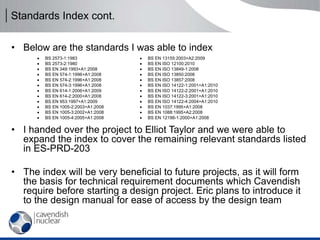

James Horne completed various engineering projects and tasks during his internship at Cavendish Nuclear. He redesigned a lifting beam and pallet to improve efficiency. He created presentation materials on CE marking standards and reviewed the ergonomics of a proposed manual operation. A significant portion of his time was spent creating an index of relevant standards to support future design work. Overall, he gained valuable experience with standards, learned about professional development resources, and benefited from hands-on training opportunities, though he wished for more practical experience in testing.