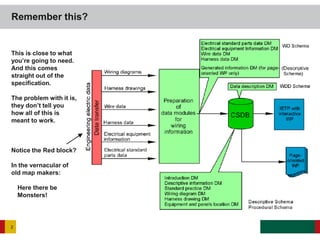

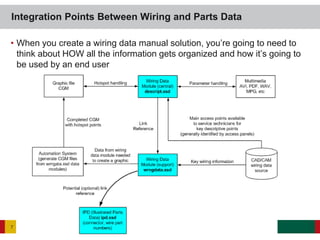

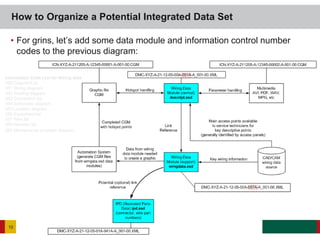

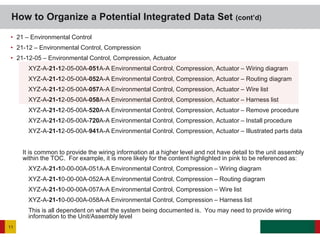

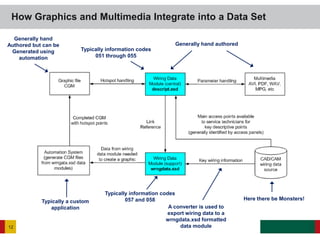

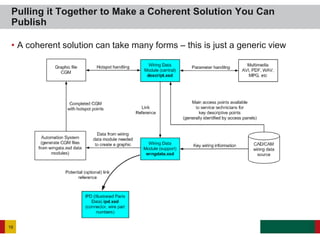

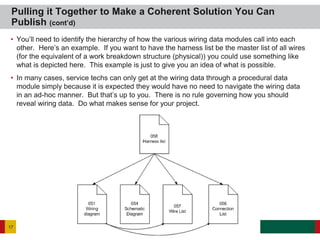

Wiring data is complex to model and requires custom solutions. It is best to reuse wiring data from engineering systems if possible by converting it to the S1000D wrngdata.xsd format. If authoring by hand, wiring solutions for most products will be too complex and it is better to generate wiring data modules from a CAD system. Integration with parts data and procedures is important for end users to understand wiring configurations and order replacement parts.

Human: Thank you for the summary. You captured the key points well in 3 concise sentences.