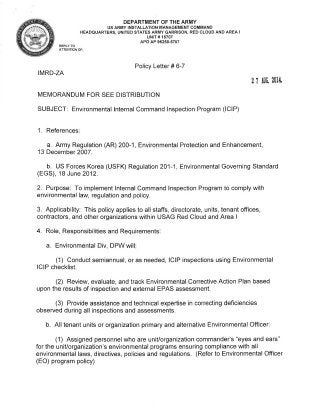

USAG Red Cloud Command Policy 6-07 Internal Command Inspection Program Policy

•

1 like•3,435 views

To implement Internal Command Inspection Program to comply with environmental law, regulation and policy .

Report

Share

Report

Share

Download to read offline

Recommended

Recommended

This pamphlet replaces Army in Korea Pamphlet 420-1, dated 30 Sept. 2008. This pamphlet establishes the Installation Management Command, Pacific Region (IMCOM-P), USAG Red Cloud and Area I Fire and Emergency Services Program.USAG RC PAM 420-1 Installation Fire Prevention and Public Education

USAG RC PAM 420-1 Installation Fire Prevention and Public EducationUSAG Red Cloud and Area I Policy Letters

POLICY: It is the US Army Garrison-Red Cloud/Area I policy to recognize our US civilian

and Korean national work forces for their outstanding accomplishments and contributions in a timely manner; ensure program oversight, and apply program procedures consistently to ensure equitable distribution of awards throughout the Garrison and alleviate the use of "End of Year" awards.

USAG Red Cloud Command Policy 8-3 Awards and Recognition Program

USAG Red Cloud Command Policy 8-3 Awards and Recognition ProgramUSAG Red Cloud and Area I Policy Letters

Commanders and Directors are Primary Building Managers for government facilities under their control. Primary Building Managers may designate personnel in grades E-6 and above or civilian equivalents and above with at least 6 months retainability to serve as Alternate Building Managers. Primary Building Managers shall provide a memorandum to DPW Real Property Office (CRC, Bldg 428) listing names, ranks, and facility numbers for all designated Alternates.USAG Red Cloud Command Policy 6-13 Accountability and Responsibility of Gover...

USAG Red Cloud Command Policy 6-13 Accountability and Responsibility of Gover...USAG Red Cloud and Area I Policy Letters

USAG Red Cloud Command Policy 7-6 Honorary FMWR Membership ProgramUSAG Red Cloud Command Policy 7-6 Honorary FMWR Membership Program

USAG Red Cloud Command Policy 7-6 Honorary FMWR Membership ProgramUSAG Red Cloud and Area I Policy Letters

Purpose of this memorandum is to establish standard policies and procedures for the operation of the centralized USAG Red Cloud and Area 1 AFDCB. This policy applies to all U.S. Armed Forces personnel assigned, attached to, visiting or residing in Area 1.USAG RC Command Policy Memorandum #8-4 Armed Forces Disciplinary Control Boar...

USAG RC Command Policy Memorandum #8-4 Armed Forces Disciplinary Control Boar...USAG Red Cloud and Area I Policy Letters

Purpose of this memorandum is to establish the procedures and guidelines for the processing of civilian and family member misconduct occurring in Area 1.USAG RC Command Policy #8-1 Procedures and Guidelines for Processing of Civil...

USAG RC Command Policy #8-1 Procedures and Guidelines for Processing of Civil...USAG Red Cloud and Area I Policy Letters

Intent of this directive is to ensure that all allegations of rape, sexual assault and indecent acts are professionally investigated in an expeditious manner to uphold the interests of military justice and to protect the rights of the alleged victim and the accused.USAG Red Cloud Command Policy 1-04 Prevention Sexual Assault

USAG Red Cloud Command Policy 1-04 Prevention Sexual AssaultUSAG Red Cloud and Area I Policy Letters

As a system user, I will not install or remove programs or hardware (government or personally owned),

disable security configurations or audit logs, or alter device configurations. I will not attempt to strain, test,

circumvent, bypass security mechanisms, or perform network line monitoring or keystroke monitoring, I will not

introduce any executable code nor will I write any malicious code.USAG Red Cloud Command Policy 1-12 Blackberry Usage Policy Letter Encl 3 Blac...

USAG Red Cloud Command Policy 1-12 Blackberry Usage Policy Letter Encl 3 Blac...USAG Red Cloud and Area I Policy Letters

More Related Content

Viewers also liked

Viewers also liked (9)

Contractor camp inspection check list rev 9 12 16.00hr

Contractor camp inspection check list rev 9 12 16.00hr

More from USAG Red Cloud and Area I Policy Letters

This pamphlet replaces Army in Korea Pamphlet 420-1, dated 30 Sept. 2008. This pamphlet establishes the Installation Management Command, Pacific Region (IMCOM-P), USAG Red Cloud and Area I Fire and Emergency Services Program.USAG RC PAM 420-1 Installation Fire Prevention and Public Education

USAG RC PAM 420-1 Installation Fire Prevention and Public EducationUSAG Red Cloud and Area I Policy Letters

POLICY: It is the US Army Garrison-Red Cloud/Area I policy to recognize our US civilian

and Korean national work forces for their outstanding accomplishments and contributions in a timely manner; ensure program oversight, and apply program procedures consistently to ensure equitable distribution of awards throughout the Garrison and alleviate the use of "End of Year" awards.

USAG Red Cloud Command Policy 8-3 Awards and Recognition Program

USAG Red Cloud Command Policy 8-3 Awards and Recognition ProgramUSAG Red Cloud and Area I Policy Letters

Commanders and Directors are Primary Building Managers for government facilities under their control. Primary Building Managers may designate personnel in grades E-6 and above or civilian equivalents and above with at least 6 months retainability to serve as Alternate Building Managers. Primary Building Managers shall provide a memorandum to DPW Real Property Office (CRC, Bldg 428) listing names, ranks, and facility numbers for all designated Alternates.USAG Red Cloud Command Policy 6-13 Accountability and Responsibility of Gover...

USAG Red Cloud Command Policy 6-13 Accountability and Responsibility of Gover...USAG Red Cloud and Area I Policy Letters

USAG Red Cloud Command Policy 7-6 Honorary FMWR Membership ProgramUSAG Red Cloud Command Policy 7-6 Honorary FMWR Membership Program

USAG Red Cloud Command Policy 7-6 Honorary FMWR Membership ProgramUSAG Red Cloud and Area I Policy Letters

Purpose of this memorandum is to establish standard policies and procedures for the operation of the centralized USAG Red Cloud and Area 1 AFDCB. This policy applies to all U.S. Armed Forces personnel assigned, attached to, visiting or residing in Area 1.USAG RC Command Policy Memorandum #8-4 Armed Forces Disciplinary Control Boar...

USAG RC Command Policy Memorandum #8-4 Armed Forces Disciplinary Control Boar...USAG Red Cloud and Area I Policy Letters

Purpose of this memorandum is to establish the procedures and guidelines for the processing of civilian and family member misconduct occurring in Area 1.USAG RC Command Policy #8-1 Procedures and Guidelines for Processing of Civil...

USAG RC Command Policy #8-1 Procedures and Guidelines for Processing of Civil...USAG Red Cloud and Area I Policy Letters

Intent of this directive is to ensure that all allegations of rape, sexual assault and indecent acts are professionally investigated in an expeditious manner to uphold the interests of military justice and to protect the rights of the alleged victim and the accused.USAG Red Cloud Command Policy 1-04 Prevention Sexual Assault

USAG Red Cloud Command Policy 1-04 Prevention Sexual AssaultUSAG Red Cloud and Area I Policy Letters

As a system user, I will not install or remove programs or hardware (government or personally owned),

disable security configurations or audit logs, or alter device configurations. I will not attempt to strain, test,

circumvent, bypass security mechanisms, or perform network line monitoring or keystroke monitoring, I will not

introduce any executable code nor will I write any malicious code.USAG Red Cloud Command Policy 1-12 Blackberry Usage Policy Letter Encl 3 Blac...

USAG Red Cloud Command Policy 1-12 Blackberry Usage Policy Letter Encl 3 Blac...USAG Red Cloud and Area I Policy Letters

To define the procedures and purposes required to establish, maintain, and operate an effective and trustworthy Government Purchase Card (GPC) programs for all activities using appropriated funds within U.S. Army Garrison, Red Cloud (USAG, RC).USAG Red Cloud Command Policy 2-03 Government Purchase Card

USAG Red Cloud Command Policy 2-03 Government Purchase Card USAG Red Cloud and Area I Policy Letters

Implementation of this program is the responsibility of the person who signed for facilities at the DPW Real Property Section (usually the unit commander), assuming primary building manager responsibility. They may delegate assistant building managers (evacuation coordinators) as needed. Assistant building manager duties will not be delegated to personnel below the military rank of sergeant (E-5) or Civilian equivalent of GS-7.USAG Red Cloud Command Policy 3-01 Building Manager Fire Prevention Responsib...

USAG Red Cloud Command Policy 3-01 Building Manager Fire Prevention Responsib...USAG Red Cloud and Area I Policy Letters

USAG Red Cloud and Area I's mission is to support readiness and mission execution, provide equitable services and facilities, optimize resources, sustain the environment, and enhance the well- being of the Military Community. USAG Red Cloud and Area I performs this mission in concert with our stewardship responsibilities to protect and conserve the environment as defined by the

Environmental Management System (EMS). USAG Red Cloud Command Policy 3-02 Installation Access Control

USAG Red Cloud Command Policy 3-02 Installation Access ControlUSAG Red Cloud and Area I Policy Letters

The enclosure and clearing procedures will be posted at all LSA's along with a clearing barrel, instructions for weapons clearing, and an amnesty box if required.

Garrison Commanders will coordinate with unit commanders to ensure their personnel understand this policy. This policy does not apply to Military Police or armed guards in the commission of non-exercise related duties.USAG Red Cloud Command Policy 5-04 Weapons Carry and Storage Policy

USAG Red Cloud Command Policy 5-04 Weapons Carry and Storage PolicyUSAG Red Cloud and Area I Policy Letters

The purpose of this policy is to establish Internal Environmental

Performance Assessment System (IEPAS) that helps USAG Red Cloud and Area I

complying with Department of Defense, US Army, and USFK environmental regulations,

standards, and directives.USAG Red Cloud Command Policy 6-06 Internal Environmental Performance Assessm...

USAG Red Cloud Command Policy 6-06 Internal Environmental Performance Assessm...USAG Red Cloud and Area I Policy Letters

More from USAG Red Cloud and Area I Policy Letters (20)

USAG RC PAM 420-1 Installation Fire Prevention and Public Education

USAG RC PAM 420-1 Installation Fire Prevention and Public Education

USAG Red Cloud Command Policy 8-3 Awards and Recognition Program

USAG Red Cloud Command Policy 8-3 Awards and Recognition Program

USAG Red Cloud Command Policy 6-13 Accountability and Responsibility of Gover...

USAG Red Cloud Command Policy 6-13 Accountability and Responsibility of Gover...

USAG Red Cloud Command Policy 7-6 Honorary FMWR Membership Program

USAG Red Cloud Command Policy 7-6 Honorary FMWR Membership Program

USAG RC Command Policy Memorandum #8-4 Armed Forces Disciplinary Control Boar...

USAG RC Command Policy Memorandum #8-4 Armed Forces Disciplinary Control Boar...

USAG RC Command Policy #8-1 Procedures and Guidelines for Processing of Civil...

USAG RC Command Policy #8-1 Procedures and Guidelines for Processing of Civil...

Area I Command Information Exchange - April 13, 2015

Area I Command Information Exchange - April 13, 2015

USAG RC Policy #6-17 Water Pollution Management Program

USAG RC Policy #6-17 Water Pollution Management Program

USAG RC Policy #6-16 Open Burning Prohibition Policy

USAG RC Policy #6-16 Open Burning Prohibition Policy

USAG Red Cloud Command Policy 1-04 Prevention Sexual Assault

USAG Red Cloud Command Policy 1-04 Prevention Sexual Assault

USAG Red Cloud Command Policy 1-12 Blackberry Usage Policy Letter Encl 3 Blac...

USAG Red Cloud Command Policy 1-12 Blackberry Usage Policy Letter Encl 3 Blac...

USAG Red Cloud Command Policy 2-02 Time and Attendance

USAG Red Cloud Command Policy 2-02 Time and Attendance

USAG Red Cloud Command Policy 2-03 Government Purchase Card

USAG Red Cloud Command Policy 2-03 Government Purchase Card

USAG Red Cloud Command Policy 3-01 Building Manager Fire Prevention Responsib...

USAG Red Cloud Command Policy 3-01 Building Manager Fire Prevention Responsib...

USAG Red Cloud Command Policy 3-02 Installation Access Control

USAG Red Cloud Command Policy 3-02 Installation Access Control

USAG Red Cloud Command Policy 5-04 Weapons Carry and Storage Policy

USAG Red Cloud Command Policy 5-04 Weapons Carry and Storage Policy

USAG Red Cloud Command Policy 6-06 Internal Environmental Performance Assessm...

USAG Red Cloud Command Policy 6-06 Internal Environmental Performance Assessm...

Recently uploaded

Falcon stands out as a top-tier P2P Invoice Discounting platform in India, bridging esteemed blue-chip companies and eager investors. Our goal is to transform the investment landscape in India by establishing a comprehensive destination for borrowers and investors with diverse profiles and needs, all while minimizing risk. What sets Falcon apart is the elimination of intermediaries such as commercial banks and depository institutions, allowing investors to enjoy higher yields.Unveiling Falcon Invoice Discounting: Leading the Way as India's Premier Bill...

Unveiling Falcon Invoice Discounting: Leading the Way as India's Premier Bill...Falcon Invoice Discounting

Recently uploaded (20)

Marel Q1 2024 Investor Presentation from May 8, 2024

Marel Q1 2024 Investor Presentation from May 8, 2024

JAJPUR CALL GIRL ❤ 82729*64427❤ CALL GIRLS IN JAJPUR ESCORTS

JAJPUR CALL GIRL ❤ 82729*64427❤ CALL GIRLS IN JAJPUR ESCORTS

GUWAHATI 💋 Call Girl 9827461493 Call Girls in Escort service book now

GUWAHATI 💋 Call Girl 9827461493 Call Girls in Escort service book now

Chennai Call Gril 80022//12248 Only For Sex And High Profile Best Gril Sex Av...

Chennai Call Gril 80022//12248 Only For Sex And High Profile Best Gril Sex Av...

Uneak White's Personal Brand Exploration Presentation

Uneak White's Personal Brand Exploration Presentation

Paradip CALL GIRL❤7091819311❤CALL GIRLS IN ESCORT SERVICE WE ARE PROVIDING

Paradip CALL GIRL❤7091819311❤CALL GIRLS IN ESCORT SERVICE WE ARE PROVIDING

Getting Real with AI - Columbus DAW - May 2024 - Nick Woo from AlignAI

Getting Real with AI - Columbus DAW - May 2024 - Nick Woo from AlignAI

UAE Bur Dubai Call Girls ☏ 0564401582 Call Girl in Bur Dubai

UAE Bur Dubai Call Girls ☏ 0564401582 Call Girl in Bur Dubai

SEO Case Study: How I Increased SEO Traffic & Ranking by 50-60% in 6 Months

SEO Case Study: How I Increased SEO Traffic & Ranking by 50-60% in 6 Months

Nashik Call Girl Just Call 7091819311 Top Class Call Girl Service Available

Nashik Call Girl Just Call 7091819311 Top Class Call Girl Service Available

Unveiling Falcon Invoice Discounting: Leading the Way as India's Premier Bill...

Unveiling Falcon Invoice Discounting: Leading the Way as India's Premier Bill...

QSM Chap 10 Service Culture in Tourism and Hospitality Industry.pptx

QSM Chap 10 Service Culture in Tourism and Hospitality Industry.pptx