500 nition of Power Supply Modules and Power Modules * Power Supply Modules PS = Power Supply Module Internal supply of the backplane bus of the modules (internal electronic / communication) One or more Power Supply Modules can be plugged in the application (no slot-limitation) with U-Connector with diagnostic information in TIA Portal urrent Supply Power Module of 24V for each module. used for the load current of the modules (PS, PLC, dule) and sensors / rs, e.g. using SITOP t U-Connector t diagnostic information in tal 0: PS S7-1500: PM S7-400: PS S7-1500: PS

- 21. © Siemens AG 2012. All Rights R Indus ATIC S7-1500 nition of Power Supply Modules and Power Modules * PM PLC / IM Modules (IO, CM, CP, TM) DC 24 V DC/DC System voltage supply: via PLC / IM Internal supply of the backplane of the mod (internal electronic) * max. number of modules depends on the consumption of the modules Load current supply: via PM = Power Module Used for the load current supply of the mod (PS, PLC, IM, Module) and sensors / actua 20/230 V Sensors Actuators Power segment 1 (max. 12 Modules*)

- 22. © Siemens AG 2012. All Rights R Indus ATIC S7-1500 nition of Power Supply Modules and Power Modules * PS DC 24 V DC/DC DC/DC 20/230 V Sensors Actuators PM PLC / IM Modules (IO, CM, CP, TM) Modules (IO, CM, CP, TM) Load current supply: via PM = Power Module Used for the load current supply of the mod (PS, PLC, IM, Module) and sensors / actua System voltage supply: via PLC / IM Internal supply of the backplane of the mod (internal electronic) * max. number of modules depends on the consumption of the modules via PS = Power Supply Module Internal supply of the backplane of the mod (internal electronic) ** max. number of the modules depends on power consumption of the modules and the supply of the PS Power segment 1 (max. 12 Modules*) Power segment 2 (max. n Module**)

- 23. © Siemens AG 2012. All Rights R Indus ATIC S7-1500 er Supply Consumption * Power Supply Consumption: Within the TIA Portal the parameter supply consumption checks if the power supply of PLC and of (the additional) System Power Supply is high enough to support the power consumption of the modules. PLC supplies the backplane

- 24. © Siemens AG 2012. All Rights R Indus 1500 Controller mory card SIMATIC Memory Card emory card with standard file system ncreased service life. 500,000 write operations possible on the memory card. Project can be sent as e-mail and written onto card using standard PC No special card reader required (SD card with FAT 32 file system) Despite openness, no data is lost when switching off the PLC Copy protection. Programs can be linked to the serial number of the memory card.

- 25. © Siemens AG 2012. All Rights R Indus mparison of Memory Cards ATIC Memory Card – Consumer Card SMC Consumer card gned for Industry Data consistency at power off Data management on memory card after last programming 10 a* 1 a e-/Erase operations min. 500 000 10 000 – 30 0 ormance requirements (e.g. faster access) Special firmware Standard firmw me Prediction ability of spare parts 10 a cial for SIMATIC designed Compatibility to installed basis (every 2 years a new speci Copy protection ory size 4 MB up to 2 GB up to 64 (128) e 51 € - 650€ 5 € - 60 € * with 50 000 Write-/Erase operations

- 26. © Siemens AG 2012. All Rights R Indus ATIC S7-1500 rview of Highlights Portfolio One system for machine and plant construction Reduction of modules by >50% for PLCs Reduction of modules by >30% for I/Os Performance Extremely fast backplane bus Extremely fast bit instructions Extremely fast response time (terminal <-> terminal) are 32 modules / row modules for U connector and backplane guration ient memory for every application memory via SIMATIC Memory Card unications O RT/IRT in every PLC erface for network isolation data (PLC, CM) in process image e programming of communication for PLC Ms ated web server

- 27. © Siemens AG 2012. All Rights R Indus 1500 Controller mmunication possibilities Same PROFINET function on every PLC PROFINET as standard interface PROFINET IO IRT (including isochronous mode) Shared Device I-Device 2 interfaces (PN IO and PN Basis) with larger PLCs for separation of networks. Web server with user-programmable websites Access to memory card possible via Web server Optimum integration of PROFIBUS and PROFINET communication modules Direct transfer of I/O data into the PLC process image Uniform SEND /RECEIVE function blocks (TSEND, TRCV) for PLC local interfaces and communication module interfaces F-IO-Controller IO-Controller IO-Device as Shared Device Shared Device IO-Controller 1 CPU1 CPU2 i-Device I-Device

- 28. © Siemens AG 2012. All Rights R Indus OFINET lights - Overview F-IO-Controller IO-Controller IO-Device as Shared Device Shared Device IO-Controller 2 IO-Controller 1 IO-Device 1 / CPU1 CPU2 IO-Device 2 i-Device I-Device MRP Web – User defined page µs IRT and Isochronous Mode PROFIenergy Controller HMI DC24V Web – Network Topology View IP Config for IO-Controller Proj_M Proj_M Proj_M IP = …2 NoS = B IP = …3 NoS = C IP = …1 NoS = A Option Handling

- 29. © Siemens AG 2012. All Rights R Indus configured connections programmed connecti ATIC S7-1500 monized communication blocks CM CP ONE set of communication blocks PLC

- 30. © Siemens AG 2012. All Rights R Indus ATIC S7-1500 strial Ethernet CP Features of the Industrial Ethernet CPs 1x 10/100/1000 MBit-Interface IPv6-Support Security: Access protection based on hardware identification, IP-/MAC-Access-List, Firewall, VPN (SP1) Two separated Networks Web sever access via http / https Communication to S5-/S7-/C7-/M7-Systems Communication to WinAC and WinCC FTP (Client/Server), E-Mail, IP-Broadcast/Multicast, SNMPv1/v3 S7-Communication PG/OP-communication Open Communication via ISO, TCP/IP, UDP Module exchange without PG Comprehensive Diagnosis information Time-synchronization via NTP and MMS

- 31. © Siemens AG 2012. All Rights R Indus ATIC S7-1500 OFIBUS CM Features of the PROFIBUS CMs 1x RS232 / RS485 PROFIBUS DPV1 Master or Slave 9,6kBit/s up to 12MBit/s 125 DP-Slaves Communication to S5-/S7-/C7-/M7-Systems Communication to WinAC and WinCC FDL-Communication S7-Communication PG/OP-Communication Sync/Freeze Module exchange without PG Comprehensive Diagnosis information Time-synchronisation

- 32. © Siemens AG 2012. All Rights R Indus ATIC S7-1500 OFINET CM Features of the PROFINET CM 2 x 10/100 MBit-Interface PROFINET IO Controller for up to 128 PN IO Devices IRT+ Two separated Networks Access protection via IP-/MAC-Access-List Web sever access via http / https Communication to S5-/S7-/C7-/M7-Systems Communication to WinAC and WinCC E-Mail-Port S7-Communication PG/OP-Communication open Communication via TCP/IP, UDP Module exchange without PG Comprehensive Diagnosis information Time-synchronization via NTP

- 33. © Siemens AG 2012. All Rights R Indus ATIC S7-1500 rview of Highlights y ommissioning gh-speed diagnosis or messages in plain text ss to MLFB, serial no., etc. Portfolio One system for machine and plant construction Reduction of modules by >50% for PLCs Reduction of modules by >30% for I/Os Performance Extremely fast backplane bus Extremely fast bit instructions Extremely fast response time (terminal <-> terminal) are 32 modules / row modules for U connector and backplane guration ient memory for every application memory via SIMATIC Memory Card unications O RT/IRT in every PLC erface for network isolation data (PLC, CM) in process image e programming of communication for PLC Ms ated web server

- 34. © Siemens AG 2012. All Rights R Indus ATIC S7-1500 Controller lay Start screen Accessible partners Diagnosi Stations status

- 35. © Siemens AG 2012. All Rights R Indus ATIC S7-1500 Controller lay very controller has a display Access of order number, FW version, series number of all modules For commissioning (e.g. setting of IP address, station name) For diagnostics: All error messages are displayed as text (system diagnostics and user alarms) Module statuses for central and distributed modules Replacement for S7-400 key switch (RUN / RUN-P mode) 2 languages (menu and error/message texts). Language can be switched over during operation. Pull&Plug Display during operation without any interrupts. PLC continues in RUN.

- 36. © Siemens AG 2012. All Rights R Indus ATIC S7-1500 rview of Highlights y ommissioning gh-speed diagnosis or messages in plain text ss to MLFB, serial no., etc. STEP7 language innovations Complete symbolic programming High-performance LAD/FBD/SCL compil Innovations in LAD/FBD/SCL DB max.: 16 MB, FBs/FCs: 512 KB Portfolio One system for machine and plant construction Reduction of modules by >50% for PLCs Reduction of modules by >30% for I/Os Performance Extremely fast backplane bus Extremely fast bit instructions Extremely fast response time (terminal <-> terminal) are 32 modules / row modules for U connector and backplane guration ient memory for every application memory via SIMATIC Memory Card unications O RT/IRT in every PLC erface for network isolation data (PLC, CM) in process image e programming of communication for PLC Ms ated web server

- 37. © Siemens AG 2012. All Rights R Indus 1500 Controller 1500 functions Optimized programming languages (STL, LAD, FBD, SCL) Fully symbolic programming LAD, FBD, SCL are equivalent to STL, i.e. all instructions are present in all IEC languages. An essential reason to program in STL no longer exists. Significant increase in performance (LAD, FBD, SCL) Significant increase in performance for F PLCs thanks to optimized F compiler Support of 64-bit data types (LREAL, LINT, LWORD) and all other IEC data types Calculate box (LAD, FBD) DBs / FBs / FCs Maximum size of DBs: 5 MB in S7-1516 (system limit 16 MB) Maximum size of FBs/FCs: 512 KB “enable”

- 38. © Siemens AG 2012. All Rights R Indus 1500 Controller ramming languages L – instruction list FBD – function plan diagram LAD – ladder

- 39. © Siemens AG 2012. All Rights R Indus 1500 Controller ramming languages SCL S7-Graph

- 40. © Siemens AG 2012. All Rights R Indus 1500 Controller CULATE Box start formula editor input of math form Inputs will be linked internally with the math formula and the result is written to the output One call instead of numerous mathematical functions Configuration time-saving CALCULATE Box

- 41. © Siemens AG 2012. All Rights R Indus INT Real Real ADD Real 1500 Controller icit type conversion automatic conversion Implicit type conversion Automatic conversion of data types to match the biggest one No explicit conversion necessary Implicit conversion is shown for supervision

- 42. © Siemens AG 2012. All Rights R Indus Conversion of strings 1500 Controller version of character and strings Example Type Type Example `A`, `B`, `C` Array of [CHAR] String `ABC` 23.45 digit String `+23.45` 16#123AF010 hex ASC II `123AF010` Chars_To_Strg Strg_To_Chars VAL_STRG STRG_VAL ATH HTA

- 43. © Siemens AG 2012. All Rights R Indus 1500 Controller CE Access BYTE WORD DWOR Operands in blocks and I/Q/M „My_DW_Variable“ „My_W_Variable“ „My_B_Variable“ „Slice“ Access: No definition necessary High programming efficiency Bit-wis Byte-wis Word-wi Exemplary operand names W0 W1 B0 B1 B3 X 0 X 1 X 2 X 31 „My_W_Variable.X0“ „My_DW_Variable.B1“ Examples:

- 44. © Siemens AG 2012. All Rights R Indus 1500 Controller ect addressing also in LAD and FBD Read / FieldWrite Directly in LAD and FBD

- 45. © Siemens AG 2012. All Rights R Indus “FieldRead” reads values of an array 1500 Controller ect addressing also in LAD and FBD Data type of array

- 46. © Siemens AG 2012. All Rights R Indus 1500 Controller ect addressing in LAD and FBD Datablock.Variable [„Indexvariable“] Indirect addressing directly in LAD and FBD Direct read and write access of array values in LAD and FBD Example: “Field_Data”. Numbers[“i”] i := INT

- 47. © Siemens AG 2012. All Rights R Indus 1500 Controller nload in Run ovative behavior of downloads nsistent download – all blocks affected by changes will be downloaded to PLC actual values exist after downloading anges of comments, start values, tag mes eely selectable tags of the DB-values, that saved in retentive memory DB values aren’t initialized anymore after Download in RUN unless there were significant changes

- 48. © Siemens AG 2012. All Rights R Indus ATIC S7-1500 vated Download behavior Name Variable1 Variable3 Variable4 Activation of Download without reinitialization Down- load to PLC Name Variable1 Variable2 Value 3.4 451 Variable3 23 Variable5 Block in Project Name Variable1 Variable2 Variable3 Down- load to PLC Block in Project Name Variable1 Variable3 Variable4 Variable5 ock with memory erve for download out re-initialization Reserve occupies more memory Actual valu the block ar Variable2 Variable2 Block in PLC Block in PLC Download without re-initialization keeps the actual values (only for optimized FBs/DBs) Anpassen der Variablen im Rahmen des Reserve- bereichs (keine UDTs) New tags can be added within the reserve memory

- 49. © Siemens AG 2012. All Rights R Indus cording of up to 16 different tags in separate PLC memory area utside of work, load or retentive memory) pport of four independent trace-jobs at the same time clic acquisition (real-time), not to lose any values ultiplex trigger conditions to filter for desired events e recording occurs independently of Engineering System on the C, to simplify the search of sporadic problems portable measurements for documentation and further processing data by user (csv and ttrec file) ATIC S7-1500 engineered with TIA Portal troller innovations Program- and application diagnostics at real-time for recognizing even sporadic prob

- 50. © Siemens AG 2012. All Rights R Indus Innovations: dardization of Startup behavior of the PLCs dardization of different startup behaviors of S7-200 / 300 / 400 with S7-1200 / S7-1500 erent startup behavior (depends on the PLC) restart from S5 •Stop •Term •Run 7-200 trol modes: fore power off) + S7-200 / S7-300 / S7-400 S7-300 S7-400 S7-1200 / 1500 Same behavior for every PLC (adjustable) Hot restart from S5 is cut < 1% used in ch customer projec Safety aspect a Advantages for the customer: Safe mode after power on identical startup behavior of each PLC type no re-initialization in the user program neces

- 51. © Siemens AG 2012. All Rights R Indus troller Innovations: anization blocks for S7-1200 / S7-1500 cyclic startup BS Interrupt - Bearbeitung Hardware Process Diagnostics Cyclic interrupt OB1 FB Instanz OB 100 OB 20x OB 20x OB 82 FC FC FC than one Startup, cyclic interrupt- and process alarm OBs are possible Global FC Global FB Instanz FC FC

- 52. © Siemens AG 2012. All Rights R Indus 1500 Controller 1500 Organization Blocks OBs Free assignment of OB types to OB numbers. 20 OBs each for Time-of-day interrupts Time-delay interrupts Cyclic interrupts 50 Process interrupts 100 cyclic OBs and 100 startup OBs possible so that library elements including OBs can be created

- 53. © Siemens AG 2012. All Rights R Indus troller Innovations: rity of Organization Blocks of the S7-1500 Up to 100 cyclic OBs (OB1 can be spitted) Up to 100 Startup OBs (OB 100 can be spitted) 20 x clock alarm 20 x time delay alarm 20 x cyclic interrupt alarm 50 x process alarm 4 x OB 6x (isochronous alarm) 1 x IPO OB (isochronous alarm) 1 x Servo OB (isochronous alarm) 1 x OB 82 (Diagnosis, error handling) ... Each OB has a priority High (27) – Low (1) OBs are interrupted by OBs with a higher priority If several OBs have the same priority then they are executed in the configured sequence Bs / Task OB Priorities NEW NEU

- 54. © Siemens AG 2012. All Rights R Indus troller Innovations: ble Handling of Organization Blocks for S7-1200 / S7-1500 FB Local FC FB Local FC Main_1 OB1 FB Local FC User Program Code OBs are called in numerical order (1. release) Modularization of the program code Ready-to-use groups (with OBs, FBs, FCs) for the lib Main_y OB200 Main_x OB300 Cyclic OBs and Startup – OBs Saving Time during Engineering: Copy and Paste of program parts e.g. from the library is easier

- 55. © Siemens AG 2012. All Rights R Indus e.g. rising edge I 0.0 e.g. falling edge I 6.1 troller Innovations: ble Handling of Organization Blocks for S7-1200 / S7-1500 Hardware interrupt OB40 Hardware interrupt_1 OB41 Called when a specific event trigger the inputs (e.g. falling/rising signal) Fast and selective reaction Process alarms Saving Time during Engineering: flexible handling of alarms – alarm analyzing in the program code is not longer necessar

- 56. © Siemens AG 2012. All Rights R Indus ATIC S7-1500 Programming rity of Organization Blocks for the S7-1500 error interrupt 80 (Prio 22), . cyclic time exceeded Cyclic interrupt, e.g. OB30 (Prio 11) e.g. every minute Cyclic OB is executed endless ..... ocess alarm OB 40 (Prio 16) ...... until there is an interrupt by another OB Priority 1 free definition of the OB priority possible free definition of the OB priority possible free definition of the OB priority possible Communication with p => It’s possible to use defined OB with a high than the communicatio The priority of Organization blocks could be defined by the user

- 57. © Siemens AG 2012. All Rights R Indus Innovations: erministic behavior – adjustable PLC controller behavior O B35 B35 OB35 Prio 12 Prio 26 peration cyclic interrupt alarm – communication S7-300 longer OB35 ommunication Communication Communication jitter Handling of the cyclic interrupt alarm is not possible without a jitter because communication has a higher priority B35 OB35 Prio 15 Prio 16 peration cyclic interrupt alarm – communication S7-1500 OB35 Communication Communication Communication No jitter Handling of the cyclic interrupt alarm is possible without a jitter because the cyclic interrupt alarm could have a higher priority than the communication Advantages for the customer: adjustable PLC behavior, independ from communication higher accuracy in the application a in smaller PLCs

- 58. © Siemens AG 2012. All Rights R Indus Innovations: ustness of the PLC – detailed error detection is possible omer advantage: PLC stays in RUN, detailed error detection is possible C stays in “RUN” if an error occurs S7-200 C turns always to STOP if there is no error OB 8x) in the user program mple wire break: PLC will start the OB 82 in the user program => no 82 -> PLC turns to STOP Every user had to program the error OBs (at least empty error OB had to be inserted) S7-300 / S7-400 S7-1200 / 1500 PLC stays in “RUN“ no error OBs (OB 8x) has to be inserted Display of error messages via the integrated system diagnosis, e.g. wire brea Active RUN -> STOP-transition is possible if an er occurs (inserting of error OBs with a STOP instruc A local error reaction is possible < 2% of the ch programs used detection in the OBs

- 59. © Siemens AG 2012. All Rights R Indus e.g. IO access error: without OB122: PLC stays in RUN, entry to diagnostic buffer with : PLC stays in RUN, entry to diagnostic buffer, call of OB12 OB122 troller Innovations: r Reactions – detailed Error Handling is possible e.g. programming error: without OB121: PLC turns to STOP, entry to diagnostic buffer with : PLC stays in RUN, entry to diagnostic buffer, call of OB12 OB121 FC rror in block S7-1500 Non mission critical errors cause no PLC-STOP Mission critical errors cause PLC-STOP (without error-OBs)

- 60. © Siemens AG 2012. All Rights R Indus ATIC S7-1500 mized Access via data storage in optimized blocks Upper Performance via optimized access of data Standard DB REAL_1 BYTE_1 X_2 X_1 WORD_1 0 1 2 3 4 5 6 7 8 9 Optimized DB REAL_1 WORD_1 X_1 BYTE_1 X_2 0 1 2 3 4 5 6 7 8 9 Reserve Each bit one byte => No ma necessar Storage tags “op access”: only one 4 bytes -> value is r one comp access ccess ting ess: d e yte each ss

- 61. © Siemens AG 2012. All Rights R Indus Optimized DB Reserve Standard DB ATIC S7-1500 imized Access via Consistency-Check Upper Performance via Compile and Consistency-Check with TIA Portal x7p_get_native_pointer_imm_u8_func: .frame $sp,112,$31 # vars= 48, regs= 2/0, args= 56, gp= 0 .mask 0xc0000000,-4 .fmask 0x00000000,0 .set noreorder .set nomacro .LBB11754: .loc 1 13809 0 lw $2,12($20) li $3,16711680 # 0xff0000 ori $3,$3,0xffff and $9,$2,$3 .LVL5133: .loc 1 13807 0 lw $2,4($20) .loc 1 13808 0 lw $3,8($20) .LBE11754: .loc 1 13796 0 addiu $sp,$sp,-112 .LCFI871: .LBB11815: .loc 1 13809 0 srl $4,$9,23 .LBE11815: .loc 1 13796 0 sw $31,108($sp) .LCFI872: sw $fp,104($sp) .LCFI873: .LBB11816: .loc 1 13806 0 move $8,$20 .loc 1 13807 0 sw $2,96($sp) .loc 1 13809 0 beq $4,$0,.L9924 sw $3,92($sp) li $2,-16777216 # 0xffffffffff000000 or $9,$9,$2 .L9924: .loc 1 13815 0 lw $2,0($8) .loc 1 13813 0 move $5,$19 .loc 1 13815 0 ext $2,$2,26,1 beq $2,$0,.L9925 addiu $20,$8,16 andi $2,$16,0x00ff beq $2,$0,.L10006 lw $31,108($sp) .L9925: .loc 1 13817 0 lui $4,%hi(g_frame) lw $10,%lo(g_frame)($4) .loc 1 13813 0 lw $4,92($sp) .loc 1 13817 0 lw $2,0($8) .loc 1 13813 0 seh $3,$4 .loc 1 13817 0 lw $4,64($10) .LVL5134: and $2,$2,$4 bne $2,$0,.L9927 addu $fp,$5,$3 .loc 1 13822 0 lw $5,96($sp) sltu $2,$5,6 bne $2,$0,.L9995 lui $3,%hi(.L9934) .L9928: .loc 1 13840 0 lw $2,96($sp) lui $4,%hi(.LC0) li $5,327680 # 0x50000 lui $7,%hi(.LC1) andi $8,$2,0xffff addiu $4,$4,%lo(.LC0) ori $5,$5,0x2 addiu $7,$7,%lo(.LC1) li $6,13840 # 0x3610 ..LVL5135: .L9991: .loc 1 13895 0 li $2,40 # 0x28 sw $2,16($sp) li $2,3073 #0xc01 li $3,16410 # 0x401a sw $2,24($sp) lui $2,%hi(sys_FatalError) sw $3,20($sp) sw $8,44($sp) sw $0,28($sp) sw $0,32 addiu $2,$2,%lo(sys_FatalError) jalr $2 sw $0,52($sp) .LVL5136: .L9988: .LBE11816: .loc 1 13977 0 lw $31,108($sp) .L10006: lw $fp,104($sp) .LVL5137: j $31 addiu $sp,$sp,112 .LVL5138: .L9927: .LBB11817: .loc 1 13846 0 lw $3,4($fp) li $2,14 # 0xe beq $3,$2,.L9996 sw $3,88($sp) .loc 1 13871 0 andi $4,$9,0x7 bne $4,$0,.L10007 lw $3,88($sp) lbu $2,3($fp) bne $2,$0,.L10008 addiu $2,$3,-4 lw $2,12($fp) sra $5,$9,3 addiu $3,$5,1 sltu $2,$2,$3 bne $2,$0,.L9936 lw $3,88($sp) .loc 1 13877 0 lw $4,96($sp) sltu $2,$4,6 bne $2,$0,.L9997 lui $3,%hi(.L9943) .L9937: .loc 1 13895 0 lw $5,96($sp) lui $4,%hi(.LC0) lui $7,%hi(.LC1) andi $8,$5,0xffff li $5,327680 # 0x50000 addiu $4,$4,%lo(.LC0) ori $5,$5,0x2 addiu $7,$7,%lo(.LC1) j .L9991 li $6,13895 # 0x3647 .L9936: .L10007: .loc 1 13901 0 addiu $2,$3,-4 .L10008: sltu $2,$2,2 bne $2,$0,.L9998 lw $2,96($sp) .LBB11755: .loc 1 13928 0 lw $5,36($fp) .loc 1 13930 0 lw $2,24($fp) .LVL5139: beq $2,$0,.L9999 sw $5,76($sp) .loc 1 13934 0 lw $2,76($sp) bne $2,$0,.L9945 nop .LVL5140: lbu $2,3($fp) addu $2,$4,$2 beq $2,$0,.L10000 sra $2,$9,3 .LVL5141: .L9945: .loc 1 13939 0 bne $4,$0,.L10009 li $2,8 # 0x8 lbu $2,3($fp) bne $2,$0,.L9946 li $2,8 # 0x8 .L9947: .loc 1 13947 0 lw $3,20($fp) .LBB11758: .LBB11761: .LBB11765: .loc 3 1767 0 lhu $2,36($10) .LBE11765: .LBE11761: .LBE11758: .loc 1 13947 0 lw $fp,8($fp) .LVL5142: .LBB11757: .LBB11760: .LBB11764: .loc 3 1767 0 beq $2,$0,.L10001 sw $3,72($sp) .LVL5143: .L9948: .LBE11764: .LBE11760: .LBE11757: .loc 1 13948 0 lui $2,%hi(_Z31ec_vm_exception_throw_or_ignore P21x7p_virtual_machine_s11x7p_error_e13x7p_esource _e) move $4,$23 li $5,32 # 0x20 addiu $2,$2,%lo(_ Z31ec_vm_exception_throw_or_ignoreP21x7p_virt ual_machine_s11x7p_error_e13x7p_esource_e) jalr $2 li $6,2 # 0x2 .LVL5144: .loc 1 13951 0 lw $4,96($sp) sltu $3,$4,6 bne $3,$0,.L10002 lui $3,%hi(.L9985) ..L9979: .loc 1 13969 0 lw $5,96($sp) lui $4,%hi(.LC0) lui $7,%hi(.LC1) andi $8,$5,0xffff li $5,327680 # 0x50000 addiu $4,$4,%lo(.LC0) ori $5,$5,0x2 addiu $7,$7,%lo(.LC1) j .L9991 li $6,13969 # 0x3691 .LVL5145: .L9995: .LBE11755: .loc 1 13822 0 sll $2,$5,2 addiu $3,$3,%lo(.L9934) addu $3,$3,$2 lw $4,0($3) j $4 nop code: with with um of er ion) lbu $17, offset($21) Compiler code: linear com code for a consisten optimized access

- 62. © Siemens AG 2012. All Rights R Indus ATIC S7-1500 sibilities of optimized access with STL Upper performance with symbolic access Usage of Slice access Usage of indexed field access L "Data".Setpoint OPN "Data" L %DBW0 besser: A "Data".Status.x0 OPN "Data" U %DBX2.0 besser: L "Data".my_array[#index] OPN "Data" L #index SLD 3 LAR1 L DBW [ AR1 , P#10.0 ] besser: Possible w optimized DBs ngle ructions Upper Performance in the program language STL via symbolic Access

- 63. © Siemens AG 2012. All Rights R Indus ATIC S7-1500 mized access and increase of performance using “ENO deactivated” Following instructions are executed dependent of the instruction’s result Following instructions are always executed Advantage: faster execution cause of fewer checks 1 More than one branch can be defined per network: seful distribution possible

- 64. © Siemens AG 2012. All Rights R Indus ATIC S7-1500 rview of Highlights y ommissioning gh-speed diagnosis or messages in plain text ss to MLFB, serial no., etc. STEP7 language innovations Complete symbolic programming High-performance LAD/FBD/SCL compil Innovations in LAD/FBD/SCL DB max.: 16 MB, FBs/FCs: 512 KB Portfolio One system for machine and plant construction Reduction of modules by >50% for PLCs Reduction of modules by >30% for I/Os Performance Extremely fast backplane bus Extremely fast bit instructions Extremely fast response time (terminal <-> terminal) are 32 modules / row modules for U connector and backplane guration ient memory for every application memory via SIMATIC Memory Card System diagnostics, alarm function Fully-integrated system diagnostics One ALARM FB Uniform display of PLC & HMI unications O RT/IRT in every PLC erface for network isolation data (PLC, CM) in process image e programming of communication for PLC Ms ated web server

- 65. © Siemens AG 2012. All Rights R Indus ATIC S7-1500 ATIC system diagnostics nnovation in system diagnostics System diagnostics possible with PLC at STOP, no problematical synchronization required Uniform display concept (representation of statuses): TIA Portal / HMI / Web server / display Diagnostics viewers are uniformly available on the CE Panels of the Comfort line Automatic updating of the diagnostics viewers via the PLC Identical display of all messages in STEP7, HMI, S7-1500 Web server and S7-1500 display

- 66. © Siemens AG 2012. All Rights R Indus ATIC S7-1500 ATIC system diagnostics Diagnosis service HWKONFIG S7-1500 TIA Portal HMI device PLC WEB Server PLC Display Identical display of all messages in STEP7, HMI, S7-1500 Web server and S7-1500 display

- 67. © Siemens AG 2012. All Rights R Indus ATIC S7-1500 engineered with TIA Portal light - Performance Simple acquisition of process values and system status ted Web Server cess to system-, process messages as well as identification data stem diagnostics of all projected modules, centralized & centralized mmunication diagnostics of parameters, statistics, connection atus cess to process data by using tag tables and freely definable tag s er defined web pages in the PLC ves & Recipes cess by using web server via filebrowser for bidirectional data mmunication in .csv format ility to record user definable tags

- 68. © Siemens AG 2012. All Rights R Indus cording of up to 16 different tags in separate PLC memory area utside of work, load or retentive memory) pport of four independent trace-jobs at the same time clic acquisition (real-time), not to lose any values ultiplex trigger conditions to filter for desired events e recording occurs independently of Engineering System on the C, to simplify the search of sporadic problems portable measurements for documentation and further processing data by user (csv and ttrec file) ATIC S7-1500 engineered with TIA Portal light – Integrated technology Program- and application diagnostics at real-time for recognizing even sporadic prob

- 69. © Siemens AG 2012. All Rights R Indus MATIC S7-1500 alarms ser alarms 1 interrupt block (Program_Alarm) for all applications Reduction in block variety/complexity (ALARM_S, ALARM_8, ... ) Program_Alarm: up to 10 associated values (also strings) nterrupt numbers need not be matched manually f program (section) is copied into further PLCs Direct configuration of the interrupts in the program Identical display of all user alarms in STEP7, HMI, S7-1500 Web server and S7-1500 display

- 70. © Siemens AG 2012. All Rights R Indus User program ATIC S7-1500 sibilities of diagnostics … RDREC … Display HMI- alarm system Web server SFB „RDREC“ asynchrony alarms system diagnostics program 1 1 1 1 1 1 1 0 QI Synchrony Alarms User program … U QI SPB OK … analyze QI in the program code Program Diagnostic Alarm read value is not valid

- 71. © Siemens AG 2012. All Rights R Indus sibilities of Analyzing the Diagnostic information em Diagnostic and Quality Information Sequence Synchrony Alarms Asynchrony A IO-module realizes an error; e.g. wire break at channel 0 Channel status and module status LEDs are activated 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 0 QI QI Diagnostic information e.g. wire break is created in the IO-module 2 1 1 1 1 1 1 1 0 QI IO-Data IO-data and QI are sent; a diagnostic event is activated, module status LEDs are activated e.g. in the PLC/ IM 3a IO-data and QI arrive synchrony in the PLC, the user can analyze the information via program code (simple binary instructions) … U QI SPB OK BEA OK: … Description 3b CALL RDREC, RDREC_DB Variant REQ:= ID:= INDEX:= MLEN:= VALID:= BUSY:= ERROR:= STATUS:= LEN:= RECORD:= Diagnostic information arrive asynchrony in the PLC, the user can analyze the information via RDREC (OB82 or per polling)

- 72. © Siemens AG 2012. All Rights R Indus ATIC S7-1500 tionship between System diagnostics and Quality Information (QI) In the user program there are no additional addresses used no red LEDs on the PLC no Diagnostic alarm In the user program there are additional addresses used no red LEDs on the PLC no Diagnostic alarm In the user program there are no additional addresses used Channel status and module status LEDs for diagnostic information Diagnostic alarms In the user program there are additional addresses used Channel status and module sta LEDs for diagnostic informatio Diagnostic alarms The user has the possibility to react individually to diagnostic alarms

- 73. © Siemens AG 2012. All Rights R Indus ATIC S7-1500 rview of Highlights y ommissioning gh-speed diagnosis or messages in plain text ss to MLFB, serial no., etc. STEP7 language innovations Complete symbolic programming High-performance LAD/FBD/SCL compil Innovations in LAD/FBD/SCL DB max.: 16 MB, FBs/FCs: 512 KB Portfolio One system for machine and plant construction Reduction of modules by >50% for PLCs Reduction of modules by >30% for I/Os Performance Extremely fast backplane bus Extremely fast bit instructions Extremely fast response time (terminal <-> terminal) are 32 modules / row modules for U connector and backplane guration ient memory for every application memory via SIMATIC Memory Card Plug and Play Read out actual configuration Complete project upload to empty PG System diagnostics, alarm function Fully-integrated system diagnostics One ALARM FB Uniform display of PLC & HMI unications O RT/IRT in every PLC erface for network isolation data (PLC, CM) in process image e programming of communication for PLC Ms ated web server

- 74. © Siemens AG 2012. All Rights R Indus & Play uick and errorless detection of hardware via upload uring project upload of hardware and software, mbolic addresses and comments will also be loaded odule expansion and upload in RUN possible ATIC S7-1500 neering with TIA Portal Efficient commissioning and service by innovative upload-/download behavior

- 75. © Siemens AG 2012. All Rights R Indus ATIC S7-1500 rview of Highlights y ommissioning gh-speed diagnosis or messages in plain text ss to MLFB, serial no., etc. STEP7 language innovations Complete symbolic programming High-performance LAD/FBD/SCL compil Innovations in LAD/FBD/SCL DB max.: 16 MB, FBs/FCs: 512 KB Portfolio One system for machine and plant construction Reduction of modules by >50% for PLCs Reduction of modules by >30% for I/Os Performance Extremely fast backplane bus Extremely fast bit instructions Extremely fast response time (terminal <-> terminal) are 32 modules / row modules for U connector and backplane guration ient memory for every application memory via SIMATIC Memory Card Plug and Play Read out actual configuration Complete project upload to empty PG Datalog (archives) and recipes On SIMATIC Memory Card in csv format Access via web server System diagnostics, alarm function Fully-integrated system diagnostics One ALARM FB Uniform display of PLC & HMI unications O RT/IRT in every PLC erface for network isolation data (PLC, CM) in process image e programming of communication for PLC Ms ated web server

- 76. © Siemens AG 2012. All Rights R Indus 1500 Controller Innovations alog and Recipes DataLog (Archive) Cyclic & event driven storage of variables incl. STRING variables e.g. storage of production data, error information, … Files are saved as *.csv file on memory card Archive download from PLC via web server Recipes Reading and writing of recipes in *.csv format from memory card e.g. machine configuration, initial values, production dependent configuration data Files are saved as *.csv file on memory card Archive download and upload from PLC via web server

- 77. © Siemens AG 2012. All Rights R Indus ATIC S7-1500 rview of Highlights y ommissioning gh-speed diagnosis or messages in plain text ss to MLFB, serial no., etc. STEP7 language innovations Complete symbolic programming High-performance LAD/FBD/SCL compil Innovations in LAD/FBD/SCL DB max.: 16 MB, FBs/FCs: 512 KB Portfolio One system for machine and plant construction Reduction of modules by >50% for PLCs Reduction of modules by >30% for I/Os Performance Extremely fast backplane bus Extremely fast bit instructions Extremely fast response time (terminal <-> terminal) are 32 modules / row modules for U connector and backplane guration ient memory for every application memory via SIMATIC Memory Card Plug and Play Read out actual configuration Complete project upload to empty PG Compatibility Within the complete product line Simple migration 300/400->1500 Datalog (archives) and recipes On SIMATIC Memory Card in csv format Access via web server System diagnostics, alarm function Fully-integrated system diagnostics One ALARM FB Uniform display of PLC & HMI unications O RT/IRT in every PLC erface for network isolation data (PLC, CM) in process image e programming of communication for PLC Ms ated web server

- 78. © Siemens AG 2012. All Rights R Indus mpatibility vestment protection of existing Know-How due to usability of current programs between all S7-1500 LCs gration tool for the switchover from S7-300/S7-400 to e S7-1500 PLCs opy & Paste from S7-1200 programs to the S7-1500 LCs ame program structure for S7-1200 and S7-1500 ATIC S7-1500 neering with TIA Portal Investment protection while switchover to S7-1500

- 79. © Siemens AG 2012. All Rights R Indus ATIC S7-1500 ess from HMI to the S7-1500 MI Panel / SCADA* S7-1500 Fast data exchange via optimized communication service Access to absolute addressed tags Access from SIMATIC HMI Panels or SIEMENS SCADA-Systems* to the S7-1500 Access to symbolic addressed tags Access to new (64-bit)-data types Automatic data consistency via central data management Diagnostic information without additional effort (Diagnostic viewer) Higher access protection for tags (only “visible” and “accessible“ tags are available for the HMI) Integration in protection level “complete lock down” with digital signature of the communication data between HMI and PLC * WinCC V12: yes WinCC V7: with Wi

- 80. © Siemens AG 2012. All Rights R Indus ATIC S7-1500 ess from HMI to the S7-1500 Fremd-HMI S7-1500 Data exchange via S7 protocol (write/read) Access to absolute addressed tags Access of non-SIEMENS HMI-Devices to the S7-1500 via S7-protocol Automatic data consistency via central data management Access to symbolic addressed tags Integration in protection level “complete lock down” with digital signature of the communication data between HMI and PLC Fast data exchange via optimized communication service Diagnostic information without additional effort (Diagnostic viewer) Access to new (64-bit) data types Higher access protection for tags (only “visible” and “accessible“ tags are available for the HMI)

- 81. © Siemens AG 2012. All Rights R Indus ATIC S7-1500 rview of Highlights y ommissioning gh-speed diagnosis or messages in plain text ss to MLFB, serial no., etc. ology ard motion (via PN IRT) for all variables PID control functions STEP7 language innovations Complete symbolic programming High-performance LAD/FBD/SCL compil Innovations in LAD/FBD/SCL DB max.: 16 MB, FBs/FCs: 512 KB Portfolio One system for machine and plant construction Reduction of modules by >50% for PLCs Reduction of modules by >30% for I/Os Performance Extremely fast backplane bus Extremely fast bit instructions Extremely fast response time (terminal <-> terminal) are 32 modules / row modules for U connector and backplane guration ient memory for every application memory via SIMATIC Memory Card Plug and Play Read out actual configuration Complete project upload to empty PG Compatibility Within the complete product line Simple migration 300/400->1500 Datalog (archives) and recipes On SIMATIC Memory Card in csv format Access via web server System diagnostics, alarm function Fully-integrated system diagnostics One ALARM FB Uniform display of PLC & HMI unications O RT/IRT in every PLC erface for network isolation data (PLC, CM) in process image e programming of communication for PLC Ms ated web server

- 82. © Siemens AG 2012. All Rights R Indus PORTAL V12 gration of Drives n control functions exible connection of drives by PROFINET, PROFIBUS or alog interfaces asy programming of the movements with PLCopen motion ocks nified configuration / parameterization for PLC / HMI / drives uitive diagnostic- and commissioning tools (Control Panel, ace) asy fault detection by automatic alarm signals to the gineering system and to the HMI Easy scalability by integrating the same motion control functions in all PLCs

- 83. © Siemens AG 2012. All Rights R Indus ATIC S7-1500 grated Technology n Control Functionality is control panel for graphical commissioning of the drive sic check of each functionality of the drive Jog mode, Positioning, Set of the drive speed set point, Reference mode, etc. ning functionality for system based optimization of the positioning ntrol Easy and fast commissioning functionalities in each Controller

- 84. © Siemens AG 2012. All Rights R Indus ated PID control r a wide range of closed loop control applications ed as a controller with continuous or discrete output or as a step ntroller for valves sy commissioning by means of automatic parameterization egrated protection of human and machine Compact / PID 3-Step ntinuous PID controller with analog or discrete (PWM) output spectively special designed for step by step controller for integrated tuators (e.g. valves) to-Tuning ATIC S7-1500 grated PID control Cost savings through integrated PID control with high quality auto-tuning

- 85. © Siemens AG 2012. All Rights R Indus ATIC S7-1500 grated Technology: closed loop control ated Trace Tuning ess and s of the ning Start/Stopp Controller Online infor

- 86. © Siemens AG 2012. All Rights R Indus ATIC S7-1500 grated Technology: closed loop control ble PID Controller PID Compact Continuous controller Analog and pulse width modulated outputs possib PID 3-Step Specialized step controller Usable for integrating actuators (e.g. valves) Error behavior Improved features in V2.0: Startup behavior Trace-Functionality Default values for PID parameter PID Basic FB41,42,43,58,59 PID Self-Tuner Instruction for self-adjustment of PID parameter (Integrated into STEP 7 V12)

- 87. © Siemens AG 2012. All Rights R Indus ATIC S7-1500 grated Technology: closed loop control High or low limit of the process value is reached Controller lost its input, calculation impossible Error disapp Inactive Controller inactive Output = 0 Controller ina Output = Current value while error Controller stays active High or low limit of the process value is reached Controller lost its input, calculation impossible Error disapp Inactive Controller inactive Output = 0 Controller ina Output = Current value while error Controller stays active Output = last valid value Substitute output value while error Output = Substitute value High or low limit of the process value is reached Controller lost its input, calculation impossible Error disapp Inactive Controller inactive Output = 0 Controller ina Output = Current value while error Controller stays active Substitute output value while error High or low limit of the process value is reached Controller lost its input, calculation impossible Error disapp High or low limit of the process value is reached Controller lost its input, calculation impossible Error disapp Inactive Controller inactive Output = 0 Controller ina Output = High or low limit of the process value is reached Controller lost its input, calculation impossible Error disapp Inactive Controller inactive Output = 0 Controller ina Output = Current value while error Controller stays active Output = last valid value Controller sw back autom mode automa Substitute output value while error Output = Substitute value Mode = automatic Less inactive states Improved Error-Reaction

- 88. © Siemens AG 2012. All Rights R Indus ATIC S7-1500 grated Technology: closed loop control Default values for PID parameter Due to the retain values, changing the offline PID parameters and down doesn‘t necessarily change actual va PID Parameters are retain values Setting the start values of the PID parameters Startup behavior ose the operating e after PLC restart Controller works w/o tuning Automatic mode after restart

- 89. © Siemens AG 2012. All Rights R Indus ATIC S7-1500 grated Technology: closed loop control fline project Load memory RAM Start values „TO PID_Compact“ S7-1500 Actual values „TO PID_Compact“ PID_Compact“ Initialization mon modify va Watch values Start tuning Change start values Start values STOP RUN

- 90. © Siemens AG 2012. All Rights R Indus ATIC S7-1500 rview of Highlights y ommissioning gh-speed diagnosis or messages in plain text ss to MLFB, serial no., etc. ology ard motion (via PN IRT) for all variables PID control functions STEP7 language innovations Complete symbolic programming High-performance LAD/FBD/SCL compil Innovations in LAD/FBD/SCL DB max.: 16 MB, FBs/FCs: 512 KB Portfolio One system for machine and plant construction Reduction of modules by >50% for PLCs Reduction of modules by >30% for I/Os Performance Extremely fast backplane bus Extremely fast bit instructions Extremely fast response time (terminal <-> terminal) are 32 modules / row modules for U connector and backplane guration ient memory for every application memory via SIMATIC Memory Card Plug and Play Read out actual configuration Complete project upload to empty PG Compatibility Within the complete product line Simple migration 300/400->1500 Datalog (archives) and recipes On SIMATIC Memory Card in csv format Access via web server System diagnostics, alarm function Fully-integrated system diagnostics One ALARM FB Uniform display of PLC & HMI unications O RT/IRT in every PLC erface for network isolation data (PLC, CM) in process image e programming of communication for PLC Ms ated web server Security Integrated Know How / Copy Protection Authentication Manipulation protection Security Integrated

- 91. © Siemens AG 2012. All Rights R Indus r Know-How Protection ssword protection against unauthorized opening of the program ocks with STEP 7 and so protecting against unauthorized copying e.g. developed algorithms ssword protection against unauthorized evaluation of the program ocks with external programs from the STEP 7 project from the data of the memory card from program libraries ATIC S7-1500 urity Integrated Protection of intellectual property and effective investment

- 92. © Siemens AG 2012. All Rights R Indus r Copy Protection nding of single blocks to the serial number of the memory card PLC otection against unauthorized copying of program blocks with EP 7 otection against unauthorized duplicating the project saved on the emory card ATIC S7-1500 urity Integrated Protection against unauthorized reproduction of executable programs

- 93. © Siemens AG 2012. All Rights R Indus r Access Protection (Authentication) w degree of Protection Level 4 for PLC, complete lockdown (also MI connections need password) * nfigurable levels of authorization (1-3 with own password) r accessing over PLC and Communication Module interfaces eneral blocking of project parameter changes via the built-in display ded access protection a Security CP1543-1 through integrated firewall and VPN (SP1) ATIC S7-1500 urity Integrated ble in connection with SIMATIC HMI Panels Extensive protection against unauthorized project changes

- 94. © Siemens AG 2012. All Rights R Indus ATIC S7-1500 urity Integrated er Protection of Manipulation proved Protection against manipulated communication of ntroller access through digital checksums otection against network attacks such as intrude of faked / corded network communication (Replay attacks) ecure password transfer at authentication etection of manipulated firmware updates through digital ngatures Protection of communication against unauthorized manipulation for high plant availab

- 95. © Siemens AG 2012. All Rights R Indus ATIC S7-1500 rview of Highlights y ommissioning gh-speed diagnosis or messages in plain text ss to MLFB, serial no., etc. ology ard motion (via PN IRT) for all variables PID control functions STEP7 language innovations Complete symbolic programming High-performance LAD/FBD/SCL compil Innovations in LAD/FBD/SCL DB max.: 16 MB, FBs/FCs: 512 KB Portfolio One system for machine and plant construction Reduction of modules by >50% for PLCs Reduction of modules by >30% for I/Os Performance Extremely fast backplane bus Extremely fast bit instructions Extremely fast response time (terminal <-> terminal) are 32 modules / row modules for U connector and backplane guration ient memory for every application memory via SIMATIC Memory Card Plug and Play Read out actual configuration Complete project upload to empty PG Compatibility Within the complete product line Simple migration 300/400->1500 Datalog (archives) and recipes On SIMATIC Memory Card in csv format Access via web server System diagnostics, alarm function Fully-integrated system diagnostics One ALARM FB Uniform display of PLC & HMI unications O RT/IRT in every PLC erface for network isolation data (PLC, CM) in process image e programming of communication for PLC Ms ated web server Security Integrated Know How / Copy Protection Authentication Manipulation protection Security Integrated

- 96. © Siemens AG 2012. All Rights R Juan Pablo Palacios Product Manager I IA AS Ecuador nk you for your attention!