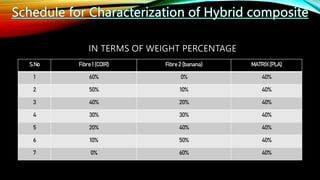

Composite materials are a combination of two materials that improve the properties of their base materials. Humans have used composites for thousands of years, starting with the Mesopotamians gluing wood strips. The matrix binds and holds reinforcements like fibers or particles to improve strength and stiffness over traditional materials. This project focuses on creating a polymer hybrid composite using coir and banana fibers reinforced in a polylactic acid matrix. These natural fibers are chosen due to their abundance, low cost, and good mechanical properties. The hand layup method will be used to fabricate the composite.

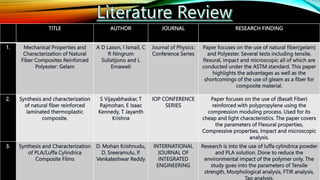

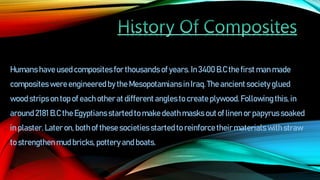

![[1] Laksono A D, Ismail I, Ningrum C R, Sulistijono and Ernawati L 2021 Mechanical Properties and Morphological Characterisationof Waste Natural Fiber Composites Reinforced

Polyester: Gelam (Melaleuca Leucadendra) J. Phys. Conf. Ser. 1803

[2] Vijayabhaskar S, Rajmohan T, Kennedy E I and Krishna T J 2020 Synthesis and characterization of natural fiber reinforcedlaminated thermoplasticcomposite IOP Conf. Ser. Mater.

Sci. Eng. 954

[3] Krishnudu D M, SreeramuluD and Reddy P V 2020 Synthesis and Characterizationof PLA/LuffaCylindrica CompositeFilms Int. J. Integr.Eng. 12 1–7

[4] Manimaran P, Sanjay M R, Senthamaraikannan P, Jawaid M, Saravanakumar S S and George R 2019 Synthesisand characterizationof cellulosic fiber from red banana peduncle as

reinforcementfor potentialapplications J. Nat. Fibers 16 768–80

[5] Musyarofah L, Puspita D, Hidayah E and Sujito2019 Tensile propertiesof coir and fleecefibers reinforcedpoly-lactic acid hybrid green composites J. Phys. Conf. Ser. 1217

[6] Vinayagamoorthy R, Manoj I V., Narendra Kumar G, Sai Chand I, Sai Charan Kumar G V. and SuneelKumar K 2018 Challenges on the synthesis, characterization and machining of

green fiber plastics: A reviewIOP Conf. Ser. Mater. Sci. Eng. 390

[7] Ramesh M, Rajeshkumar L and Balaji D 2021 Influenceof Process Parameterson the Properties of AdditivelyManufactured Fiber-ReinforcedPolymer CompositeMaterials: A

Review J. Mater. Eng. Perform.30 4792–807

[8] Vinayagamoorthy R, Manoj I V., Narendra Kumar G, Sai Chand I, Sai Charan Kumar G V. and SuneelKumar K 2018 Challenges on the synthesis, characterizationand machining of

green fiber plastics: A reviewIOP Conf. Ser. Mater. Sci. Eng. 390](https://image.slidesharecdn.com/updatedprojectpresentation-projectcompositea-221223041752-c5daec57/85/updated-project-presentation-Project-Composite-A-pptx-18-320.jpg)

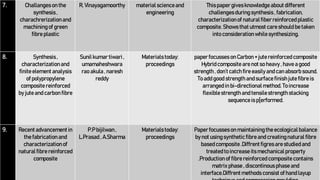

![[9] Tiwari S K, Umamaheswara Rao A, ReddyN, Sharma H and Pandey J K 2021 Synthesis, characterization and finite element analysis of polypropylene

composite reinforced by jute and carbon fiber Mater. Today Proc. 46 10884–91

[10] Bijlwan P P, Prasad L and Sharma A 2021 Recent advancement in the fabrication and characterization of natural fiber reinforced composite:A review

Mater. Today Proc. 44 1718–22

[11] Saindane U V., Soni S and Menghani J V. 2019 Recent research status on synthesis and characterization of natural fibers reinforced polymercomposites

and modern friction materials - An overview Mater. Today Proc. 26 1616–20

[12] Prashanth K P, Hanumantharaju H G and Lokesh G N 2019 Synthesis and characterization study of chitosan based natural fiber: Biodegradablepolymer

composite AIP Conf. Proc. 2057

[13] R V 2020 Trends and Challenges on the Development of HybridizedNatural Fiber CompositesJ. Nat. Fibers 17 1757–74](https://image.slidesharecdn.com/updatedprojectpresentation-projectcompositea-221223041752-c5daec57/85/updated-project-presentation-Project-Composite-A-pptx-19-320.jpg)