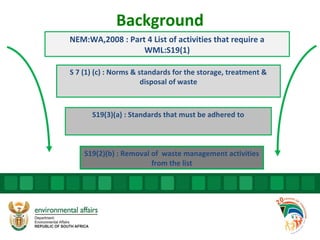

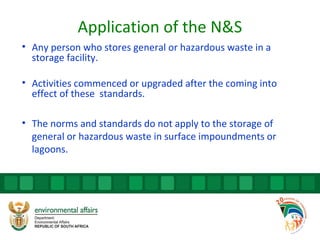

The document outlines norms and standards for the storage of waste in South Africa. It provides guidelines on the design, construction, operation, monitoring, auditing and decommissioning of waste storage facilities. Key requirements include registration of facilities, impermeable floors and containment systems, protection of underground containers from corrosion, weekly inspections, biannual auditing, and rehabilitation planning. The standards aim to provide uniform practices and minimum environmental protection measures for safe waste storage.