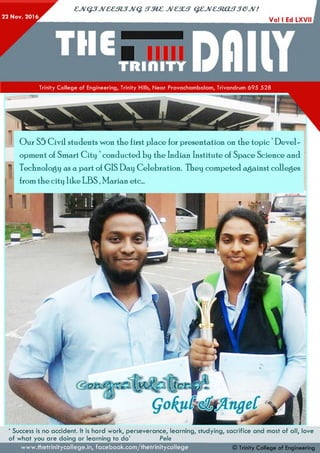

Trinity College of Engineering students won first place in a presentation competition on smart cities. Aeuro Info Tech conducted on-campus interviews. Dr. David Natarajan was a keynote speaker on composites engineering and structural health monitoring. A research paper by mechanical engineering students on friction stir processing of aluminum was accepted for an international conference. The robotic club is working on robots for a technical festival. Safety improvements were implemented in the production lab. Students completed lab exams for various subjects. Work is ongoing on a mechanism to enable two-wheelers for physically disabled people.