Eurecat palladium catalyst reactivation

•

1 like•792 views

EURECAT has developed a skillset to rejuvenate your spent Pd based catalyst systems used in selective hydrogenation operations.

Report

Share

Report

Share

Download to read offline

Recommended

Recommended

More Related Content

Similar to Eurecat palladium catalyst reactivation

Similar to Eurecat palladium catalyst reactivation (20)

Adiabatic Reactor Analysis for Methanol Synthesis Plant Note Book Series: P...

Adiabatic Reactor Analysis for Methanol Synthesis Plant Note Book Series: P...

Study and Implementation of Advanced Control and Optimization for Ethylene Fu...

Study and Implementation of Advanced Control and Optimization for Ethylene Fu...

In-Situ Oxidation Procedure for High and Low Temperature Shift Catalysts

In-Situ Oxidation Procedure for High and Low Temperature Shift Catalysts

The Selective Oxidation of n-Butane to Maleic Anhydride in a Catalyst Packed ...

The Selective Oxidation of n-Butane to Maleic Anhydride in a Catalyst Packed ...

Naphtha Steam Reforming Catalyst Reduction with Methanol

Naphtha Steam Reforming Catalyst Reduction with Methanol

Turbulent Heat Transfer to Non Newtonian Fluids in Circular Tubes

Turbulent Heat Transfer to Non Newtonian Fluids in Circular Tubes

Low Temperature Shift Catalyst Reduction Procedure

Low Temperature Shift Catalyst Reduction Procedure

Distillation Sequences, Complex Columns and Heat Integration

Distillation Sequences, Complex Columns and Heat Integration

ACTIVATED CARBON- AIR-STEAM REGENERATION PROCEDURE

ACTIVATED CARBON- AIR-STEAM REGENERATION PROCEDURE

Naphtha Steam Reforming Catalyst Reduction by NH3 Cracking

Naphtha Steam Reforming Catalyst Reduction by NH3 Cracking

High Temperature Shift Catalyst Reduction Procedure

High Temperature Shift Catalyst Reduction Procedure

Reactor Arrangement for Continuous Vapor Phase Chlorination

Reactor Arrangement for Continuous Vapor Phase Chlorination

Determination of Carbon Dioxide, Ethane And Nitrogen in Natural Gas by Gas C...

Determination of Carbon Dioxide, Ethane And Nitrogen in Natural Gas by Gas C...

Recently uploaded

💉💊+971581248768>> SAFE AND ORIGINAL ABORTION PILLS FOR SALE IN DUBAI AND ABUDHABI}}+971581248768

+971581248768 Mtp-Kit (500MG) Prices » Dubai [(+971581248768**)] Abortion Pills For Sale In Dubai, UAE, Mifepristone and Misoprostol Tablets Available In Dubai, UAE CONTACT DR.Maya Whatsapp +971581248768 We Have Abortion Pills / Cytotec Tablets /Mifegest Kit Available in Dubai, Sharjah, Abudhabi, Ajman, Alain, Fujairah, Ras Al Khaimah, Umm Al Quwain, UAE, Buy cytotec in Dubai +971581248768''''Abortion Pills near me DUBAI | ABU DHABI|UAE. Price of Misoprostol, Cytotec” +971581248768' Dr.DEEM ''BUY ABORTION PILLS MIFEGEST KIT, MISOPROTONE, CYTOTEC PILLS IN DUBAI, ABU DHABI,UAE'' Contact me now via What's App…… abortion Pills Cytotec also available Oman Qatar Doha Saudi Arabia Bahrain Above all, Cytotec Abortion Pills are Available In Dubai / UAE, you will be very happy to do abortion in Dubai we are providing cytotec 200mg abortion pill in Dubai, UAE. Medication abortion offers an alternative to Surgical Abortion for women in the early weeks of pregnancy. We only offer abortion pills from 1 week-6 Months. We then advise you to use surgery if its beyond 6 months. Our Abu Dhabi, Ajman, Al Ain, Dubai, Fujairah, Ras Al Khaimah (RAK), Sharjah, Umm Al Quwain (UAQ) United Arab Emirates Abortion Clinic provides the safest and most advanced techniques for providing non-surgical, medical and surgical abortion methods for early through late second trimester, including the Abortion By Pill Procedure (RU 486, Mifeprex, Mifepristone, early options French Abortion Pill), Tamoxifen, Methotrexate and Cytotec (Misoprostol). The Abu Dhabi, United Arab Emirates Abortion Clinic performs Same Day Abortion Procedure using medications that are taken on the first day of the office visit and will cause the abortion to occur generally within 4 to 6 hours (as early as 30 minutes) for patients who are 3 to 12 weeks pregnant. When Mifepristone and Misoprostol are used, 50% of patients complete in 4 to 6 hours; 75% to 80% in 12 hours; and 90% in 24 hours. We use a regimen that allows for completion without the need for surgery 99% of the time. All advanced second trimester and late term pregnancies at our Tampa clinic (17 to 24 weeks or greater) can be completed within 24 hours or less 99% of the time without the need surgery. The procedure is completed with minimal to no complications. Our Women's Health Center located in Abu Dhabi, United Arab Emirates, uses the latest medications for medical abortions (RU-486, Mifeprex, Mifegyne, Mifepristone, early options French abortion pill), Methotrexate and Cytotec (Misoprostol). The safety standards of our Abu Dhabi, United Arab Emirates Abortion Doctors remain unparalleled. They consistently maintain the lowest complication rates throughout the nation. Our Physicians and staff are always available to answer questions and care for women in one of the most difficult times in their lives. The decision to have an abortion at the Abortion Cl+971581248768>> SAFE AND ORIGINAL ABORTION PILLS FOR SALE IN DUBAI AND ABUDHA...

+971581248768>> SAFE AND ORIGINAL ABORTION PILLS FOR SALE IN DUBAI AND ABUDHA...?#DUbAI#??##{{(☎️+971_581248768%)**%*]'#abortion pills for sale in dubai@

Recently uploaded (20)

Modular Monolith - a Practical Alternative to Microservices @ Devoxx UK 2024

Modular Monolith - a Practical Alternative to Microservices @ Devoxx UK 2024

Elevate Developer Efficiency & build GenAI Application with Amazon Q

Elevate Developer Efficiency & build GenAI Application with Amazon Q

Biography Of Angeliki Cooney | Senior Vice President Life Sciences | Albany, ...

Biography Of Angeliki Cooney | Senior Vice President Life Sciences | Albany, ...

Connector Corner: Accelerate revenue generation using UiPath API-centric busi...

Connector Corner: Accelerate revenue generation using UiPath API-centric busi...

Vector Search -An Introduction in Oracle Database 23ai.pptx

Vector Search -An Introduction in Oracle Database 23ai.pptx

Apidays New York 2024 - The value of a flexible API Management solution for O...

Apidays New York 2024 - The value of a flexible API Management solution for O...

Boost Fertility New Invention Ups Success Rates.pdf

Boost Fertility New Invention Ups Success Rates.pdf

WSO2's API Vision: Unifying Control, Empowering Developers

WSO2's API Vision: Unifying Control, Empowering Developers

Apidays New York 2024 - Accelerating FinTech Innovation by Vasa Krishnan, Fin...

Apidays New York 2024 - Accelerating FinTech Innovation by Vasa Krishnan, Fin...

CNIC Information System with Pakdata Cf In Pakistan

CNIC Information System with Pakdata Cf In Pakistan

Repurposing LNG terminals for Hydrogen Ammonia: Feasibility and Cost Saving

Repurposing LNG terminals for Hydrogen Ammonia: Feasibility and Cost Saving

+971581248768>> SAFE AND ORIGINAL ABORTION PILLS FOR SALE IN DUBAI AND ABUDHA...

+971581248768>> SAFE AND ORIGINAL ABORTION PILLS FOR SALE IN DUBAI AND ABUDHA...

Polkadot JAM Slides - Token2049 - By Dr. Gavin Wood

Polkadot JAM Slides - Token2049 - By Dr. Gavin Wood

Strategize a Smooth Tenant-to-tenant Migration and Copilot Takeoff

Strategize a Smooth Tenant-to-tenant Migration and Copilot Takeoff

"I see eyes in my soup": How Delivery Hero implemented the safety system for ...

"I see eyes in my soup": How Delivery Hero implemented the safety system for ...

Rising Above_ Dubai Floods and the Fortitude of Dubai International Airport.pdf

Rising Above_ Dubai Floods and the Fortitude of Dubai International Airport.pdf

Eurecat palladium catalyst reactivation

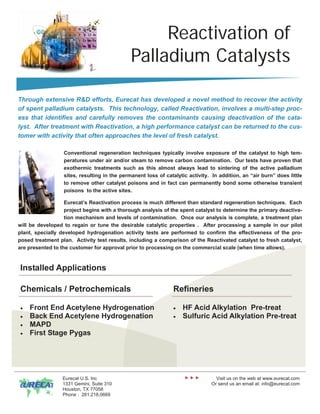

- 1. Reactivation of Palladium Catalysts Through extensive R&D efforts, Eurecat has developed a novel method to recover the activity of spent palladium catalysts. This technology, called Reactivation, involves a multi-step proc- ess that identifies and carefully removes the contaminants causing deactivation of the cata- lyst. After treatment with Reactivation, a high performance catalyst can be returned to the cus- tomer with activity that often approaches the level of fresh catalyst. Conventional regeneration techniques typically involve exposure of the catalyst to high tem- peratures under air and/or steam to remove carbon contamination. Our tests have proven that exothermic treatments such as this almost always lead to sintering of the active palladium sites, resulting in the permanent loss of catalytic activity. In addition, an “air burn” does little to remove other catalyst poisons and in fact can permanently bond some otherwise transient poisons to the active sites. Eurecat’s Reactivation process is much different than standard regeneration techniques. Each project begins with a thorough analysis of the spent catalyst to determine the primary deactiva- tion mechanism and levels of contamination. Once our analysis is complete, a treatment plan will be developed to regain or tune the desirable catalytic properties . After processing a sample in our pilot plant, specially developed hydrogenation activity tests are performed to confirm the effectiveness of the pro- posed treatment plan. Activity test results, including a comparison of the Reactivated catalyst to fresh catalyst, are presented to the customer for approval prior to processing on the commercial scale (when time allows). Installed Applications Chemicals / Petrochemicals Refineries • Front End Acetylene Hydrogenation • HF Acid Alkylation Pre-treat • Back End Acetylene Hydrogenation • Sulfuric Acid Alkylation Pre-treat • MAPD • First Stage Pygas Eurecat U.S. Inc Visit us on the web at www.eurecat.com 1331 Gemini, Suite 310 Or send us an email at: info@eurecat.com Houston, TX 77058 Phone : 281.218.0669

- 2. Hydro Isom erization Com parison 3.5 As Received Methyl 2-butene 3.0 Fresh Methyl 2-butene Reactivated Methyl 2-butene 2.5 2.0 Wt% 1.5 1.0 0.5 0.0 0 18 36 54 72 90 108 126 144 162 180 198 Tim e Above catalyst installed in a refinery for a hydrofluoric acid alkylation pre-treat application. Butadiene conversion to the more desirable butene-2 was observed in Eurecat testing. The refinery experienced an octane boost over 2 points in their alkylate when compared to previously installed charges. Front-end Ethylene Catalyst Reactivated isoprene Reactivated isopentene Reactivated isopentane 5.5 Reference isoprene Reference isopentene Reference isopentane 5.0 4.5 4.0 3.5 3.0 2.5 2.0 1.5 1.0 0.5 0.0 0.00 18.00 36.00 54.00 72.00 90.00 108.00 126.00 144.00 162.00 180.00 T ime Front end total raw gas acetylene converter catalyst installed and operating on its 3rd REACTIVATION cy- cle (2+ years for each cycle). Catalyst demonstrates superior selectivity and comparable activity to its reference standard and has demonstrated a wide range of operational stability thus eliminating flaring incidents from hyper-activity.