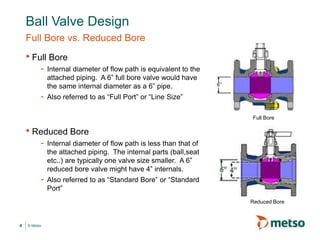

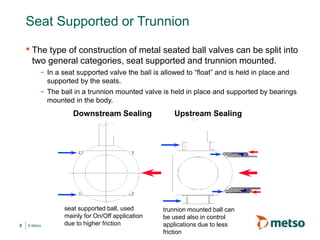

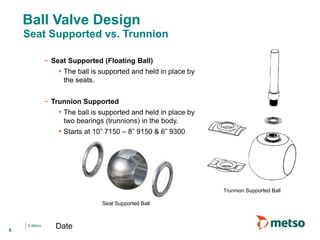

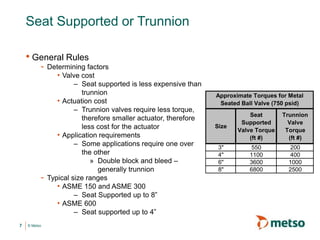

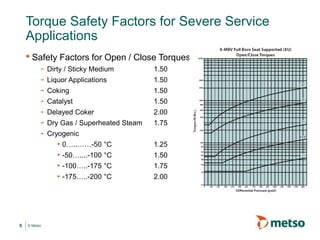

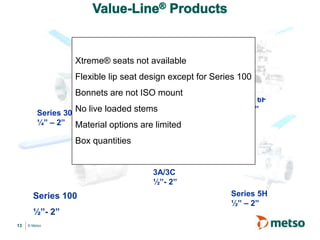

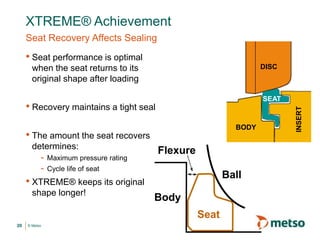

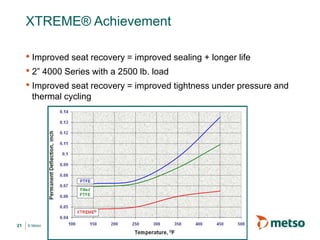

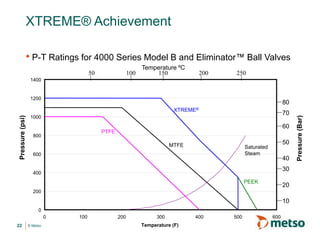

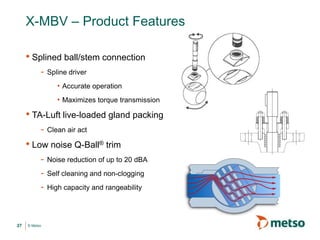

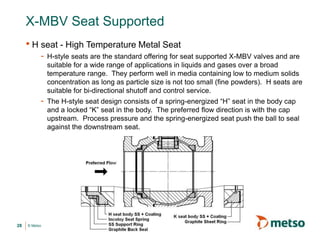

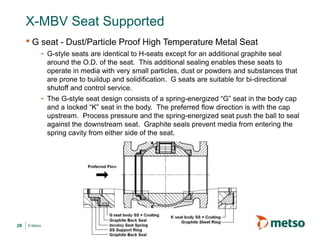

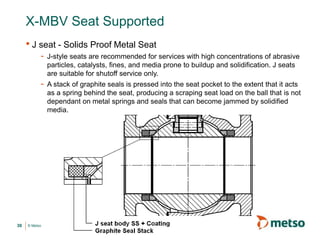

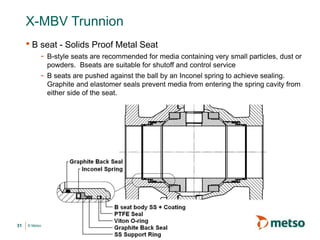

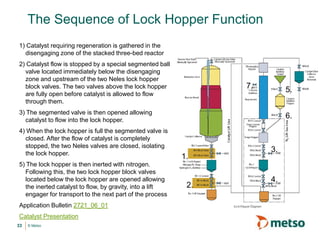

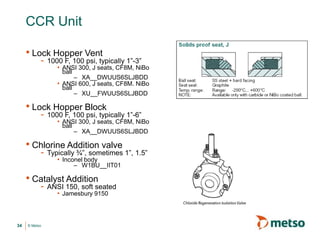

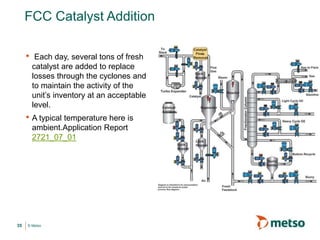

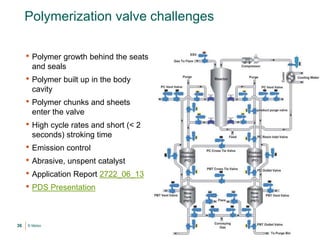

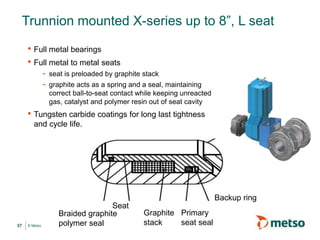

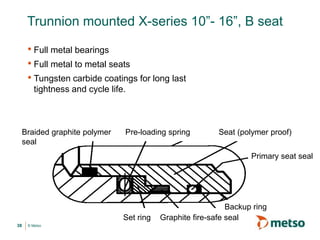

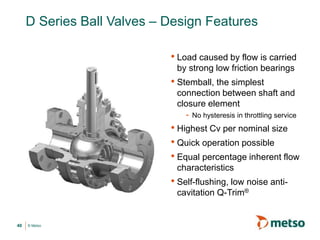

The document discusses Neles metal seated ball valves, including the X-MBV ball valve product line. The X-MBV line includes seat supported and trunnion style valves in full bore and reduced bore configurations up to ANSI 600. Key features discussed include the splined ball/stem connection, live loaded gland packing, and low noise Q-Ball trim. The document describes the H, G, J, and B seat styles available for seat supported and trunnion valves, suited for different media types and applications.