Tableting Technology for the Pharmaceutical Industry

•Download as DOCX, PDF•

2 likes•763 views

Tableting machines are used for quality assurance main purpose, to ensure exact time to deliver with error free pharmaceutical products. Different kinds of pharma tableting machines largely depend upon the area of its application. You can check out for more detail our websites at: http://goo.gl/nvEpGI

Report

Share

Report

Share

Recommended

Book Paid Powai Call Girls Mumbai 𖠋 9930245274 𖠋Low Budget Full Independent H...

Book Paid Powai Call Girls Mumbai 𖠋 9930245274 𖠋Low Budget Full Independent H...Call Girls in Nagpur High Profile

More Related Content

Recently uploaded

Book Paid Powai Call Girls Mumbai 𖠋 9930245274 𖠋Low Budget Full Independent H...

Book Paid Powai Call Girls Mumbai 𖠋 9930245274 𖠋Low Budget Full Independent H...Call Girls in Nagpur High Profile

Recently uploaded (20)

Call Girls Faridabad Just Call 9907093804 Top Class Call Girl Service Available

Call Girls Faridabad Just Call 9907093804 Top Class Call Girl Service Available

(Low Rate RASHMI ) Rate Of Call Girls Jaipur ❣ 8445551418 ❣ Elite Models & Ce...

(Low Rate RASHMI ) Rate Of Call Girls Jaipur ❣ 8445551418 ❣ Elite Models & Ce...

Pondicherry Call Girls Book Now 9630942363 Top Class Pondicherry Escort Servi...

Pondicherry Call Girls Book Now 9630942363 Top Class Pondicherry Escort Servi...

Call Girls Guntur Just Call 8250077686 Top Class Call Girl Service Available

Call Girls Guntur Just Call 8250077686 Top Class Call Girl Service Available

Call Girls Ludhiana Just Call 9907093804 Top Class Call Girl Service Available

Call Girls Ludhiana Just Call 9907093804 Top Class Call Girl Service Available

O963O942363 Call Girls In Ahmedabad Escort Service Available 24×7 In Ahmedabad

O963O942363 Call Girls In Ahmedabad Escort Service Available 24×7 In Ahmedabad

Call Girls Service Jaipur {9521753030} ❤️VVIP RIDDHI Call Girl in Jaipur Raja...

Call Girls Service Jaipur {9521753030} ❤️VVIP RIDDHI Call Girl in Jaipur Raja...

Call Girls Bangalore Just Call 8250077686 Top Class Call Girl Service Available

Call Girls Bangalore Just Call 8250077686 Top Class Call Girl Service Available

Call Girls Bareilly Just Call 8250077686 Top Class Call Girl Service Available

Call Girls Bareilly Just Call 8250077686 Top Class Call Girl Service Available

Call Girls Dehradun Just Call 9907093804 Top Class Call Girl Service Available

Call Girls Dehradun Just Call 9907093804 Top Class Call Girl Service Available

Book Paid Powai Call Girls Mumbai 𖠋 9930245274 𖠋Low Budget Full Independent H...

Book Paid Powai Call Girls Mumbai 𖠋 9930245274 𖠋Low Budget Full Independent H...

Call Girls Jabalpur Just Call 8250077686 Top Class Call Girl Service Available

Call Girls Jabalpur Just Call 8250077686 Top Class Call Girl Service Available

VIP Hyderabad Call Girls Bahadurpally 7877925207 ₹5000 To 25K With AC Room 💚😋

VIP Hyderabad Call Girls Bahadurpally 7877925207 ₹5000 To 25K With AC Room 💚😋

Call Girls Varanasi Just Call 8250077686 Top Class Call Girl Service Available

Call Girls Varanasi Just Call 8250077686 Top Class Call Girl Service Available

Call Girls Gwalior Just Call 8617370543 Top Class Call Girl Service Available

Call Girls Gwalior Just Call 8617370543 Top Class Call Girl Service Available

Premium Call Girls Cottonpet Whatsapp 7001035870 Independent Escort Service

Premium Call Girls Cottonpet Whatsapp 7001035870 Independent Escort Service

Night 7k to 12k Navi Mumbai Call Girl Photo 👉 BOOK NOW 9833363713 👈 ♀️ night ...

Night 7k to 12k Navi Mumbai Call Girl Photo 👉 BOOK NOW 9833363713 👈 ♀️ night ...

♛VVIP Hyderabad Call Girls Chintalkunta🖕7001035870🖕Riya Kappor Top Call Girl ...

♛VVIP Hyderabad Call Girls Chintalkunta🖕7001035870🖕Riya Kappor Top Call Girl ...

Top Rated Bangalore Call Girls Richmond Circle ⟟ 9332606886 ⟟ Call Me For Ge...

Top Rated Bangalore Call Girls Richmond Circle ⟟ 9332606886 ⟟ Call Me For Ge...

Call Girls Agra Just Call 8250077686 Top Class Call Girl Service Available

Call Girls Agra Just Call 8250077686 Top Class Call Girl Service Available

Featured

Featured (20)

Product Design Trends in 2024 | Teenage Engineerings

Product Design Trends in 2024 | Teenage Engineerings

How Race, Age and Gender Shape Attitudes Towards Mental Health

How Race, Age and Gender Shape Attitudes Towards Mental Health

AI Trends in Creative Operations 2024 by Artwork Flow.pdf

AI Trends in Creative Operations 2024 by Artwork Flow.pdf

Content Methodology: A Best Practices Report (Webinar)

Content Methodology: A Best Practices Report (Webinar)

How to Prepare For a Successful Job Search for 2024

How to Prepare For a Successful Job Search for 2024

Social Media Marketing Trends 2024 // The Global Indie Insights

Social Media Marketing Trends 2024 // The Global Indie Insights

Trends In Paid Search: Navigating The Digital Landscape In 2024

Trends In Paid Search: Navigating The Digital Landscape In 2024

5 Public speaking tips from TED - Visualized summary

5 Public speaking tips from TED - Visualized summary

Google's Just Not That Into You: Understanding Core Updates & Search Intent

Google's Just Not That Into You: Understanding Core Updates & Search Intent

The six step guide to practical project management

The six step guide to practical project management

Beginners Guide to TikTok for Search - Rachel Pearson - We are Tilt __ Bright...

Beginners Guide to TikTok for Search - Rachel Pearson - We are Tilt __ Bright...

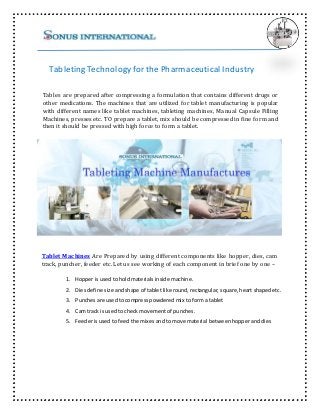

Tableting Technology for the Pharmaceutical Industry

- 1. 1. Hopper is used to hold materials inside machine. 2. Dies define size and shape of tablet like round, rectangular, square, heart shaped etc. 3. Punches are used to compress powdered mix to form a tablet 4. Cam track is used to check movement of punches. 5. Feeder is used to feed the mixes and to move material between hopper and dies TabletingTechnology for the Pharmaceutical Industry Tables are prepared after compressing a formulation that contains different drugs or other medications. The machines that are utilized for tablet manufacturing is popular with different names like tablet machines, tableting machines, Manual Capsule Filling Machines, presses etc. TO prepare a tablet, mix should be compressed in fine form and then it should be pressed with high force to form a tablet. Tablet Machines Are Prepared by using different components like hopper, dies, cam track, puncher, feeder etc. Let us see working of each component in brief one by one –

- 2. Types of Tableting Machines 1. Single station or eccentric tablet machines 2. Multiple station or rotary tablet machines How It Actually Works? We have already discussed on components for tableting machines. Now it would be easy for you to understand how it actually works. First of all, material is put inside so that it can be adjusted properly for further process. Now it is compressed to convert into powdered form so that it can raise powder to process further. Now compressed material will move between both punches to take its actual shape where heavy or small tablets are manufactured. Once tablets are ready, they are ejected from other end. Now they are packed with packaging machines and ready to export into market. Nowyou must be sure about tabletmachines,Its Typesand Working.Afterreadingthis article,itwould be easy for you to decide best solution for your industry.