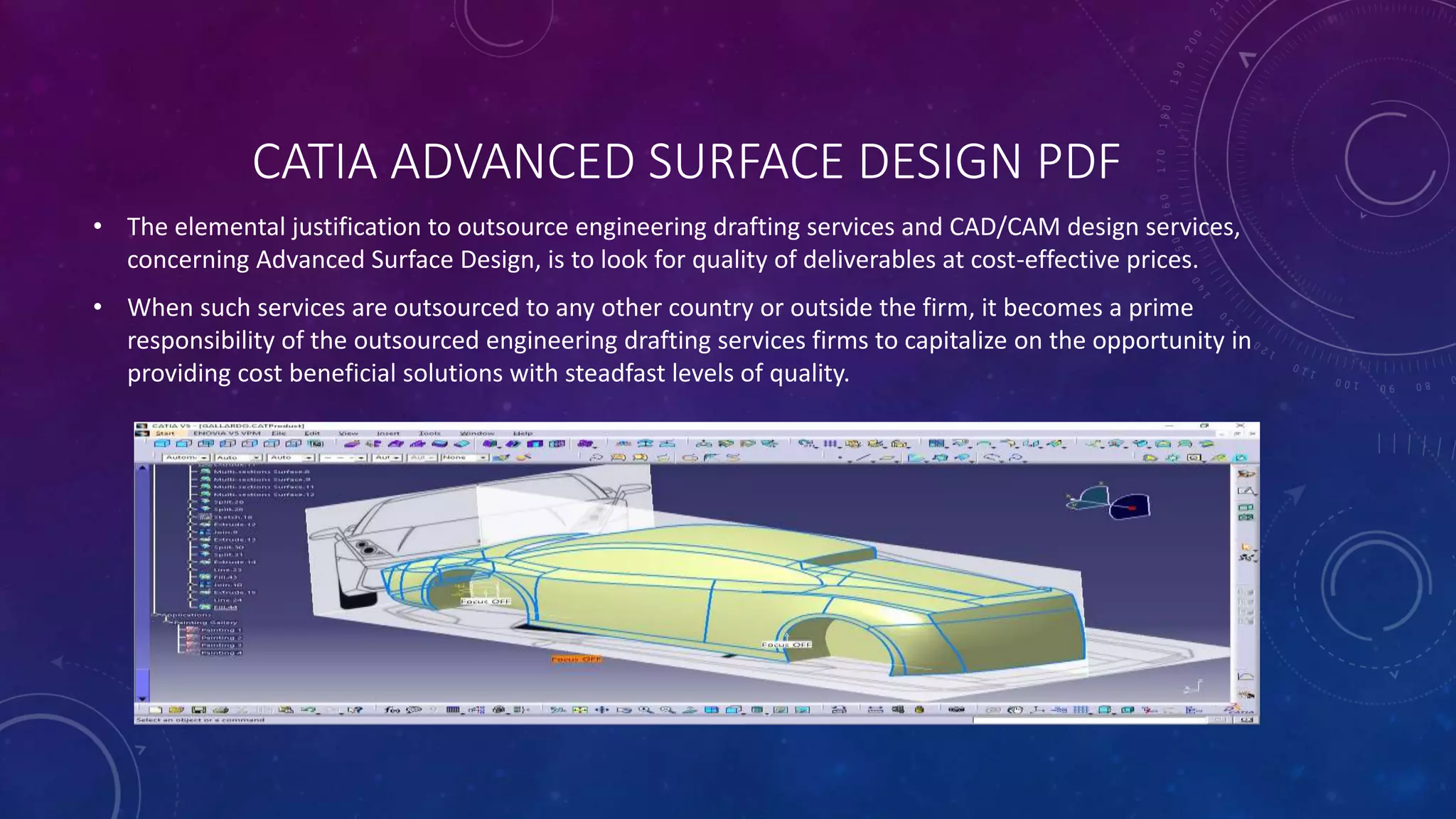

The document discusses the capabilities and advantages of using SolidWorks 3D CAD software for product development, highlighting functionalities like model accuracy, collaboration, and enhanced communication among project teams. It outlines the use of CAD/CAM services for creating SolidWorks models, advanced surface modeling, and applications in engine design and turbine modeling. Additionally, it mentions the benefits of outsourcing engineering drafting services for advanced surface design to achieve high-quality deliverables at competitive prices.