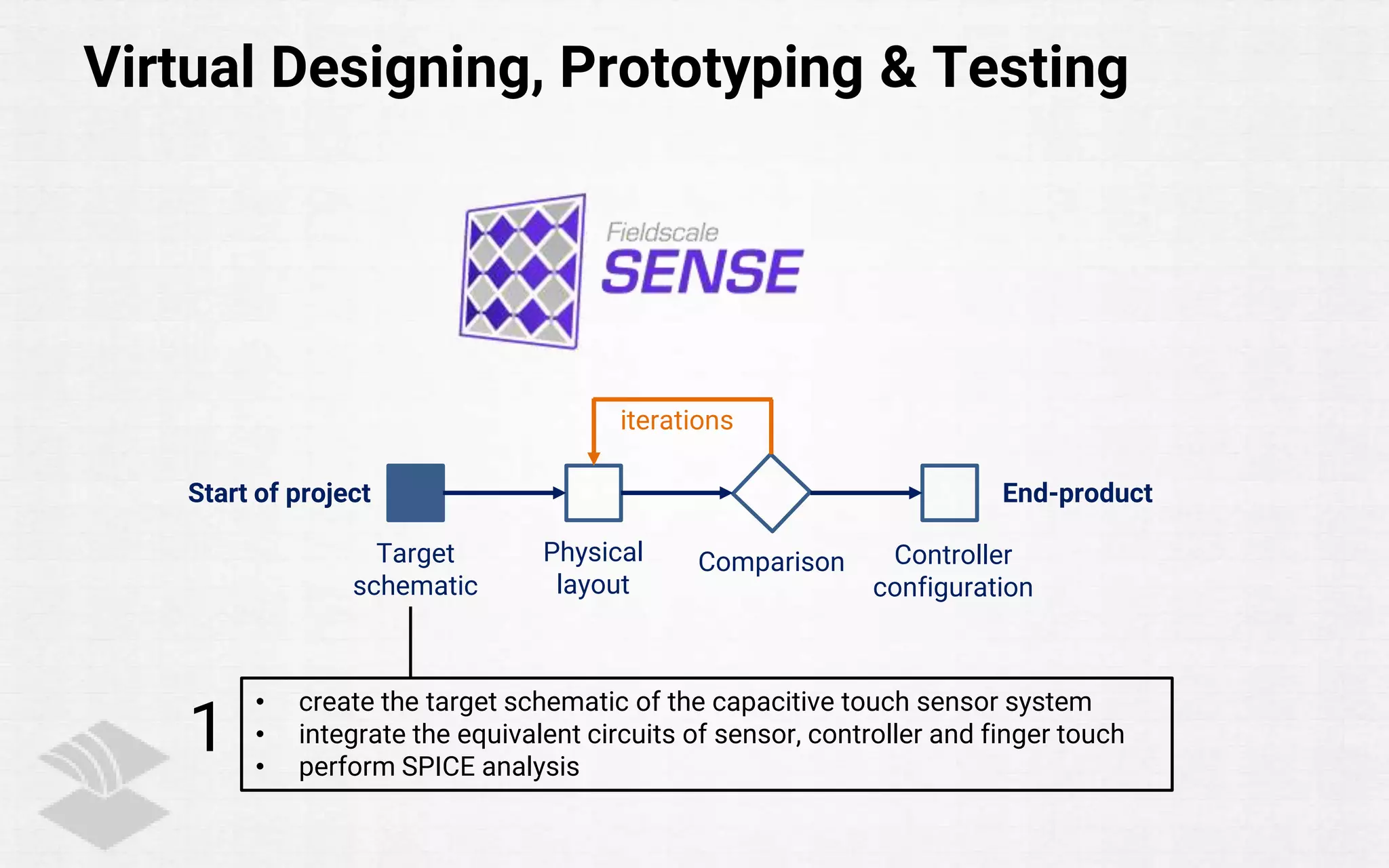

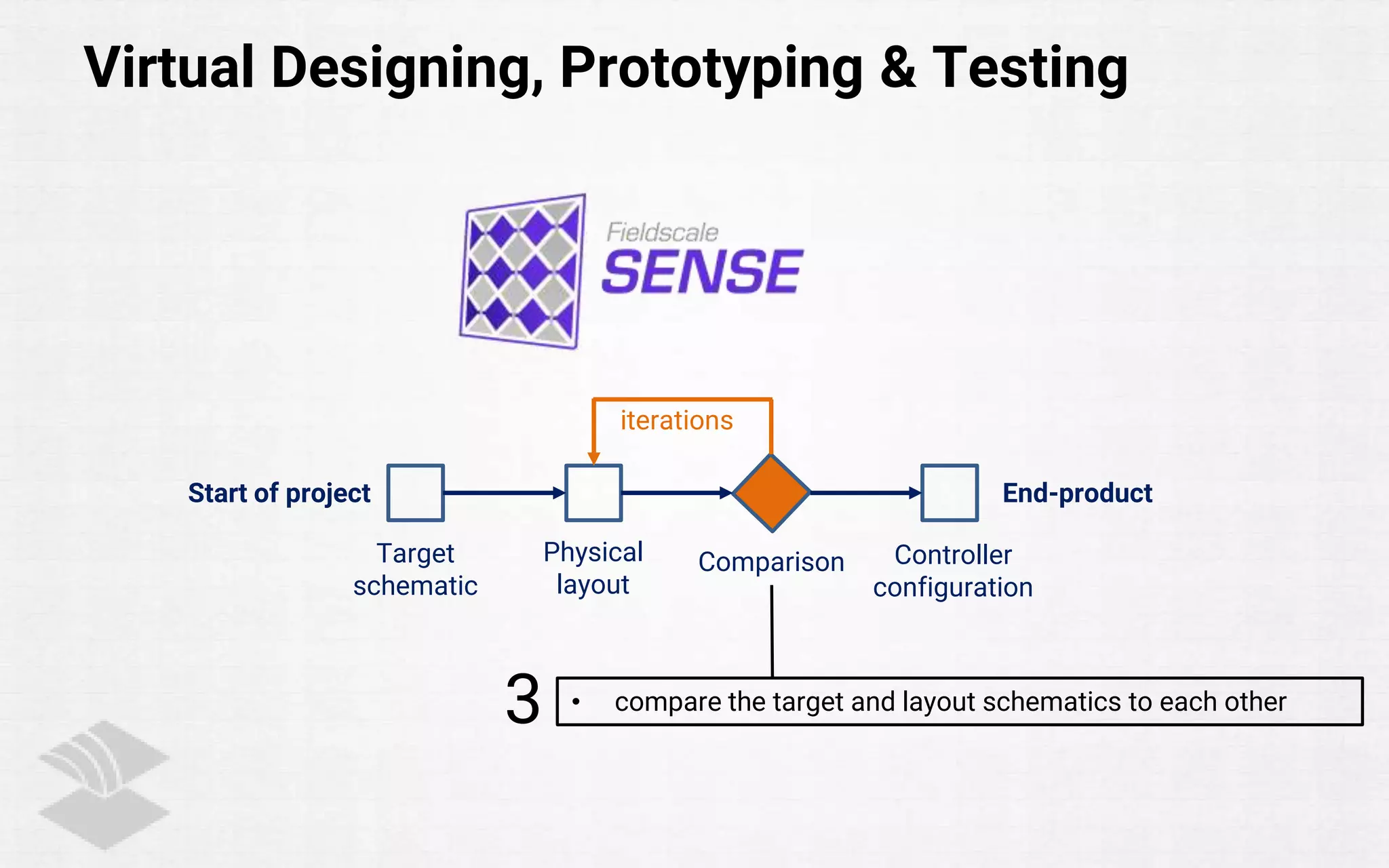

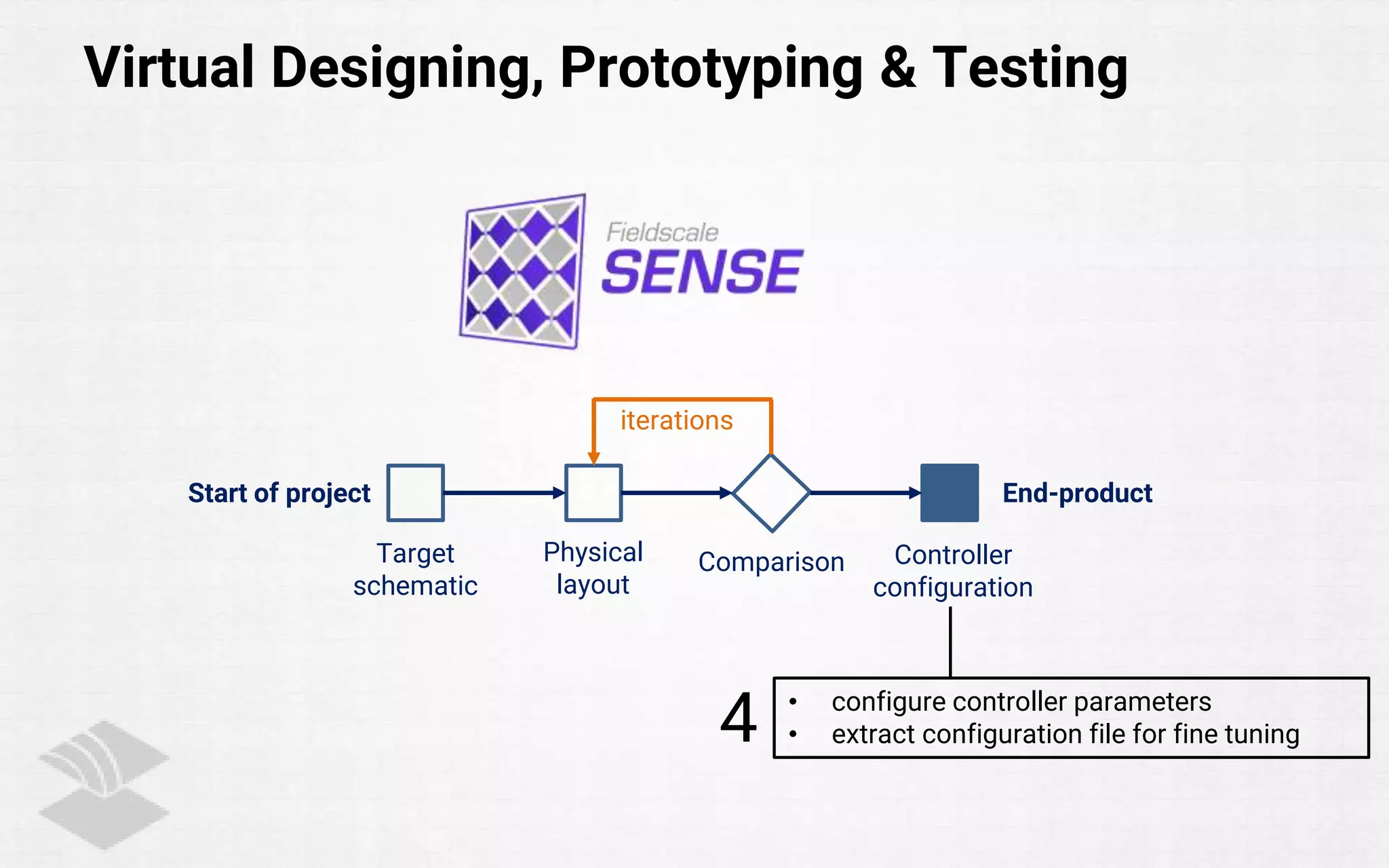

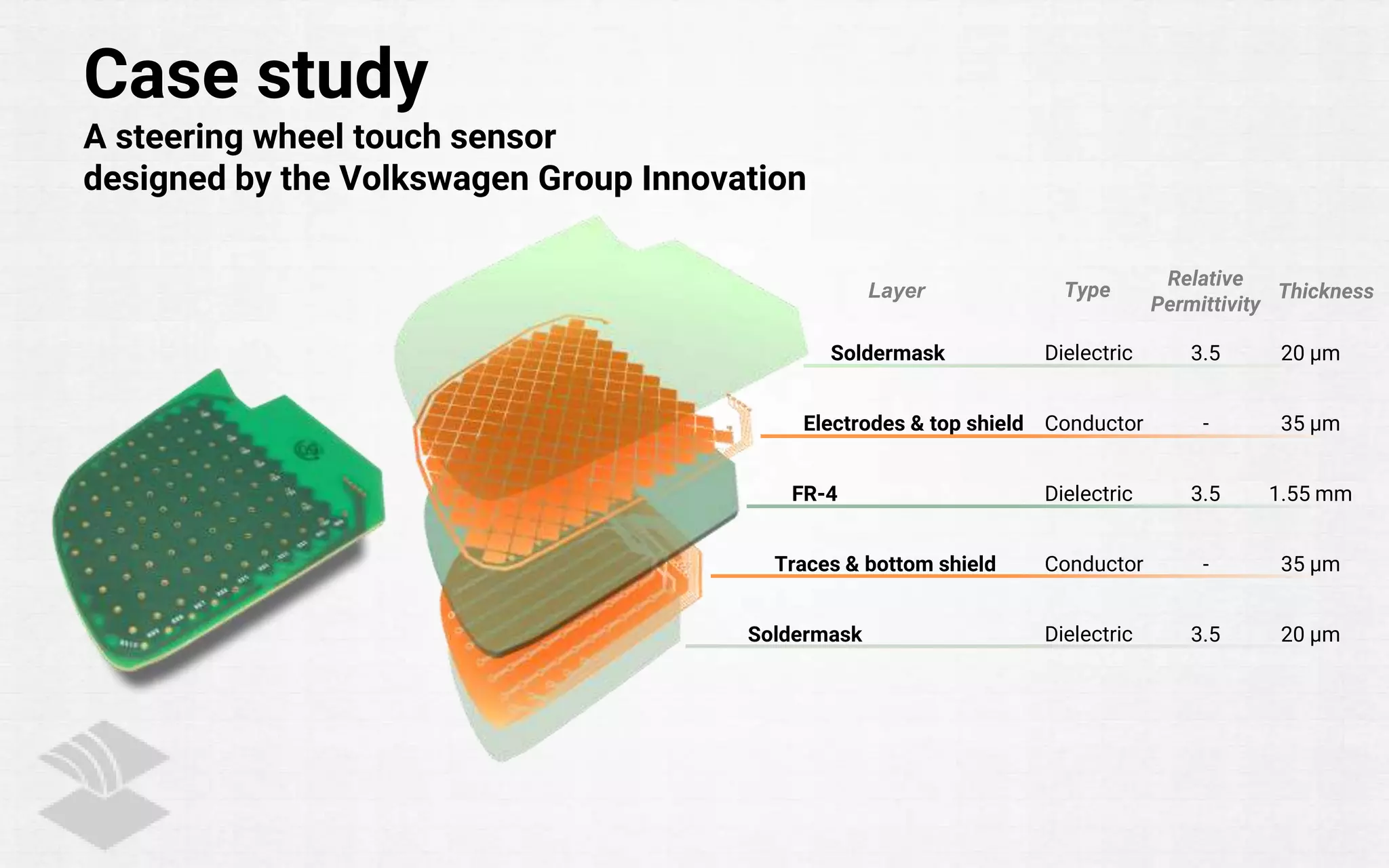

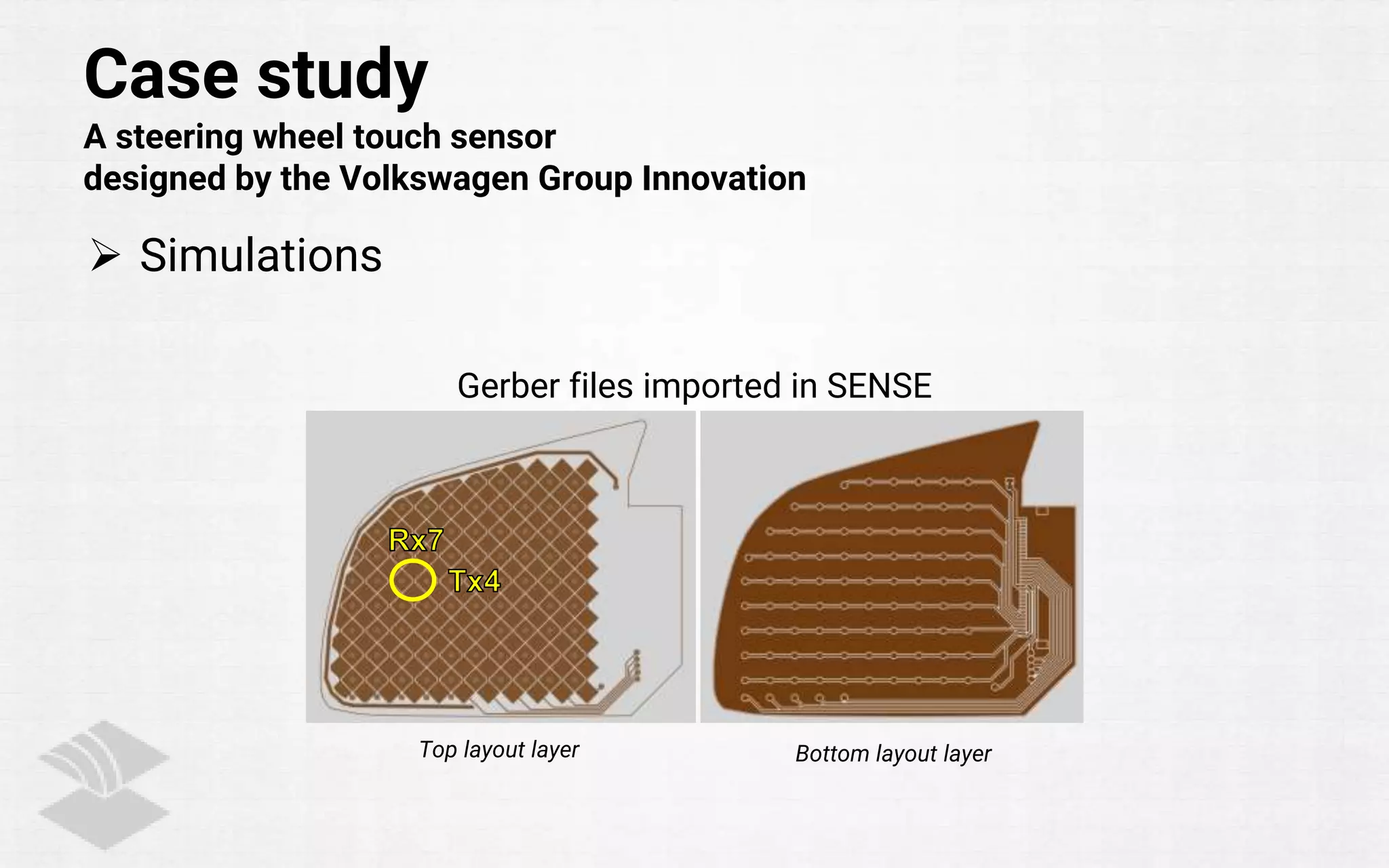

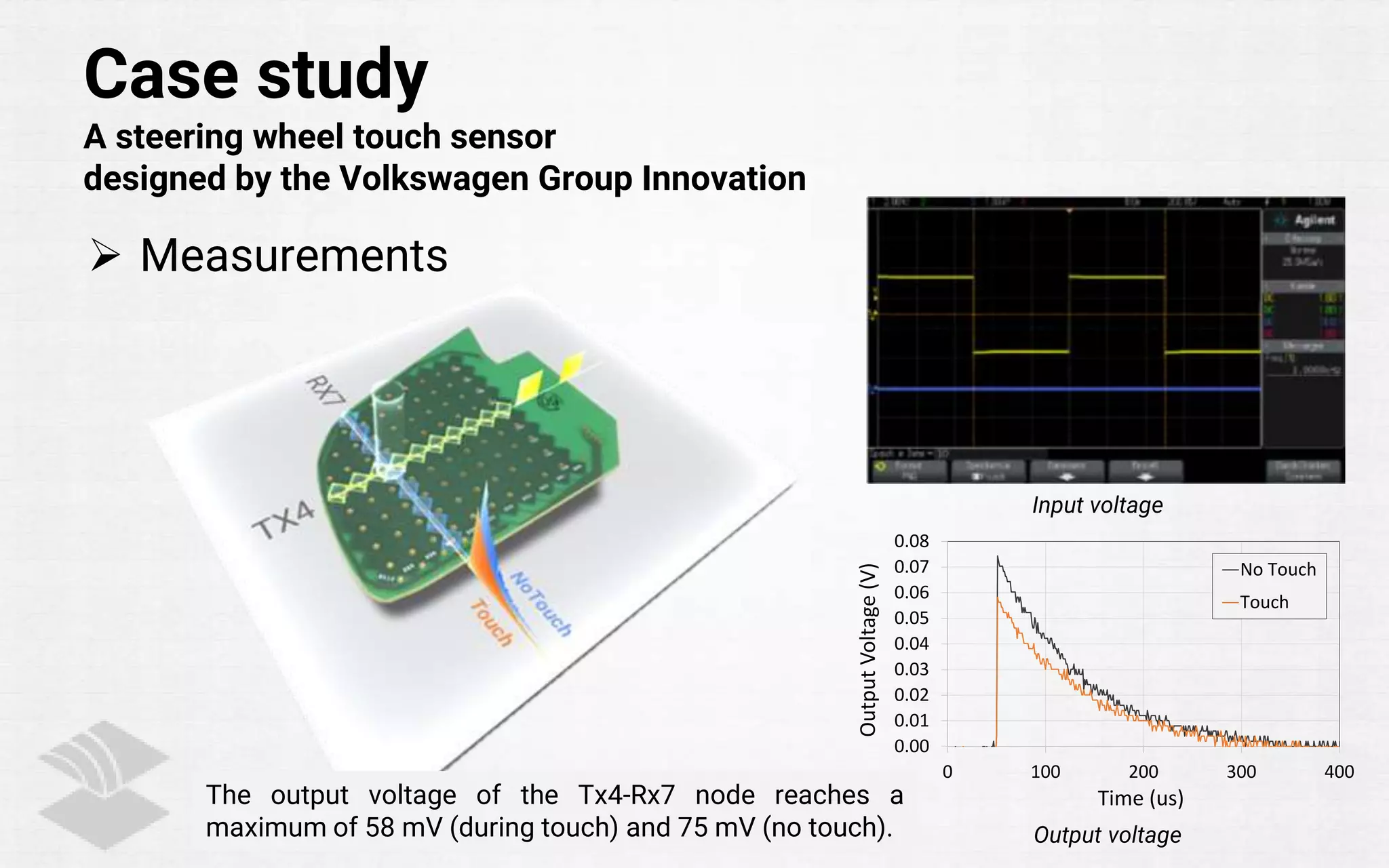

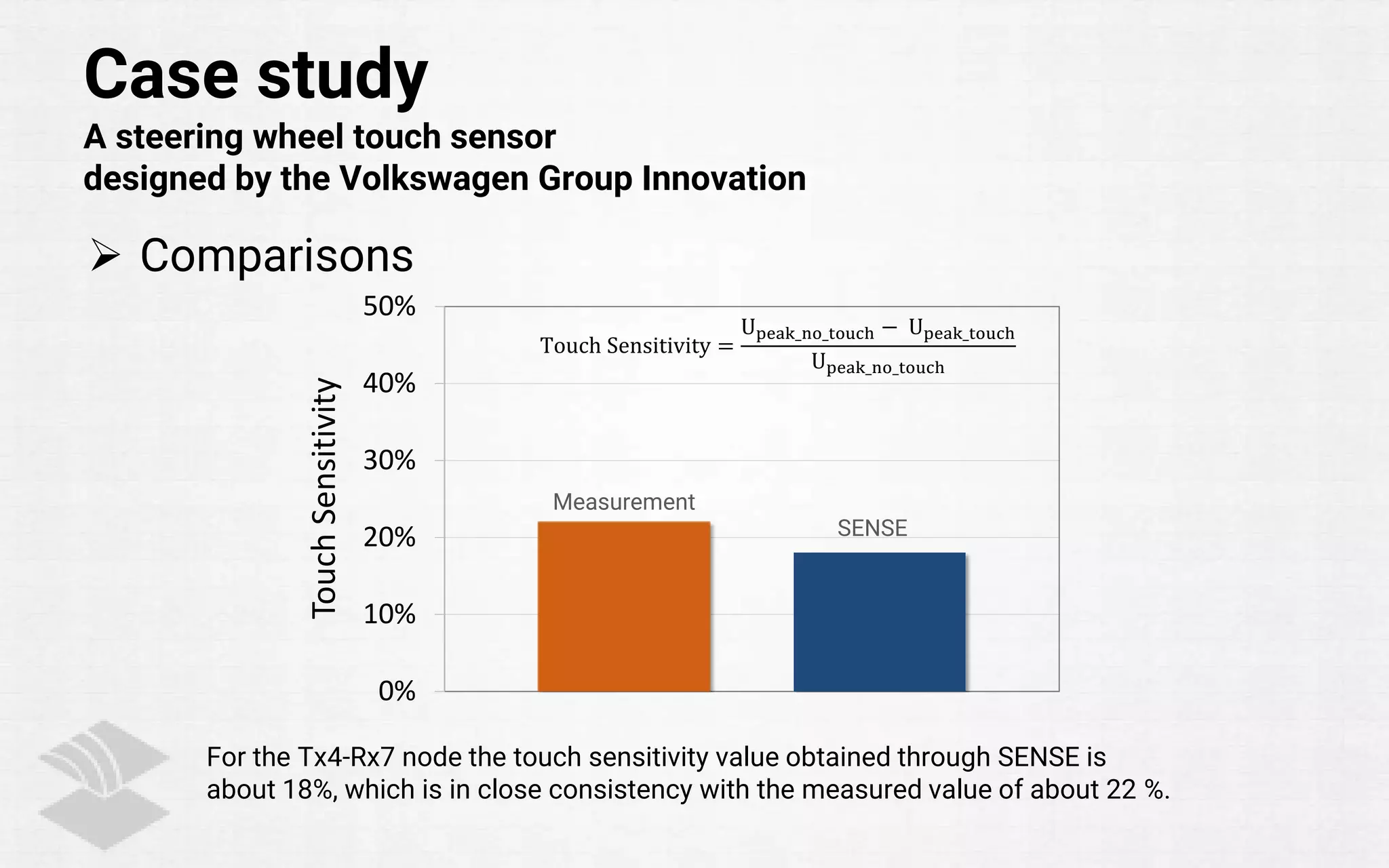

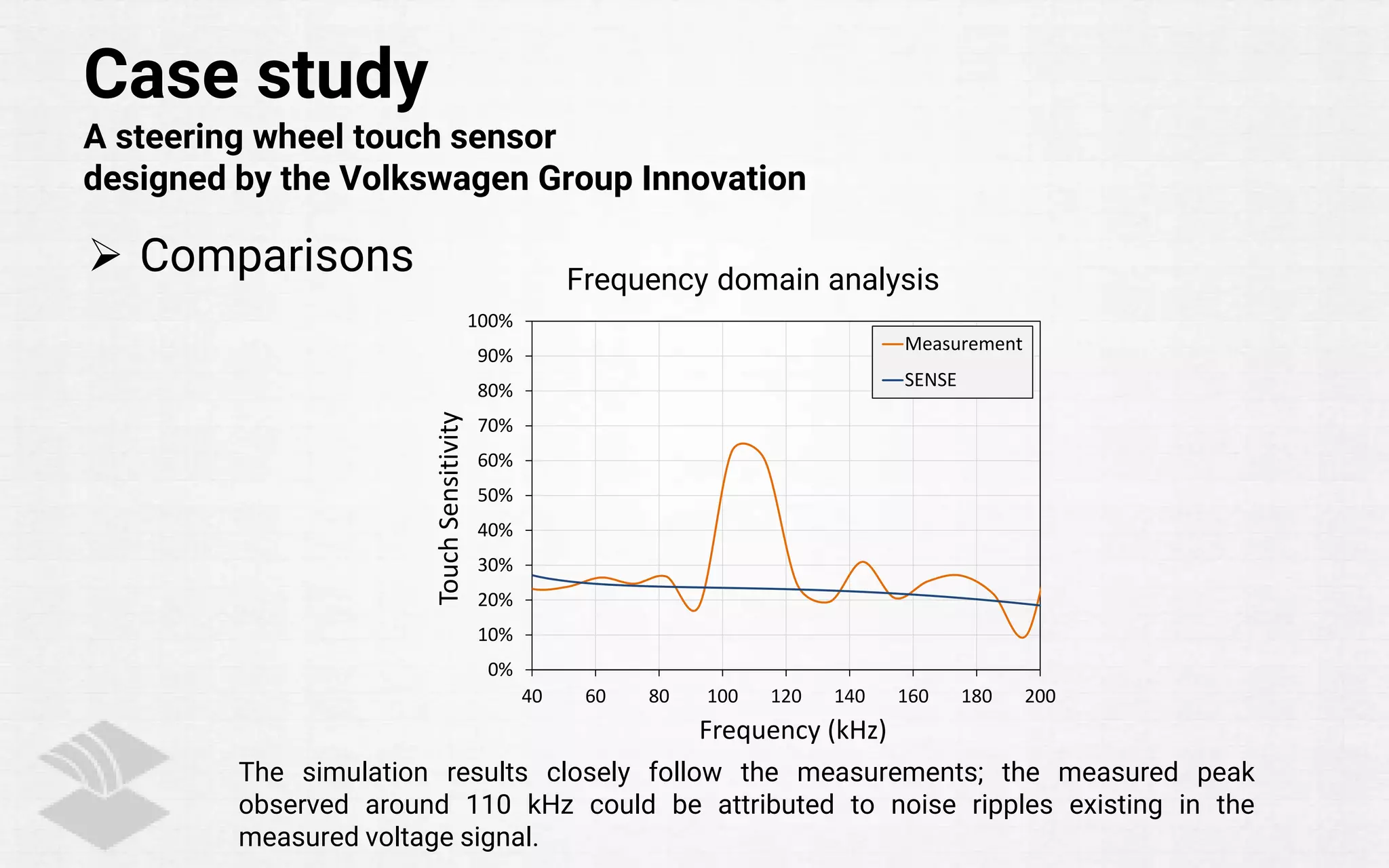

This document discusses virtual designing, prototyping, and testing of automotive capacitive sensors using simulation software. The software allows engineers to (1) create schematics and layouts of capacitive sensors, (2) automatically generate equivalent circuit models, and (3) perform SPICE simulations to test sensor performance before physical prototyping. A case study on a steering wheel touch sensor shows simulation results closely match measurements of touch sensitivity and frequency response, demonstrating the tool's ability to virtually prototype and test automotive electronics. This virtual approach can minimize design iterations and accelerate innovation in capacitive sensor development.