High pressure gate valves

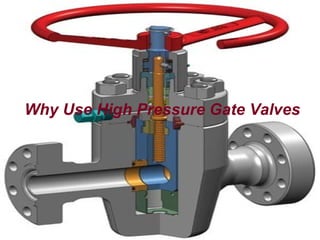

- 1. Why Use High Pressure Gate Valves

- 2. * Safe drinking water is provided to homes and offices through well engineered system of pipes and valves which control the entire distribution of water. * There are different types of valves used for various purposes. Gate valves are mainly used to open and shut the straight line flow of any type of liquid including water. * These valves are mainly used in high pressure areas to either stop the flow of water or to start it. It is never used to regulate the flow of water. * Gate valves are known for its durability, rugged construction, performance and accuracy. These devices are in great demand due to its cost effectiveness and easy installation.

- 3. Various Types of Gate Valves - Designs, Sizes And Materials * Gate valves are available in different designs and sizes to suit different purposes. These high pressure valves are classified according to its design and structure. There are basically two types of gate valve which include the rising stem valve and the nourishing or the non rising stem valve. * Gate valves are available in different designs and sizes to suit different purposes. These high pressure valves are classified according to its design and structure. There are basically two types of gate valve which include the rising stem valve and the nourishing or the non rising stem valve.

- 4. Rising Stem Gate Valve In it the valve rises when the stem is rotated to open. So it is quite easy to identify the position of the valve. Ample amount of space is required for these types of devices. It is not suitable for underground applications.

- 5. Non Rising Stem Gate Valve This valve is ideal for all types of spaces and applications. Different bonnets are also used for these devices. Screw in bonnet is one of the smallest devices used for simple applications. Bolted bonnets are essential for high pressure applications as it is considered to be safe and efficient. Union style bonnet is another variety of gate valve design which is used in areas which requires regular inspection.

- 6. High Pressure Gate Valves With Designs High pressure gate valves are also classified according to its designs which include the parallel valves and the wedge valves.

- 7. Wedge Gate Valve Sub divided into flexible gate type, single gate type and the dual gate type.

- 8. Parallel Gate Valves This valve can also be divided into double and single plate types.

- 9. Applications of Slide Gate Valves In the earlier days slide gate valves was used in steam engines but nowadays it is used in automobiles for proper functioning of the engines. There are devices which are designed specifically for cement, coal and fly ash applications. Most of these devices are in-built with self cleaning valves. Some of the most important applications and uses are mentioned below. 1. Control of powder flow: These devices are mainly used to control the flow of powder which includes cement, coal and other granules such as plastic pellets. 2. Dust collection: Another important application of the slide gate valves include the dust collection feature. 3. Shut off: These devices are mainly used to shut off the flow of products from the outlets of the storage cans, conveyors and other types of discharge bins which are used to store dry bulk materials. 4. Dust tight transition: Most of the devices are equipped with dust frames which prevent the accumulation of dusts. 5. Adjustable seals: The valves are inbuilt with adjustable seals which eradicates the need for constant seal replacements. It is easy to adjust the seals from the outer side of the valve frames. 6. Efficient and fast: These are also known for its precise accuracy, efficiency and fast action. 7. Suit all application: The devices are known to be versatile and suit different types of applications.

- 10. Ball valve Two elastomeric O-rings provided with backup in PTFE perform a double stem barrier to the fluid. The outer O-ring can be replaced with the valves under pressure.

- 11. Butterfly valve Optional “trim” features allow valves to accommodate a wide range of chemical, food and pharmaceutical (sanitary) applications.

- 12. Control Gate Valve The opening or closing of control valves is usually done automatically by electrical, hydraulic or pneumatic actuators. Positioners are used to control the opening or closing of the actuator based on electric, or pneumatic signals.

- 13. Globe Gate Valve A globe valve is a type of valve used for regulating flow in a pipeline, consisting of a movable disk type element and a stationary ring seat in a generally spherical body.

- 14. Needle Gate Valve A needle valve is a type of valve having a small port and a threaded, needle-shaped plunger. It allows precise regulation of flow, although it is generally only capable of relatively low flow rates.