Service Manual for GC/GLC080VX, 100VX & 120VX Lift Trucks

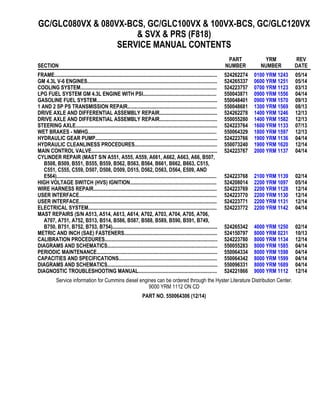

- 1. GC/GLC080VX & 080VX-BCS, GC/GLC100VX & 100VX-BCS, GC/GLC120VX & SVX & PRS (F818) SERVICE MANUAL CONTENTS SECTION PART NUMBER YRM NUMBER REV DATE FRAME............................................................................................................................ 524262274 0100 YRM 1243 05/14 GM 4.3L V-6 ENGINES................................................................................................... 524265337 0600 YRM 1251 05/14 COOLING SYSTEM........................................................................................................ 524223757 0700 YRM 1123 03/13 LPG FUEL SYSTEM GM 4.3L ENGINE WITH PSI........................................................ 550043871 0900 YRM 1556 04/14 GASOLINE FUEL SYSTEM............................................................................................ 550048401 0900 YRM 1570 09/13 1 AND 2 SP PS TRANSMISSION REPAIR.................................................................... 550048681 1300 YRM 1569 08/13 DRIVE AXLE AND DIFFERENTIAL ASSEMBLY REPAIR............................................ 524262278 1400 YRM 1246 12/13 DRIVE AXLE AND DIFFERENTIAL ASSEMBLY REPAIR............................................ 550055280 1400 YRM 1582 12/13 STEERING AXLE............................................................................................................ 524223764 1600 YRM 1133 07/13 WET BRAKES - NMHG.................................................................................................. 550064329 1800 YRM 1597 12/13 HYDRAULIC GEAR PUMP............................................................................................. 524223766 1900 YRM 1136 04/14 HYDRAULIC CLEANLINESS PROCEDURES............................................................... 550073240 1900 YRM 1620 12/14 MAIN CONTROL VALVE................................................................................................ 524223767 2000 YRM 1137 04/14 CYLINDER REPAIR (MAST S/N A551, A555, A559, A661, A662, A663, A66, B507, B508, B509, B551, B555, B559, B562, B563, B564, B661, B662, B663, C515, C551, C555, C559, D507, D508, D509, D515, D562, D563, D564, E509, AND E564).......................................................................................................................... 524223768 2100 YRM 1139 02/14 HIGH VOLTAGE SWITCH (HVS) IGNITION.................................................................. 524208014 2200 YRM 1097 05/14 WIRE HARNESS REPAIR.............................................................................................. 524223769 2200 YRM 1128 12/14 USER INTERFACE......................................................................................................... 524223770 2200 YRM 1130 12/14 USER INTERFACE......................................................................................................... 524223771 2200 YRM 1131 12/14 ELECTRICAL SYSTEM.................................................................................................. 524223772 2200 YRM 1142 04/14 MAST REPAIRS (S/N A513, A514, A613, A614, A702, A703, A704, A705, A706, A707, A751, A752, B513, B514, B586, B587, B588, B589, B590, B591, B749, B750, B751, B752, B753, B754)................................................................................ 524265342 4000 YRM 1250 02/14 METRIC AND INCH (SAE) FASTENERS....................................................................... 524150797 8000 YRM 0231 10/13 CALIBRATION PROCEDURES...................................................................................... 524223780 8000 YRM 1134 12/14 DIAGRAMS AND SCHEMATICS.................................................................................... 550055283 8000 YRM 1585 04/14 PERIODIC MAINTENANCE............................................................................................ 550064334 8000 YRM 1598 04/14 CAPACITIES AND SPECIFICATIONS........................................................................... 550064342 8000 YRM 1599 04/14 DIAGRAMS AND SCHEMATICS.................................................................................... 550096331 8000 YRM 1689 04/14 DIAGNOSTIC TROUBLESHOOTING MANUAL............................................................ 524221866 9000 YRM 1112 12/14 Service information for Cummins diesel engines can be ordered through the Hyster Literature Distribution Center. 9000 YRM 1112 ON CD PART NO. 550064306 (12/14)

- 2. SAFETY PRECAUTIONS MAINTENANCE AND REPAIR • The Service Manuals are updated on a regular basis, but may not reflect recent design changes to the product. Updated technical service information may be available from your local authorized Yale® dealer. Service Manuals provide general guidelines for maintenance and service and are intended for use by trained and experienced technicians. Failure to properly maintain equipment or to follow instructions con- tained in the Service Manual could result in damage to the products, personal injury, property damage or death. • When lifting parts or assemblies, make sure all slings, chains, or cables are correctly fastened, and that the load being lifted is balanced. Make sure the crane, cables, and chains have the capacity to support the weight of the load. • Do not lift heavy parts by hand, use a lifting mechanism. • Wear safety glasses. • DISCONNECT THE BATTERY CONNECTOR before doing any maintenance or repair on electric lift trucks. Disconnect the battery ground cable on internal combustion lift trucks. • Always use correct blocks to prevent the unit from rolling or falling. See HOW TO PUT THE LIFT TRUCK ON BLOCKS in the Operating Manual or the Periodic Maintenance section. • Keep the unit clean and the working area clean and orderly. • Use the correct tools for the job. • Keep the tools clean and in good condition. • Always use YALE APPROVED parts when making repairs. Replacement parts must meet or exceed the specifications of the original equipment manufacturer. • Make sure all nuts, bolts, snap rings, and other fastening devices are removed before using force to re- move parts. • Always fasten a DO NOT OPERATE tag to the controls of the unit when making repairs, or if the unit needs repairs. • Be sure to follow the WARNING and CAUTION notes in the instructions. • Gasoline, Liquid Petroleum Gas (LPG), Compressed Natural Gas (CNG), and Diesel fuel are flammable. Be sure to follow the necessary safety precautions when handling these fuels and when working on these fuel systems. • Batteries generate flammable gas when they are being charged. Keep fire and sparks away from the area. Make sure the area is well ventilated. NOTE: The following symbols and words indicate safety information in this man- ual: WARNING Indicates a hazardous situation which, if not avoided, could result in death or serious injury. CAUTION Indicates a hazardous situation which, if not avoided, could result in minor or moderate injury and property damage. On the lift truck, the WARNING symbol and word are on orange back- ground. The CAUTION symbol and word are on yellow background.

- 3. ©2014 Yale Materials Handling Corp. TABLE OF CONTENTS General .....................................................................................................................................................................1 Hydraulic Gear Pump Assembly ...................................................................................................................... 1 Variable Displacement Pump Assembly .......................................................................................................... 2 Single Gear Pump Assembly Repair ........................................................................................................................ 4 Remove ................................................................................................................................................................ 4 Disassemble .......................................................................................................................................................12 Clean .................................................................................................................................................................. 14 Inspect ................................................................................................................................................................14 Assemble ............................................................................................................................................................14 Install .................................................................................................................................................................. 14 Tandem Gear Pump Assembly ...............................................................................................................................20 Remove .............................................................................................................................................................. 20 Disassemble .......................................................................................................................................................22 Clean .................................................................................................................................................................. 24 Inspect ................................................................................................................................................................24 Assemble ............................................................................................................................................................24 Install .................................................................................................................................................................. 25 Gear Pump Specifications ...................................................................................................................................... 26 Variable Displacement Pump Repair ......................................................................................................................31 Remove .............................................................................................................................................................. 31 Disassemble .......................................................................................................................................................41 Clean .................................................................................................................................................................. 45 Inspect ................................................................................................................................................................45 Assemble ............................................................................................................................................................46 Install .................................................................................................................................................................. 46 Variable Displacement Pump Checks and Adjustments .........................................................................................51 Margin Pressure Check ......................................................................................................................................51 Flow Compensator Adjustment .......................................................................................................................... 52 Pressure Compensator Adjustment ....................................................................................................................52 Variable Displacement Pump Specifications .......................................................................................................... 54 Torque Specifications ............................................................................................................................................. 55 Hydraulic Gear Pump ......................................................................................................................................... 55 Variable Displacement Pump ............................................................................................................................. 56 Table of Contents i

- 4. This section is for the following models: (GC/GLC030VX, GC/GLC035VX, GC/GLC040SVX) [C809]; GLP/GDP16VX, GLP/GDP18VX, GLP/GDP20SVX (GP/GLP/GDP030VX, GP/GLP/GDP035VX, GP/GLP/GDP040SVX) [C810]; GLC20-35VX (GC/GLC040-070VX, GCGLC055SVX) [A910]; (GLC050LX) [A967]; GLP/GDP20-35VX (GP/GLP/GDP040-070VX) [B875]; GLP/GDP20-25LX (GLP/GDP050LX) [A974]; GLC40, 45, 55VX; GLC55SVX (GC/GLC080, 100, 120VX; GC/GLC080, 100VXBCS; GC/GLC120SVX; GC/GLC120VXPRS) [E818, F818]; GLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/GDP45VX6; GLP/GDP50-55VX (GP/GLP/GDP080, 090, 100, 110, 120VX) [F813, G813, H813, J813]; GLP/GDP60VX, GLP/GDP70VX (GP/GLP/GDP135VX, GP/GLP/GDP155VX) [C878, D878, E878]; GLC/GDC60VX, GLC/GDC70VX (GC/GLC/GDC135VX, GC/GLC/GDC155VX) [C879, D879, E879, F879]; GLP/GDP80VX, GLP/GDP80VX9, GLP/GDP90VX (GLP/GDP170VX, GLP/ GDP175VX36, GLP/GDP190VX) [A909, B909] Table of Contents ii

- 5. General This section includes a description and the repair procedures for the hydraulic gear pump assembly and for the variable displacement pump (VDP) assembly. Hydraulic Gear Pump Assembly Lift truck models listed below can be equipped with one of three different gear pumps: 24 cc/rev, 25.7 cc/ rev, or 29.4 cc/rev • GC/GLC030VX, GC/GLC035VX, GC/ GLC040SVX) (C809) • GLP/GDP16VX, GLP/GDP18VX, GLP/ GDP20SVX, (GP/GLP/GDP030VX, GP/GLP/ GDP035VX, GP/GLP/GDP040SVX) (C810) • GLC20-35VX (GC/GLC040-070VX, GC/ GLC055SVX) (A910) • GLP/GDP20-35VX (GP/GLP/GDP040-070VX) (B875) Lift truck models listed below can be equipped with the 24 cc/rev gear pump • GLC050LX (A967) • GLP20-25LX (GLP050LX) (A974) Lift truck models listed below can be equipped with the 25.7 cc/rev gear pump • GDP20-25LX (GDP050LX) (A974) Lift truck models listed below can be equipped with a 32.5 cc/rev gear pump • GLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/GDP45VX6; GLP/GDP50-55VX (GP/GLP/ GDP080, 090, 100, 110, 120VX) (H813, J813) • GLC40, 45, 55VX; GLC55SVX; (GC/GLC080, 100, 120VX; GC/GLC080, 100VXBCS; GC/ GLC120SVX; GC/GLC120VXPRS) (E818, F818) Lift truck models listed below can be equipped with one of two different gear pumps: 41.3 cc/rev, or 51.6 cc/rev • GLC40, 45, 55VX; GLC55SVX; (GC/GLC080, 100, 120VX; GC/GLC080, 100VXBCS; GC/ GLC120SVX; GC/GLC120VXPRS) (E818, F818) • GLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/GDP45VX6; GLP/GDP50-55VX (GP/GLP/ GDP080, 090, 100, 110, 120VX) (F813, G813, H813, J813) Lift truck model listed below can also be equipped with a 46.5 cc/rev gear pump • GLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/GDP45VX6; GLP/GDP50-55VX (GP/GLP/ GDP080, 090, 100, 110, 120VX) (F813, G813, H813, J813) Lift truck models listed below can be equipped with one of two different tandem gear pumps: 63.3 cc/rev or 68.5 cc/rev • GLC/GDC60VX, GLC/GDC70VX, (GC/GLC/ GDC135VX, GC/GLC/GDC155VX) (C879, D879, E879, F879) • GLP/GDP60VX, GLP/GDP70VX (GP/GLP/ GDP135VX, GP/GLP/GDP155VX) (C878, D878, E878) Lift truck model listed below is equipped with a tandem gear pump: 63.3 cc/rev • GLP/GDP80VX, GLP/GDP80VX9, GLP/ GDP90VX (GLP/GDP170VX, GLP/ GDP175VX36, GLP/GDP190VX) (A909, B909). 1900 YRM 1136 General 1

- 6. The repair procedures are similar for each type of gear pump. When the repair has been completed, see the Gear Pump Specifications section in this manual. Variable Displacement Pump Assembly Lift truck models listed below can be equipped with one of three different variable displacement pumps: 24 cc/rev, 26 cc/rev, or 28 cc/rev • GLP/GDP20-35VX (B875) Lift truck models listed below can be equipped with one of two different variable displacement pumps: 42 cc/rev or 45 cc/rev • GLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/GDP45VX6; GLP/GDP50-55VX (G813, H813) The repair procedures are similar for each size of VDP. When the repair has been completed, see the section Variable Displacement Pump Specifications. Repair information for other components of the hydraulic system, equipped with either a hydraulic gear pump or variable displacement pump, are found in the following manuals See Steering Axle 1600YRM1133 for lift truck models • GC/GLC030VX, GC/GLC035VX, GC/ GLC040SVX (C809) • GLP/GDP16VX, GLP/GDP18VX, GLP/ GDP20SVX, (GP/GLP/GDP030VX, GP/GLP/ GDP035VX, GP/GLP/GDP040SVX) (C810) • GLC20-35VX (GC/GLC040-070VX, GC/ GLC055SVX) (A910) • GLP/GDP20-35VX (GP/GLP/GDP040-070VX) (B875) • GLC40, 45, 55VX; GLC55SVX; (GC/GLC080, 100, 120VX; GC/GLC080, 100VXBCS; GC/ GLC120SVX; GC/GLC120VXPRS) (E818, F818) • GLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/GDP45VX6; GLP/GDP50-55VX (GP/GLP/ GDP080, 090, 100, 110, 120VX) (F813, G813, H813, J813) • GLC/GDC60VX, GLC/GDC70VX, (GC/GLC/ GDC135VX, GC/GLC/GDC155VX) (C879, D879, E879, F879) • GLP/GDP60VX, GLP/GDP70VX (GP/GLP/ GDP135VX, GP/GLP/GDP155VX) (C878, D878, E878) • GLP/GDP80VX, GLP/GDP80VX9, GLP/ GDP90VX (GLP/GDP170VX, GLP/ GDP175VX36, GLP/GDP190VX) (A909, B909). See Steering Axle 1600YRM1425 for lift truck models • GLC050LX (A967) • GLP/GDP20-25LX (GLP/GDP050LX) (A974) See Main Control Valve 2000YRM1137 for lift truck models • GC/GLC030VX, GC/GLC035VX, GC/ GLC040SVX (C809) • GLP/GDP16VX, GLP/GDP18VX, GLP/ GDP20SVX, (G{/GLP/GDP030VX, GP/GLP/ GDP035VX, GP/GLP/GDP040SVX) (C810) • GLC20-35VX (GC/GLC040-070VX, GC/ GLC055SVX) (A910) • GLP/GDP20-35VX (GP/GLP/GDP040-070VX) (B875) • GLC050LX (A967) • GLP/GDP20-25LX (GLP/GDP050LX) (A974) • GLC40, 45, 55VX; GLC55SVX; (GC/GLC080, 100, 120VX; GC/GLC080, 100VXBCS; GC/ GLC120SVX; GC/GLC120VXPRS) (E818, F818) General 1900 YRM 1136 2

- 7. • GLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/GDP45VX6; GLP/GDP50-55VX (GP/GLP/ GDP080, 090, 100, 110, 120VX) (F813, G813, H813, J813) • GLC/GDC60VX, GLC/GDC70VX, (GC/GLC/ GDC135VX, GC/GLC/GDC155VX) (C879, D879, E879, F879) • GLP/GDP60VX, GLP/GDP70VX (GP/GLP/ GDP135VX, GP/GLP/GDP155VX) (C878, D878, E878) • GLP/GDP80VX, GLP/GDP80VX9, GLP/ GDP90VX (GLP/GDP170VX, GLP/ GDP175VX36, GLP/GDP190VX) (A909, B909). See Main Control Valve 2000YRM1457 for lift truck models • GLP/GDP20-35VX (B875) • GLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/GDP45VX6; GLP/GDP50-55VX (G813, H813) See Mast Repairs (S/N A551, A555, A559, A661, A662, A663, A664, B507, B508, B509, B551, B555, B559, B562, B563, B564, B661, B662, B663, C515, C551, C555, C559, D507, D508, D509, D515, D562, D563, D564, E509, and E564) 4000YRM1148 for lift truck models • GC/GLC030VX, GC/GLC035VX, GC/ GLC040SVX (C809) • GLP/GDP16VX, GLP/GDP18VX, GLP/ GDP20SVX, (GP/GLP/GDP030VX, GP/GLP/ GDP035VX, GP/GLP/GDP040SVX) (C810) • GLC20-35VX (GC/GLC040-070VX, GC/ GLC055SVX) (A910) • GLP/GDP20-35VX (GP/GLP/GDP040-070VX) (B875) See Mast Repairs (S/N A513, A514, A613, A614, A702, A703, A704, A705, A706, A707, A751, A752, B513, B514, B586, B587, B588, B589, B590, B591, B749, B750, B751, B752, B753, B754) 4000YRM1250 for lift truck models • GLC40, 45, 55VX; GLC55SVX; (GC/GLC080, 100, 120VX; GC/GLC080, 100VXBCS; GC/ GLC120SVX; GC/GLC120VXPRS) (E818, F818) • GLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/GDP45VX6; GLP/GDP50-55VX (GP/GLP/ GDP080, 090, 100, 110, 120VX) (F813, G813, H813, J813) • GLC/GDC60VX, GLC/GDC70VX, (GC/GLC/ GDC135VX, GC/GLC/GDC155VX) (C879, D879, E879, F879) • GLP/GDP60VX, GLP/GDP70VX (GP/GLP/ GDP135VX, GP/GLP/GDP155VX) (C878, D878, E878) See Mast Repair (S/N A513, A514, A613, A614, A643, A644, A683, A684) 4000YRM1406 for lift truck models • GLP/GDP80VX, GLP/GDP80VX9, GLP/ GDP90VX (GLP/GDP170VX, GLP/ GDP175VX36, GLP/GDP190VX) (A909, B909) See Mast Repair (S/N A698, A699, B551) 4000YRM1431 for lift truck models • GLC050LX (A967) • GLP/GDP20-25LX (GLP/GDP050LX) (A974) 1900 YRM 1136 General 3

- 8. Single Gear Pump Assembly Repair REMOVE WARNING PUTTING THE LIFT TRUCK ON BLOCKS The lift truck must be put on blocks for some types of maintenance and repair. The removal of the following assemblies will cause large changes in the center of gravity: mast, drive axle, engine, transmission, and counterweight. When the lift truck is put on blocks, put additional blocks in the following positions to maintain stability: • Before removing the mast and drive axle, put blocks under the counterweight so the lift truck cannot fall backward. • Before removing the counterweight, put blocks under the mast assembly so the lift truck cannot fall forward. The surface must be solid, even, and level when the lift truck is put on blocks. Make sure any blocks used to support the lift truck are solid, one-piece units. NOTE: Worn or damaged seals are the most com- mon cause of pump damage. The pump bushings, gears, and shafts also wear. They must be checked during disassembly. DO NOT make any repairs to the parts. To prevent more failures, always replace parts that are worn or damaged. If several main parts need replacing, replace the complete group. 1. Put the lift truck on blocks. See the Operating Manual or the Periodic Maintenance Manual for your lift truck for the procedures to put the lift truck on blocks. 2. Place a drain pan under the hydraulic tank, re- move drain plug at the bottom of hydraulic oil tank, and drain oil from tank. a. Drain pan capacity approximately 30 li- ter (8 gal) for lift truck models • GC/GLC030VX, GC/GLC035VX, GC/ GLC040SVX (C809) • GLP/GDP16VX, GLP/GDP18VX, GLP/ GDP20SVX, (GP/GLP/GDP030VX, GP/GLP/GDP035VX, GP/GLP/ GDP040SVX) (C810) • GLC20-35VX (GC/GLC040-070VX, GC/ GLC055SVX) (A910) • GLC050LX (A967) • GLP/GDP20-35VX (GP/GLP/ GDP040-070VX) (B875) • GLP/GDP20-25LX (GLP/GDP050LX) (A974) NOTE: For lift trucks equipped with dual hudraulic tanks, place a second drain pan with same capacity under opposite hydraulic tank. Single Gear Pump Assembly Repair 1900 YRM 1136 4

- 9. b. Drain pan capacity approximately 40 li- ter (11 gal) for lift truck model • GLC40, 45, 55VX; GLC55SVX; (GC/ GLC080, 100, 120VX; GC/GLC080, 100VXBCS; GC/GLC120SVX; GC/ GLC120VXPRS) (E818, F818) c. Drain pan capacity approximately 51 li- ter (13.5 gal) for lift truck model • GLP/GDP40VX5/VX6; GLP/ GDP45SVX5, GLP/GDP45VX6; GLP/ GDP50-55VX (GP/GLP/GDP080, 090, 100, 110, 120VX) (F813, G813, H813, J813) NOTE: Perform Step 3 and Step 4 for lift trucks equipped with an iron transmission housing. 3. Put a drain pan under the pump assembly. Dis- connect all hydraulic lines connected to the pump assembly. Remove the pump outlet fitting and suction adapter. Put caps on all the hose fittings and hydraulic pump ports. See Figure 1 for lift truck models • GC/GLC030VX, GC/GLC035VX, GC/ GLC040SVX (C809) • GLP/GDP16VX, GLP/GDP18VX, (GLP/ GDP20SVX, (GP/GLP/GDP030VX, GP/GLP/GDP035VX, GP/GLP/ GDP040SVX) (C810) • GLC20-35VX (GC/GLC040-070VX, GC/ GLC055SVX) (A910) • GLP/GDP20-35VX (GP/GLP/ GDP040-070VX) (B875) See Figure 2 for lift truck models • GLC40, 45, 55VX; GLC55SVX; (GC/ GLC080, 100, 120VX; GC/GLC080, 100VXBCS; GC/GLC120SVX; GC/ GLC120VXPRS) (E818, F818) • GLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/GDP45VX6; GLP/GDP50-55VX (GP/GLP/GDP080, 090, 100, 110, 120VX) (F813, G813, H813, J813) See Figure 3 for lift truck model • GLC40, 45, 55VX; GLC55SVX; (GC/ GLC080, 100, 120VX; GC/GLC080, 100VXBCS; GC/GLC120SVX; GC/ GLC120VXPRS) (F818) equipped with dual hydraulic tanks. 1900 YRM 1136 Single Gear Pump Assembly Repair 5

- 10. A. EARLY LIFT TRUCK MODELS B. NEWER LIFT TRUCK MODELS 1. SUCTION HOSE 2. HYDRAULIC INLET HOSE 3. SUCTION ADAPTER 4. SOCKET HEAD SCREW (2) 5. HYDRAULIC PUMP 6. TRANSMISSION 7. PUMP OUTLET FITTING Figure 1. Hydraulic Pump for 1.5 to 3.5 Ton Lift Truck Models Equipped With an Iron Transmission Housing Single Gear Pump Assembly Repair 1900 YRM 1136 6

- 11. A. FOR EARLY MODEL GLC40, 45, 55VX; GLC55SVX; (GC/GLC080, 100, 120VX; GC/GLC080, 100VXBCS; GC/GLC120SVX; GC/GLC120VXPRS) (E818) LIFT TRUCKS ONLY B. FOR NEWER MODEL GLC40, 45, 55VX; GLC55SVX; (GC/GLC080, 100, 120VX; GC/GLC080, 100VXBCS; GC/GLC120SVX; GC/GLC120VXPRS) (E818, F818) LIFT TRUCKS ONLY AND FOR ALL GLP/GDP40VX5/ VX6; GLP/GDP45SVX5, GLP/GDP45VX6; GLP/GDP50-55VX (GP/GLP/GDP080, 090, 100, 110, 120VX) (F813, G813, H813, J813) LIFT TRUCKS 1. TRANSMISSION 2. SOCKET HEAD SCREW 3. HYDRAULIC PUMP 4. SUCTION HOSE 5. SUCTION ADAPTER 6. PUMP OUTLET FITTING 7. HYDRAULIC INLET HOSE Figure 2. Hydraulic Pump for 4 to 5.5 Ton Lift Truck Models 1900 YRM 1136 Single Gear Pump Assembly Repair 7

- 12. 1. TRANSMISSION 2. SOCKET HEAD SCREW 3. HYDRAULIC PUMP 4. SUCTION HOSE 5. SUCTION ADAPTER 6. PUMP OUTLET FITTING 7. HYDRAULIC INLET HOSE Figure 3. Hydraulic Pump for Lift Truck Model GLC40, 45, 55VX; GLC55SVX; (GC/GLC080, 100, 120VX; GC/ GLC080, 100VXBCS; GC/GLC120SVX; GC/GLC120VXPRS) ( F818) with Dual Hydraulic Tanks Single Gear Pump Assembly Repair 1900 YRM 1136 8

- 13. 4. Hold the pump assembly to keep it from falling. Remove the two socket head screws and the lockwashers that fasten the pump to the transmis- sion housing. Remove the pump assembly. NOTE: Perform Step 5 through Step 8 for lift trucks equipped with an aluminum transmission housing. 5. Put a drain pan under the pump assembly. Cover charge pump with liquid proof covering to prevent damage. NOTE: Lift truck models GLP/GDP20-35VX (GP/GLP/GDP040-070VX) (B875), with a single speed transmission, electronic or manual control valve, and manufactured after January, 2011, may be equipped with an optional Quick-Lok™ hydraulic hose and adapters. 6. On lift truck models not equipped with a Quick- Lok™ hydraulic hose, disconnect all hydraulic lines connected to the pump assembly. Remove pump outlet fitting and suction adapter from hy- draulic gear pump. Put caps on all hose fittings and hydraulic gear pump ports. See Figure 4 for lift truck models • GC/GLC030VX, GC/GLC035VX, GC/ GLC040SVX (C809) • GLP/GDP16VX, GLP/GDP18VX, GLP/ GDP20SVX, (GP/GLP/GDP030VX, GP/GLP/GDP035VX, GP/GLP/ GDP040SVX) (C810) • GLC20-35VX (GC/GLC040-070VX, GC/ GLC055SVX) (A910) • GLP/GDP20-35VX (GP/GLP/ GDP040-070VX) (B875) See Figure 5 for lift truck models • GC/GLC030VX, GC/GLC035VX, GC/ GLC040SVX (C809) • GLP/GDP16VX, GLP/GDP18VX, GLP/ GDP20SVX, (GP/GLP/GDP030VX, GP/GLP/GDP035VX, GP/GLP/ GDP040SVX) (C810) • GLC20-35VX (GC/GLC040-070VX, GC/ GLC055SVX) (A910) • GLP/GDP20-35VX (GP/GLP/ GDP040-070VX) (B875) • GLC050LX (A967) • GLP/GDP20-25LX (GLP/GDP050LX) (A974) 7. On lift truck models GLP/GDP20-35VX (GP/GLP/ GDP040-070VX) (B875) equipped with a Quick- Lok™ hydraulic hose and single speed transmis- sion, remove the adapter and hydraulic hose from gear pump assembly. Disconnect all other hy- draulic hoses connected to gear pump assembly. Remove pump outlet fitting from hydraulic gear pump. Put caps on all hose fittings and hydraulic gear pump ports. See Figure 5 for lift truck model • GLP/GDP20-35VX (GP/GLP/ GDP040-070VX) (B875) See Figure 6 for lift truck models • GLP/GDP20-35VX (GP/GLP/ GDP040-070VX) (B875) 1900 YRM 1136 Single Gear Pump Assembly Repair 9

- 14. 8. Hold the pump assembly to keep it from falling. Remove the two flange head capscrews that fas- ten the pump to the transmission housing. Re- move the pump assembly. See Figure 4 for lift truck models • GC/GLC030VX, GC/GLC035VX, GC/ GLC040SVX (C809) • GLP/GDP16VX, GLP/GDP18VX, GLP/ GDP20SVX, (GP/GLP/GDP030VX, GP/GLP/GDP035VX, GP/GLP/ GDP040SVX) (C810) • GLC20-35VX (GC/GLC040-070VX, GC/ GLC055SVX) (A910) • GLP/GDP20-35VX (GP/GLP/ GDP040-070VX) (B875) See Figure 5 for lift truck models • GC/GLC030VX, GC/GLC035VX, GC/ GLC040SVX (C809) • GLP/GDP16VX, GLP/GDP18VX, GLP/ GDP20SVX, (GP/GLP/GDP030VX, GP/GLP/GDP035VX, GP/GLP/ GDP040SVX) (C810) • GLC20-35VX (GC/GLC040-070VX, GC/ GLC055SVX) (A910) • GLP/GDP20-35VX (GP/GLP/ GDP040-070VX) (B875) • GLC050LX (A967) • GLP/GDP20-25LX (GLP/GDP050LX) (A974) 1. SUCTION HOSE 2. HYDRAULIC INLET HOSE 3. SUCTION ADAPTER 4. PUMP OUTLET FITTING 5. FLANGE HEAD CAPSCREW (2) 6. HYDRAULIC PUMP 7. TRANSMISSION Figure 4. Hydraulic Pump for 1.5 to 3.5 Ton Lift Truck Models, Equipped With Aluminum Transmission Housing, Prior to January, 2011 Single Gear Pump Assembly Repair 1900 YRM 1136 10

- 15. NOTE: QUICK-LOK™ HYDRAULIC HOSE AND ADAPTERS NOT SHOWN. A. 1.5 TO 3.5 TON MODELS B. LIFT TRUCK MODELS GLC050LX (A967) AND GLP/GDP20-25LX (GLP/GDP050LX) (A974) 1. SUCTION HOSE 2. HYDRAULIC INLET HOSE 3. FLANGE HEAD CAPSCREW (2) 4. PUMP OUTLET FITTING 5. SUCTION ADAPTER 6. HYDRAULIC PUMP 7. TRANSMISSION Figure 5. Hydraulic Pump for 1.5 to 3.5 Ton Lift Truck Models, and Lift Trucks GLC050LX (A967) and GLP/ GDP20-25LX (GLP/GDP050LX) (A974) Equipped with Aluminum Transmission Housing, After January, 2011 1900 YRM 1136 Single Gear Pump Assembly Repair 11

- 16. NOTE: ELECTRO-HYDRAULIC MAIN CONTROL VALVE SHOWN. 1. STEERING CONTROL UNIT 2. QUICK-LOK™ ADAPTER 3. QUICK-LOK™ HYDRAULIC HOSE 4. HYDRAULIC GEAR PUMP Figure 6. Quick-LokQuick-Lok™ Hydraulic Supply Hose System, Lift Truck Models GLP/GDP20-35VX (GP/GLP/GDP040-070VX) (B875) With Single Speed and Aluminum Transmission, After January, 2011 DISASSEMBLE 1. Put the pump body in a vise. Put an alignment mark on each section of the pump body to aid in reassembly. 2. Remove the capscrews that hold the pump to- gether. Remove the flange end housing. Remove the rear valve housing. DO NOT let the seals and gears fall. See Figure 7. 3. Make a note of the position of the plate seals and pressure plates. Carefully remove the plate seals, pressure plates, and gears from the housings. Discard plate seals and backup seals. Remove the snap ring and shaft seal from the flange end housing. Single Gear Pump Assembly Repair 1900 YRM 1136 12

- 17. 1. SNAP RING 2. SHAFT SEAL 3. FLANGE END HOUSING 4. PLATE SEAL 5. PRESSURE PLATE 6. GEAR HOUSING 7. DRIVEN GEAR 8. DRIVE GEAR 9. REAR VALVE HOUSING 10. CAPSCREW 11. BACKUP SEAL Figure 7. Hydraulic Pump Assembly 1900 YRM 1136 Single Gear Pump Assembly Repair 13

- 18. CLEAN WARNING Cleaning solvents can be flammable and toxic and can cause skin irritation. When using cleaning solvents, always follow the solvent manufacturers recommended safety precautions. WARNING Compressed air can move particles so that they cause injury to the user or to other personnel. Make sure that the path of the compressed air is away from all personnel. Wear protective goggles or a face shield to prevent injury to the eyes. Clean all parts in solvent. Dry parts with compressed air. DO NOT dry the parts with a cloth. Make sure all surfaces are free of scratches and sharp edges. INSPECT Check parts for wear and damage. If any parts are worn or damaged, replace the damaged parts. If the pump housing is damaged, replace the pump. ASSEMBLE 1. Coat all pump components with hydraulic oil. Use hydraulic oil meeting specification ISO VG 46 hy- draulic oil −15°C (5°F) and above. 2. Use new plate and backup seals and install the pressure plates and gears. Make sure to install the pressure plates as removed during disassem- bly. See the notes made during disassembly. Make sure all seals are complete and in the cor- rect positions. See Figure 7. 3. Install a new shaft seal in the flange end housing. Carefully install the flange end housing. DO NOT move the pressure plates. Make sure the seals do not move out of the correct position. See Figure 7. 4. Carefully install the valve end housing on the pump body using the four capscrews and lock- washers. Make sure the pressure plates do not move and that the seals stay in the correct posi- tion. Make sure the marks made during disassem- bly are aligned. Tighten the capscrews to 88 to 98 N•m (65 to 72 lbf ft). INSTALL 1. Install pump outlet fitting and tighten to: a. 88 to 98 N•m (65 to 72 lbf ft) for lift truck mod- els below • GC/GLC030VX, GC/GLC035VX, GC/ GLC040SVX (C809) • GLP/GDP16VX, GLP/GDP18VX, GLP/ GDP20SVX, (GP/GLP/GDP030VX, GP/GLP/GDP035VX, GP/GLP/ GDP040SVX) (C810) • GLC20-35VX (GC/GLC040-070VX, GC/ GLC055SVX) (A910) • GLC050LX (A967) • GLP/GDP20-35VX (GP/GLP/ GDP040-070VX) (B875) • GLP/GDP20-25LX (GLP/GDP050LX) (A974) • GLP/GDP60VX, GLP/GDP70VX (GP/GLP/GDP135VX, GP/GLP/ GDP155VX) (C878, D878, E878) b. 98 to 118 N•m (72 to 87 lbf ft) for lift truck models below • GLC40, 45, 55VX; GLC55SVX; (GC/ GLC080, 100, 120VX; GC/GLC080, 100VXBCS; GC/GLC120SVX; GC/ GLC120VXPRS) (E818, F818) • GLP/GDP40VX5/VX6; GLP/ GDP45SVX5, GLP/GDP45VX6; GLP/ GDP50-55VX (GP/GLP/GDP080, 090, 100, 110, 120VX) (F813, G813, H813, J813) Single Gear Pump Assembly Repair 1900 YRM 1136 14

- 19. 2. On lift truck models not equipped with a Quick- Lok™ hydraulic hose, install suction adapter and tighten to 78 to 88 N•m (58 to 65 lbf ft). NOTE: The information in Step 3 is used when the Quick-Lok™ hydraulic hose is installed for the first time. 3. For lift truck models GLP/GDP20-35VX (GP/GLP/ GDP040-070VX) (B875) equipped with a Quick- Lok™ hydraulic hose: a. Disconnect standard hydraulic hose from steer- ing control unit (SCU) and remove fitting from SCU port. b. Install Quick-Lok™ adapters into the SCU and gear pump ports. See Figure 6. Tighten adapter at the gear pump to 59 to 69 N•m (44 to 51 lbf ft). Tighten the adapter at the SCU port to 170 to 183 N•m (125 to 135 lbf ft). c. Install hydraulic gear pump to transmission. Go to Step 6. NOTE: Once the Quick-Lok™ hydraulic hose clicks into place on the adapters, the adapters are perma- nently installed on the hose. To remove the Quick- Lok™ hydraulic hose again, remove the adapters from the SCU and gear pump ports. When replacing the Quick-Lok™ hydraulic hose, replace both adapt- ers and the hose at the same time. See Parts Man- ual. d. Push each end of Quick-Lok™ hydraulic hose into adapters on the SCU and gear pump, until they click into place. Pull on the Quick-Lok™ hydraulic hose to ensure that it is securely in the adapters. e. Position the Quick-Lok™ hydraulic hose (inlet hose) as shown in Figure 11. NOTE: Perform Step 4 and Step 5 for lift trucks equipped with an iron transmission housing. 4. Clean the pump flange and transmission mount- ing surfaces and put a 3 to 5 mm (0.118 to 0.197 in.) bead of Loctite™ 515 (Yale Part No. 520042831) on the pump flange or transmission mounting surface. Hold the pump in the correct position on the transmission. Install the socket head screws and lockwashers that fasten the pump to the transmission housing. Tighten socket head screws to 38 N•m (28 lbf ft). See Figure 1 for lift truck models • GC/GLC030VX, GC/GLC035VX, GC/ GLC040SVX (C809) • GLP/GDP16VX, GLP/GDP18VX, GLP/ GDP20SVX, (GP/GLP/GDP030VX, GP/GLP/GDP035VX, GP/GLP/ GDP040SVX) (C810) • GLC20-35VX (GC/GLC040-070VX, GC/ GLC055SVX) (A910) • GLP/GDP20-35VX (GP/GLP/ GDP040-070VX) (B875) See Figure 2 for lift truck models • GLC40, 45, 55VX; GLC55SVX; (GC/ GLC080, 100, 120VX; GC/GLC080, 100VXBCS; GC/GLC120SVX; GC/ GLC120VXPRS) (E818, F818) • GLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/GDP45VX6; GLP/GDP50-55VX (GP/GLP/GDP080, 090, 100, 110, 120VX) (F813, G813, H813, J813) See Figure 3 for lift truck model • GLC40, 45, 55VX; GLC55SVX; (GC/ GLC080, 100, 120VX; GC/GLC080, 100VXBCS; GC/GLC120SVX; GC/ GLC120VXPRS) (F818) equipped with dual hydraulic tanks. 1900 YRM 1136 Single Gear Pump Assembly Repair 15

- 20. 5. Connect the hydraulic lines to the hydraulic pump assembly. Position the hydraulic inlet hose as shown in figures specified below: See Figure 8 for lift trucks models • GC/GLC030VX, GC/GLC035VX, GC/ GLC040SVX (C809) • GLP/GDP16VX, GLP/GDP18VX, GLP/ GDP20SVX, (GP/GLP/GDP030VX, GP/GLP/GDP035VX, GP/GLP/ GDP040SVX) (C810) • GLC20-35VX (GC/GLC040-070VX, GC/ GLC055SVX) (A910) • GLP/GDP20-35VX (GP/GLP/ GDP040-070VX) (B875) See Figure 9 for lift truck models • GLC40, 45, 55VX; GLC55SVX; (GC/ GLC080, 100, 120VX; GC/GLC080, 100VXBCS; GC/GLC120SVX; GC/ GLC120VXPRS) (E818, F818) • GLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/GDP45VX6; GLP/GDP50-55VX (GP/GLP/GDP080, 090, 100, 110, 120VX) (F813, G813, H813, J813) NOTE: Perform Step 6, Step 7, and Step 8 for lift truck equipped with an aluminum transmission hous- ing. 6. Make sure pump flange and transmission mount- ing surfaces are clean. Put a 3 to 5 mm (0.118 to 0.197 in.) bead of sealant on either pump or transmission housing face. Hold the pump in the correct position on the transmission and install flange head capscrews into pump and transmis- sion housing. Tighten capscrews to 38 N•m (28 lbf ft). A. Z = 60° ±5° FOR 1-SPEED TRANSMISSION, LIFT TRUCK MODELS GC/GLC030-035VX, GC/ GLC040SVX (C809), GLP/GDP16-18VX, GLP/ GDP20SVX (GP/GLP/GDP030-035VX, GP/GLP/ GDP040SVX) (C810), AND GLC20-35VX (GC/ GLC040-070VX, GC/GLC055SVX) (A910) B. Z = 75° ±5° FOR 2-SPEED TRANSMISSION, LIFT TRUCK MODELS GC/GLC040-070VX, GC/ GLC055SVX (A910) C. Z = 50° ±5° FOR LIFT TRUCK MODELS GLP/ GDP20-35VX (GP/GLP/GDP040-070VX) (B875) D. X = 10° ±5° FOR LIFT TRUCK MODELS GC/ GLC030VX, GC/GLC035VX, GC/GLC040SVX (C809); GLP/GDP16VX, GLP/GDP18VX, GLP/ GDP20SVX, (GP/GLP/GDP030VX, GP/GLP/ GDP035VX, GP/GLP/GDP040SVX) (C810); GLC20-35VX (GC/GLC040-070VX, GC/ GLC055SVX) (A910) GLP/GDP20-35VX (GP/GLP/GDP040-070VX) (B875) 1. HYDRAULIC INLET HOSE 2. SUCTION HOSE Figure 8. Inlet Hose Orientation for Lift Truck Models, With Iron Transmission Housing,GC/ GLC030VX, GC/GLC035VX, GC/GLC040SVX (C809), GLP/GDP16VX, GLP/GDP18VX, GLP/ GDP20SVX, (GP/GLP/GDP030VX, GP/GLP/ GDP035VX, GP/GLP/GDP040SVX) (C810), GLC20-35VX (GC/GLC040-070VX, GC/GLC055SVX) (A910), and GLP/GDP20-35VX (GP/GLP/ GDP040-070VX) (B875) Single Gear Pump Assembly Repair 1900 YRM 1136 16

- 21. A. X = 32° ±5° FOR ALL LIFT TRUCK MODELS EX- CEPT GLC40, 45, 55VX; GLC55SVX; (GC/ GLC080, 100, 120VX; GC/GLC080, 100VXBCS; GC/GLC120SVX; GC/GLC120VXPRS) (E818, F818) AND GLP/GDP40VX5/VX6; GLP/ GDP45SVX5, GLP/GDP45VX6; GLP/ GDP50-55VX (GP/GLP/GDP080, 090, 100, 110, 120VX) (F813, G813, H813, J813) B. X = 30° ±5° FOR LIFT TRUCK MODELS GLC40, 45, 55VX; GLC55SVX; (GC/GLC080, 100, 120VX; GC/GLC080, 100VXBCS; GC/ GLC120SVX; GC/GLC120VXPRS) (E818, F818) AND GLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/GDP45VX6; GLP/GDP50-55VX (GP/GLP/ GDP080, 090, 100, 110, 120VX) (F813, G813, H813, J813) 1. HYDRAULIC INLET HOSE 2. SUCTION HOSE Figure 9. Inlet Hose Orientation for Lift Truck Models GLC40, 45, 55VX; GLC55SVX; (GC/ GLC080, 100, 120VX; GC/GLC080, 100VXBCS; GC/ GLC120SVX; GC/GLC120VXPRS) (E818, F818) and GLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/ GDP45VX6; GLP/GDP50-55VX (GP/GLP/GDP080, 090, 100, 110, 120VX) (F813, G813, H813, J813) See Figure 4 for lift truck models • GC/GLC030VX, GC/GLC035VX, GC/ GLC040SVX (C809) • GLP/GDP16VX, GLP/GDP18VX, GLP/ GDP20SVX, (GP/GLP/GDP030VX, GP/GLP/GDP035VX, GP/GLP/ GDP040SVX) (C810) • GLC20-35VX (GC/GLC040-070VX, GC/ GLC055SVX) (A910) • GLP/GDP20-35VX (GP/GLP/ GDP040-070VX) (B875) See Figure 5 for lift truck models • GC/GLC030VX, GC/GLC035VX, GC/ GLC040SVX (C809) • GLP/GDP16VX, GLP/GDP18VX, GLP/ GDP20SVX, (GP/GLP/GDP030VX, GP/GLP/GDP035VX, GP/GLP/ GDP040SVX) (C810) • GLC20-35VX (GC/GLC040-070VX, GC/ GLC055SVX) (A910) • GLP/GDP20-35VX (GP/GLP/ GDP040-070VX) (B875) • GLC050LX (A967) • GLP/GDP20-25LX (GLP/GDP050LX) (A974) 7. On lift truck models not equipped with a Quick- Lok™ hydraulic hose, connect hydraulic lines to hydraulic pump assembly. Position inlet hydraulic line as shown in Figure 10. NOTE: If the Quick-Lok™ hydraulic supply hose and adapter is being installed for the first time, go to Step 3 for procedures. 8. On lift truck models equipped with a Quick-Lok™ hydraulic hose and adapter, connect hydraulic lines, except for the Quick-Lok™ hydraulic hose, to hydraulic gear pump assembly. Install the Quick-Lok™ hydraulic hose and adapter into gear pump and position inlet hydraulic line as shown in Figure 11. Tighten adapter at the gear pump to 59 to 69 N•m (44 to 51 lbf ft). Tighten the adapter at the SCU port to 170 to 183 N•m (125 to 135 lbf ft). 9. Remove the lift truck from the blocks. See the Op- erating Manual or the Periodic Maintenance Manual for the procedures to remove lift truck from blocks. 10. Fill the tank using the hydraulic oil shown in the Maintenance Table located in the Operating Manual or the Periodic Maintenance Manual for your lift truck model. When the oil level is correct, operate the system and check for leaks. Check the hydraulic oil level and add hydraulic oil if nec- essary. 1900 YRM 1136 Single Gear Pump Assembly Repair 17

- 22. NOTE: QUICK-LOK™ HYDRAULIC HOSE AND ADAPTERS NOT SHOWN. 1. HYDRAULIC INLET HOSE 2. SUCTION HOSE Figure 10. Inlet Hose Orientation for Lift Truck Models, GC/GLC030VX, GC/GLC035VX, GC/GLC040SVX (C809), GLP/GDP16VX, GLP/GDP18VX, GLP/GDP20SVX, (GP/GLP/GDP030VX, GP/GLP/GDP035VX, GP/GLP/GDP040SVX) (C810), GLC20-35VX (GC/GLC040-070VX, GC/GLC055SVX) (A910), GLC050LX (A967), GLP/GDP20-35VX (GP/GLP/GDP040-070VX) (B875) and GLP/GDP20-25LX (GLP050LX) (A974) With Aluminum Transmission Housing Before January, 2011 and Equipped With Mazda Engine Single Gear Pump Assembly Repair 1900 YRM 1136 18

- 23. NOTE: ELECTRO-HYDRAULIC CONTROL VALVE SHOWN. ORIENTATION IS THE SAME ON MANUAL CON- TROL VALVE. A. 40° ±5° B. 15° ±5° 1. INLET HOSE 2. SUCTION HOSE Figure 11. Inlet Hose Orientation for All Lift Truck Models With Single Speed and Aluminum Transmission After January, 2011 and Equipped With Quick-Lok™ Hydraulic Supply Hose and Adapters 1900 YRM 1136 Single Gear Pump Assembly Repair 19

- 24. Tandem Gear Pump Assembly REMOVE WARNING PUTTING THE LIFT TRUCK ON BLOCKS The lift truck must be put on blocks for some types of maintenance and repair. The removal of the following assemblies will cause large changes in the center of gravity: mast, drive axle, engine, transmission, and counterweight. When the lift truck is put on blocks, put additional blocks in the following positions to maintain stability: • Before removing the mast and drive axle, put blocks under the counterweight so the lift truck cannot fall backward. • Before removing the counterweight, put blocks under the mast assembly so the lift truck cannot fall forward. The surface must be solid, even, and level when the lift truck is put on blocks. Make sure any blocks used to support the lift truck are solid, one-piece units. NOTE: Worn or damaged seals are the most com- mon cause of pump damage. The pump bushings, gears, and shafts also wear. They must be checked during disassembly. DO NOT make any repairs to the parts. To prevent more failures, always replace parts that are worn or damaged. If several main parts need replacing, replace the complete group. 1. Put the lift truck on blocks. See the Operating Manual or the Periodic Maintenance Manual for your lift truck for the procedures to put the lift truck on blocks. The following lift trucks are equip- ped with the tandem gear pump assembly: • GLC/GDC60VX, GLC/GDC70VX, (GC/GLC/GDC135VX, GC/GLC/ GDC155VX) (C879, D879, E879, F879) • GLP/GDP60VX, GLP/GDP70VX (GP/GLP/ GDP135VX, GP/GLP/GDP155VX) (C878, D878, E878) • GLP/GDP80VX, GLP/GDP80VX9, GLP/ GDP90VX (GLP/GDP170VX, GLP/ GDP175VX36, GLP/GDP190VX) (A909, B909) 2. Place a drain pan under the hydraulic tank, re- move the drain plug at the bottom of hydraulic oil tank, and drain oil from tank. a. Drain pan capacity approximately 64 li- ter (16.9 gal) for lift truck models • GLC/GDC60VX, GLC/GDC70VX, (GC/GLC/GDC135VX, GC/GLC/ GDC155VX) (C879, D879, E879, F879) • GLP/GDP60VX, GLP/GDP70VX (GP/GLP/GDP135VX, GP/GLP/ GDP155VX) (C878, D878, E878) • GLP/GDP80VX, GLP/GDP80VX9, GLP/ GDP90VX (GLP/GDP170VX, GLP/ GDP175VX36, GLP/GDP190VX) (A909, B909) 3. Put a drain pan under the tandem gear pump as- sembly. Remove hydraulic outlet hoses at the fit- tings on the tandem gear pump assembly. Re- move the inlet hose clamps and inlet hoses from the tandem gear pump assembly. Put caps on all the hose fittings and hydraulic pump ports. See Figure 12. 4. Support the tandem gear pump assembly to keep it from falling. Remove the two socket head screws and lock washers that fasten the tandem gear pump assembly to the transmission charge pump housing. Remove the tandem gear pump assembly. Tandem Gear Pump Assembly 1900 YRM 1136 20

- 25. 1. OUTLET HOSES 2. OUTLET HOSE FITTINGS 3. INLET HOSE CLAMPS 4. INLET HOSES 5. HEX SOCKET CAPSCREW 6. LOCK WASHER 7. TRANSMISSION CHARGE PUMP 8. TANDEM GEAR PUMP Figure 12. Hydraulic Pump Removal for Lift Truck Models GLP/GDP60VX, GLP/GDP70VX (GP/GLP/ GDP135VX, GP/GLP/GDP155VX) (C878, D878, E878), GLC/GDC60VX, GLC/GDC70VX, (GC/GLC/GDC135VX, GC/GLC/GDC155VX) (C879, D879, E879, F879), and GLP/GDP80VX, GLP/GDP80VX9, GLP/GDP90VX (GLP/ GDP170VX, GLP/GDP175VX36, GLP/GDP190VX) (A909, B909) 1900 YRM 1136 Tandem Gear Pump Assembly 21

- 26. DISASSEMBLE 1. Secure the tandem gear pump assembly in a vise. Put an alignment mark on each section of the pump body to aid in reassembly. NOTE: The tandem gear pump assembly consists of a driven pump attached to a drive pump. Each pump has an inlet adapter and outlet fitting. 2. Remove inlet adapters and outlet fittings from drive pump and driven pump of tandem gear pump assembly. See Figure 13. 1. FITTING 2. DRIVEN PUMP 3. ADAPTER 4. DRIVE PUMP Figure 13. Tandem Gear Pump Fittings 3. Remove two capscrews and washers attaching driven pump to drive pump. See Figure 14. NOTE: Drive pump shaft and driven pump shaft are connected by a coupling. 4. Slowly remove driven pump from drive pump. Note position of O-rings on coupling. Remove O- rings, and coupling. Discard O-rings. 5. Place driven pump on a clean work space and continue with disassembly of the drive pump. 6. Remove snap ring and oil seal from drive pump flange end housing. Discard snap ring. 7. Remove the socket head screws and washers that hold the pump together, and remove from vise. Remove adapter plate, cover plate and housing from drive pump flange end housing. DO NOT let the seals and gears fall. 8. Make a note of the position of the plate seals and pressure plates. Carefully remove the plate seals, back up seals, pressure plates, gear plate, cover plate, oil seal and gears from the housings. Dis- card plate seals and backup seals. Tandem Gear Pump Assembly 1900 YRM 1136 22

- 27. Figure 14. Tandem Gear Pump Assembly 1900 YRM 1136 Tandem Gear Pump Assembly 23

- 28. Legend for Figure 14 1. SOCKET HEAD FLANGE SCREW 2. MOUNTING FLANGE COVER 3. PLATE SEAL 4. BACKUP SEAL 5. PRESSURE PLATE 6. GEAR PLATE 7. DOWEL PIN 8. GEARS 9. CAPSCREW 10. WASHER 11. FLANGE END HOUSING 12. SNAP RING 13. O-RING 14. COUPLING 15. SOCKET HEAD SCREW 16. ADAPTER PLATE 17. COVER PLATE 18. HOUSING 19. OIL SEAL 20. DRIVE PUMP FLANGE END HOUSING 9. Secure the driven pump body in a vise. 10. Remove the socket head flange screws that hold the pump together. Remove the mounting flange cover. Remove the rear valve housing. DO NOT let the seals and gears fall. See Figure 14. 11. Make a note of the position of the plate seals and pressure plates. Carefully remove the plate seals, pressure plates, gear plate and gears from the housings. Discard plate seals and backup seals. Remove the snap ring from the flange end hous- ing. Discard snap ring. CLEAN WARNING Cleaning solvents can be flammable and toxic and can cause skin irritation. When using cleaning solvents, always follow the solvent manufacturers recommended safety precautions. WARNING Compressed air can move particles so that they cause injury to the user or to other personnel. Make sure that the path of the compressed air is away from all personnel. Wear protective goggles or a face shield to prevent injury to the eyes. Clean all parts in solvent. Dry parts with compressed air. DO NOT dry the parts with a cloth. Make sure all surfaces are free of scratches and sharp edges. INSPECT Check parts for wear and damage. If any parts are worn or damaged, replace the damaged parts. If the pump housing is damaged, replace the pump. ASSEMBLE 1. Coat all pump components with hydraulic oil. Use hydraulic oil meeting specification ISO VG 46 hy- draulic oil −15°C (5°F) and above. 2. Begin assembly of the driven pump. Use new plate and backup seals and install the pressure plates, gear plate and gears. Make sure to install the pressure plates as removed during disassem- bly. See the notes made during disassembly. Make sure all seals are in the correct positions. See Figure 14. 3. Carefully install the mounting flange cover. DO NOT move the pressure plates. Make sure the seals do not move out of the correct position. Tandem Gear Pump Assembly 1900 YRM 1136 24

- 29. 4. Carefully install the flange end housing on the pump body using the four socket head flange screws. Make sure the pressure plates do not move and that the seals stay in the correct posi- tion. Make sure the marks made during disassem- bly are aligned. Tighten the capscrews to 88 to 98 N•m (65 to 72 lbf ft). Install new snap ring in flange end housing. 5. Begin assembly of the drive pump. Use new plate and backup seals and install the pressure plates and gears. Make sure to install the pressure plates, cover plate, housing, oil seal and adapter plate as removed during disassembly. See the notes made during disassembly. Make sure all seals are in the correct positions. 6. Install a new shaft seal in the drive pump flange end housing. Carefully install the flange end hous- ing. DO NOT move the pressure plates. Make sure the seals do not move out of the correct po- sition. 7. Carefully install the adapter plate on the drive pump body using the four socket head screws and lock washers. Make sure the pressure plates do not move and that the seals stay in the correct position. Make sure the marks made during disas- sembly are aligned. Tighten the capscrews to 123 to 132 N•m (91 to 97 lbf ft). Install new snap ring in front of shaft seal. 8. Assemble tandem gear pump. Place drive pump in vise and install oil seal, adapter, sleeve and O- ring to shaft of drive pump. Fit shaft of driven pump into adapter and install two capscrews and washers securing the driven pump to the drive pump. Tighten the capscrews to 42 to 46 N•m (31 to 34 lbf ft). 9. Reposition tandem gear pump in the vise and in- stall two outlet hose fittings. See Figure 13. Tighten the fittings to 78 to 88 N•m (58 to 65 lbf ft). 10. Install two inlet adapters, tighten to 88 to 98 N•m (65 to 72 lbf ft). Remove tandem gear pump from vise. INSTALL 1. Clean the tandem gear pump flange and trans- mission charge pump mounting surfaces and put a 3-5 mm (0.118-0.197 in.) bead of Loctite™ 515 (Yale Part No. 520042831) on the pump flange or transmission charge pump mounting surface. Hold the pump in the correct position on the trans- mission. Install the socket head screws and lock- washers that fasten the pump to the transmission housing. Tighten socket head screws to 108 N•m (80 lbf ft). See Figure 12. 2. Loosen inlet hose clamps and install inlet hoses to inlet hose fittings. Tighten inlet hose clamps. In- stall outlet hoses to outlet hose fittings. 3. Remove the lift truck from the blocks. See the Op- erating Manual or the Periodic Maintenance Manual for the procedures to remove lift truck from blocks. 4. Fill the tank using the hydraulic oil shown in the Maintenance Table located in the Operating Manual or the Periodic Maintenance Manual for your lift truck model. When the oil level is correct, operate the system and check for leaks. Check the hydraulic oil level and add hydraulic oil if nec- essary. 1900 YRM 1136 Tandem Gear Pump Assembly 25

- 30. Gear Pump Specifications Table 1. Hydraulic Gear Pumps for Lift Truck Models GC/GLC030VX, GC/GLC035VX, GC/GLC040SVX (C809) and GLP/GDP16VX, GLP/GDP18VX, GLP/GDP20SVX, (GP/GLP/GDP030VX, GP/GLP/GDP035VX, GP/GLP/GDP040SVX) (C810) Model Engine Displacement Governed Speed Main Relief Valve Pressure - Mpa (PSI) Pump Flow Rate - LPM (GPM) GC/GLC030VX, GC/GLC035VX, GC/ GLC040SVX (C809) GLP/ GDP16VX, GLP/ GDP18VX, GLP/ GDP20SVX (GP/GLP/ GDP030VX, GP/GLP/ GDP035VX, GP/GLP/ GDP040SVX) (C810) Mazda 2.0L 24.0 cc/rev 2400 rpm 19.31 MPa (2800 psi) 56.1 liter/min (14.8 gal/min) GC/GLC030VX, GC/GLC035VX, GC/ GLC040SVX (C809) GLP/ GDP16VX, GLP/ GDP18VX, GLP/ GDP20SVX (GP/GLP/ GDP030VX, GP/GLP/ GDP035VX, GP/GLP/ GDP040SVX) (C810) Yanmar 2.6L 29.4 cc/rev 2400 rpm 19.31 MPa (2800 psi) 68.7 liter/min (18.1 gal/min) Gear Pump Specifications 1900 YRM 1136 26

- 31. Table 2. Hydraulic Gear Pumps for Lift Truck Models GLC20-35VX (GC/GLC040-070VX, GC/GLC055SVX) (A910), GLC050LX (A967), GLP/GDP20-35VX (GP/GLP/GDP040-070VX) (B875), and GLP/GDP20-25LX (GLP/ GDP050LX) (A974) Model Engine Displacement Governed Speed Main Relief Valve Pressure - Mpa (PSI) Pump Flow Rate - LPM (GPM) GLC050LX (A967) Mazda 2.0L 24.0 cc/rev 2400 rpm 21.4 MPa (3104 psi) 57.6 liter/min (15.2 gal/min) GLP20-25L (A974) Mazda 2.0L 24.0 cc/rev 2400 rpm 23.4 MPa (3394 psi) 57.6 liter/min (15.2 gal/min)GLP050LX (A974) 21.4 MPa (3104 psi) GDP20-25LX (A974) Yanmar 2.6L 25.7 cc/rev 2400 rpm 23.4 MPa (3394 psi) 61.7 liter/min (16.3 gal/min)GDP050LX (A974) 21.4 MPa (3104 psi) GLC20-30VX (GC/ GLC040-060VX, GC/ GLC055SVX) (A910) GLP/ GDP20-30VX (GP/GLP/ GDP040-060VX ) (B875) Mazda 2.0L/2.2L 24.0 cc/rev 2700 rpm 21.37 MPa (3100 psi) 63.1 liter/min (16.7 gal/min) GM 2.4L 25.7 cc/rev 67.5 liter/min (17.8 gal/min) Yanmar 2.6L 29.4 cc/rev 77.3 liter/min (20.4 gal/min) Yanmar 3.3L 2600 rpm 74.4 liter/min (19.7 gal/min) GLC35VX (GC/ GLC070VX) (A910) GLP/ GDP35VX (GP/GLP/ GDP070VX) (B875) Mazda 2.0L/2.2L 24.0 cc/rev 2700 rpm 23.44 MPa (3400 psi) 63.1 liter/min (16.7 gal/min) GM 2.4L 25.7 cc/rev 67.5 liter/min (17.8 gal/min) Yanmar 2.6L 29.4 cc/rev 77.3 liter/min (20.4 gal/min) Yanmar 3.3L 2600 rpm 74.4 liter/min (19.7 gal/min) 1900 YRM 1136 Gear Pump Specifications 27

- 32. Table 3. Hydraulic Gear Pumps for Lift Truck Model GLC40, 45, 55VX; GLC55SVX; (GC/GLC080, 100, 120VX; GC/GLC080, 100VXBCS; GC/GLC120SVX; GC/GLC120VXPRS) (E818, F818) Model Engine Displacement Governed Speed Main Relief Valve Pressure - Mpa (PSI) Pump Flow Rate - LPM (GPM) GLC40VX (GC/ GLC080VX, GC/ GLC080VXBCS) (E818, F818) GM 4.3L 32.5 cc/rev 2400 rpm 22.06 MPa (3200 psi) 75.9 liter/min (20.1 gal/min) 41.3 cc/rev 96.5 liter/min (25.5 gal/min) GLC45, 55VX; GLC55SVX; (GC/ GLC100, 120VX; GC/ GLC100VXBCS; GC/GLC120SVX; GC/ GLC120VXPRS) (E818, F818) 96.5 liter/min (25.5 gal/min) 51.6 cc/rev 120.5 liter/min (31.8 gal/min) Table 4. Hydraulic Gear Pumps for Lift Truck Models GLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/ GDP45VX6; GLP/GDP50-55VX (GP/GLP/GDP080, 090, 100, 110, 120VX) (F813, G813, H813, J813) Model Engine Displacement Governed Speed Main Relief Valve Pressure - Mpa (PSI) Pump Flow Rate - LPM (GPM) GLP/ GDP40VX5/VX6 (GP/GLP/ GDP080, 090VX) (F813, G813, H813, J813) GM 4.3L / Kubota 3.8L (Paper Kit Industry) 32.5 cc/rev 2400 rpm 22.06 MPa (3200 psi) 75.9 liter/min (20.1 gal/min) GM 4.3L 41.3 cc/rev 2400 rpm 22.06 MPa (3200 psi) 96.5 liter/min (25.5 gal/min) Kubota 41.3 cc/rev 2450 rpm 22.1 MPa (3200 psi) 96.5 liter/min (25.5 gal/min) Cummins 3.3L Turbo / Kubota 3.8L (Paper Kit Industry) 41.3 cc/rev 2200 rpm 22.06 MPa (3200 psi) 88.4 liter/min (23.4 gal/min) Cummins 3.3L Turbo 46.5 cc/rev 2200 rpm 22.06 MPa (3200 psi) 99.6 liter/min (26.3 gal/min) Kubota 3.8L 46.5 cc/rev 2450 rpm 22.06 MPa (3200 psi) 96.5 liter/min (25.5 gal/min) GLP/ GDP45SVX5, GLP/GDP45VX6; GLP/ GDP50-55VX (GP/GLP/ GDP100, 110, 120VX) (F813, GM 4.3L (Paper Kit Industry) 41.3 cc/rev 2400 rpm 22.06 MPa (3200 psi) 96.5 liter/min (25.5 gal/min) Kubota 41.3 cc/rev 2450 rpm 22.1 MPa (3200 psi) 96.5 liter/min (25.5 gal/min) Gear Pump Specifications 1900 YRM 1136 28

- 33. Table 4. Hydraulic Gear Pumps for Lift Truck Models GLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/ GDP45VX6; GLP/GDP50-55VX (GP/GLP/GDP080, 090, 100, 110, 120VX) (F813, G813, H813, J813) (Continued) Model Engine Displacement Governed Speed Main Relief Valve Pressure - Mpa (PSI) Pump Flow Rate - LPM (GPM) G813, H813, J813) GM 4.3L 51.6 cc/rev 2400 rpm 22.06 MPa (3200 psi) 120.5 liter/min (31.8 gal/min) Cummins 3.3L Turbo (Paper Kit Industry) 51.6 cc/rev 2200 rpm 22.06 MPa (3200 psi) 110.5 liter/min (29.2 gal/min) Cummins 3.3L Turbo 51.6 cc/rev 2200 rpm 22.06 MPa (3200 psi) 110.5 liter/min (29.2 gal/min) Kubota 3.8L 51.6 cc/rev 2500 rpm 22.1 MPa (3200 psi) 96.5 liter/min (25.5 gal/min) Table 5. Hydraulic Gear Pumps for Lift Truck Models GLC/GDC60VX, GLC/GDC70VX, (GC/GLC/ GDC135VX, GC/GLC/GDC155VX) (C879, D879, E879, F879) and GLP/GDP60VX, GLP/GDP70VX (GP/GLP/ GDP135VX, GP/GLP/GDP155VX) (C878, D878, E878) Model Engine Displacement Governed Speed Main Relief Valve Pressure - Mpa (PSI) Pump Flow Rate - LPM (GPM) GLC/GDC60VX (GC/GLC/ GDC135VX) (C879, D879, E879, F879); GLP/GDP60VX (GP/GLP/ GDP135VX) (C878, D878, E878) GM 4.3L 41.3 cc/rev 2500 rpm 22.06 MPa (3200 psi) 144.3 liter/min (38.1 gal/min) Cummins 3.3L Turbo 41.3 cc/rev 2500 rpm 22.06 MPa (3200 psi) 132.3 liter/min (35.0 gal/min) Kubota 41.3 cc/rev 2500 rpm 22.1 MPa (3200 psi) 96.5 liter/min (25.5 gal/min) GLC/GDC70VX, (GC/GLC/ GDC155VX) (C879, D879, E879, F879); GLP/GDP70VX (GP/GLP/ GDP155VX) GM 4.3L 63.3 cc/rev 2400 rpm 22.06 MPa (3200 psi) 144.3 liter/min (38.1 gal/min) 1900 YRM 1136 Gear Pump Specifications 29

- 34. Table 5. Hydraulic Gear Pumps for Lift Truck Models GLC/GDC60VX, GLC/GDC70VX, (GC/GLC/ GDC135VX, GC/GLC/GDC155VX) (C879, D879, E879, F879) and GLP/GDP60VX, GLP/GDP70VX (GP/GLP/ GDP135VX, GP/GLP/GDP155VX) (C878, D878, E878) (Continued) Model Engine Displacement Governed Speed Main Relief Valve Pressure - Mpa (PSI) Pump Flow Rate - LPM (GPM) (C878, D878, E878) Kubota 41.3 cc/rev 2500 rpm 22.1 MPa (3200 psi) 96.5 liter/min (25.5 gal/min) Table 6. Hydraulic Gear Pumps for Lift Truck Model GLP/GDP80VX, GLP/GDP80VX9, GLP/GDP90VX (GLP/ GDP170VX, GLP/GDP175VX36, GLP/GDP190VX) (A909, B909) Model Engine Displacement Governed Speed Main Relief Valve Pressure - Mpa (PSI) Pump Flow Rate - LPM (GPM) GDP80VX (GDP170VX) (A909, B909) Cummins 3.3L Turbo 46.5cc/rev 2500 rpm 22.06 MPa (3200 psi) 177.2 liter/min (46.8 gal/min) GDP80VX9 (GDP175VX36) (A909, B909) GDP90VX (GDP190VX) (A909, B909) GLP80VX (GLP170VX) (A909, B909) GM 5.7L 46.5 cc/rev 2500 rpm 22.06 MPa (3200 psi) 177.2 liter/min (46.8 gal/min) GLP80VX9 (GLP175VX36) (A909, B909) GLP90VX (GLP190VX) (A909, B909) Gear Pump Specifications 1900 YRM 1136 30

- 35. Variable Displacement Pump Repair REMOVE WARNING PUTTING THE LIFT TRUCK ON BLOCKS The lift truck must be put on blocks for some types of maintenance and repair. The removal of the following assemblies will cause large changes in the center of gravity: mast, drive axle, engine, transmission, and counterweight. When the lift truck is put on blocks, put additional blocks in the following positions to maintain stability: • Before removing the mast and drive axle, put blocks under the counterweight so the lift truck cannot fall backward. • Before removing the counterweight, put blocks under the mast assembly so the lift truck cannot fall forward. The surface must be solid, even, and level when the lift truck is put on blocks. Make sure any blocks used to support the lift truck are solid, one-piece units. NOTE: Worn or damaged seals and O-rings are the most common cause of pump damage. The pump shaft, plugs, and plates also wear. They must be checked during disassembly. DO NOT make any re- pairs to the parts. To prevent more failures, always re- place parts that are worn or damaged. If several main parts need replacing, replace the with a new pump. 1. Put the lift truck on blocks. See the Operating Manual or one of the following service manuals for the procedures to put the lift truck on blocks: Periodic Maintenance 8000YRM1150 for lift truck models • GLP/GDP20-35VX (B875) Periodic Maintenance 8000YRM1248 for lift truck models • GLP/GDP40VX5/VX6, GLP/GDP45SVX5, GLP/GDP45VX6, GLP/GDP50-55VX (G813) Periodic Maintenance 8000YRM1558 for lift truck model • GLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/GDP45VX6; GLP/GDP50-55VX (GP/GLP/GDP080, 090, 100, 110, 120VX) (H813) Capacities and Specifications 8000YRM1605 for lift truck model • GLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/GDP45VX6; GLP/GDP50-55VX (GP/GLP/GDP080, 090, 100, 110, 120VX) (J813) 2. Place a drain pan under the hydraulic tank, re- move drain plug at bottom of hydraulic oil tank, and drain oil from tank. See Figure 15. a. Drain pan capacity approximately 40 li- ter (11 gal) for lift truck models • GLP/GDP20-35VX (B875) b. Drain pan capacity approximately 62 li- ter (16.5 gal) for lift truck models • GLP/GDP40VX5/VX6, GLP/ GDP45SVX5, GLP/GDP45VX6, GLP/ GDP50-55VX (G813, H813, J813) with short wheel base. • GP/GLP/GDP080, 090, 100, 110, 120VX (J813) with short wheel base. 1900 YRM 1136 Variable Displacement Pump Repair 31

- 36. c. Drain pan capacity approximately 78 li- ter (21 gal) for lift truck models • GLP/GDP40VX5/VX6, GLP/ GDP45SVX5, GLP/GDP45VX6, GLP/ GDP50-55VX (G813, H813, J813) with long wheel base. • GP/GLP/GDP080, 090, 100, 110, 120VX (J813) with long wheel base. 3. Once hydraulic oil has finished draining from hy- draulic tank, install drain plug. 4. Place drain pan under variable displacement pump (VDP). 5. Disconnect all hydraulic lines connected to varia- ble displacement pump and steering control unit. See Figure 16 for lift truck models • GLP/GDP40VX5/VX6, GLP/GDP45SVX5, GLP/GDP45VX6, GLP/GDP50-55VX (G813, H813, J813) See Figure 17 for lift truck model • GP/GLP/GDP080, 090, 100, 110, 120VX (J813) See Figure 18 or Figure 19 for lift truck models • GLP/GDP20-35VX (B875) 6. Remove the suction adapter from the VDP. See Figure 16 for lift truck models • GLP/GDP40VX5/VX6, GLP/GDP45SVX5, GLP/GDP45VX6, GLP/GDP50-55VX (G813, H813, J813) See Figure 17 for lift truck model • GP/GLP/GDP080, 090, 100, 110, 120VX (J813) See Figure 18 or Figure 19 for lift truck models • GLP/GDP20-35VX (B875) 7. Allow hydraulic oil to drain from VDP. Put caps on all hose fittings and VDP ports. 8. Support the VDP assembly to prevent it from fall- ing. Remove two flange head capscrews and VDP from transmission housing. See Figure 16 for lift truck models • GLP/GDP40VX5/VX6, GLP/GDP45SVX5, GLP/GDP45VX6, GLP/GDP50-55VX (G813, H813, J813) See Figure 17 for lift truck model • GP/GLP/GDP080, 090, 100, 110, 120VX (J813) See Figure 18 or Figure 19 for lift truck models • GLP/GDP20-35VX (B875) Variable Displacement Pump Repair 1900 YRM 1136 32

- 37. 1. HYDRAULIC TANK 2. DRAIN PLUG Figure 15. Drain Hydraulic Oil 1900 YRM 1136 Variable Displacement Pump Repair 33

- 38. Figure 16. Variable Displacement Pump Arrangement, Lift Truck Models GLP/GDP40VX5/VX6, GLP/ GDP45SVX5, GLP/GDP45VX6, GLP/GDP50-55VX (G813, H813, J813) Variable Displacement Pump Repair 1900 YRM 1136 34

- 39. Legend for Figure 16 A. FRONT VIEW B. TOP VIEW 1. HYDRAULIC INLET HOSE 2. LOAD SENSE LINE 3. DRAIN CASE LINE 4. DRAIN CASE FILL PLUG 5. VARIABLE DISPLACEMENT PUMP 6. FLANGE HEAD CAPSCREWS 7. SUCTION HOSE 8. MAIN CONTROL VALVE 9. STEERING CONTROL UNIT 10. ACCUMULATOR 11. DRAIN CASE DRAIN PLUG 12. TRANSMISSION 13. SUCTION HOSE ADAPTER 1900 YRM 1136 Variable Displacement Pump Repair 35

- 40. Figure 17. Variable Displacement Pump Arrangement, Lift Truck Models GP/GLP/GDP080, 090, 100, 110, 120VX (J813) Variable Displacement Pump Repair 1900 YRM 1136 36

- 41. Legend for Figure 17 A. FRONT VIEW B. TOP VIEW 1. HYDRAULIC INLET HOSE 2. LOAD SENSE LINE 3. DRAIN CASE LINE 4. DRAIN CASE FILL PLUG 5. VARIABLE DISPLACEMENT PUMP 6. FLANGE HEAD CAPSCREWS 7. SUCTION HOSE 8. MAIN CONTROL VALVE 9. STEERING CONTROL UNIT 10. ACCUMULATOR 11. DRAIN CASE DRAIN PLUG 12. TRANSMISSION 13. SUCTION HOSE ADAPTER 1900 YRM 1136 Variable Displacement Pump Repair 37

- 42. Figure 18. Variable Displacement Pump Arrangement, Lift Truck Models GLP/GDP20-35VX (B875) With 1- Speed Transmission Variable Displacement Pump Repair 1900 YRM 1136 38

- 43. Legend for Figure 18 A. FRONT VIEW B. TOP VIEW 1. HYDRAULIC INLET HOSE 2. LOAD SENSE LINE 3. DRAIN CASE LINE 4. VARIABLE DISPLACEMENT PUMP 5. FLANGE HEAD CAPSCREWS 6. SUCTION HOSE 7. MAIN CONTROL VALVE 8. ACCUMULATOR 9. STEERING CONTROL UNIT 10. DRAIN CASE DRAIN PLUG 11. TRANSMISSION 12. SUCTION HOSE ADAPTER 1900 YRM 1136 Variable Displacement Pump Repair 39

- 44. Figure 19. Variable Displacement Pump Arrangement, Lift Truck Models GLP/GDP20-35VX (B875) With 2- Speed Transmission Variable Displacement Pump Repair 1900 YRM 1136 40

- 45. Legend for Figure 19 A. FRONT VIEW B. TOP VIEW 1. HYDRAULIC INLET HOSE 2. LOAD SENSE LINE 3. DRAIN CASE LINE 4. DRAIN CASE FILL PLUG 5. VARIABLE DISPLACEMENT PUMP 6. FLANGE HEAD CAPSCREWS 7. SUCTION HOSE 8. MAIN CONTROL VALVE 9. ACCUMULATOR 10. STEERING CONTROL UNIT 11. DRAIN CASE DRAIN PLUG 12. TRANSMISSION 13. SUCTION ADAPTER DISASSEMBLE 1. Put the variable displacement pump in a vise. CAUTION Protect the drive shaft from damage before re- moving the retaining ring and shaft seal. NOTE: Perform Step 2 ONLY if shaft seal is leaking. NOTE: Kits are available that include materials and tools to remove and install shaft seal. See the Parts Manual for kit part numbers. 2. Remove retaining ring and shaft seal from drive shaft as described below: a. Clean the shaft and shaft seal area. Wrap the pump drive shaft splines in tape or other pro- tective material to protect drive shaft before re- moving retaining ring and shaft seal. See Fig- ure 20. b. Remove the retaining ring. See Figure 20. 1. RETAINING RING 2. SHAFT SEAL 3. DRIVE SHAFT Figure 20. Retaining Ring Removal 1900 YRM 1136 Variable Displacement Pump Repair 41

- 46. c. Punch two holes into top surface of old shaft seal being replaced. Make sure holes are 180° apart from each other. Insert two screws into holes and into steel layer of the shaft seal. Pull on screws and remove existing shaft seal from drive shaft. See Figure 21. 1. SCREWS 2. SHAFT SEAL 3. DRIVE SHAFT Figure 21. Shaft Seal Removal d. Inspect and clean shaft and internal shaft seal- ing area. Remove any metal shavings created while inserting screws into old shaft seal. See Figure 21. NOTE: Be sure solid surface area of shaft seal is pointing outwards from pump. NOTE: On lift truck models GLP/GDP40VX5/VX6, GLP/GDP45SVX5, GLP/GDP45VX6, GLP/ GDP50-55VX (GP/GLP/GDP080, 090, 100, 110, 120VX) (G813, H813, J813), use the end of the VDP shaft seal installation tool that has two rings to install the shaft seal. For lift truck models GLP/GDP20-35VX (B875), use the end of the VDP shaft seal installation tool that has one ring to install the shaft seal. See Fig- ure 22. e. Install new shaft seal onto drive shaft. Use spe- cial VDP shaft seal installation tool, Yale Part Number 582016143, and seat shaft seal down onto pump stop ring. f. Use rubber hammer and tap on VDP shaft seal tool until VDP shaft seal tool shoulder stops against the face of VDP housing. See Fig- ure 22. g. Install the retaining ring. Be sure retaining ring correctly rests in the groove. See Figure 20. Variable Displacement Pump Repair 1900 YRM 1136 42

- 47. Figure 22. Shaft Seal Installation Legend for Figure 22 NOTE: SHAFT SEAL INSTALLATION FOR VDP USED ON GLP/GDP20-35VX (B875) LIFT TRUCK MODELS SHOWN (ONE RING SIDE OF VDP SHAFT SEAL TOOL PUSHING DOWN ON SHAFT SEAL). TO INSTALL SHAFT SEAL ON LIFT TRUCKS GLP/GDP40VX5/VX6, GLP/GDP45SVX5, GLP/GDP45VX6, GLP/GDP50-55VX (GP/GLP/ GDP080, 090, 100, 110, 120VX) (G813, H813, J813), USE PART OF VDP SHAFT SEAL TOOL WITH TWO RINGS. 1. VDP SHAFT SEAL TOOL 2. TWO RINGS 3. ONE RING 4. VDP SHAFT SEAL TOOL SHOULDER 5. STOP RING 6. BEARING 7. RETAINING RING 8. DRIVE SHAFT 3. Remove four socket head screws from control valve and VDP. Remove seal from control valve. See Figure 23 for lift truck models • GLP/GDP40VX5/VX6, GLP/GDP45SVX5, GLP/GDP45VX6, GLP/GDP50-55VX (G813, H813, J813) See Figure 24 for lift truck model • GP/GLP/GDP080, 090, 100, 110, 120VX (J813) See Figure 25 for lift truck models • GLP/GDP20-35VX (B875) 1900 YRM 1136 Variable Displacement Pump Repair 43

- 48. 1. SOCKET HEAD SCREW 2. CONTROL VALVE 3. SEAL 4. VARIABLE DISPLACEMENT PUMP 5. DRIVE SHAFT 6. CONTROL VALVE ASSEMBLY Figure 23. Variable Displacement Pump Dissembly, Lift Truck Models GLP/GDP40VX5/ VX6, GLP/GDP45SVX5, GLP/GDP45VX6, GLP/ GDP50-55VX (G813, H813, J813) 1. SOCKET HEAD SCREW 2. CONTROL VALVE 3. SEAL 4. VARIABLE DISPLACEMENT PUMP 5. DRIVE SHAFT 6. CONTROL VALVE ASSEMBLY Figure 24. Variable Displacement Pump Dissembly, Lift Truck Models GP/GLP/GDP080, 090, 100, 110, 120VX (J813) Variable Displacement Pump Repair 1900 YRM 1136 44

- 49. 1. SOCKET HEAD SCREW 2. CONTROL VALVE 3. SEAL 4. VARIABLE DISPLACEMENT PUMP 5. DRIVE SHAFT 6. CONTROL VALVE ASSEMBLY Figure 25. Variable Displacement Pump Dissembly, Lift Truck Models GLP/GDP20-35VX (B875) CLEAN WARNING Cleaning solvents can be flammable and toxic, can cause skin irritation. When using cleaning solvents, always follow the recommendations of the manufacturer. WARNING Compressed air can move particles so that they cause injury to the user or to other personnel. Make sure that the path of the compressed air is away from all personnel. Wear protective goggles or a face shield to prevent injury to the eyes. Clean all components in solvent. Dry components with compressed air. DO NOT dry components with a cloth. Make sure all surfaces are free of scratches and sharp edges. INSPECT Check the control valve seal, drive shaft seal, and re- taining ring for wear or damage and replace if neces- sary. Check the rest of the variable displacement pump assembly. If any parts other than the control valve seal, drive shaft seal, and retaining ring are worn or damaged, replace with a new variable dis- placement pump. 1900 YRM 1136 Variable Displacement Pump Repair 45

- 50. ASSEMBLE 1. Coat seal with clean hydraulic oil. Install seal, control valve, and four socket head screws on VDP. See Figure 23 for lift truck models • GLP/GDP40VX5/VX6, GLP/GDP45SVX5, GLP/GDP45VX6, GLP/GDP50-55VX (G813, H813, J813) See Figure 24 for lift truck model • GP/GLP/GDP080, 090, 100, 110, 120VX (J813) See Figure 25 for lift truck models • GLP/GDP20-35VX (B875) 2. Apply clean hydraulic oil to shaft seal and retain- ing ring. Install shaft seal and retaining ring onto drive shaft. See Figure 23 for lift truck models • GLP/GDP40VX5/VX6, GLP/GDP45SVX5, GLP/GDP45VX6, GLP/GDP50-55VX (G813, H813, J813) See Figure 25 for lift truck models • GLP/GDP20-35VX (B875) INSTALL 1. Install the suction adapter and tighten flange hardware 70 to 77 N•m (52 to 57 lbf ft). Position suction adapter as shown in: Figure 27 and Figure 28 for lift truck models • GLP/GDP20-35VX (B875) Figure 29 for lift truck models • GLP/GDP40VX5/VX6, GLP/GDP45SVX5, GLP/GDP45VX6, GLP/GDP50-55VX (G813, H813, J813) See Figure 30 for lift truck model • GP/GLP/GDP080, 090, 100, 110, 120VX (J813) 2. Clean the VDP flange and transmission mounting surface and put a 3 to 5 mm (0.118 to 0.197 in.) bead of Loctite™ 515 (Yale P/N 520042831) on the VDP flange or transmission mounting surface. Hold the pump in the correct position on the trans- mission. Install two socket head screws on VDP and transmission housing. Tighten socket head screws to 38 N•m (28 lbf ft). 3. Connect the hydraulic lines to the VDP and steer- ing control unit. Tighten the flange head cap- screws at the VDP, using sequence shown in Fig- ure 26, to 70 to 77 N•m (52 to 57 lbf ft). Figure 26. Torque Tightening Sequence, Flange Head Capscrews 4. Position the hydraulic lines as shown in: Figure 27, Figure 28, and Figure 31 for lift truck models • GLP/GDP20-35VX (B875) Variable Displacement Pump Repair 1900 YRM 1136 46

- 51. Figure 29 and Figure 31 for lift truck models • GLP/GDP40VX5/VX6, GLP/GDP45SVX5, GLP/GDP45VX6, GLP/GDP50-55VX (G813, H813, J813) Figure 30 and Figure 31for lift truck model • GP/GLP/GDP080, 090, 100, 110, 120VX (J813) A. X = 45° ±5° B. Y = 54° ±5° 1. HYDRAULIC INLET HOSE 2. SUCTION HOSE 3. LOAD SENSE LINE 4. DRAIN CASE LINE 5. VARIABLE DISPLACEMENT PUMP Figure 27. Hydraulic Hose Orientation at the Variable Displacement Pump, Lift Truck Models GLP/GDP20-35VX (B875) Equipped With 1-Speed Transmission NOTE: HYDRAULIC INLET HOSE OMITTED FROM VIEW D FOR CLARITY. A. X = 74° ±5° B. Y = 20° ±5° C. Z = 35° ±5° D. FRONT VIEW E. SIDE VIEW 1. LOAD SENSE LINE 2. SUCTION HOSE 3. DRAIN CASE LINE 4. HYDRAULIC INLET HOSE 5. VARIABLE DISPLACEMENT PUMP Figure 28. Hydraulic Hose Orientation at the Variable Displacement Pump, Lift Truck Models GLP/GDP20-35VX (B875) Equipped With 2-Speed Transmission 1900 YRM 1136 Variable Displacement Pump Repair 47

- 52. A. X = 30° ±5° B. Y = 12° ±5° 1. LOAD SENSE LINE 2. SUCTION HOSE 3. VARIABLE DISPLACEMENT PUMP 4. DRAIN CASE LINE Figure 29. Hydraulic Hose Orientation at the Variable Displacement Pump, Lift Truck Models GLP/GDP40VX5/VX6, GLP/GDP45SVX5, GLP/ GDP45VX6, GLP/GDP50-55VX (G813, H813, J813) A. X = 30° ±5° B. Y = 12° ±5° 1. LOAD SENSE LINE 2. SUCTION HOSE 3. VARIABLE DISPLACEMENT PUMP 4. DRAIN CASE LINE Figure 30. Hydraulic Hose Orientation at the Variable Displacement Pump, Lift Truck Models GP/GLP/GDP080, 090, 100, 110, 120VX (J813) Variable Displacement Pump Repair 1900 YRM 1136 48

- 53. Figure 31. Hydraulic Hose Orientation at the Steering Control Unit Legend for Figure 31 A. X = 10° ±5° FOR LIFT TRUCK MODELS GLP/ GDP40VX5/VX6, GLP/GDP45SVX5, GLP/ GDP45VX6, GLP/GDP50-55VX (G813, H813, J813) AND GLP/GDP20-35VX (B875), 1-SPEED TRANSMISSION B. X = 28° ±5° FOR LIFT TRUCK MODELS GLP/ GDP20-35VX (B875), 2-SPEED TRANSMISSION C. Y = 65° ±5° FOR LIFT TRUCK MODELS GLP/ GDP20-35VX (B875), 1-SPEED TRANSMISSION D. Y = 55° ±5° FOR LIFT TRUCK MODELS GLP/ GDP20-35VX (B875), 2-SPEED TRANSMISSION E. 1-SPEED TRANSMISSION F. 2-SPEED TRANSMISSION 1. STEERING CONTROL UNIT 2. MAIN CONTROL VALVE 3. HYDRAULIC INLET HOSE 4. LOAD SENSE LINE 1900 YRM 1136 Variable Displacement Pump Repair 49

- 54. 5. Remove the lift truck from the blocks. See the Op- erating Manual or one of the following service manuals for the procedures: Periodic Maintenance 8000YRM1150 for lift truck models • GLP/GDP20-35VX (B875) Periodic Maintenance 8000YRM1248 for lift truck models • GLP/GDP40VX5/VX6, GLP/GDP45SVX5, GLP/GDP45VX6, GLP/GDP50-55VX (G813) Periodic Maintenance 8000YRM1558 for lift truck model • GLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/GDP45VX6; GLP/GDP50-55VX (GP/GLP/GDP080, 090, 100, 110, 120VX) (H813) Capacities and Specifications 8000YRM1605 for lift truck model • GLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/GDP45VX6; GLP/GDP50-55VX (GP/GLP/GDP080, 090, 100, 110, 120VX) (J813) 6. Fill the hydraulic tank using hydraulic oil specified in the Operating Manual or one of the following service manuals: Periodic Maintenance 8000YRM1150 for lift truck models • GLP/GDP20-35VX (B875) Periodic Maintenance 8000YRM1248 for lift truck models • GLP/GDP40VX5/VX6, GLP/GDP45SVX5, GLP/GDP45VX6, GLP/GDP50-55VX (G813) Periodic Maintenance 8000YRM1558 for lift truck model • GLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/GDP45VX6; GLP/GDP50-55VX (GP/GLP/GDP080, 090, 100, 110, 120VX) (H813) Capacities and Specifications 8000YRM1605 for lift truck model • GLP/GDP40VX5/VX6; GLP/GDP45SVX5, GLP/GDP45VX6; GLP/GDP50-55VX (GP/GLP/GDP080, 090, 100, 110, 120VX) (J813) 7. When the hydraulic oil level is correct, operate the hydraulic system and check for leaks. Check the hydraulic oil level and add hydraulic oil if neces- sary. Variable Displacement Pump Repair 1900 YRM 1136 50

- 55. Variable Displacement Pump Checks and Adjustments MARGIN PRESSURE CHECK The margin pressure is the difference between the pressure at the P-port and LS-port. If the margin pres- sure is not within the range shown in Table 7, the flow of hydraulic oil out of the variable displacement pump (VDP) will be either too low or too high. Table 7. Margin Pressure Lift Truck Model Margin Pressure GLP/GDP20-35VX (B875) 12.5 ±1 bar (180 ±15 psi) GLP/GDP40VX5/VX6, GLP/GDP45SVX5, GLP/ GDP45VX6, GLP/ GDP50-55VX (GP/GLP/ GDP080, 090, 100, 110, 120VX) (G813, H813, J813) 14.0 ±1 bar (203 ±15 psi) WARNING DO NOT operate the hydraulic functions while checking the margin pressure. Serious injury to personnel and damage to the lift truck can result if hydraulic functions are operated. 1. Install a 70 bar (1000 psi) gauge on the P-port and a 35 bar (500 psi) gauge on the LS-port on the main control valve. See Figure 32. 1. P-PORT 2. LS-PORT Figure 32. Margin Pressure Check Ports 2. Start lift truck engine and keep truck at idle for five minutes. 3. Check the pressure on the gauges against those listed in Table 7. 1900 YRM 1136 Variable Displacement Pump Checks and Adjustments 51

- 56. 4. If the margin pressure is not within range speci- fied in Table 7, go to Flow Compensator Adjust- ment section. FLOW COMPENSATOR ADJUSTMENT WARNING DO NOT operate the hydraulic functions while ad- justing the flow compensator. Serious injury to personnel and damage to the lift truck can result if hydraulic functions are operated. 1. Insert an allen wrench into flow compensator ad- justment screw. Hold allen wrench in flow com- pensator screw and turn jam nut counter clock- wise all the way. See Figure 33. 2. Turn the flow compensator adjustment screw to adjust the P-port pressure: • Clockwise to increase the P-port pressure by 16 bar (232 psi) per turn. • Counter clockwise to decrease the P-port pressure by 16 bar (232 psi) per turn. 3. Check the margin pressure as described in Mar- gin Pressure Check. If margin pressure is not cor- rect, perform Step 1 and Step 2 until correct mar- gin pressure is reached. 4. Tighten the jam nut to 21 N•m (186 lbf in). See Figure 33. PRESSURE COMPENSATOR ADJUSTMENT WARNING DO NOT operate the hydraulic functions while ad- justing the pressure compensator. Serious injury to personnel and damage to the lift truck can re- sult if hydraulic functions are operated. 1. FLOW COMPENSATOR 2. JAM NUT 3. FLOW COMPENSATOR ADJUSTMENT SCREW 4. PRESSURE COMPENSATOR 5. PRESSURE COMPENSATOR ADJUSTMENT SCREW Figure 33. Flow and Pressure Compensators 1. Mark or measure the screw locations of the flow and pressure compensators. See Figure 34. A. MEASURE AND NOTE THIS DISTANCE 1. PRESSURE COMPENSATOR 2. FLOW COMPENSATOR Figure 34. Screw Location Variable Displacement Pump Checks and Adjustments 1900 YRM 1136 52