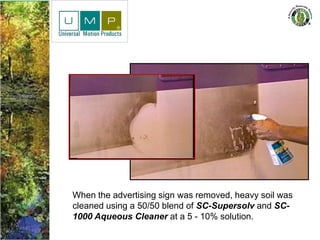

This document summarizes the products and services of Alternative Fuel & Power, which offers environmentally-friendly cleaners and solvents for industrial applications. Their products are non-toxic, non-reactive, readily biodegradable and derived from renewable resources. They provide cleaners and solvents for transportation, manufacturing, facilities maintenance, and other industrial sectors. Their core products include cleaners, solvents, and specialty chemicals that are certified by various organizations for safety and effectiveness in cleaning applications.