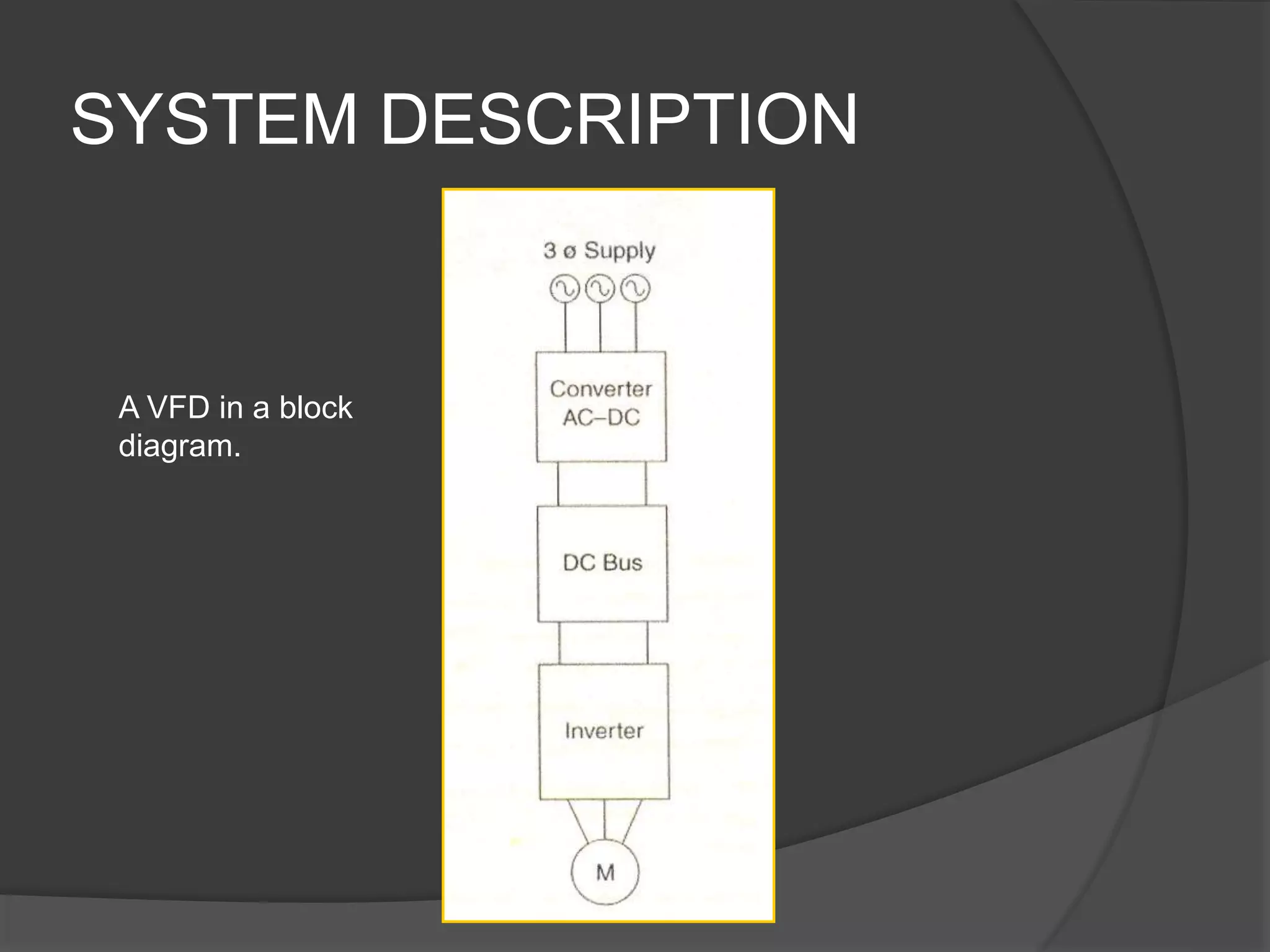

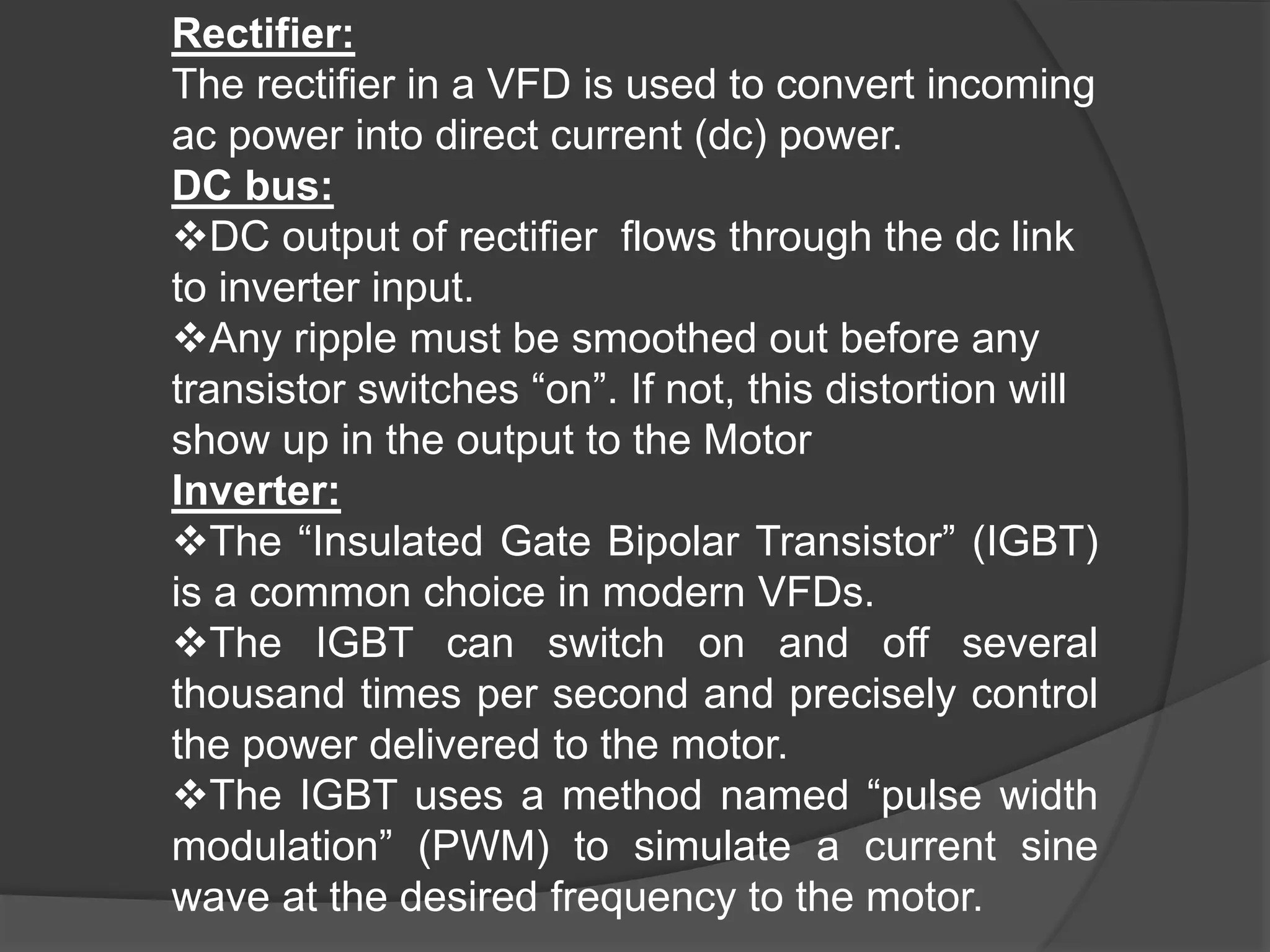

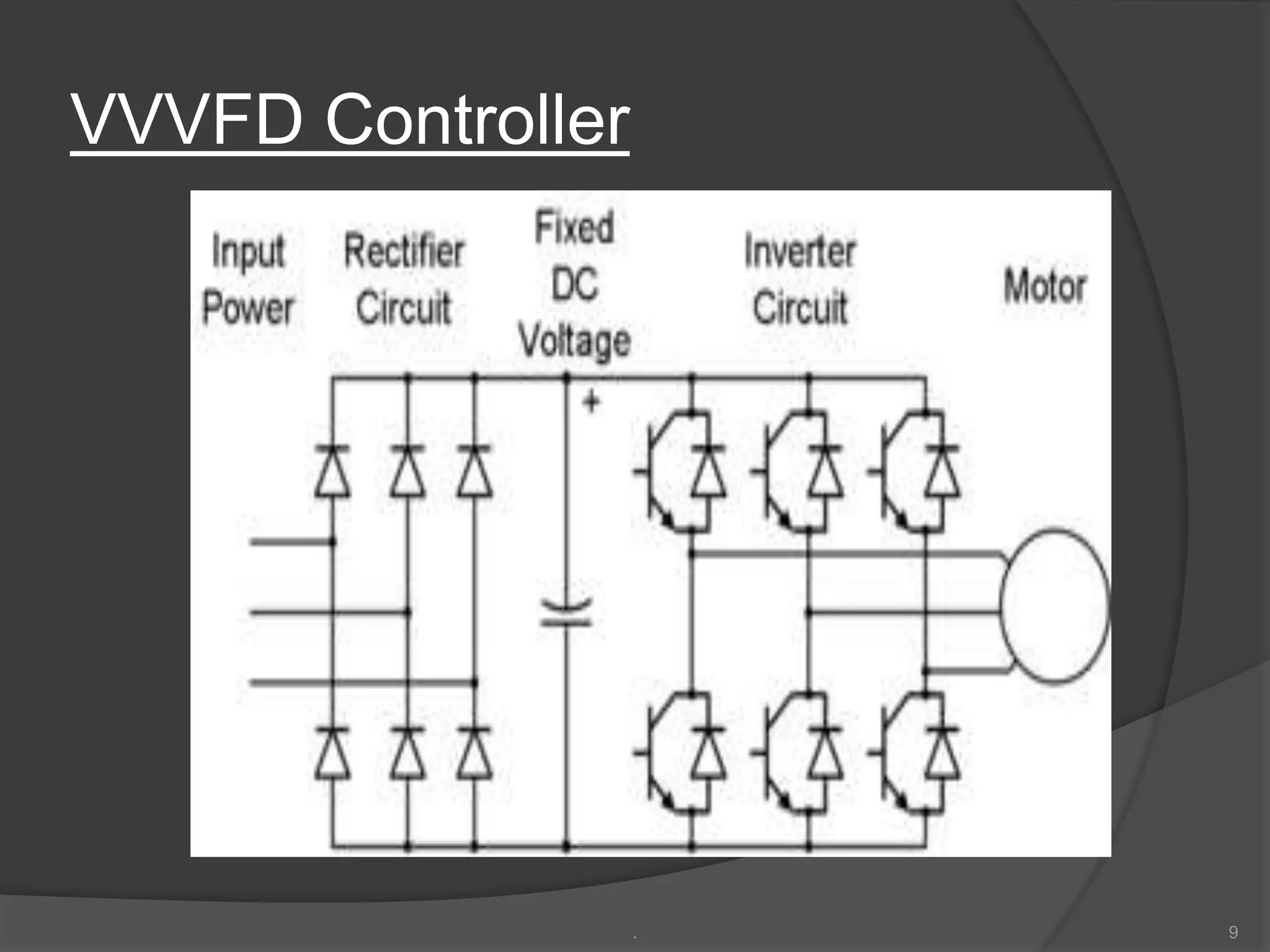

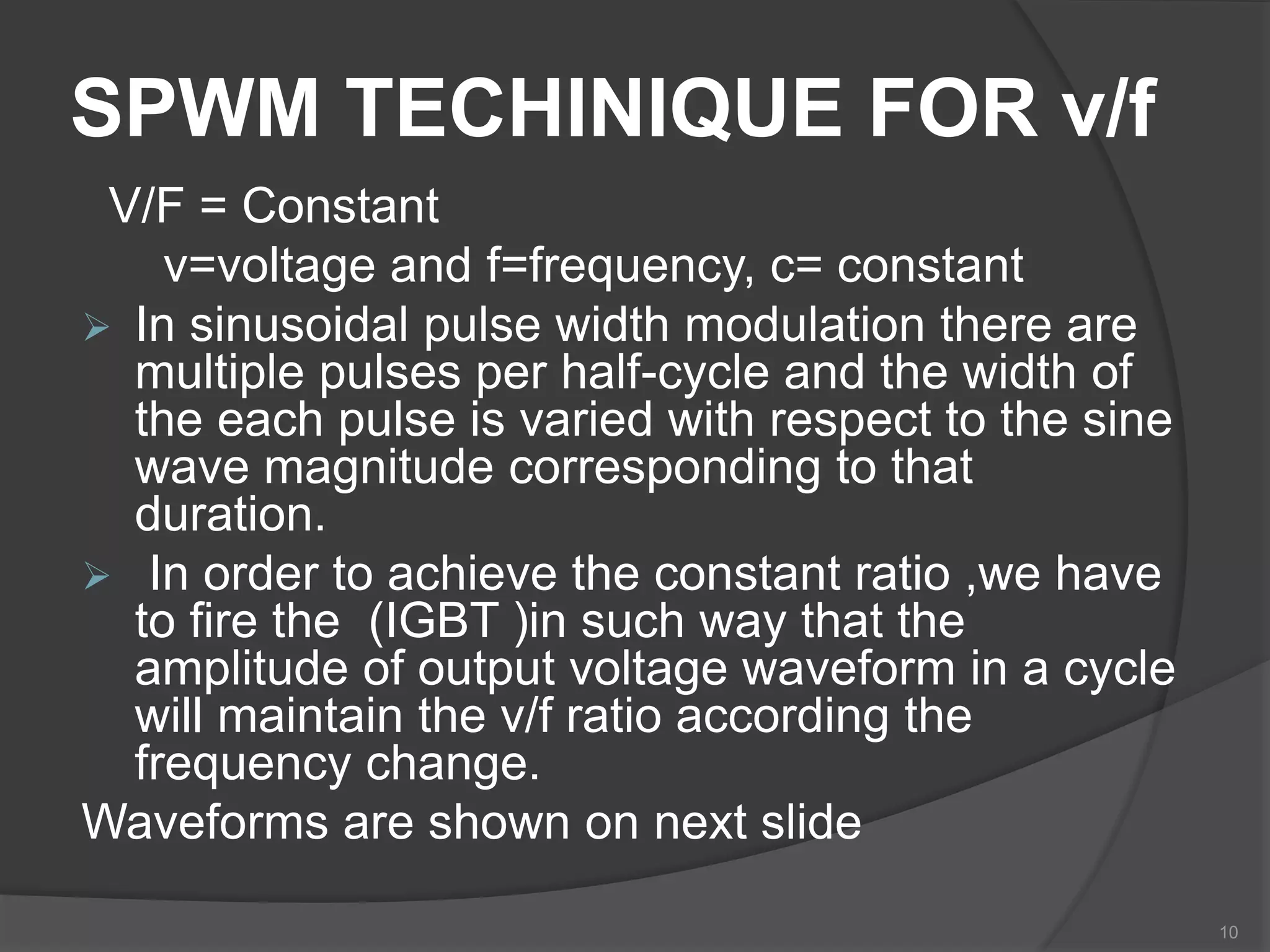

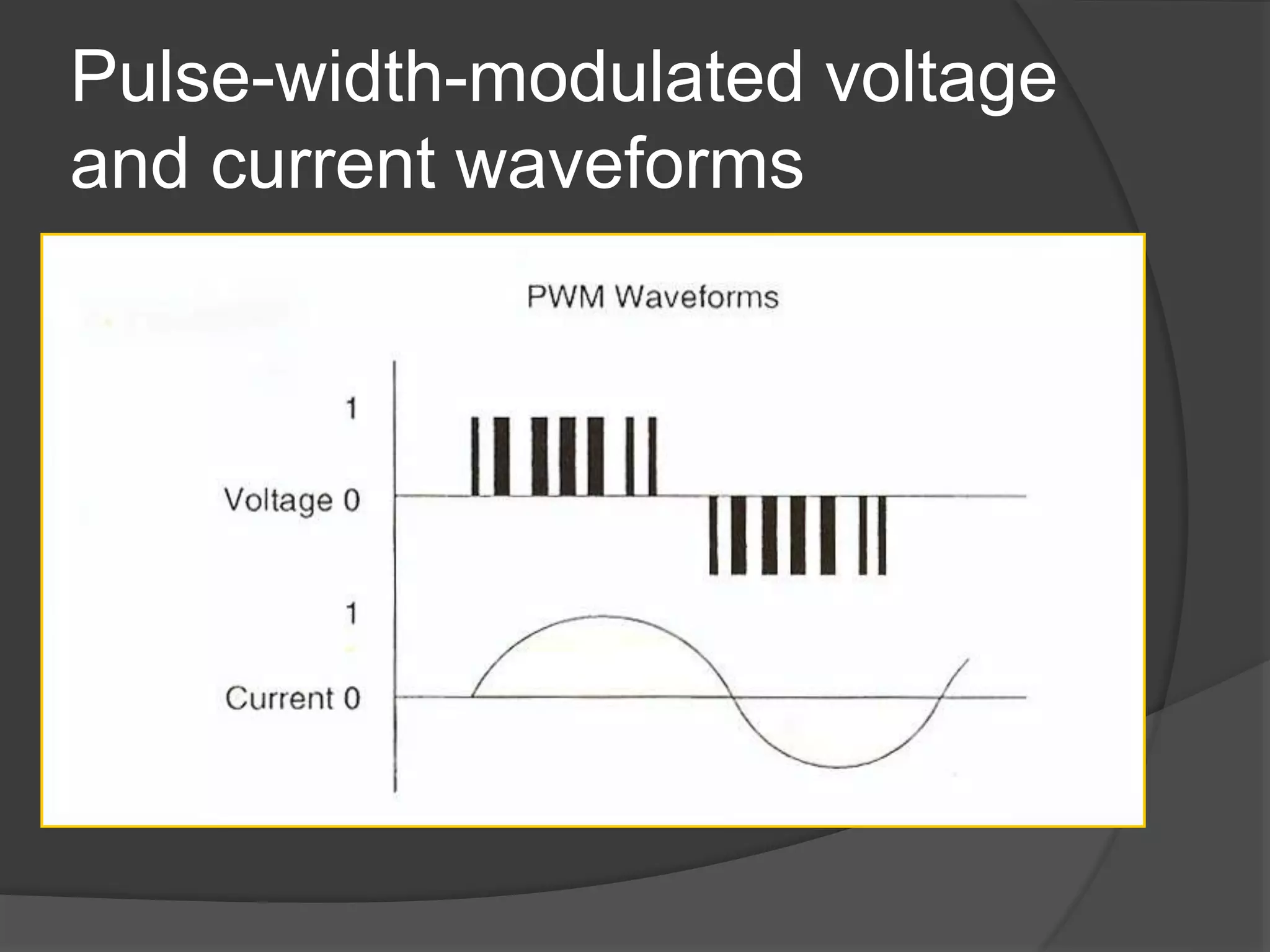

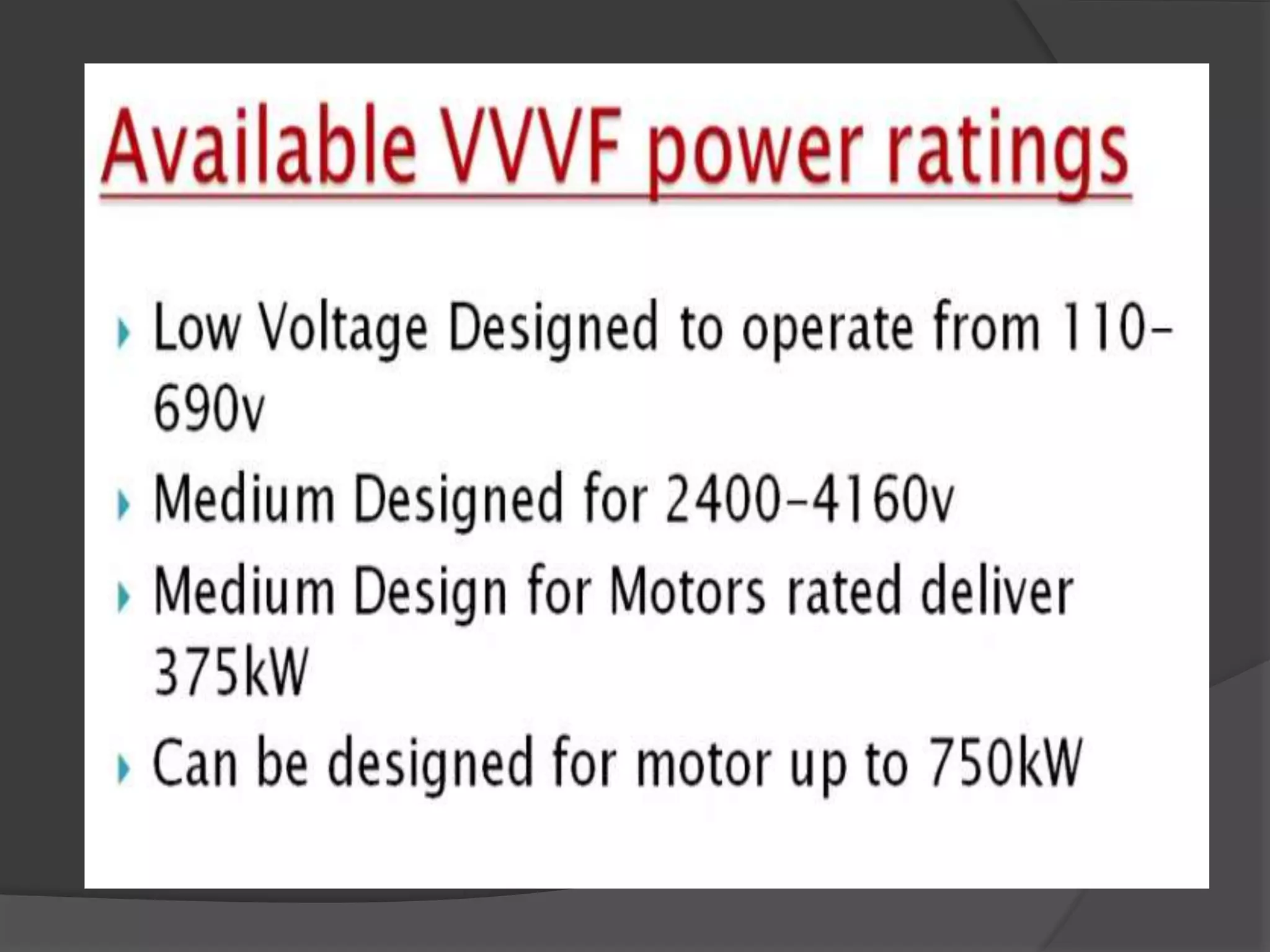

This document discusses variable voltage variable frequency (VVVF) drives. It begins with an introduction that explains how induction motors were previously only used for constant speed applications but advances in power transistors now allow for variable speed control. It then describes the operating principle of VVVF drives in controlling AC motor speed and torque by varying motor input frequency and voltage. The document outlines the key components of a VVVF drive system and explains the pulse width modulation technique used for voltage-frequency control. It concludes by listing some common applications and advantages of VVVF drives along with some drawbacks.

![Presented by:

BHEEMANNA ANGADI

[1OX13EE020]

The Oxford college of engg-bangalore

1

VARIABLE VOLTAGE VARIABLE FREQUENCY

DRIVES](https://image.slidesharecdn.com/variablevoltagevariablefrequencydrive-170511172727/75/Variable-voltage-variable-frequency-drive-1-2048.jpg)