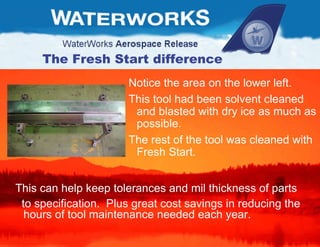

Zyvax is a company that started in 1960 and specializes in semi-permanent mold release products. Their products can be used with various resin and tool substrate combinations at temperatures up to 500°F. Their mold release system helps provide consistent molding results and reduces tool maintenance costs. Zyvax is committed to providing high quality products and services according to their quality management system.

![Send an e-mail to Cage Code: 1QNX9 [email_address] Customer Service: 1 (800) 858-4111 (in N.A. only) 1 (706) 698-4405 +34 96 338 4338 (European sales) +61 2 9807 4132 (Asia Pacific) To Order WaterWorks or other Zyvax Products](https://image.slidesharecdn.com/waterworks2008-123731342511-phpapp02/85/Water-Works2008-18-320.jpg)