Concrete Canvas Lining Protects Chilean Mine Channels

- 1. Concrete Impregnated Fabric... MOST INNOVATIVE PRODUCT National Winner Chambers of Commerce Award 2011 Top Innovation BRE Insite 2011 CHAMBER AWARDS 2011 NATIONAL WINNER 2011 Nominee, 2007 Finalist Design to Improve Life Award 2009 Winner Material Connexion Medium Award Material of the Year MTP Gold Medal Award BUDMA 2011 POZNANI N TERNATI ONALFAIR AT WORLD OF CONCRETE 2011 Expert’s Choice Winner Most Innovative Product Modern Built Environment Knowledge Transfer Network 2012 R&D 100 Award winner R&D Magazine 13.05.UK MADE IN UK

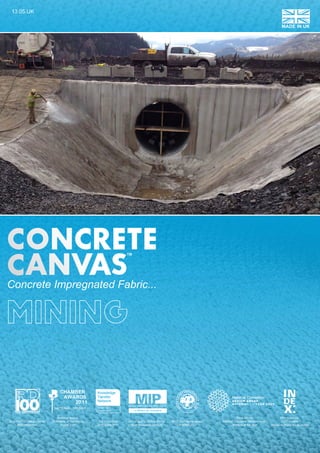

- 2. TM Concrete Impregnated Fabric... TM Concrete Impregnated Fabric... © Concrete Canvas Ltd. 2012 The information contained herein is offered free of charge and is, to the best of our knowledge, accurate. However, since the circumstances and conditions in which such information and the products discussed therein can be used may vary and are beyond our control, we make no warranty, express or implied, of merchantability, fitness or otherwise, or against patent infringement, and we accept no liability, with respect to or arising from use of such information or any such product. www.concretecanvas.co.ukinfo@concretecanvas.co.uk+ 44 (0) 845 680 1908 www In late 2011, Concrete Canvas (CC) was specified to line melt water channels at an open pit mine in southern Chile. The pit, mined for gold, silver, copper and other minerals is located in the Andes mountains, in the southern reaches of the Atacama Desert, at the border between Chile and Argentina. Melt water erosion, high UV levels and wind speeds of over 100km/hr had degraded the existing channels over a number of years. The integrity of the channel network is vital to avoid flooding of the pit from glacier melt water. Located at over 5000m above sea level and subject to sub- zero conditions, traditional concrete solutions are cost prohibitive, time intensive and difficult to install. Using plant, spreader beam equipment and bulk rolls of CC, the contractors were able to line the channels at a rate of over 200m/hr. The speed and ease of installation was critical to the safety of the installers. To combat the low temperature conditions, frost sheets and warm water from the nearby mine were used to hydrate the CC. Different thicknesses of CC were used to match variations in ground quality and profile at different sections of the channels. 1, 2 or 3 longitudinal CC layers were used as the width and depth of the channels varied. Adjacent CC layers were overlapped and screwed together using collated auto-fed screws, whilst joints and steep sections were fixed to the rocky substrate using steel ground pegs. In total, over 52’000sqm of CC was used to successfully line the remote network of channels in extreme conditions. Project Info CC5, CC8 and CC13 22 / 02 / 2012 52’000sqm 1-3 longitudinal layers Alta Montaña III region, Chile - Melt water channel network. - High altitude. - Low temperature. - Variable ground conditions. - CC installed at 200m/hr. - 52’000sqm CC used. i # 7 MAY Channel section being lined with CC at high altitude Extreme conditions YTRADELP www.polytrade.cl

- 3. TM Concrete Impregnated Fabric... TM Concrete Impregnated Fabric... © Concrete Canvas Ltd. 2012 The information contained herein is offered free of charge and is, to the best of our knowledge, accurate. However, since the circumstances and conditions in which such information and the products discussed therein can be used may vary and are beyond our control, we make no warranty, express or implied, of merchantability, fitness or otherwise, or against patent infringement, and we accept no liability, with respect to or arising from use of such information or any such product. www.concretecanvas.co.ukinfo@concretecanvas.co.uk+ 44 (0) 845 680 1908 www Canal Alta Montaña, Chile Alta Montaña III region, Chile Spreader beam and plant bulk roll dispensing Fixing longitudinal CC layer to channel bank CC bulk rolls Cutting CC layer to length using hand knives Degraded melt water channel CC laid at rate of 200m/hr

- 4. TM Concrete Impregnated Fabric... TM Concrete Impregnated Fabric... © Concrete Canvas Ltd. 2012 The information contained herein is offered free of charge and is, to the best of our knowledge, accurate. However, since the circumstances and conditions in which such information and the products discussed therein can be used may vary and are beyond our control, we make no warranty, express or implied, of merchantability, fitness or otherwise, or against patent infringement, and we accept no liability, with respect to or arising from use of such information or any such product. www.concretecanvas.co.ukinfo@concretecanvas.co.uk+ 44 (0) 845 680 1908 www Project Info Bulk CC8 and CC13 22 / 02 / 2012 10’150sqm Transverse layers British Columbia, Canada - Carrier drain directing effluent from coal mine to settling pond. - Low temperature. - Variable ground conditions. i # 7 MAY Completed lined ditch channel and culvert. Concrete Canvas (CC) is a versatile construction material that has a wide variety of applications across a range of sectors. CC has predominantly been used for ditch lining in the private civil construction industry, but increasingly CC is being specified in the mining sector for general water management projects across the globe. CC can be installed quickly, and is uniquely suited for installation in remote, difficult to access sites of all terrains and in all weather conditions making it ideal for time-critical mining works. Following the recent success of a 52’000sqm CC installation in the Alta Montaña III region of Chile, Ledcor Group, acting on behalf of Walter Energy, specified CC as a protective liner for a large carrier ditch, directing mining industrial waste water from Willow Creek mine to a nearby settling pond. Willow Creek is a large open pit mine located 45 kilometres west of the town of Chetwynd, in northeast British Columbia. The mine is a truck and shovel operation and is capable of producing both hard coking coal and low-volatile PCI coal for steelmaking. The customer specified that the lined ditch had to be as water proof as possible, handle freeze/thaw conditions, and be easy to repair. The carrier ditch was 10.5-12 meters wide, between 3 and 5 meters deep and approximately 650 metres long. The overall size, performance requirements of this particular application, as well as the cost potential meant that Ledcor were reluctant to use Shotcrete. CC was dispensed in bulk rolls from spreader beam equipment and was cut to length on site, minimising waste as lengths were cut specifically to each section of profile. No perishable formwork or additional reinforcement was required. Tailings containment

- 5. TM Concrete Impregnated Fabric... TM Concrete Impregnated Fabric... © Concrete Canvas Ltd. 2012 The information contained herein is offered free of charge and is, to the best of our knowledge, accurate. However, since the circumstances and conditions in which such information and the products discussed therein can be used may vary and are beyond our control, we make no warranty, express or implied, of merchantability, fitness or otherwise, or against patent infringement, and we accept no liability, with respect to or arising from use of such information or any such product. www.concretecanvas.co.ukinfo@concretecanvas.co.uk+ 44 (0) 845 680 1908 www British Columbia Ditch Lining cont. Large settling pond collecting effluent from nearby Willow Creek coal mine, British Columbia, Canada Using plant to unroll CC bulk rolls across channelCC dispensed from bulk rollsExcavating the sump and constructing the culvert CC layers were laid transversely across the width of the ditch, with adjacent layers overlapped by 100mm and beaded with Sikaflex 1A to create water tight joints. Overlaps were fixed together using 25mm screws for neatness and flushness. Where possible, end edges were buried with loose shale and aggregate to prevent water ingress under the CC and to provide a neat seamless termination with the crest of the ditch. The ditch was excavated from a blasted rock substrate, with some sections reinforced with concrete block work. CC layers were pinned into position at the top of the profile using 10” Ardox galvanized spikes. When fixing CC to the concrete block work sections, Hilti rock anchors were used. In its unset flexible state prior to hydration, CC can be fixed to almost every type of substrate using standard off-the-shelf fixings or adhesives. The ditch terminated in a 4m diameter corrugated steel and concrete block work culvert and sump which was also lined with CC to ensure minimum water loss, as water was contaminated from tailings and could not come into contact with any other water sources. Grouting was chosen in areas that may be prone to heavier flows and related scouring. In an effort to minimize the possibility of potential debris dams, grouting also eliminated the lip that was caused from the overlap of CC layers. The fibre reinforcement inherent in CC gives a durability and design life well above competitor geomembrane products, whilst the integral PVC backing ensures minimal water loss in the carrier ditch. The CC will moss over in time, blending in with the surrounding environment but will prevent root growing vegetation, reducing the need for maintenance of the ditch.

- 6. TM Concrete Impregnated Fabric... TM Concrete Impregnated Fabric... © Concrete Canvas Ltd. 2012 The information contained herein is offered free of charge and is, to the best of our knowledge, accurate. However, since the circumstances and conditions in which such information and the products discussed therein can be used may vary and are beyond our control, we make no warranty, express or implied, of merchantability, fitness or otherwise, or against patent infringement, and we accept no liability, with respect to or arising from use of such information or any such product. www.concretecanvas.co.ukinfo@concretecanvas.co.uk+ 44 (0) 845 680 1908 www Swale was formed on the north ridge of the ditch at a nearby tree line to collect surface rainfall from an adjacent hillside. 6” steel anchor nails with 1” hex head washersApplying Sikaflex beading to joints Hydration of CC using bowser equipment Lining the culvert with CC8 British Columbia Ditch Lining cont.

- 7. TM Concrete Impregnated Fabric... TM Concrete Impregnated Fabric... © Concrete Canvas Ltd. 2012 The information contained herein is offered free of charge and is, to the best of our knowledge, accurate. However, since the circumstances and conditions in which such information and the products discussed therein can be used may vary and are beyond our control, we make no warranty, express or implied, of merchantability, fitness or otherwise, or against patent infringement, and we accept no liability, with respect to or arising from use of such information or any such product. www.concretecanvas.co.ukinfo@concretecanvas.co.uk+ 44 (0) 845 680 1908 www Project Info Bulk CC8 24 / 02 / 2012 125sqm Longitudinal layers Chillepin, Chile Pacifitek LTDA Ditch to divert irrigation waters from a mineral transport pipeline i # 7 MAY Completed lined ditch channel. In February 2012, Concrete Canvas (CC) was specified to line a ditch that would channel irrigation water away from a mineral transport pipeline owned by the Los Pelambres Mining Company in Chillepin, Chile. Traditionally, poured concrete would have been used to line the ditch. However, site access for plant and machinery was limited and the project had time constraints due to upcoming work on an archeological site adjacent to the proposed location of the ditch. CC was deemed to be the perfect solution to these problems due to its portability, speed of installation and ease of use in difficult to access areas. The ditch site was prepared and cleared and two bulk rolls of CC8 delivered to site using a crane truck and spreader beam equipment. The CC8 was unrolled at the foot of the site and carried by the installation team along the length of the proposed ditch in two sections, before being shaped to the ditch profile and fixed in place with ground pegs. A 200mm overlap was created on the join between each section in the direction of water flow and secured with screws. The CC was then hydrated using man-portable water tanks, poured along the full length of the ditch. A 14-man installation team were able to complete the 125sqm ditch in four hours, with little training and readily available hand tools. The nearby archaeological site remained undisturbed and the Los Pelambres Mining Company, impressed with the ease and speed with which CC was installed have already specified that it be used in several future projects. No plant required

- 8. TM Concrete Impregnated Fabric... TM Concrete Impregnated Fabric... © Concrete Canvas Ltd. 2012 The information contained herein is offered free of charge and is, to the best of our knowledge, accurate. However, since the circumstances and conditions in which such information and the products discussed therein can be used may vary and are beyond our control, we make no warranty, express or implied, of merchantability, fitness or otherwise, or against patent infringement, and we accept no liability, with respect to or arising from use of such information or any such product. www.concretecanvas.co.ukinfo@concretecanvas.co.uk+ 44 (0) 845 680 1908 www Cleared and prepared ditch site CC fixed in place using ground pegs and hand tools CC8 delivered by crane truck and spreader beam CC undergoing hydration One length of CC8 carried to site by installation team

- 9. TM Concrete Impregnated Fabric... TM Concrete Impregnated Fabric... © Concrete Canvas Ltd. 2012 The information contained herein is offered free of charge and is, to the best of our knowledge, accurate. However, since the circumstances and conditions in which such information and the products discussed therein can be used may vary and are beyond our control, we make no warranty, express or implied, of merchantability, fitness or otherwise, or against patent infringement, and we accept no liability, with respect to or arising from use of such information or any such product. www.concretecanvas.co.ukinfo@concretecanvas.co.uk+ 44 (0) 845 680 1908 www Project Info CC8 Batched Rolls 06 / 06 / 2011 20sqm per opening Nuna Innovations Inc. Vertical layers Creighton Mine, Ontario, Canada CC used to create a simple, effective vent closure in remote, hard to access areas of the mine in a timely, safe and cost effective manner. i # 7 MAY Completed vent wall closure In underground mining, up to 35% of the cost of running the mine is devoted to supplying a fresh air supply and ventilation. When the mining is finished in a particular shaft it is often closed and a vent wall is erected, as a fresh air supply is no longer needed. In the past this could prove logistically difficult, requiring multiple work crews and specialised equipment, which are often difficult to mobilise in remote areas of a mine. Nuna Innovations Inc. were commissioned by mine owners Vale Canada Ltd, to supply Concrete Canvas (CC) and relevant installation advice on erecting vent seals at Creighton Mine, an underground nickel mine in Ontario, Canada. The use of CC has changed the way vent walls are now constructed within the mine. Traditionally shotcrete would have been used, which not only requires multiple crews for installation but also planning and considerable expense. Batched rolls of CC8 were chosen for the project; these are man-portable and the length of each roll matched the diameter of the vent openings, reducing waste. CC also gave favourable results during concussion testing, which was important due to the fact that blasting was still taking place in nearby shafts. CC interface with floor and joints screwed every 200mm

- 10. TM Concrete Impregnated Fabric... TM Concrete Impregnated Fabric... © Concrete Canvas Ltd. 2012 The information contained herein is offered free of charge and is, to the best of our knowledge, accurate. However, since the circumstances and conditions in which such information and the products discussed therein can be used may vary and are beyond our control, we make no warranty, express or implied, of merchantability, fitness or otherwise, or against patent infringement, and we accept no liability, with respect to or arising from use of such information or any such product. www.concretecanvas.co.ukinfo@concretecanvas.co.uk+ 44 (0) 845 680 1908 www CC undergoing hydration prior to installationCC trimmed to size using hand tools Attaching CC to the wire frame using 8mm gauge industrial cable ties Spray foam was used to fill any voids between the vent wall and the surrounding rock

- 11. TM Concrete Impregnated Fabric... TM Concrete Impregnated Fabric... © Concrete Canvas Ltd. 2012 The information contained herein is offered free of charge and is, to the best of our knowledge, accurate. However, since the circumstances and conditions in which such information and the products discussed therein can be used may vary and are beyond our control, we make no warranty, express or implied, of merchantability, fitness or otherwise, or against patent infringement, and we accept no liability, with respect to or arising from use of such information or any such product. www.concretecanvas.co.ukinfo@concretecanvas.co.uk+ 44 (0) 845 680 1908 www Creighton Mine Vent Wall Closure Case Study Cont. Very little training or instruction is required in the use of CC; the mine’s installation team were fully instructed in just under two hours and the installation was completed without the need for specialist equipment or labour. Several vent seals were constructed using CC, each with an average area of 20sqm. On each vent opening a brattice-backed wire frame was erected and CC was cut and hydrated, before being fastened to the frame using 8mm industrial gauge cable ties to create the vent wall. Voids between the surrounding rock and the CC vent wall were then filled with a low off-gassing spray foam that is approved for underground use. Vale were impressed with their first experience of CC and cited the following advantages over their traditional methods as reasons for the success of the installation and why they would recommend CC for future projects: - Quick installation - Less challenging to install than shotcrete - Safe in remote locations - Cost savings of around 20% compared to traditional methods The speed of installation on the project reduced planned closure times, which in turn resulted in financial and time savings. The use of CC in remote areas also meant that fewer workers were involved in moving equipment, supplies and machinery, allowing further savings. CC is now used to erect vent walls in three Vale properties and is scheduled for use in other underground mines. “We think that the CC is tailor-made for our remote mine locations. It offers us a reliable solution for these areas and makes our daily work lives easier.” Paul Aho Ventilation Specialist Creighton Mine Detail showing partial opening used to control/interrupt air flow

- 12. TM Concrete Impregnated Fabric... TM Concrete Impregnated Fabric... © Concrete Canvas Ltd. 2012 The information contained herein is offered free of charge and is, to the best of our knowledge, accurate. However, since the circumstances and conditions in which such information and the products discussed therein can be used may vary and are beyond our control, we make no warranty, express or implied, of merchantability, fitness or otherwise, or against patent infringement, and we accept no liability, with respect to or arising from use of such information or any such product. www.concretecanvas.co.ukinfo@concretecanvas.co.uk+ 44 (0) 845 680 1908 www Vent walls had also been constructed out of the gypsum board the mine produced, but these were prone to rotting Concrete Canvas (CC) was specified in the construction of vent walls at Marblaegis Mine, an underground gypsum mine in Loughborough, UK. The mine’s owners, British Gypsum, had encountered problems in building vent walls in the past; using concrete blocks was a slow, expensive process requiring specialist labour. Brattice cloth could only be used as a temporary measure due to its durability, whilst their self-produced gypsum boards were quick to install but prone to rotting. British Gypsum therefore required a durable, flexible, cost-effective alternative. Using batched rolls of CC5 meant that the 3-man installation team were able to carry the material to site without any plant or specialist equipment. After being cut to length on site using hand tools, the CC5 was hung, shaped and fixed to a British Gypsum branded aluminium stud wall system and securely fastened using wooden battens, 200mm steel strips and screws. The whole structure was then hydrated using a portable water supply. British Gypsum were very impressed with the end result. They were confident that CC would prove to be more durable than brattice cloth, whilst being less expensive and easier to mobilise and install than concrete block walls Project Info CC5 Batched Rolls 25 / 10 / 2012 20sqm per opening British Gypsum Vertical layers Marblaegis Mine, Loughborough, UK CC used as effective alternative to traditional mining vent wall solutions. i # 7 MAY Completed vent wall closure

- 13. TM Concrete Impregnated Fabric... TM Concrete Impregnated Fabric... © Concrete Canvas Ltd. 2012 The information contained herein is offered free of charge and is, to the best of our knowledge, accurate. However, since the circumstances and conditions in which such information and the products discussed therein can be used may vary and are beyond our control, we make no warranty, express or implied, of merchantability, fitness or otherwise, or against patent infringement, and we accept no liability, with respect to or arising from use of such information or any such product. www.concretecanvas.co.ukinfo@concretecanvas.co.uk+ 44 (0) 845 680 1908 www Battens, 200mm steel and screws used to provide strong fixing to rockConcrete Canvas cut to size, held in place and screwed to frame Completed vent wall closure using Concrete CanvasCC hydrated using on-site equipment Frame created using British Gypsum branded aluminium stud wall system

- 14. TM Concrete Impregnated Fabric... TM Concrete Impregnated Fabric... © Concrete Canvas Ltd. 2012 The information contained herein is offered free of charge and is, to the best of our knowledge, accurate. However, since the circumstances and conditions in which such information and the products discussed therein can be used may vary and are beyond our control, we make no warranty, express or implied, of merchantability, fitness or otherwise, or against patent infringement, and we accept no liability, with respect to or arising from use of such information or any such product. www.concretecanvas.co.ukinfo@concretecanvas.co.uk+ 44 (0) 845 680 1908 www Project Info CC5 Bulk Rolls 02 / 10 / 2012 53,200sqm Transverse layers 3rd Region of Atacama, Chile Lined ditch to divert glacial melt waters away from copper mine i # 7 MAY Section of CC-lined ditch undergoing hydration The Caserones Project is a ditch-lining project located in the 3rd Region of Atacama, 800 kilometres to the north of Santiago, with the aim of diverting glacial melt water that threatens to flood a nearby copper mine, owned and operated by Minera Lumina Copper Chile (MLCC). The project was being undertaken in a remote and challenging environment, with the bulk of the installation over 4,000m above sea level in an area subject to temperatures ranging from -10o C to 20o C. CC5 was delivered to site in bulk rolls and dispensed using a spreader beam and crane truck. Lengths of 6.4m were cut on site to allow the CC to be laid across the width of the ditch, then held in place with ground pegs before being buried in an anchor trench situated at the head of the ditch sides. Adjoining layers of CC were overlapped by 100mm in the direction of water flow and held together with screws. The CC was hydrated using a sprayer truck, dispensing water that had been mixed with a CC-approved accelerant to help the material set faster in the cold environment. The hydrated CC was then covered in plastic sheeting for three days to again protect it from freezing temperatures during setting. CC’s ease of use meant that two 5-man teams were able to install it at an average rate of 144sqm/hour, without the need for specialist training, equipment or heavy plant. 53,200sqm of CC5 was installed in total. Extreme conditions

- 15. TM Concrete Impregnated Fabric... TM Concrete Impregnated Fabric... © Concrete Canvas Ltd. 2012 The information contained herein is offered free of charge and is, to the best of our knowledge, accurate. However, since the circumstances and conditions in which such information and the products discussed therein can be used may vary and are beyond our control, we make no warranty, express or implied, of merchantability, fitness or otherwise, or against patent infringement, and we accept no liability, with respect to or arising from use of such information or any such product. www.concretecanvas.co.ukinfo@concretecanvas.co.uk+ 44 (0) 845 680 1908 www Parts of the ditch had been lined using poured concrete in the past Water/accelerant mix dispensed from water tanker during hydration Completed lined section of ditch The ditch was graded and cleared of rocks and debris prior to installation CC pegged to head of ditch edges and buried in anchor trench Hydrated CC covered with plastic sheeting to protect from low temperatures

- 16. Concrete Canvas Ltd. CF37 5SP, United Kingdom 11 EN12467:2004 Concrete Canvas: Fibre cement sheet NT Oversize sheets Class 1, Category A Reaction to Fire B-s1,d0 TM Concrete Canvas™ Material Data Post Set CC Properties Pre-Set CC Properties CC Physical Properties* Setting Method of Hydration Working Time 1-2 hours subject to ambient temperature CC will achieve 80% strength at 24 hours after hydration. Spray the fibre surface with water until it feels wet to touch for several minutes after spraying. Re-spray the CC again after 1 hour if: - Installing CC5 - Installing CC on a steep or vertical surface - Installing in warm climates Notes: - CC cannot be over hydrated and an excess of water is always recommended. - Minimum ratio of water:CC is 1:2 by weight. - Do not jet high pressure water directly onto the CC as this may wash a channel in the material. - CC can be hydrated using saline or non-saline water. - CC will hydrate and set underwater. - CC has a working time of 1-2 hours after hydration. Do not move CC once it has begun to set. - Working time will be reduced in hot climates. - CC will set hard in 24 hours but will continue to gain strength for years. - If CC is not fully saturated, the set may be delayed and strength reduced. If the set is delayed, re-wet with a large excess of water. * Indicative values Freeze-thaw testing (ASTM C1185) Freeze-thaw testing (BS EN 12467:2004 part 5.5.2) Soak-Dry testing (BS EN 12467:2004 part 5.5.5) Water impermeability (BS EN 12467:2004 part 5.4.4) Patent Protected Pat Pend/Granted: AE (766/2011), AE (932/2006), ARIPO (AP/P/2011/005842), AU (2010209524), AU (2005254788), BR (PI1005309-3), CA (2655054), CA (2749991), CA (2570532), CL (01809-2011), CN(201080005835.6), CO (11-092824), EP (2027319), EP (2393970), EP (1766162), GB (2455008), HK (12100037.1), ID (W00 2011 028 25), IL (214350), IN (5429/DELNP/2011), IN (20/DELNP/2007), JP (2011-546952), KR (10-2011-7020005), MN (3644),MX (MX/a/2011/007802), MY (PI2011003536), NO (20070245), NZ (594823), OM (OM/P/2011/00162), PH (1-2011-501468), RU (2011134016), RU (2386767), SG (201105143-0), TH (1101001335), US (8287982), US (US-2010-0233417-A1), US (13/146836), US(7721749), US (13/708074), VN (1-2011-02023), ZA (2009/00222), ZA (2011/06289), ZA (2007/0471) and other patents pending. Strength Other Abrasion Resistance (DIN 52108) - Similar to twice that of OPC Manning’s Value (ASTM D6460) CBR Puncture Resistance EN ISO 12236: 2007 (CC8 & CC13 only) - Min. Push-through force - Max. Deflection at Peak Standard Test Method for Impact Resistance of Pipeline Coatings ASTM G13 (CC13 only) Very high early strength is a fundamental characteristic of CC. Typical strengths and physical characteristics are as follows: Compressive tests based on ASTM C109 – 02 (initial crack) - 10 day compressive failure stress (MPa) Bending tests based on BS EN 12467:2004 (initial crack) - 10 day bending failure stress (MPa) - 10 day bending Youngs modulus (MPa) Tensile data (Initial crack) 40 3.4 180 2.69kN 38mm Passed Passed** n = 0.011 Passed 200 Cycles Passed Passed Max 0.10 gm/cm2 Tensile strength (kN/m) Length direction Width direction CC5 6.7 3.8 CC8 8.6 6.6 CC13 19.5 12.8 The information contained herein is offered free of charge and is, to the best of our knowledge, accurate. However, since the circumstances and conditions in which such information and the products discussed therein can be used may vary and are beyond our control, we make no warranty, express or implied, of merchantability, fitness or otherwise, or against patent infringement, and we accept no liability, with respect to or arising from use of such information or any such product. ** For containment applications where a 100% waterproof seal is required, it is recommended to use CC as a protective overlay in combination with an appropriate sealed membrane liner. CC is not recommended as the sole barrier layer where 100% impermeability is critical. Post set data is based on CC hydrated in accordance with the CC Hydration Guide. Reaction to Fire CC has achieved Euroclass B certification: BS EN 13501-1:2007+A1:2009 B-s1, d0 CC has achieved MSHA approval: 30 CFR, Part 7, Subchapter B, Section 7.24 © Concrete Canvas Ltd 2013 Contact Concrete Canvas CC Patent Information CC Thickness (mm) Batch Roll Size (sqm) Bulk Roll Size (sqm) Roll Width (m) CC5 5 10 200 1.0 CC8 8 5 125 1.1 CC13 13 N/A 80 1.1 CC Mass (unset) (kg/m2) Density (unset) (kg/m3) Density (set) (kg/m3) CC5 7.0 1500 +30-35% CC8 12.0 1500 +30-35% CC13 19.0 1500 +30-35% Concrete Impregnated Fabric... For further information or technical support contact: www www.concretecanvas.co.ukinfo@concretecanvas.co.uk+ 44 (0) 845 680 1908 * Occasionally there will be a Beam Fault (fabric imperfection under 100mm wide running across the width) in a Bulk Roll. This fault is unavoidable due to the manufacturing process and the fault will be clearly marked with a red tag, there will be a maximum of (1) one Beam Fault in any Bulk Roll. A joint may need to be made on site where there is a Beam Fault as the material at a fault will not reach the performance specified in this Data Sheet. The maximum un-useable material due to any Beam Fault will be 100mm. There are no beam faults in standard batched rolls. Address Unit 3, Block A22, Trefforest Ind. Estate, CF37 5SP, UK Email: info@concretecanvas.co.uk Phone: +44 (0) 845 690 1908 Web: www.concretecanvas.com