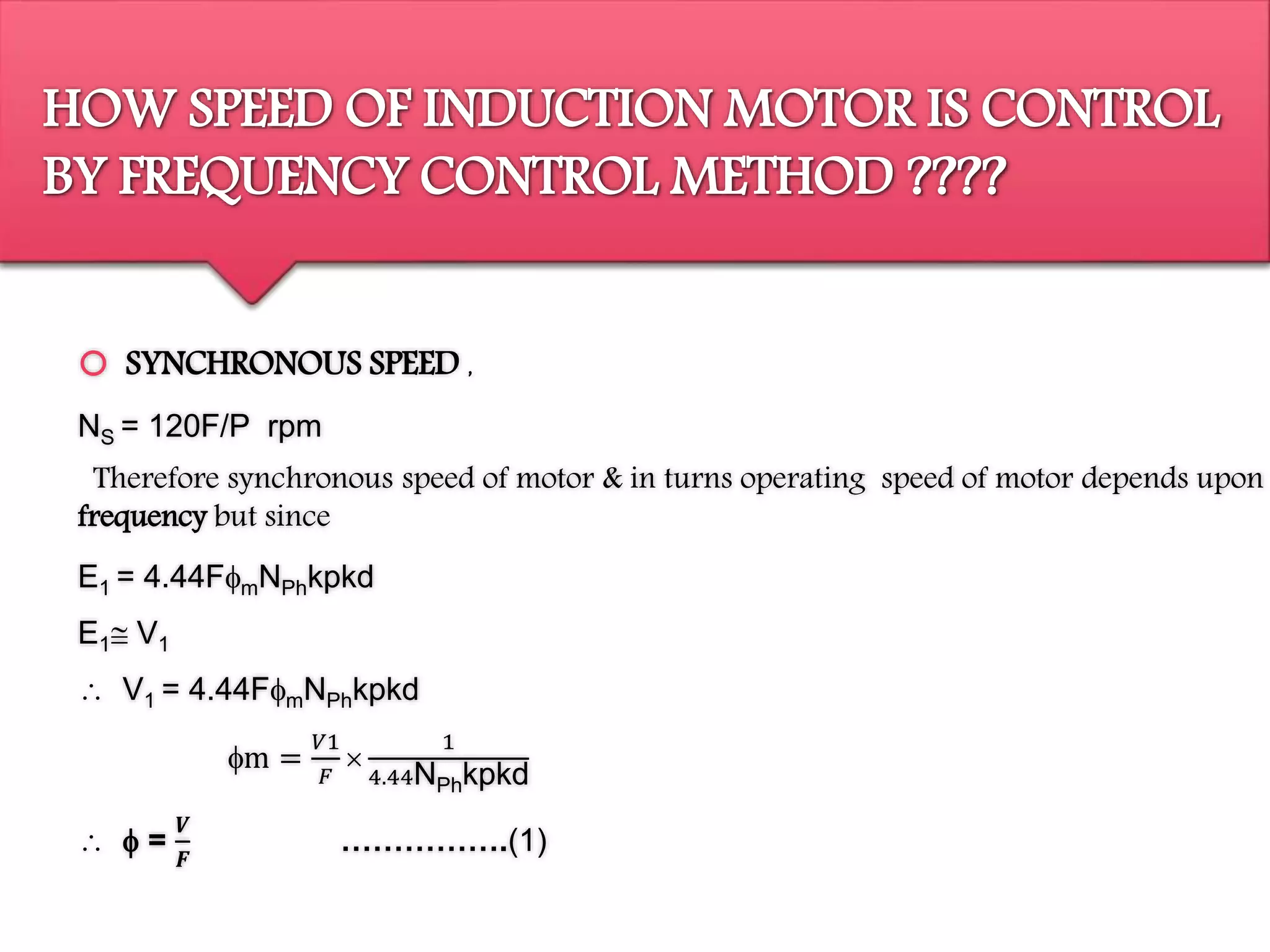

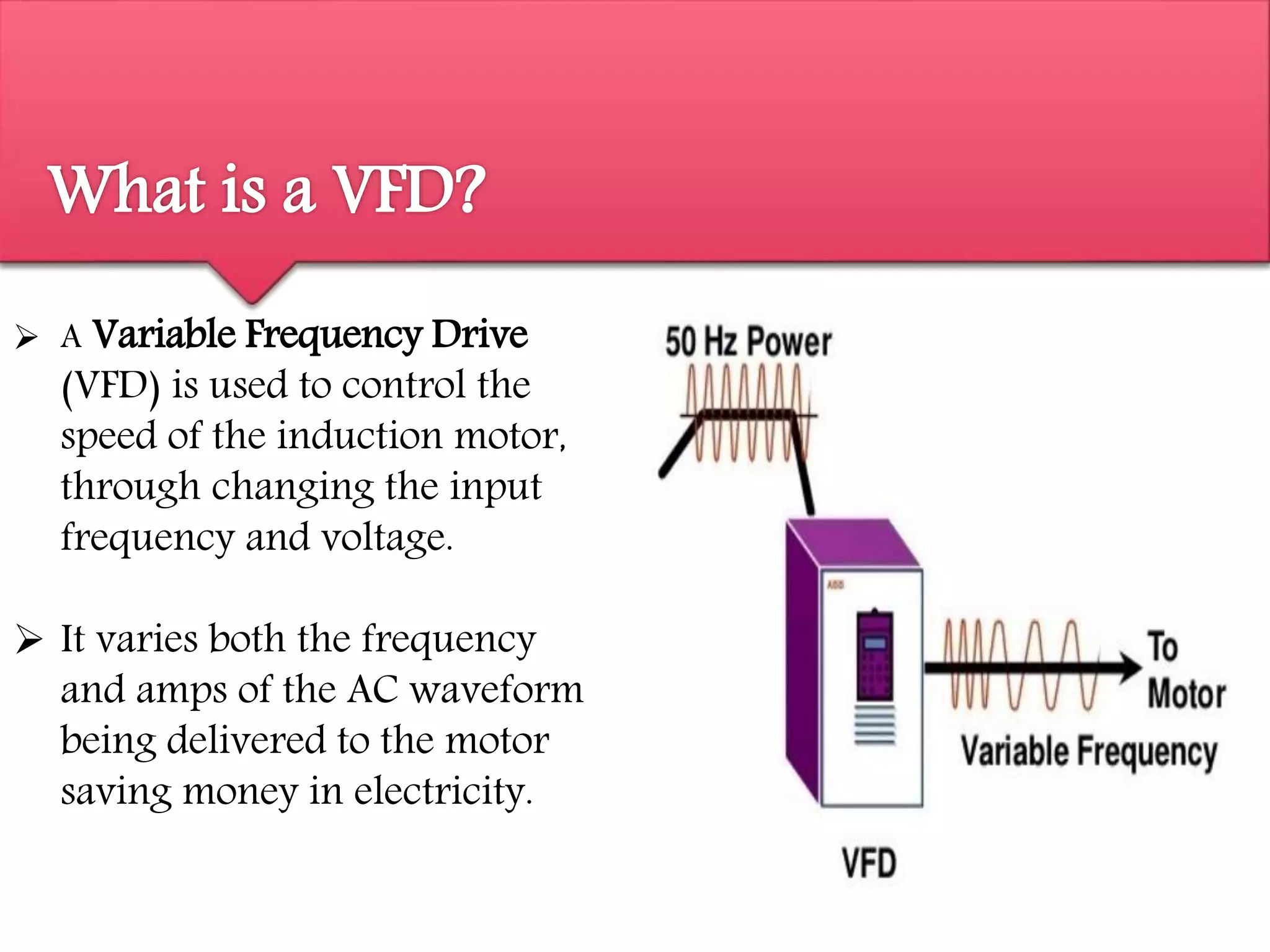

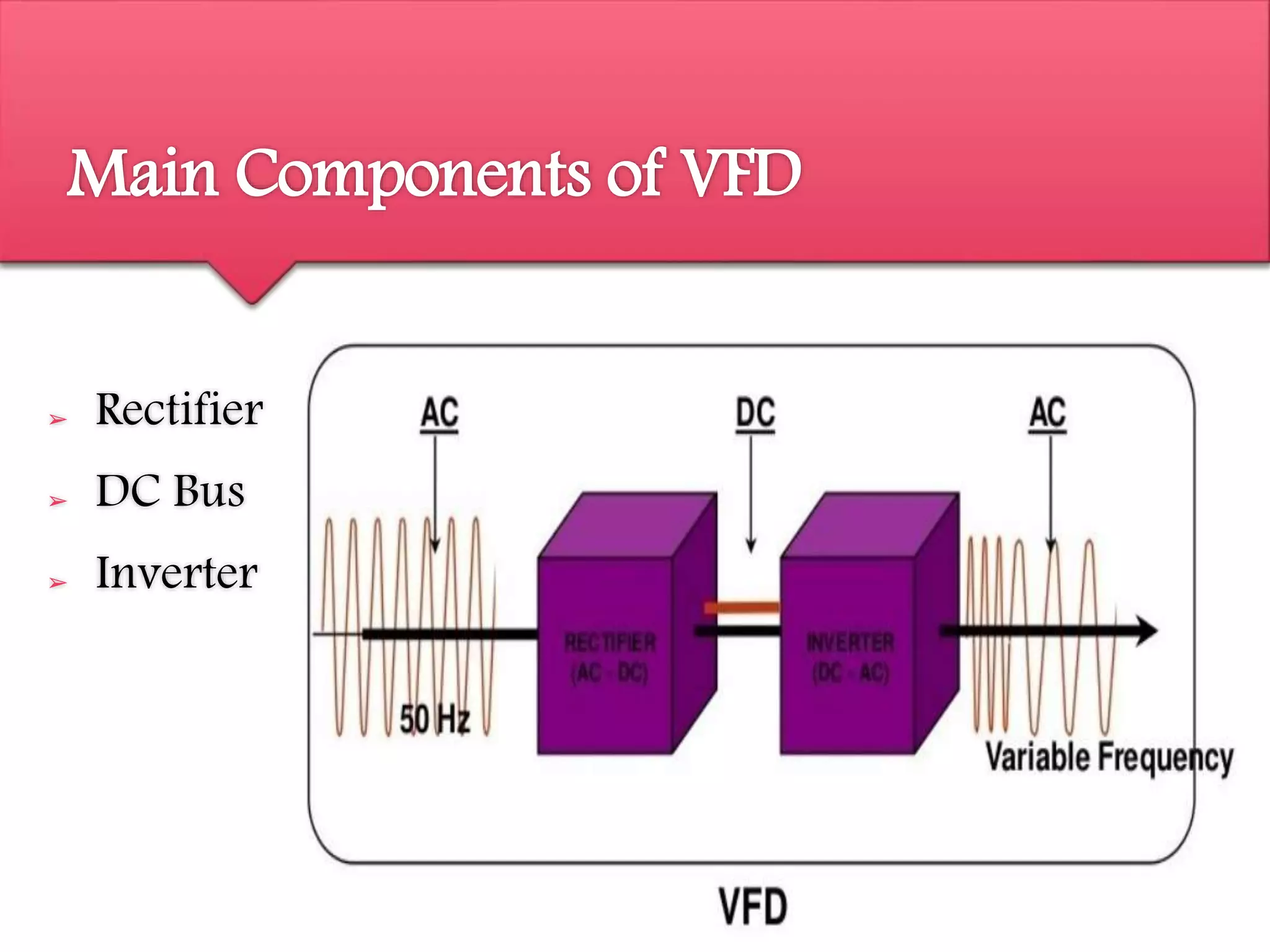

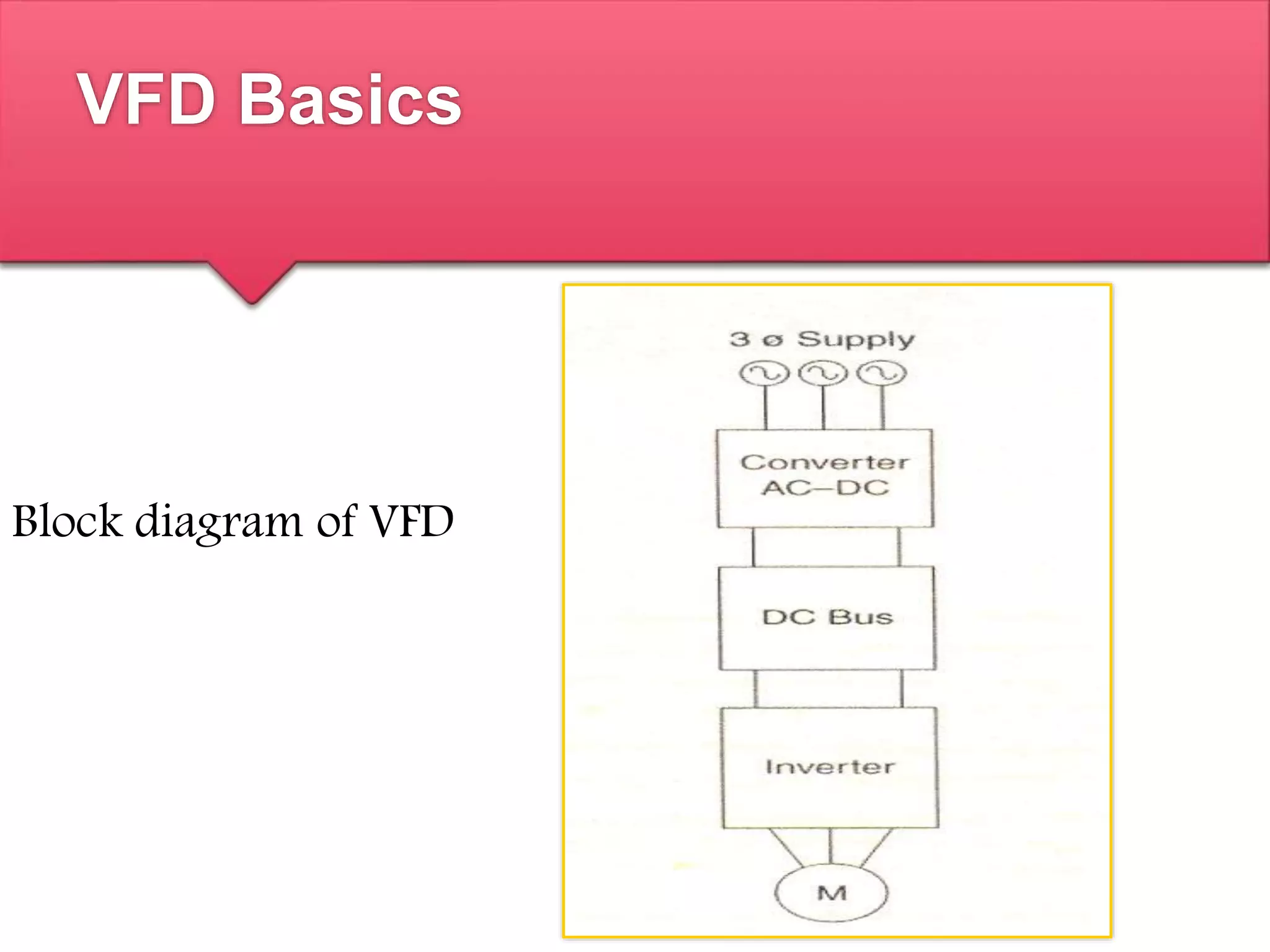

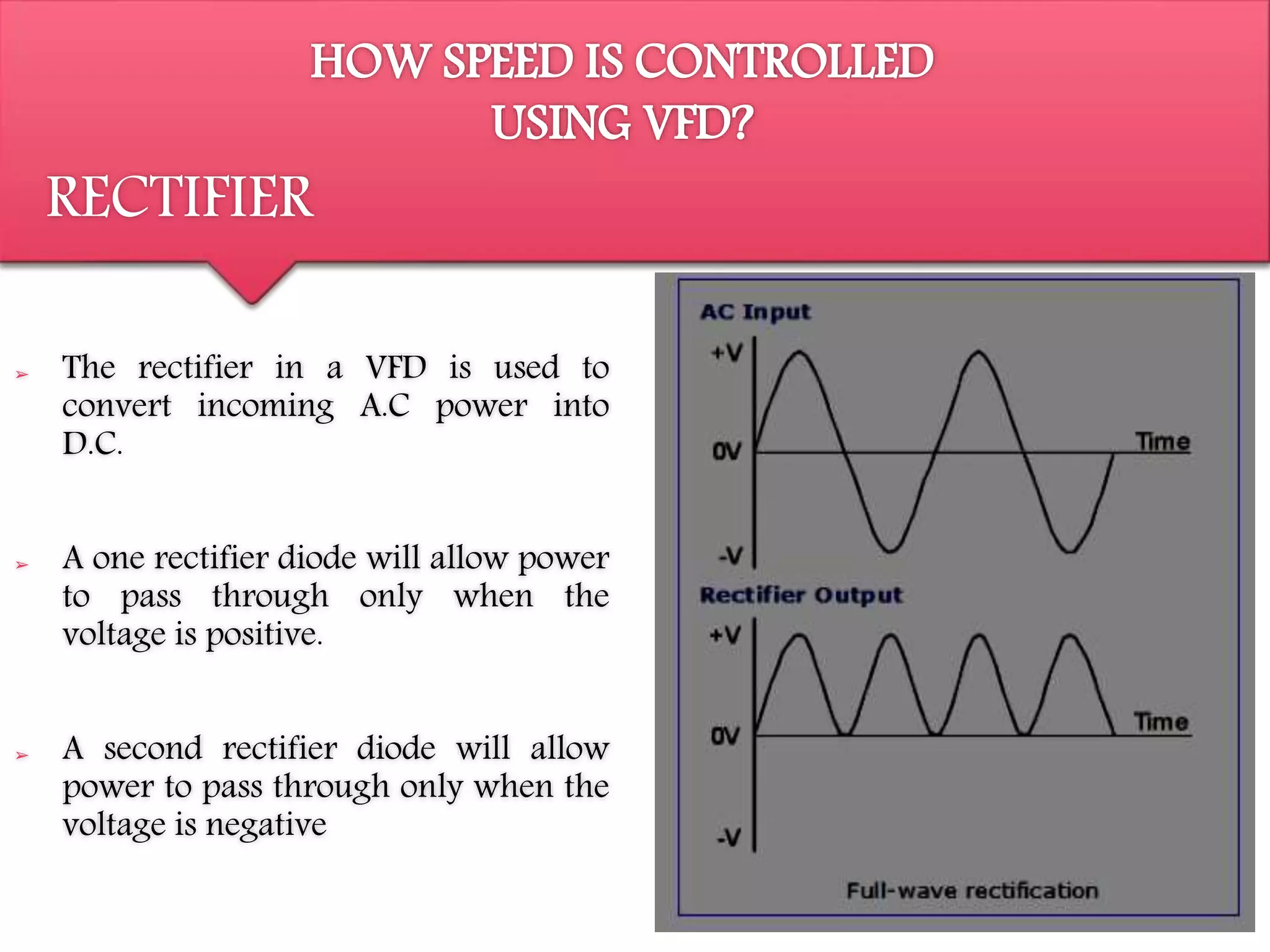

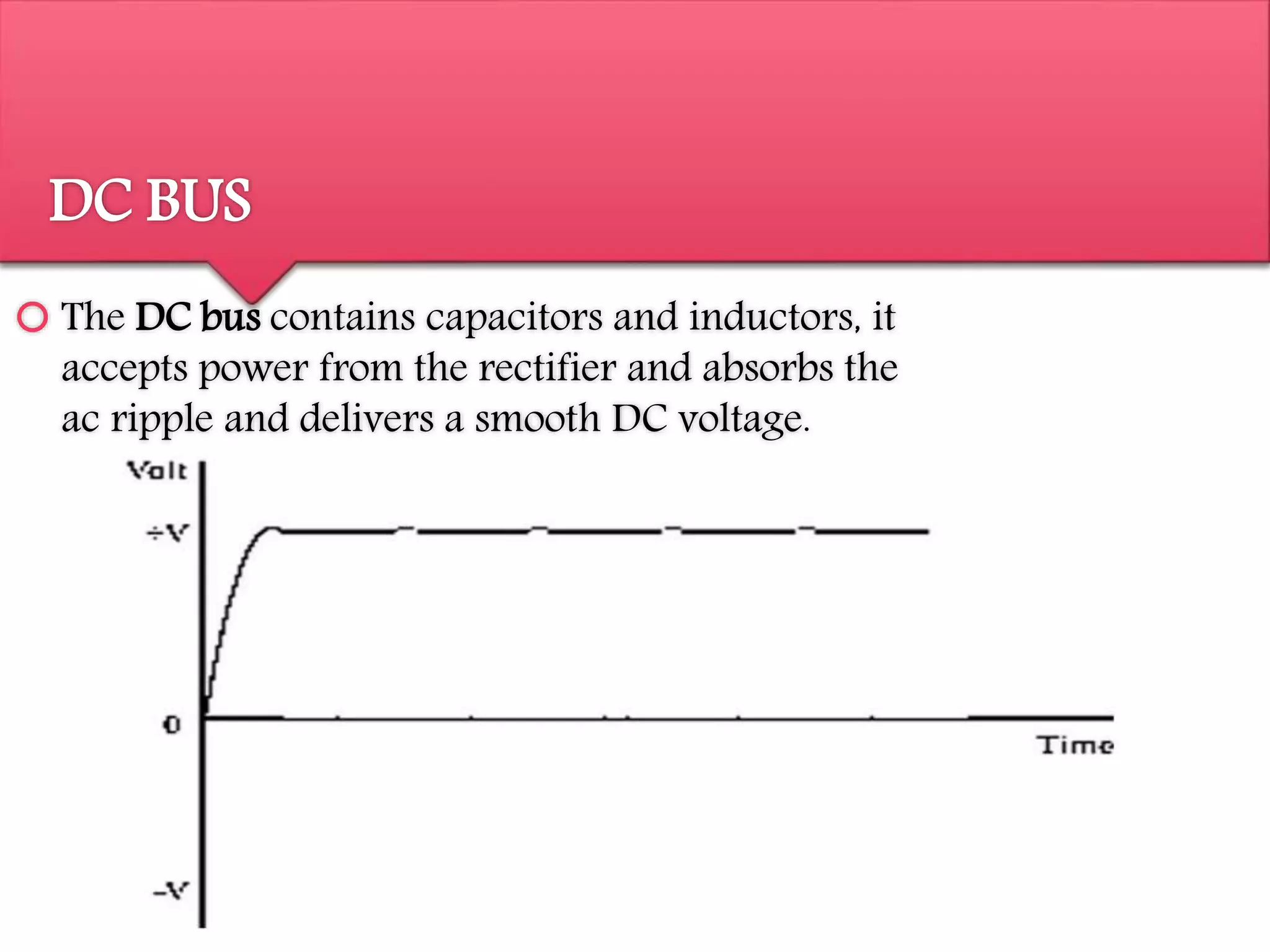

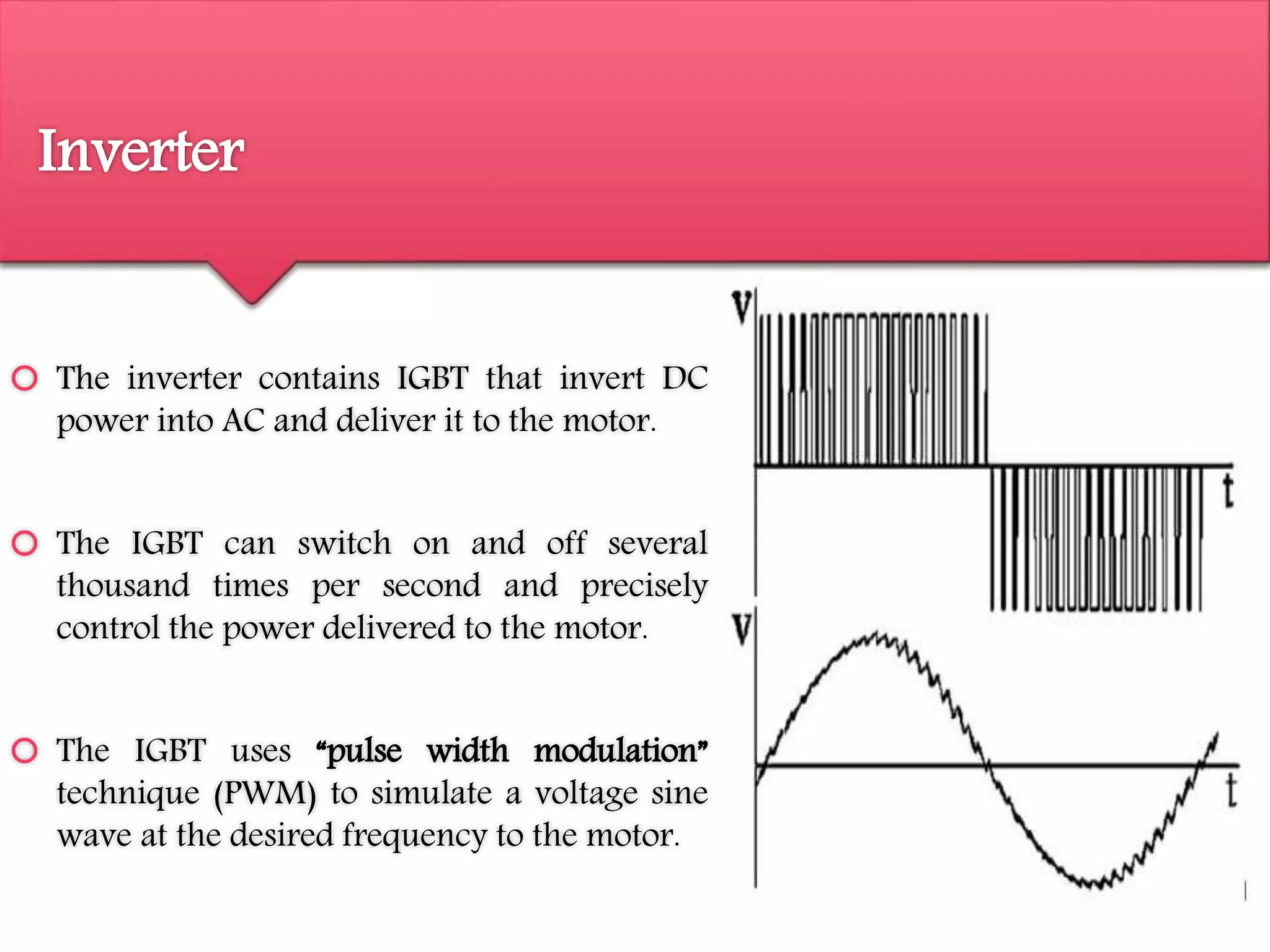

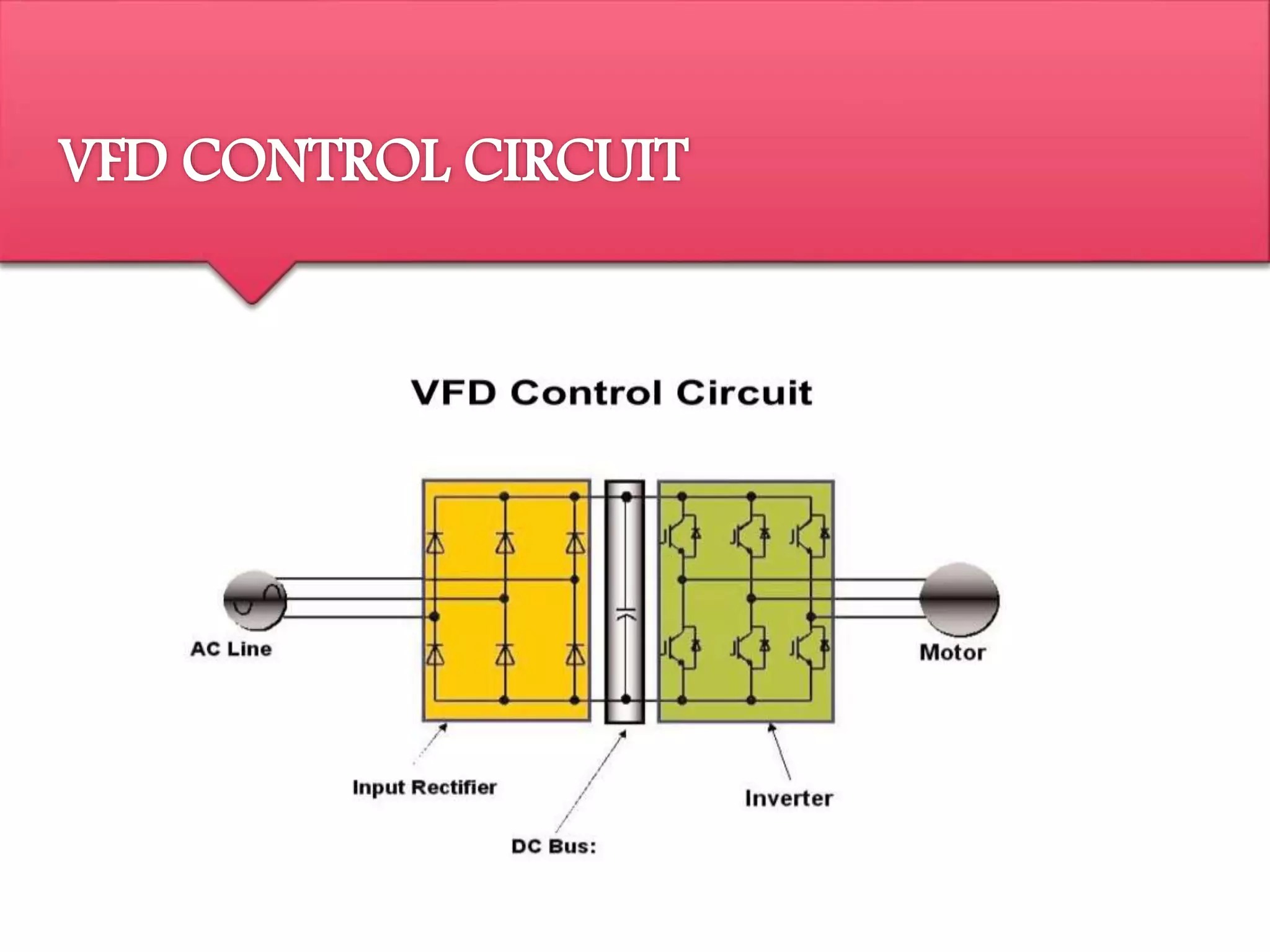

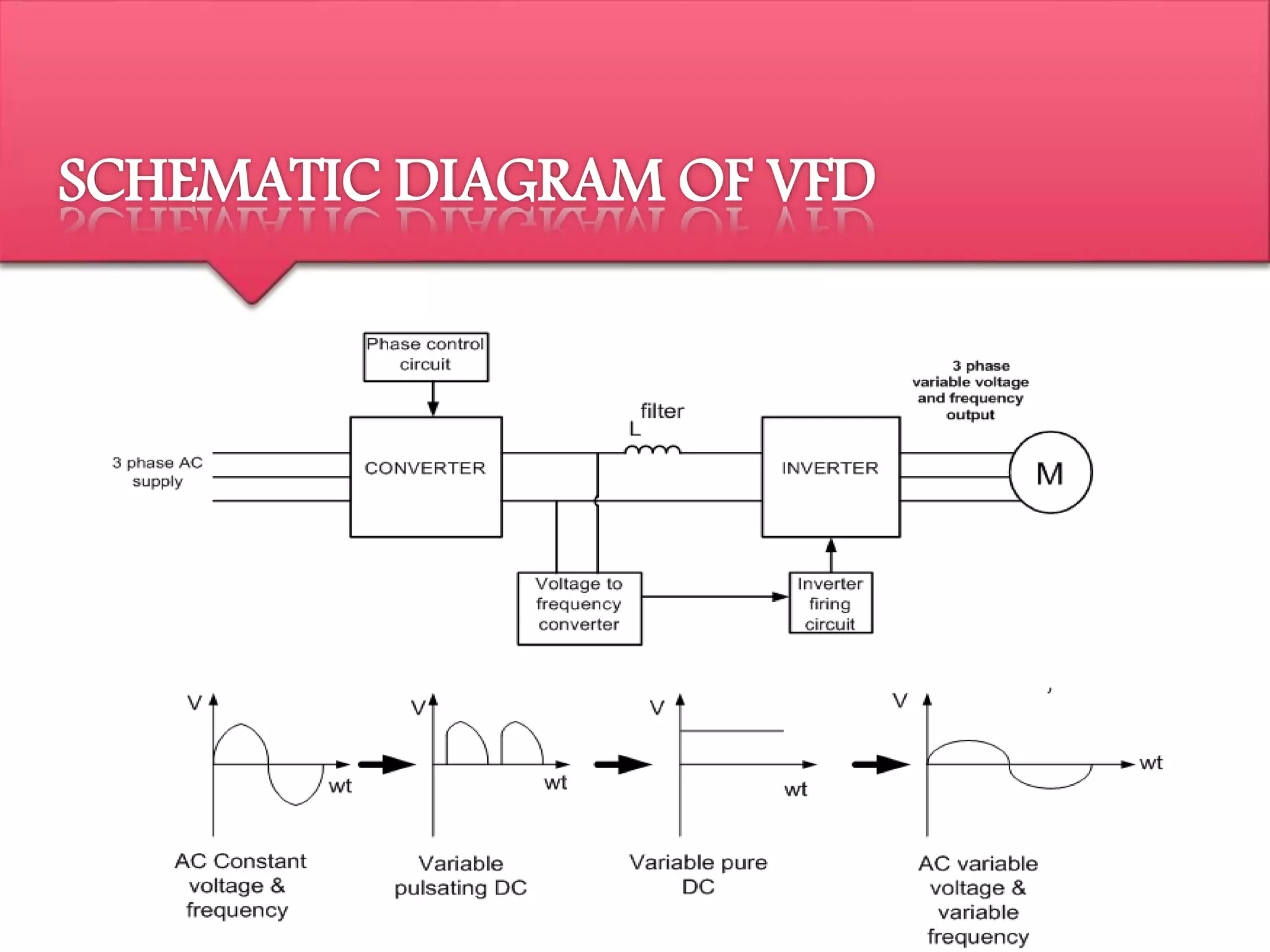

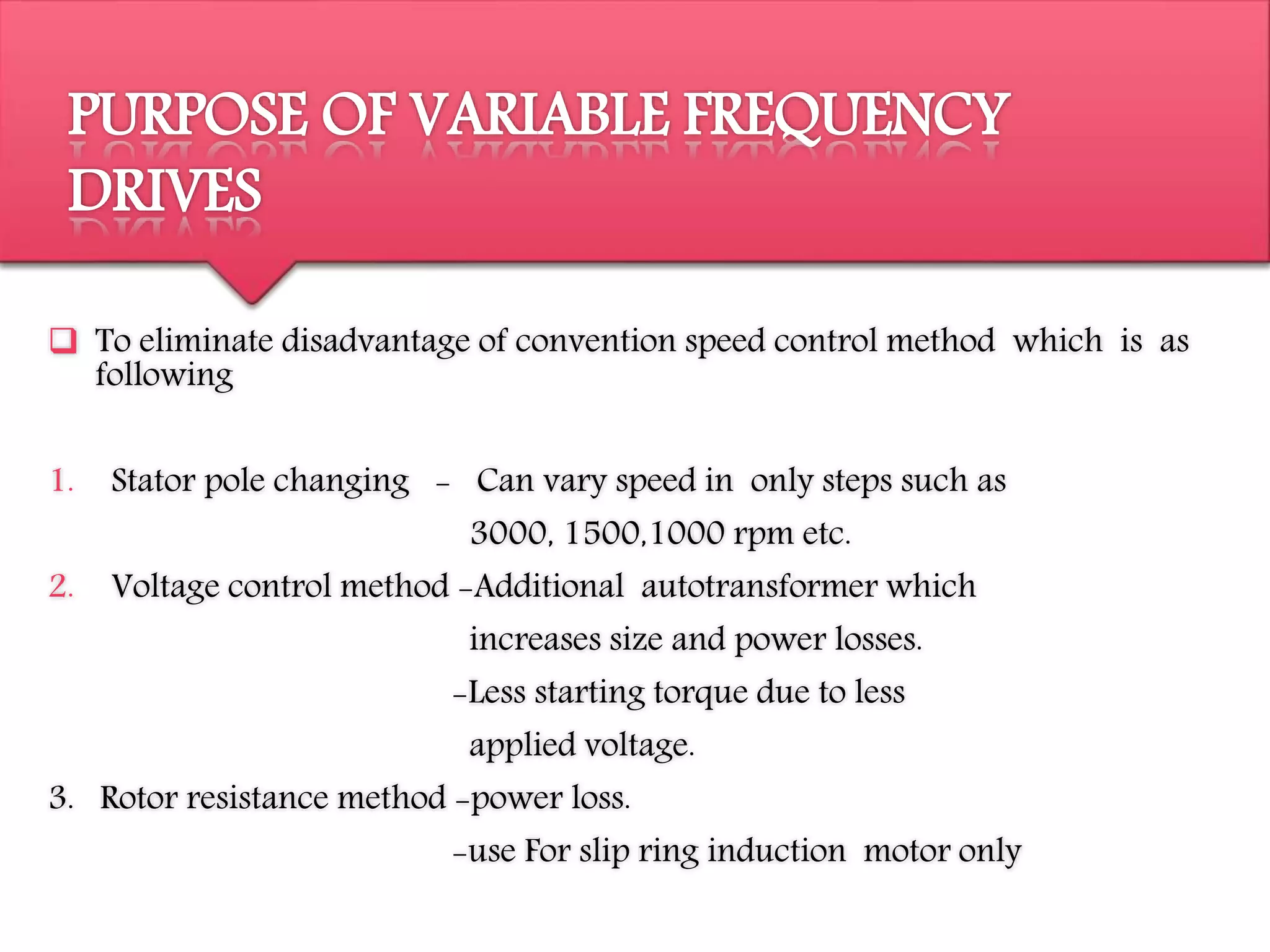

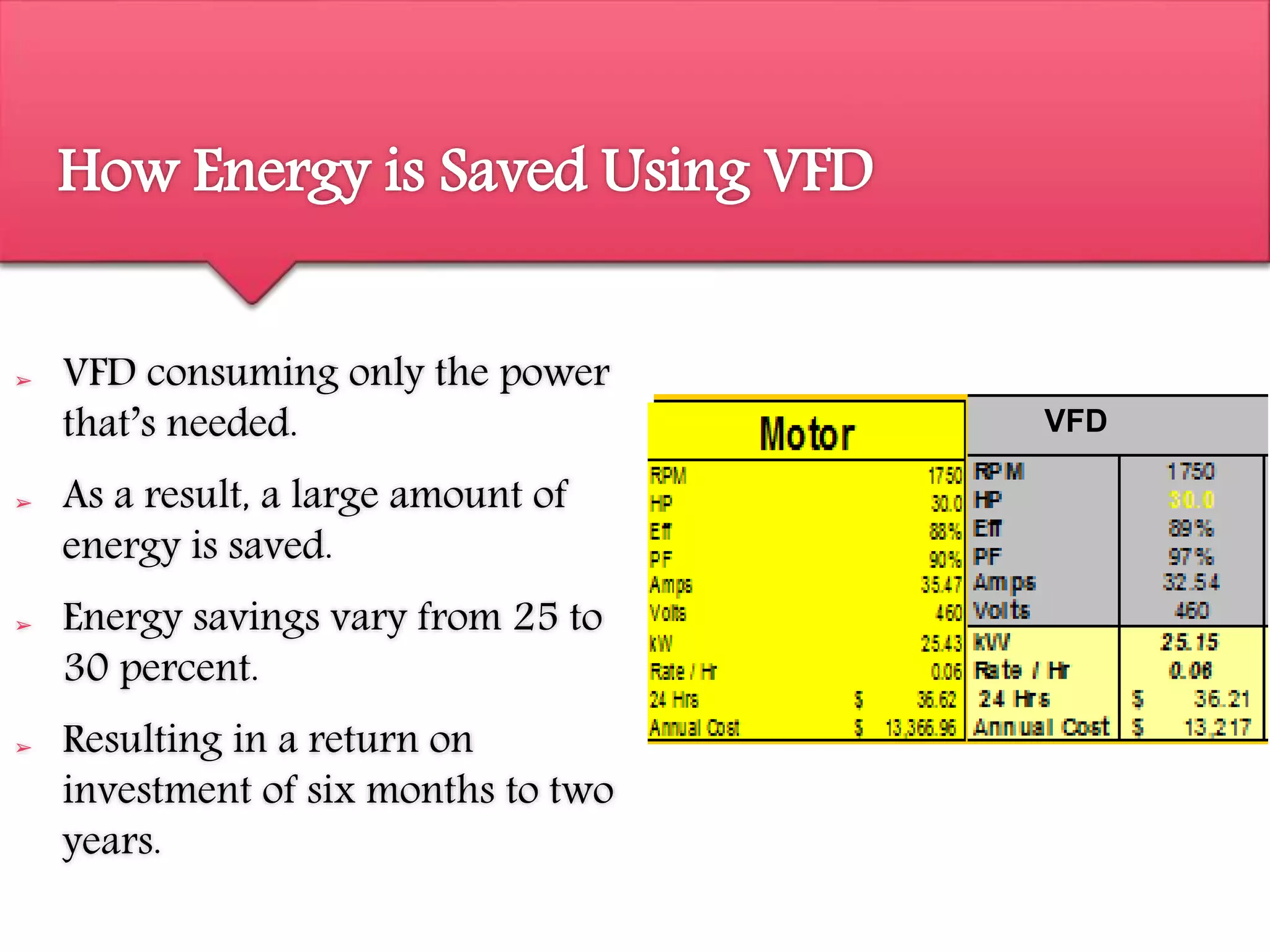

The document discusses the use of Variable Frequency Drives (VFDs) for speed control of three-phase AC motors, highlighting their operation, components, and advantages such as energy savings and reduced mechanical stress. It details the process of controlling motor speed by varying frequency and voltage, along with applications and potential drawbacks of VFDs. Overall, VFDs are presented as an efficient solution for motor control, particularly in industrial settings.