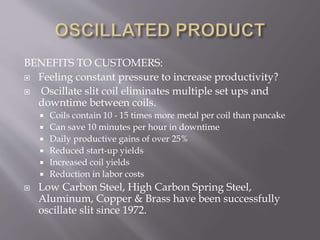

Three D Metals is a 160,000 square foot metal distributor located in Valley City, OH that stocks copper coil and bar, aluminum coil and bar, high carbon spring steel, low carbon steel, brass, and stainless steel. They have long-lasting partnerships with automotive, appliance, construction, and electrical industries. They offer fast turnaround, flexible minimums, and delivery across North America to reduce customers' inventory and space needs. Their products include high quality slit copper, cold rolled high carbon spring steel slit in oscillating coils, and copper and aluminum bus bar for transformers and switchgear.