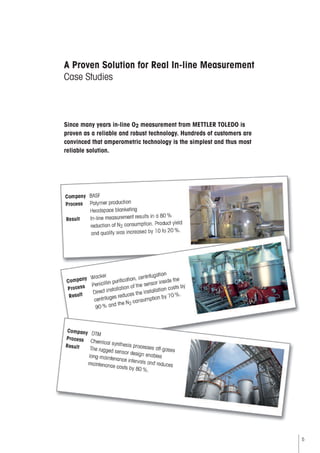

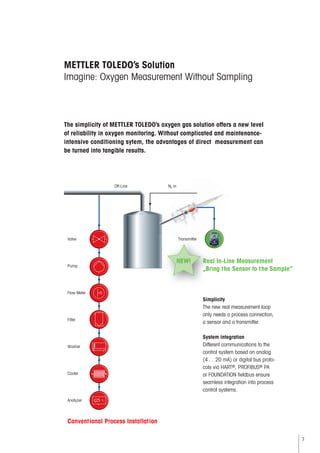

Mettler Toledo offers a robust and easy-to-use oxygen measurement system for gas-phase applications, primarily aimed at enhancing safety and preventing oxidation. The system minimizes costs associated with gas sampling and conditioning, providing fast, real-time monitoring without complex maintenance. Case studies demonstrate significant reductions in nitrogen consumption and operational costs, making it a proven solution for various industrial processes.