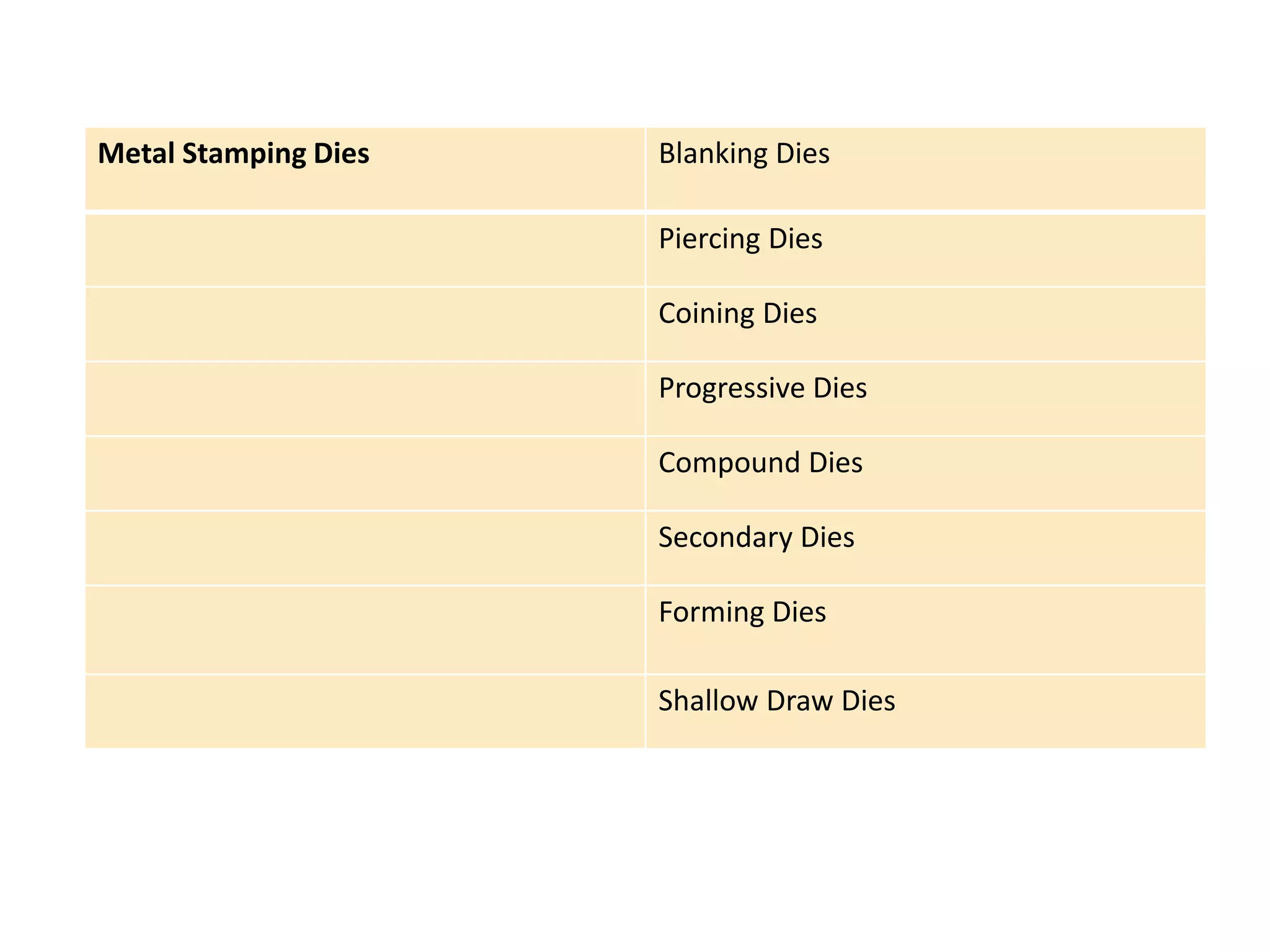

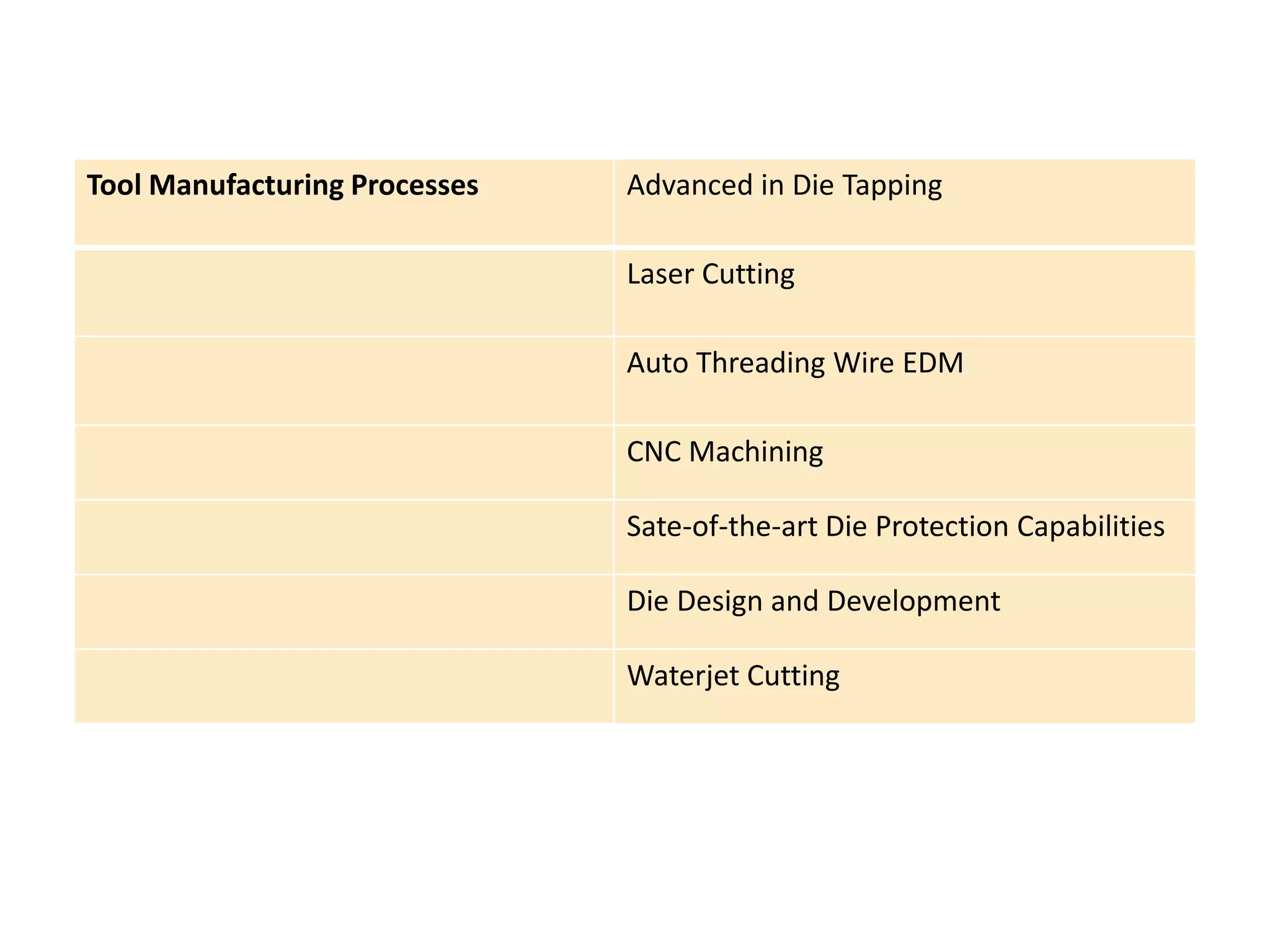

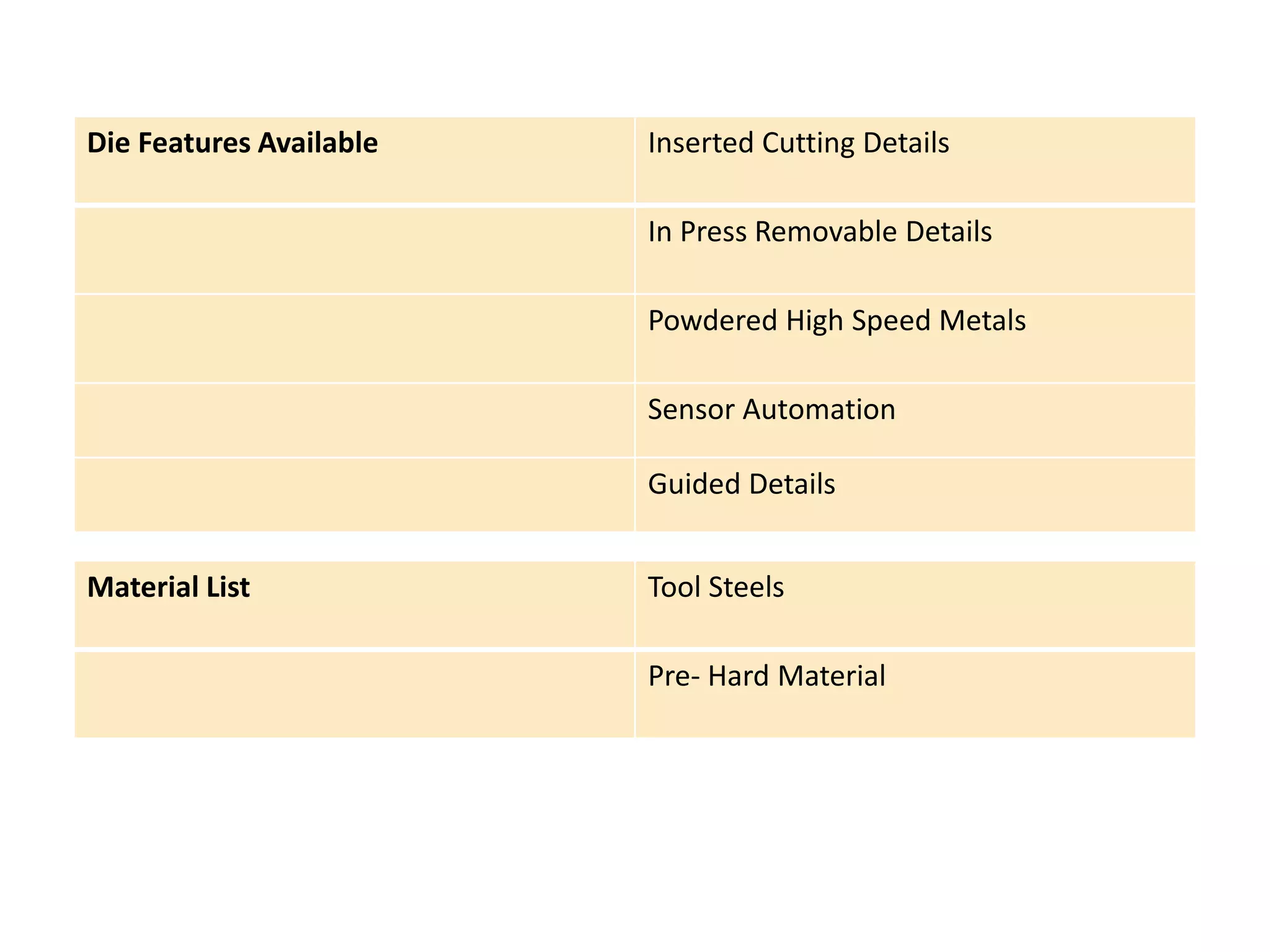

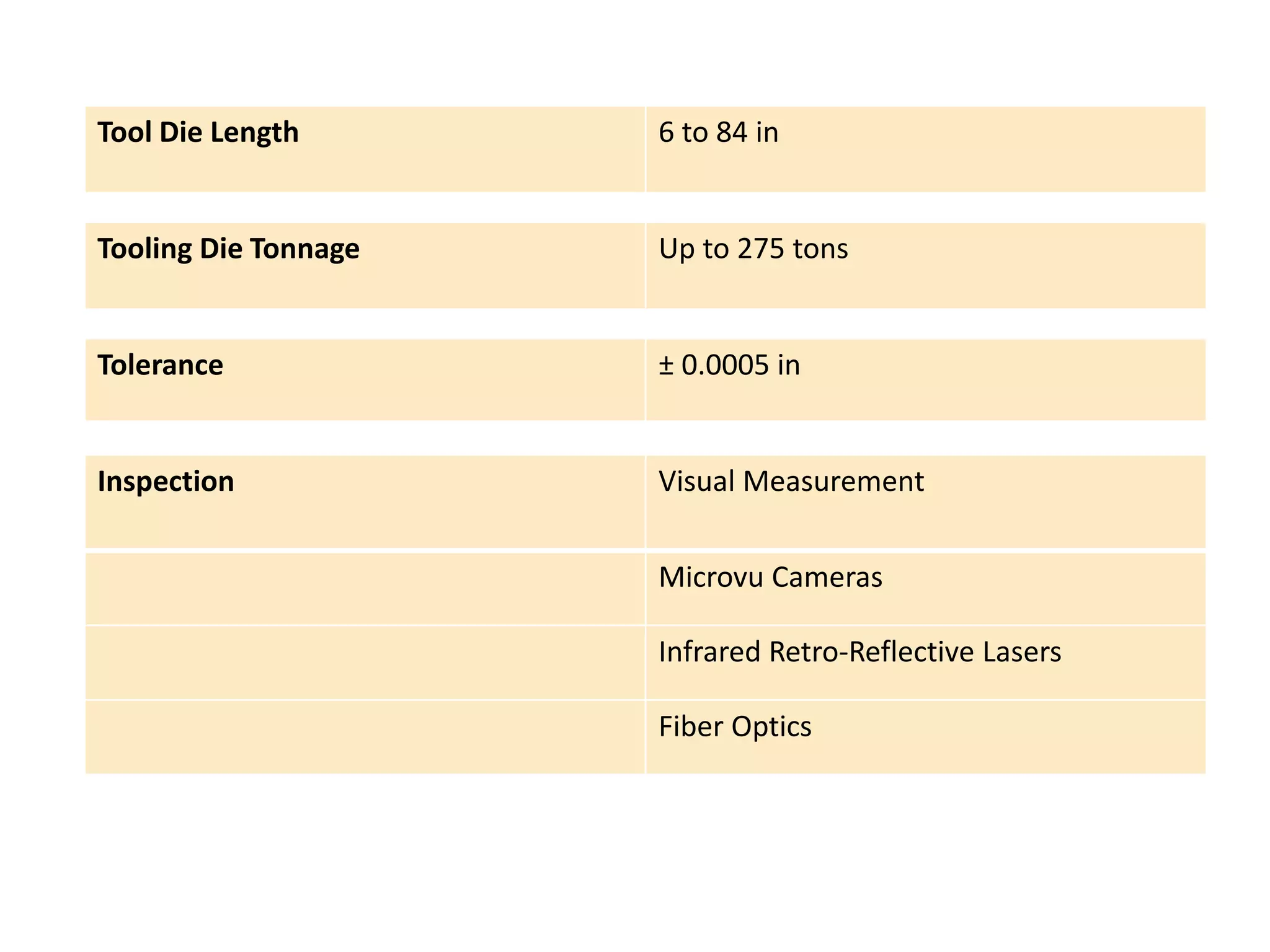

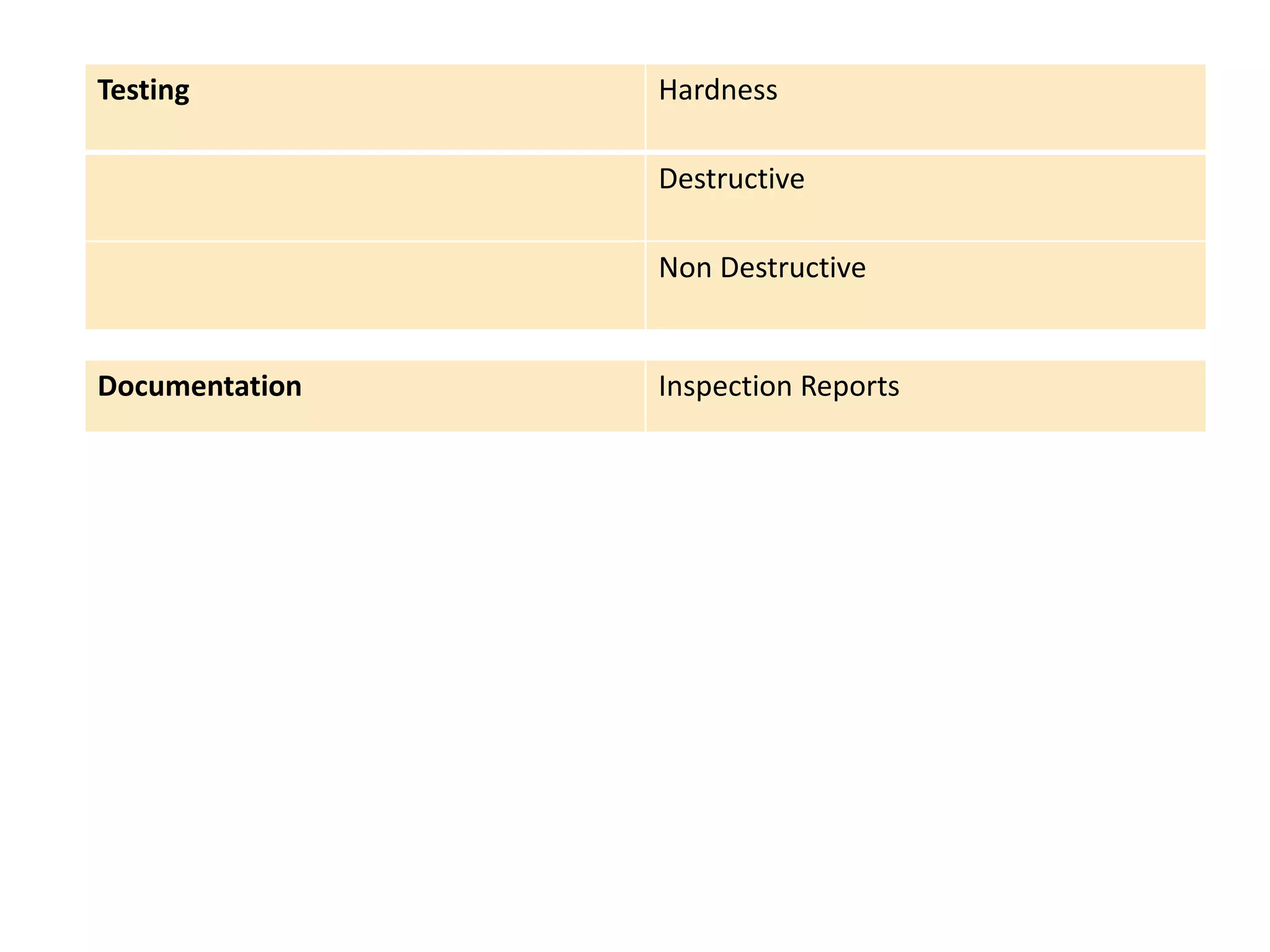

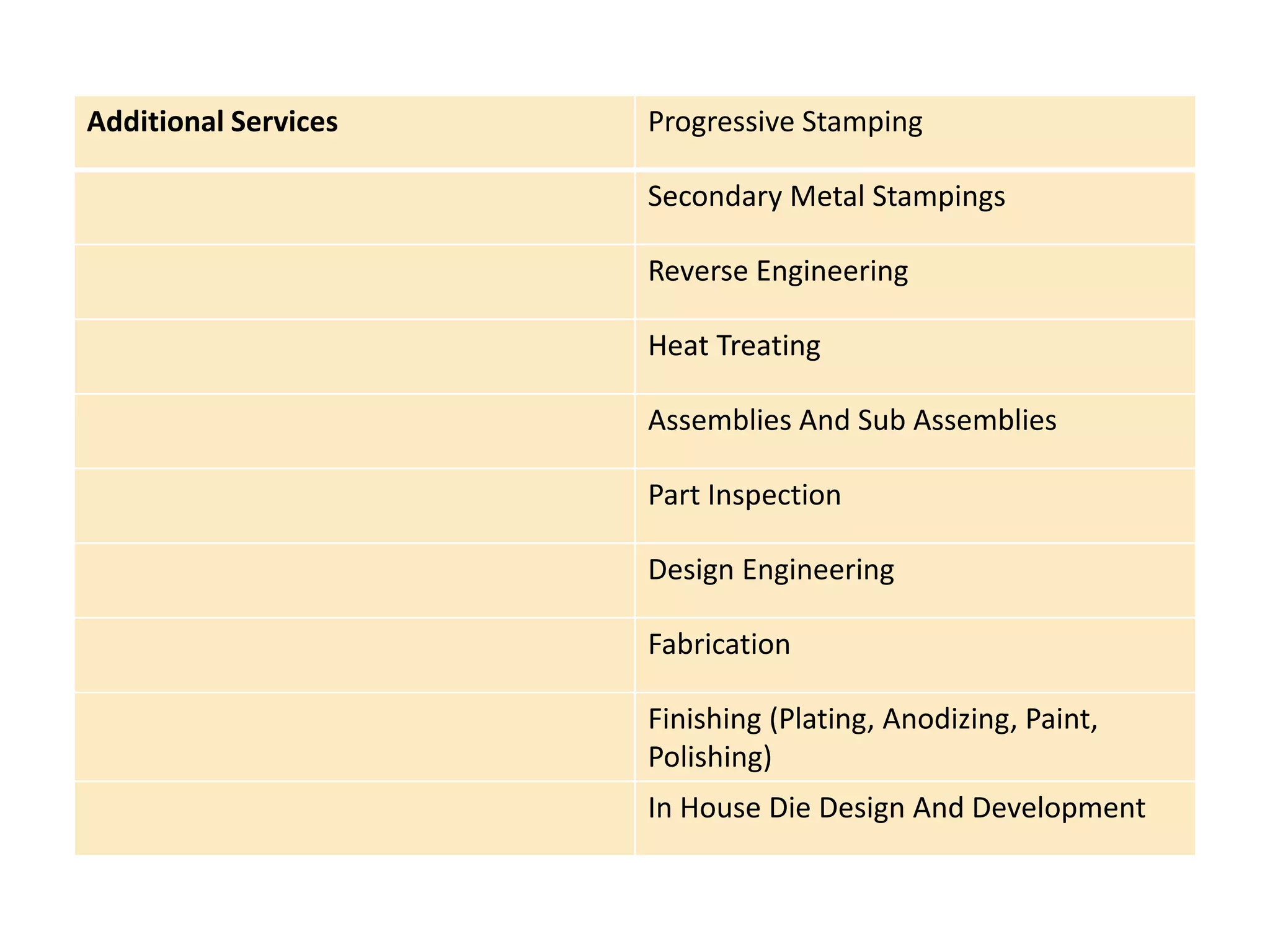

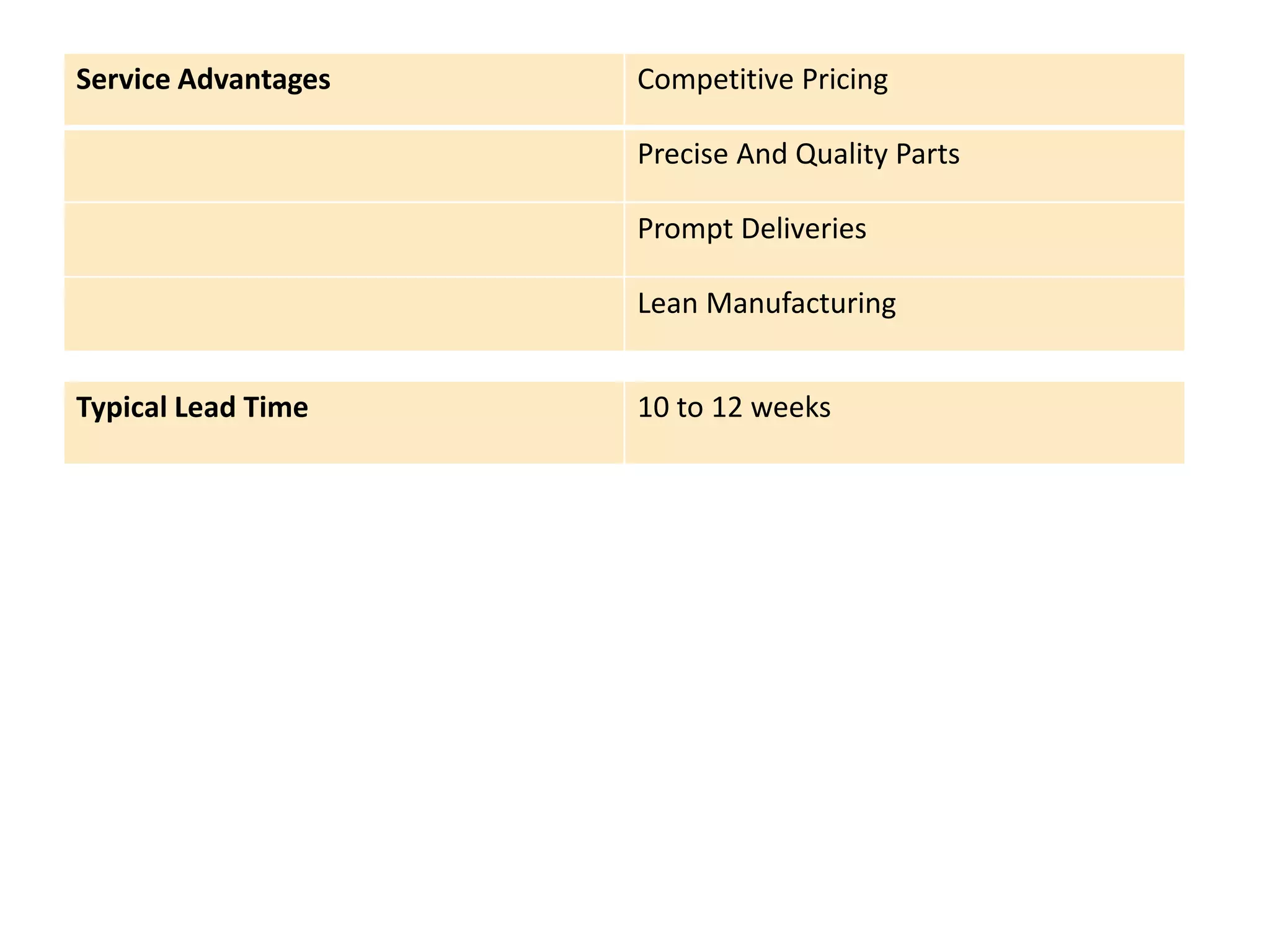

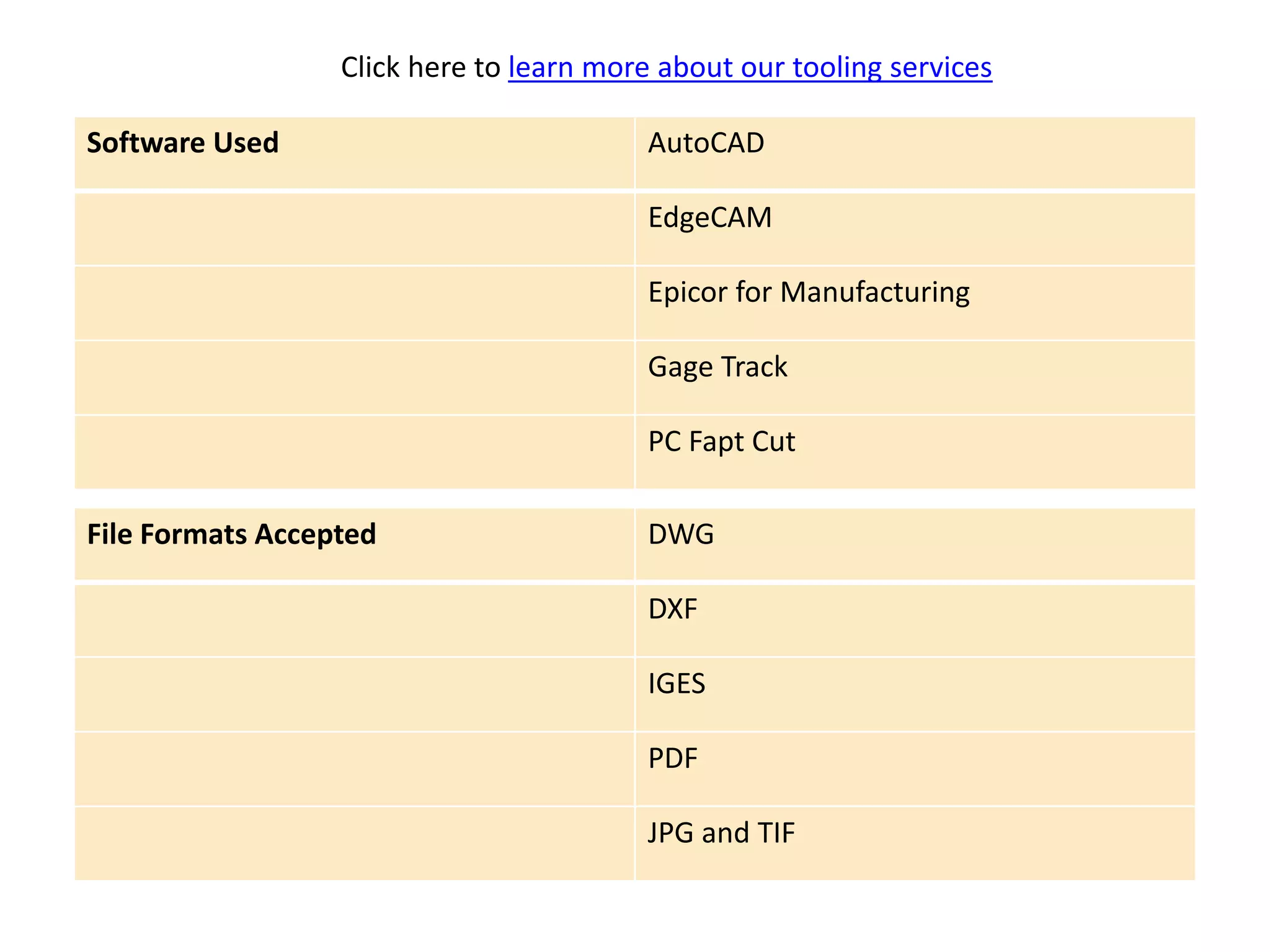

This document provides information about metal stamping dies and tool manufacturing processes. It details the types of dies available including blanking, piercing, coining, progressive, compound, and secondary dies. It also lists the tool manufacturing capabilities such as laser cutting, auto threading, wire EDM, and CNC machining. Additionally, it provides specifications for die features, tolerances, inspection methods, testing, documentation, and additional metal stamping services.